A kind of bioabsorbable composite scaffold and preparation method thereof

A composite scaffold and biological technology, applied in the field of medical devices, can solve the problems of unknown long-term impact of non-degradable fluoride, unknown impact of Al element on the human body, etc., to enhance binding force, avoid rebound, improve strength and plastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

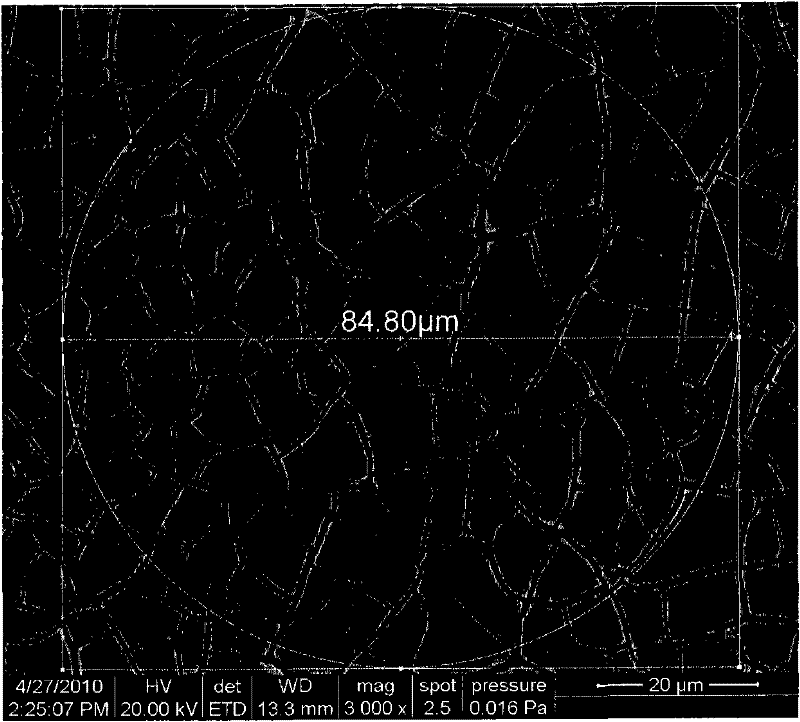

[0046] 1. Preparation of ultra-fine-grained magnesium alloy powder: put 3g of raw materials into a quartz tube with a diameter of 0.5mm at the bottom of d16mm×300mm, and then place the quartz tube on a copper roller equipped with a vacuum cover Top, evacuated to 1.0 x 10 -3 After Pa, reverse-fill high-purity argon to 1 atmosphere; after repeated vacuuming and argon filling for 3 to 5 times, use high-frequency induction melting equipment to heat to melt the magnesium alloy and overheat it at 100K, keep it for 2 minutes; then pour it into the quartz tube Blow in 2kPa high-pressure argon, and use the above-mentioned high-pressure argon to shoot the molten magnesium alloy on the surface of the copper roller with a rotation speed of 2500rpm and a thermal conductivity of 390W / mK. The liquid magnesium alloy is rapidly cooled on the roller surface, and the cooling rate is about 10 5 K / s, the magnesium alloy is solidified into a thin strip and thrown out along the direction of rotation...

Embodiment 1

[0050] (1) Select Mg-Zn binary alloy wire as the stent matrix material, wherein the content of Zn element is 4%, the grain size of the ultrafine-grained magnesium-based alloy adopted is 3 μm, and the diameter of the cross-section of the wire is 0.06 mm, It is embedded in the groove on the surface of the mold designed according to the bracket structure to form a structural unit, and the adjacent structural unit brackets are connected with wires, and the joints are welded. The welding method is resistance welding, the welding current is 5A, the welding time is 3 seconds, the welding pressure is 2atm, and high-purity argon is used for protection to prevent oxidation of the magnesium-based alloy during welding. The outer diameter of the finally prepared stent matrix is 2mm.

[0051] (2) Put the magnesium-based alloy bracket prepared in step (1) into absolute ethanol for ultrasonic cleaning, the ultrasonic frequency is 300KHz, and the ultrasonic time is 10 minutes. After removing t...

Embodiment 2

[0055](1) Select Mg-Zn-Ca ternary magnesium-based alloy pipe as the support matrix material, wherein the content of Zn element is 2%, the content of Ca element is 4%, and the grain size of the ultrafine-grained magnesium-based alloy used is 10 μm, the selected pipe has an outer diameter of 2 mm and a wall thickness of 0.05 mm, and is laser cut into a magnesium-based alloy stent matrix by using a Nd-YAG light source laser cutting machine.

[0056] (2) Put the magnesium-based alloy stent matrix prepared in step (1) into absolute ethanol for ultrasonic cleaning, the ultrasonic frequency is 300KHz, and the ultrasonic time is 10 minutes. After removing the dirt residue on the surface, put 0.01mol / L dilute hydrochloric acid solution for 30 seconds to remove burrs and other defects on the surface, and then use absolute ethanol to sonicate for 10 minutes and dry to complete the surface treatment of the stent matrix.

[0057] (3) choose the polylactic acid-glycolic acid copolymer that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com