Flue gas desulfurization and demercuration method

A mercury and flue gas removal technology, which is applied in the field of environmental pollution control, can solve the problems of cumbersome preparation of high-activity absorbents, high operating costs of activated carbon, and easy failure of additives, etc., to prolong the ionization reaction time, occupy a small area, and The effect of convenient operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

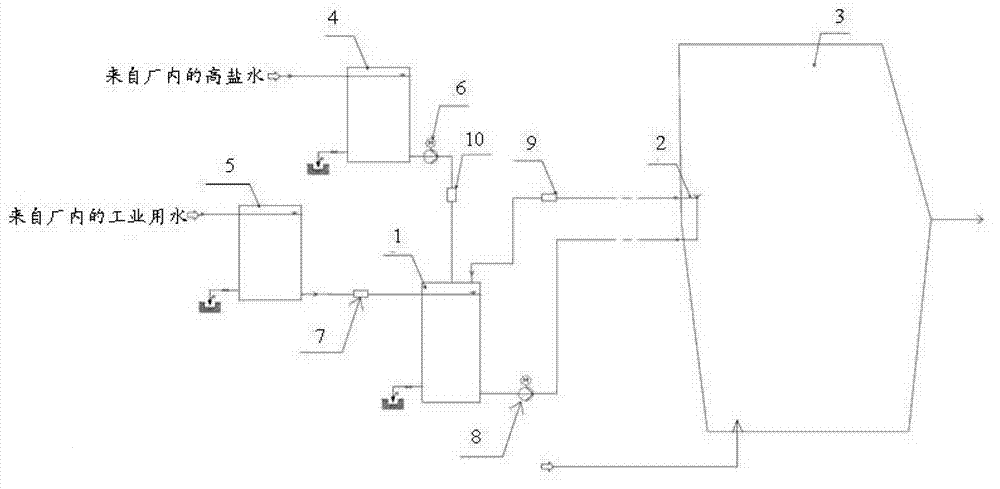

Image

Examples

Embodiment 1

[0042] The generator set of a power plant with a power generation capacity of 300MW provides raw flue gas, and sulfur dioxide (SO 2 ) concentration is 1500mg / Nm 3 , the concentration of heavy metal mercury (Hg) is 3×10 -3 mg / m 3 , the original flue gas temperature is 130°C; the waste water produced during the regeneration of the ion exchange resin of the power plant boiler is mixed with industrial water to obtain water containing chloride ions, and the concentration of chloride ions in the water containing chloride ions is 0.1 mg / L; Calcium and calcium hydroxide mixture as absorbent in the circulating fluidized bed dry desulfurization and mercury dedusting device with 2030000m 3 The above-mentioned raw flue gas is fed at a speed of 39t / h, and at the same time, the above-mentioned mixed water is sprayed at a speed of 39t / h for treatment. After the treatment, the purified flue gas with an outlet temperature of about 72°C is obtained.

[0043] Detect the purified flue gas, pur...

Embodiment 2

[0045] The generator set of a power plant with a power generation capacity of 300MW provides raw flue gas, and sulfur dioxide (SO 2 ) concentration is 1500mg / Nm 3 , the concentration of heavy metal mercury (Hg) is 3×10 -3 mg / m 3 , the original flue gas temperature is 130°C; the waste water produced during the regeneration of the ion exchange resin of the power plant boiler is mixed with industrial water to obtain water containing chloride ions, and the concentration of chloride ions in the water containing chloride ions is 0.2 mg / L; Calcium and calcium hydroxide mixture as absorbent in the circulating fluidized bed dry desulfurization and mercury dedusting device with 2030000m 3 The above-mentioned raw flue gas is fed at a speed of 39t / h, and at the same time, the above-mentioned mixed water is sprayed at a speed of 39t / h for treatment. After the treatment, the purified flue gas with an outlet temperature of about 72°C is obtained.

[0046] Detect the purified flue gas, pur...

Embodiment 3

[0048] The generator set of a power plant with a power generation capacity of 300MW provides raw flue gas, and sulfur dioxide (SO 2 ) concentration is 1500mg / Nm 3 , the concentration of heavy metal mercury (Hg) is 3×10 -3 mg / m 3 , the original flue gas temperature is 130°C; the waste water produced during the regeneration of the ion exchange resin of the power plant boiler is mixed with industrial water to obtain water containing chloride ions, and the concentration of chloride ions in the water containing chloride ions is 0.3 mg / L; Calcium and calcium hydroxide mixture as absorbent in the circulating fluidized bed dry desulfurization and mercury dedusting device with 2030000m 3 The above-mentioned raw flue gas is fed at a speed of 39t / h, and at the same time, the above-mentioned mixed water is sprayed at a speed of 39t / h for treatment. After the treatment, the purified flue gas with an outlet temperature of about 72°C is obtained.

[0049] Detect the purified flue gas, pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com