Method for treating exhaust gases by utilizing wet polyphase visible light catalytic oxidation

A photocatalytic oxidation and catalytic oxidation technology, applied in the environmental field, can solve the problems of low recycling rate and reduced photocatalyst activity, and achieve the effects of increased catalytic efficiency, enhanced stability, high-efficiency photocatalytic activity and removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: the preparation of supported BiOI photocatalyst

[0020] Weigh 0.8311 g of KI into a conical flask, add 40 ml of ethylene glycol, and sonicate until completely dissolved. Weigh 2.425 g Bi(NO 3 ) 3 10H 2 O was dissolved in the above solution and continued to sonicate until completely dissolved. Weigh 40 g active Al 2 o 3 Or molecular sieve particles, add to the above solution, shake in a constant temperature shaking box for 30 min. The synthetic reaction chemical equation of BiOI is:

[0021] Bi(NO 3 ) 3 + KI+H 2 O = BiOI + KNO 3 + 2HNO 3 (I)

[0022] The above-mentioned substances were transferred to a high-pressure reactor with a polytetrafluoroethylene liner so that the filling volume of the reactor was 80%, and after reacting in a vacuum oven at 160 °C for 12 hours, it was taken out and naturally cooled to room temperature. Then filter and wash several times with ethanol solution until the filtrate becomes clear. The activated alumina ...

Embodiment 2

[0024] Example 2: Supported BiOI photocatalyst wet oxidation treatment of nitrogen oxides NO

[0025] The wet heterogeneous visible light catalytic reaction device uses a reactor made of hard glass as the core device of the system. The prepared supported BiOI catalyst microspheres are filled in it, and a visible light tube is fixed on the outer wall of the reactor and a 150 W The iodine-gallium lamp light source is a visible light source to provide visible light of λ≥ 420 nm. The whole device is wrapped in tin foil, and is equipped with a peristaltic pump to provide a liquid-phase aqueous solution at a certain flow rate.

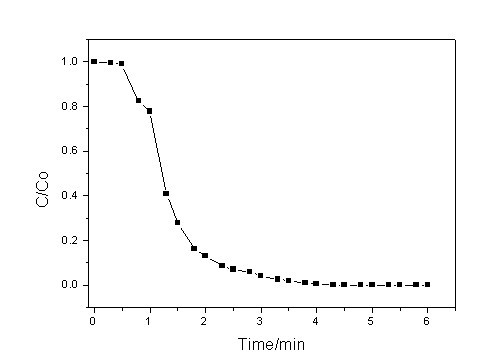

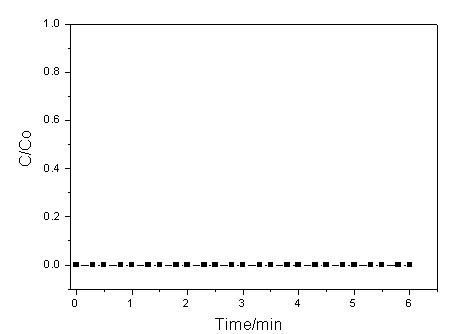

[0026] Weigh 40 g Wt. 2.53% of the BiOI catalyst loaded on activated alumina and fill it in the photocatalytic reactor. Under the condition of air flow rate of 0.1 L / min, 50 ppm of NO gas, while providing an aqueous solution with a flow rate of 10 mL / min through a peristaltic pump and spraying the aqueous solution from the upper nozzle of the reactor. When t...

Embodiment 3

[0045] Example 3: Supported BiOI photocatalyst wet oxidation treatment of sulfur dioxide SO 2

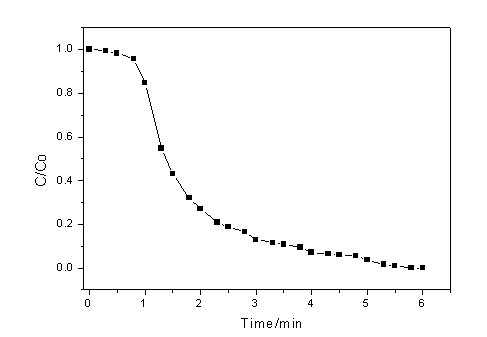

[0046] The wet-type heterogeneous visible-light catalytic reaction device adopts the heterogeneous wet-type visible-light catalytic reactor described in Example 2, and uses a 150 W iodine-gallium lamp as the visible light source to provide visible light of λ≥420 nm. Weigh 40 g Wt. 2.53% of the BiOI catalyst loaded on activated alumina and fill it in the photocatalytic reactor, and pass 50 ppm from the sand core aeration head at the bottom of the reactor under the condition of air flow rate of 0.1 L / min SO 2 At the same time, a peristaltic pump is used to provide an aqueous solution with a flow rate of 10 mL / min and the aqueous solution is sprayed from the upper nozzle of the reactor. When the gas / liquid / solid three-phase reaches adsorption equilibrium, the visible light source is turned on. SO 2 can be completely removed by wet heterogeneous photocatalytic oxidation (see figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com