Method for preparing doping-type crystalline titanium dioxide photoelectrode at low temperature by virtue of microwave auxiliary reaction supercharge method

A titanium dioxide, microwave-assisted technology, applied in capacitor electrodes, circuits, electrical components and other directions, can solve the problem of difficulty in preparing doped crystalline titanium dioxide, achieve short preparation process time, high conversion efficiency, and overcome the easy loss of doping elements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

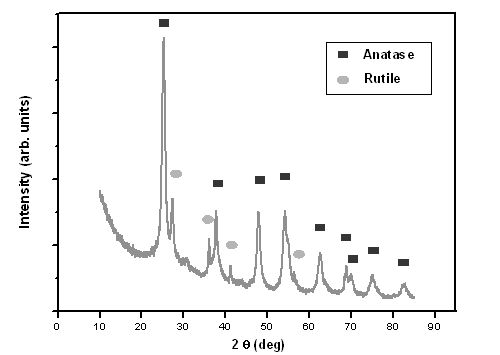

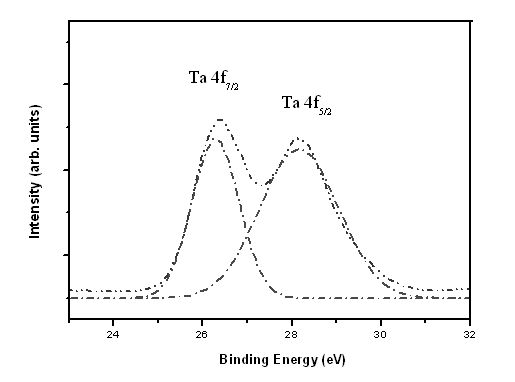

[0021] Example 1: Add 0.07mol tetrabutyl titanate to 2.30mol ethanol, stir and mix evenly, add 0.013mol tantalum ethoxide, stir well, add 0.08mol concentrated nitric acid dropwise, stir for 5min, then slowly add 0.20mol deionized water , maintain high-speed stirring during the dropwise addition to obtain a mixed solution. Heat the above-prepared mixed solution with a water bath at a temperature of 65° C., keep stirring and reflux, and react for 1 hour to prepare a colloid containing titanium and tantalum. After the colloid to be prepared is cooled to room temperature, move it into a high-pressure container, then add 2.90 mol of hydrogen peroxide, and quickly seal the container. Put the sealed container into a microwave reaction device with a microwave power of 200W, rapidly heat it to 95°C, keep it warm for 2.5h until the reaction is complete, and keep stirring during the whole process. The reaction product was filtered, rinsed with deionized water, and dried at 60° C. to obt...

Embodiment 2

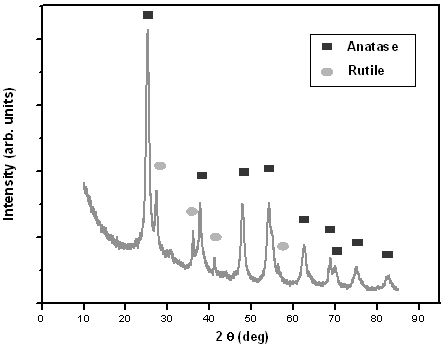

[0026] Example 2: Add 0.05 mol tetrabutyl titanate to 1.60 mol ethanol, stir and mix evenly, add 0.03 mol zinc acetate, add 0.04 mol concentrated nitric acid dropwise after fully stirring, slowly add 0.10 mol deionized water dropwise after stirring for 5 minutes , maintain high-speed stirring during the dropwise addition to obtain a mixed solution. Heat the above-prepared mixed solution with a water bath at a temperature of 60° C., keep stirring and reflux, and react for 1.5 hours to obtain a colloid containing titanium and zinc. After the prepared colloid is cooled to room temperature, move it into a high-pressure container, then add 0.05mol zinc carbonate, and quickly seal the container. Put the sealed container into a microwave reaction device with a microwave power of 300W, rapidly heat it to 90°C, keep it warm for 2h until the reaction is complete, and keep stirring during the whole process. The reaction product was filtered, rinsed with deionized water, and dried at 60°...

Embodiment 3

[0027] Example 3: Add 0.20 mol tetrabutyl titanate to 3.05 mol isopropanol, stir and mix evenly, add 0.20 mol tin tetrachloride, add 0.15 mol concentrated nitric acid dropwise after fully stirring, slowly add 0.40 mol deionized water, keep stirring at a high speed during the dropwise addition to obtain a mixed solution. Heat the above-prepared mixed solution with a water bath at a temperature of 70° C., keep stirring and reflux, and react for 1 hour to prepare a colloid containing titanium and tin. After the colloid to be prepared is cooled to room temperature, move it into a high-pressure container, then add 0.04mol ammonium carbonate, and quickly seal the container. Put the sealed container into a microwave reaction device with a microwave power of 500W, rapidly heat it to 98°C, keep it warm for 2.5h until the reaction is complete, and keep stirring during the whole process. The reaction product was filtered, rinsed with deionized water, and dried at 60° C. to obtain tin-do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com