Sulfonated polyimide with hydrolysis resistance, and preparation method and application thereof

A technology of sulfonated polyimide and sulfonated polyimide block, applied in the field of polymers, can solve the problems of limited range of hydrolysis resistance, difficult synthesis, etc., achieve easy operation and control, good application prospect, The effect of improving hydrolytic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

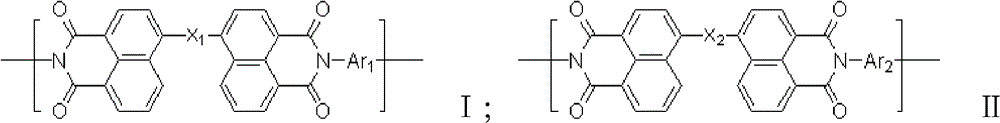

Method used

Image

Examples

Embodiment 1

[0061] Add 10mmol 4,4′-diaminobiphenyl-2,2′-disulfonic acid and 21mmol triethylamine to 56mL m-cresol, and so on 4,4′-diaminobiphenyl-2,2′-disulfonic acid After the sulfonic acid was completely dissolved, 10 mmol of 4,4'-(4",4'''-dioxy-diphenylsulfone)-1,1',8,8'-naphthalene tetracarboxylic dianhydride and 10 mmol of benzoic acid were added. First raise the temperature to 100°C for 2 hours, then raise the temperature to 200°C for 4 hours. After cooling, pour it into 600mL acetone to obtain a fibrous solid, which is fully washed and dried to obtain a polymer.

[0062] The comparative logarithmic viscosity of the prepared polymer is: 0.42dL / g (test conditions: test in m-cresol, temperature is 30°C; concentration is 0.5g / dL).

[0063] Infrared spectrum characterization of the prepared polymer: the typical absorption peak of the imide ring: 1708cm -1 (C=O asymmetric stretching vibration), 1668cm -1 (C=O symmetrical stretching vibration), 1366cm -1 (C-N stretching vibration); typ...

Embodiment 2

[0068] Add 10mmol of 4,4'-diaminodiphenyl ether-2,2'-disulfonic acid and 23mmol of triethylamine into 60mL of m-cresol, etc. 4,4'-diaminodiphenyl ether-2,2' - After the disulfonic acid is completely dissolved, add 10mmol of 4,4'-(4",4'''-dimercaptobenzophenone)-1,1',8,8'-naphthalene tetracarboxylic dianhydride and 12mmol of triethylene Diamine. First raise the temperature to 100°C for 2 hours, then raise the temperature to 200°C for 6 hours. After cooling, pour it into 800mL acetone to obtain a fibrous solid, which is fully washed and dried to obtain a polymer.

[0069] The comparative logarithmic viscosity of the prepared polymer is: 0.45dL / g (test conditions: test in m-cresol, temperature is 30°C; concentration is 0.5g / dL).

[0070] Infrared spectrum characterization of the prepared polymer: the typical absorption peak of the imide ring: 1708cm -1 , 1669cm -1 , 1366cm -1 ;Typical absorption peak of sulfonic acid group: 1192cm -1 , 1028cm -1 .

[0071] The polymer obtai...

Embodiment 3

[0075] Add 10mmol 9,9′-bis(4-aminophenyl)fluorene-2,7′disulfonic acid and 20mmol tri-n-butylamine into 68mL m-cresol, and treat 9,9′-bis(4-aminophenyl After completely dissolving fluorene-2,7'disulfonic acid, add 10mmol 4,4'-(4",4'''-dioxy-diphenylisohexafluoropropane)-1,1',8 , 8'-naphthalene tetracarboxylic dianhydride and 12mmol triethylenediamine. First heat up to 80°C for 2h, then heat up to 180°C for 16h. Cool and pour into 800mL ethanol to obtain a fibrous solid, fully wash and Dry to obtain the polymer.

[0076] The comparative logarithmic viscosity of the prepared polymer is: 0.41dL / g (test conditions: test in m-cresol, temperature is 30°C; concentration is 0.5g / dL)

[0077] Infrared spectrum characterization of the prepared polymer: the typical absorption peak of the imide ring: 1707cm -1 , 1666cm -1 , 1366cm -1 ;Typical absorption peak of sulfonic acid group: 1192cm -1 , 1022cm -1 .

[0078] The polymer obtained is a sulfonated polyimide homopolymer with the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

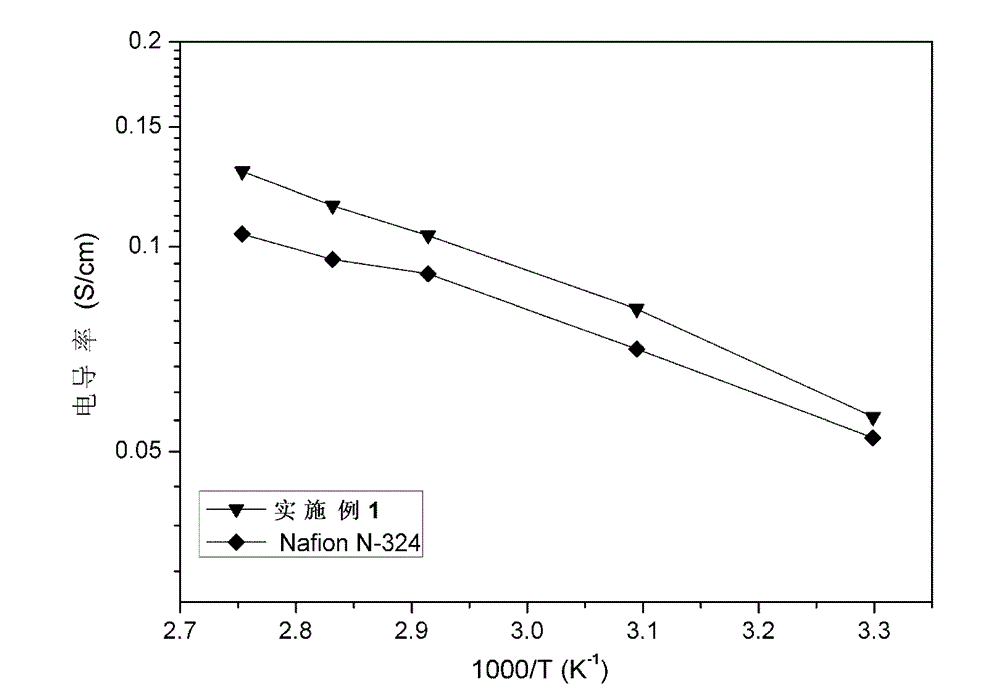

| Conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com