Method for preparing 1,3-diglyceride from surface active magnetic nanoparticle immobilized lipase

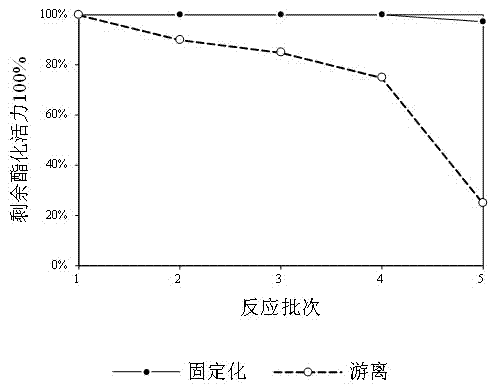

A technology of magnetic nanoparticles and immobilized lipase, which is applied in the direction of immobilization on or in inorganic carriers, fermentation, etc., to achieve the effects of improved activity and operational stability, great application value, and convenient recycling and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 3.0 g FeSO 4 ·7H 2 O, 5.8 g FeCl 3 ·6H 2 O was dissolved in 200 mL of anaerobic water and sonicated for 30 min to make the solution evenly mixed, heated to 85 °C, and stirred at 1 300 rpm under N 2 After bubbling for 30 min, quickly add 7.5 mL concentrated ammonia water, keep the temperature, stir and N 2After reacting for 30 min, the precipitate obtained was magnetically separated and washed with anaerobic water to pH = 7, and washed three times with 0.015 mol / L ethanol aqueous solution;

[0028] 2) Add 80 mL of ethanol aqueous solution with a volume fraction of 50%, 8 mL of silane crosslinking agent, stir at 50 °C and 200 rpm for 5 h, and wash with pH = 7 phosphate buffer three times;

[0029] 3) Add 20 mL pH = 7 phosphate buffer solution and 16 mL 5% glutaraldehyde aqueous solution, stir at 200 rpm for 2 h, magnetically separate, wash with pH = 7 phosphate buffer solution for 3 times, and dry in vacuum to obtain Surface activated magnetic nanoparticles.

[003...

Embodiment 2

[0034] 1) Add 0.20 mol of ferric salt and 0.10 mol of ferrous salt to 200 mL of anaerobic water, adjust to pH = 1.7 with hydrochloric acid, and sonicate for 20 min; 2 After bubbling for 20-30 min, add 10 mL of ammonia water with a mass fraction of 28%, after 30 min, magnetically separate, wash with anaerobic water 10 times, and wash with 0.010 mol / L ethanol aqueous solution twice;

[0035] 2) Add 100 mL of ethanol aqueous solution with a volume fraction of 50%, 8 mL of silane cross-linking agent, stir at 50-60 °C and 220 rpm for 6 h, and wash with pH = 7 phosphate buffer for 3-5 times;

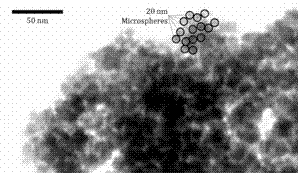

[0036] 3) Add 20 mL pH = 7 phosphate buffer and 20 mL 5% glutaraldehyde aqueous solution, stir at 220 rpm for 3 h, magnetically separate, wash 5 times with pH = 7 phosphate buffer, and vacuum dry to obtain Surface-activated magnetic nanoparticle microsphere carrier.

[0037] At 4 °C, 50 mg Mucor javanicus Dissolve lipase crude enzyme powder in 1 mL pH = 10 phosphate buffer, vortex for 90 ...

Embodiment 3

[0040] 1) Add 0.30 mol of ferric salt and 0.15 mol of ferrous salt to 200 mL of anaerobic water, adjust to pH = 1.7 with hydrochloric acid, and sonicate for 20 min; 2 After bubbling for 20-30 min, add 10 mL of ammonia water with a mass fraction of 28%, after 15 min, magnetically separate, wash 10 times with anaerobic water, and wash 2 times with 0.010 mol / L ethanol aqueous solution;

[0041] 2) Add 80 mL of ethanol aqueous solution with a volume fraction of 50%, 4 mL of silane crosslinking agent, stir at 60 °C and 180 rpm for 6 h, and wash with pH = 7 phosphate buffer for 5 times;

[0042] 3) Add 16 mL pH = 7 phosphate buffer solution and 16 mL 5% glutaraldehyde aqueous solution, stir at 180 rpm for 3 h, magnetically separate, wash 5 times with pH = 7 phosphate buffer solution, and vacuum dry to obtain Surface-activated magnetic nanoparticle microsphere carrier.

[0043] At 4 °C, 50 mg Mucor javanicus Dissolve lipase crude enzyme powder in 1 mL pH = 10 phosphate buffer, v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com