Method for growing high-antistatic LED (light-emitting diode) by adopting metal organic compound vapor phase epitaxy technology

An organic compound, light-emitting diode technology, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve the problems of limited effect, high additional cost, complicated process flow, etc., to increase the built-in capacitance and improve the expansion effect. , the effect of increasing the hole concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

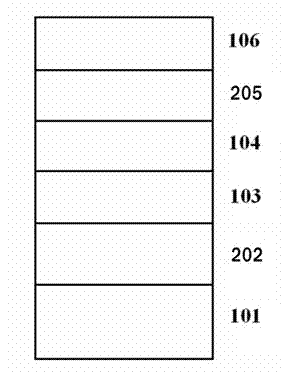

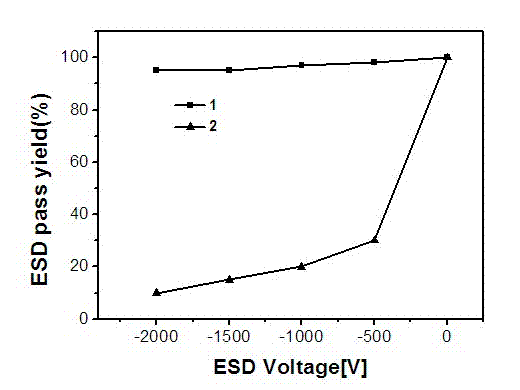

[0039] Aixtron, close-coupled vertical reaction chamber MOCVD growth system, was used. Trimethylgallium (TMGa), trimethylindium (TMIn), trimethylaluminum (TMAl) were used as group III sources during the growth process, and ammonia (NH 3 ) as the V group source, silane (SiH4) as the n-type doping source, and dimagnesium (Cp2Mg) as the p-type doping source, first heat the sapphire AlO3 substrate 101 to 1100 in the MOCVD reaction chamber , at H 2 5 minutes, then lower the temperature to 530~550 On Al2O3 substrates, high chamber pressure, hydrogen (H 2 ) atmosphere, the GaN buffer layer after three-dimensional growth of 20-30 nm, at 1000-1500 grow a 4 μm thick n-GaN layer 102 under nitrogen (N 2 ) atmosphere, at 750~850 grown 15 nm thick with an electron concentration of 10 19 cm -3 n-In 0.1 Ga 0.9 N (15nm) insertion layer 103, followed by growth of 10 cycles of In 0.18 Ga 0.82 N (2.5nm) / GaN (15nm) multiple quantum well active region 104'. on the active area, under...

Embodiment 2

[0041] Aixtron, close-coupled vertical reaction chamber MOCVD growth system was used. Trimethylgallium (TMGa), trimethylindium (TMIn), trimethylaluminum (TMAl) were used as group III sources during the growth process, and ammonia (NH 3 ) as the V group source, silane (SiH4) as the n-type doping source, and dimagnesium (Cp2Mg) as the p-type doping source, first heat the sapphire AlO3 substrate 101 to 1100 in the MOCVD reaction chamber , at H 2 5 minutes, then lower the temperature to 530~550 On Al2O3 substrates, high chamber pressure, hydrogen (H 2 ) atmosphere, the GaN buffer layer after three-dimensional growth of 20-30 nm, at 1000-1500 grow a 4 μm thick n-GaN layer 102 under nitrogen (N 2 ) atmosphere, at 750~850 Under multi-cycle growth, the electron concentration is 10 19 cm -3 n-In 0.1 Ga 0.9 N (2.5nm) / GaN (5nm) superlattice insertion layer 203, the number of periods of the superlattice is 10, and then grows 10 periods of In 0.18 Ga 0.82 N (2.5nm) / GaN (15nm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com