Additive high-thermal-conductivity organic silicon electronic pouring sealant and preparation method thereof

A high thermal conductivity, silicone technology, applied in chemical instruments and methods, adhesives, adhesive additives, etc., can solve the problems of lack of fluidity, incapable of electronic potting, etc., to make up for low thermal conductivity, excellent fluidity, The effect of high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

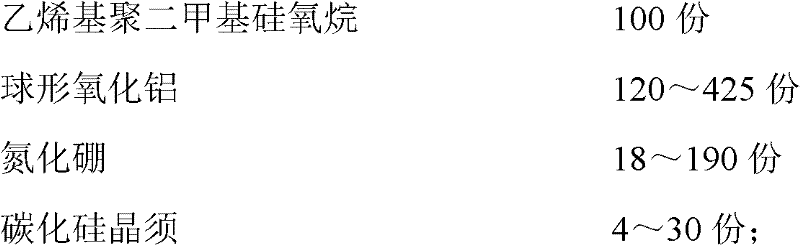

Embodiment 1

[0028] 100 parts by mass of linear vinyl siloxane with a viscosity of 200 mPa·s and a vinyl content of 0.8 wt %, 425 parts by mass of spherical aluminum oxide with a diameter of 50 μm, and 45 parts by mass of boron nitride with a diameter of 0.1 μm. Add 30 parts by mass of silicon carbide whiskers with a diameter of 2.5 μm and an aspect ratio of 20 into a vacuum kneader, dehydrate and blend for 120 minutes at a temperature of 120°C and a vacuum of 0.08 MPa, and grind 3 times with a three-roller machine to obtain a base material .

[0029] 11.9 parts by mass of a hydrogen-containing silicone oil crosslinking agent with a hydrogen content of 0.1%, an appropriate amount of a crosslinking inhibitor, and 100 parts by mass of a base material were fully stirred and mixed for 20 minutes to obtain component A. An appropriate amount of platinum catalyst and 100 parts by mass of the base material were stirred and mixed under a mixer for 20 minutes to obtain component B.

[0030] Take eq...

Embodiment 2

[0032] 80 parts by mass of linear vinyl siloxane with a viscosity of 1000 mPa·s and a vinyl content of 0.3 wt%, 20 parts by mass of a branched vinyl siloxane with a viscosity of 450 mPa·s and a vinyl content of 3.0 wt%. Parts by mass, 100 parts by mass of spherical aluminum oxide of 1 μm, 20 parts by mass of spherical aluminum oxide of 50 μm, 76 parts by mass of boron nitride of 5 μm, silicon carbide whiskers with a diameter of 0.05 μm and an aspect ratio of 10 4 The parts by mass were put into a vacuum kneader, dehydrated and blended for 120 minutes at a temperature of 120° C. and a vacuum of 0.08 MPa, and then ground three times with a three-roll machine to obtain a base material.

[0033] 7.5 parts by mass of a hydrogen-containing silicone oil crosslinking agent with a hydrogen content of 0.3%, an appropriate amount of a crosslinking inhibitor, and 100 parts by mass of a base material were fully stirred and mixed for 20 minutes to obtain component A. An appropriate amount o...

Embodiment 3

[0036]100 parts by mass of linear vinyl siloxane with a viscosity of 500 mPa·s and a vinyl content of 0.45 wt %, 160 parts by mass of spherical aluminum oxide of 5 μm, 30 parts by mass of boron nitride of 2 μm, and a diameter of 0.5 10 parts by mass of silicon carbide whiskers with μm and an aspect ratio of 40 were put into a vacuum kneader, dehydrated and blended for 120 minutes at a temperature of 120°C and a vacuum of 0.08 MPa, and then ground three times with a three-roll machine to obtain a base material.

[0037] 8.2 parts by mass of a hydrogen-containing silicone oil crosslinking agent with a hydrogen content of 0.22%, an appropriate amount of a crosslinking inhibitor and 100 parts by mass of a base material were fully stirred and mixed for 20 minutes to obtain component A. An appropriate amount of platinum catalyst and 100 parts by weight of the base material were stirred and mixed under a mixer for 20 minutes to obtain component B.

[0038] Take equal parts of compone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com