Preparation method of biological ceramic coating rich in calcium and phosphate phases on surface of magnesium alloy

A bioceramic and magnesium alloy technology, applied in the field of materials, can solve the problems of stress shielding, poor biological activity, inflamed tissue, etc., achieve good corrosion resistance and wear resistance, improve compactness and thickness, and stabilize spark discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

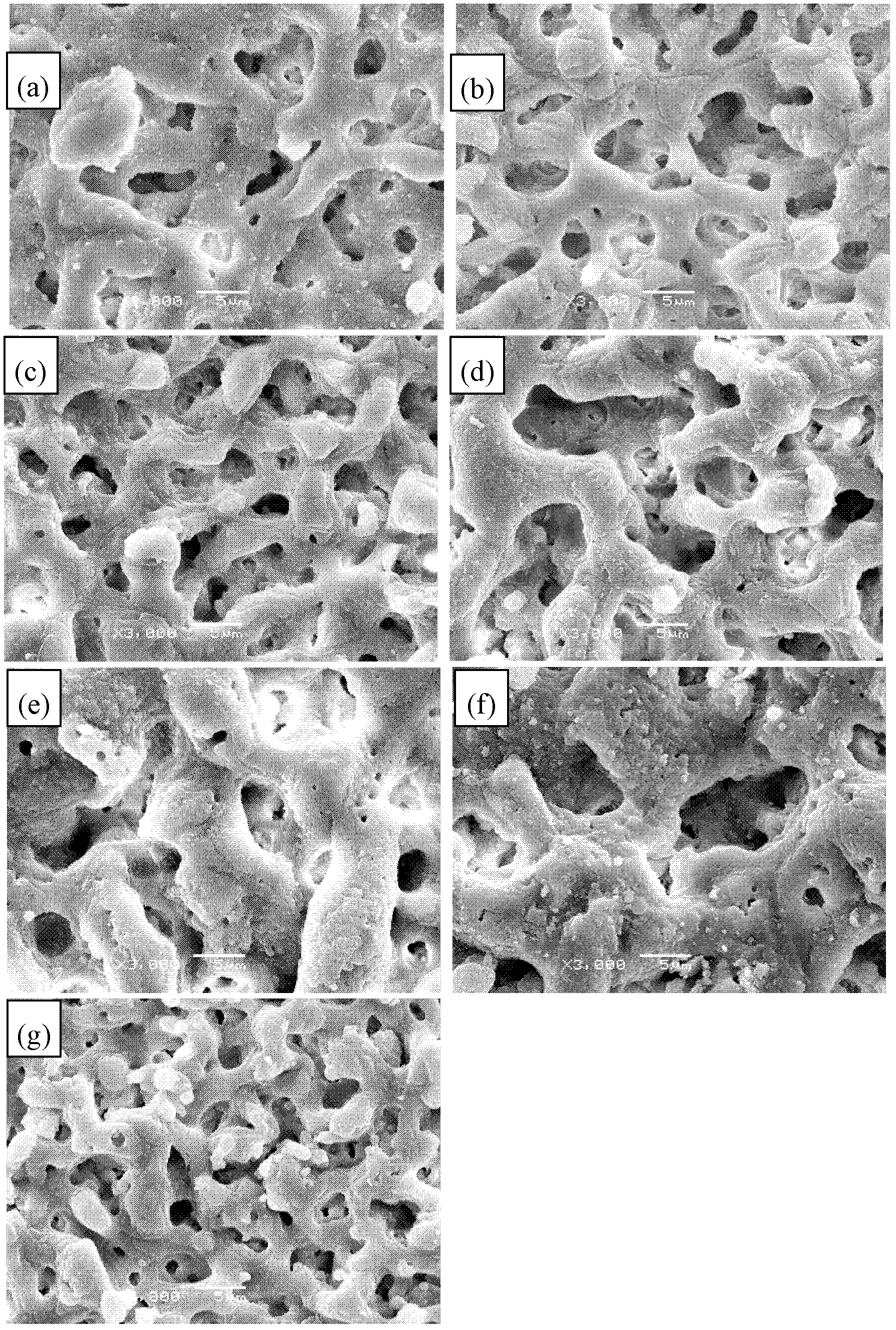

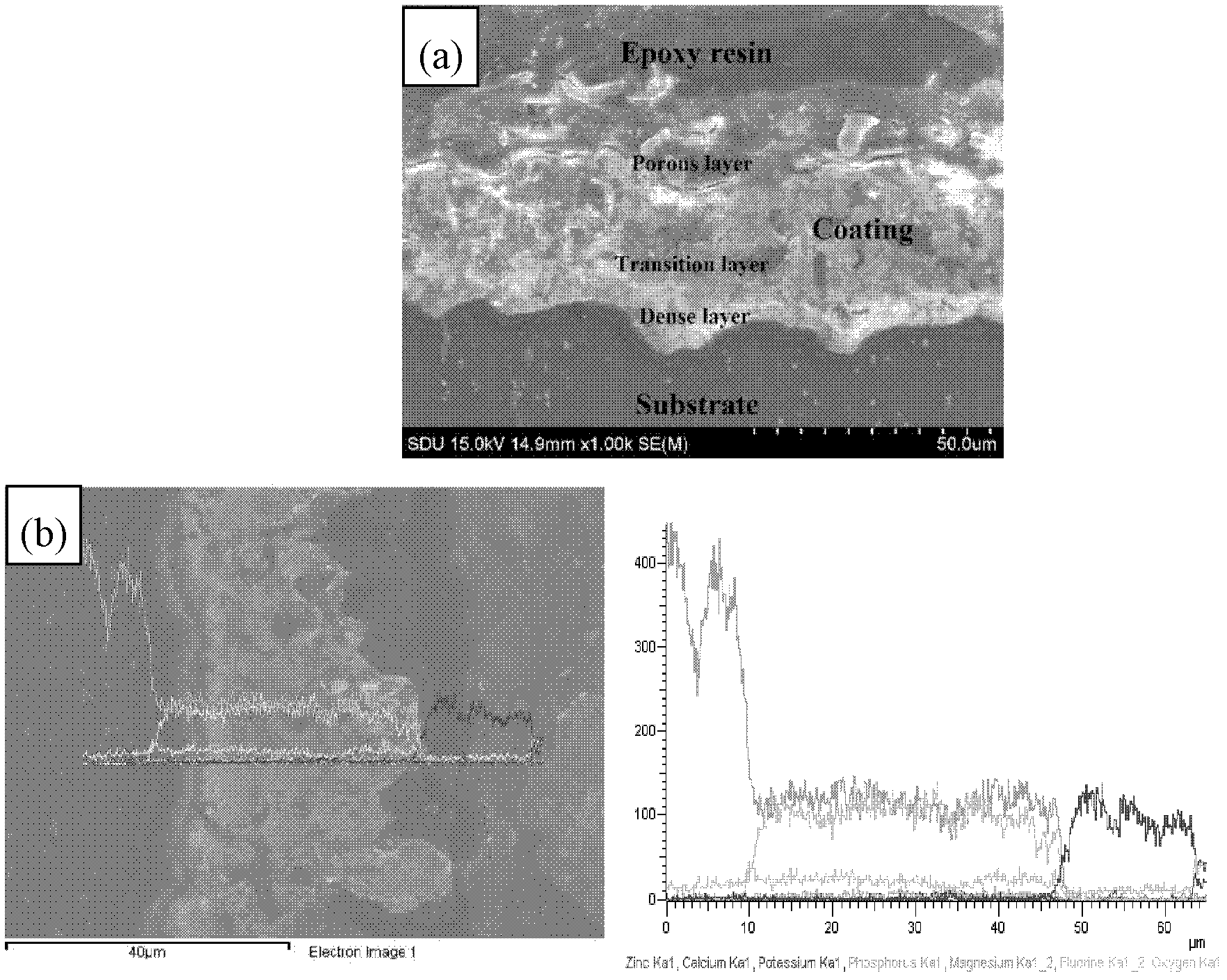

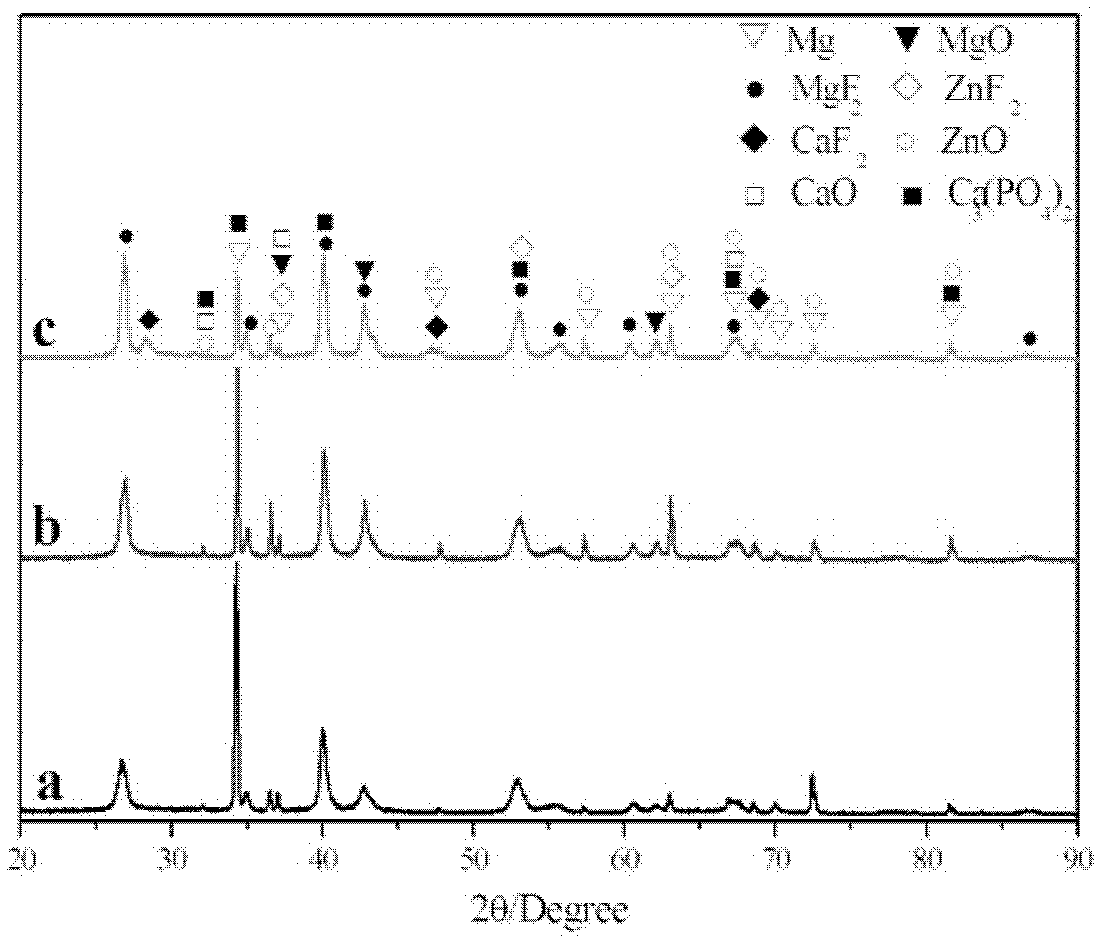

[0037] Example 1 Preparation of a calcium-phosphorus-rich bioceramic coating on the surface of a magnesium alloy

[0038] Proceed as follows:

[0039] (1) Preparation of electrolyte: add (C 6 h 5 o 7 ) 2 Ca 3 4H 2 O as a calcium source, and adding Na 3 PO 4 As a phosphorus additive, add KOH, NH at the same time 4 HF 2 , N(CH 2 CH 2 Oh) 3 , C 3 h 8 o 3 and H 2 o 2 , to prepare an electrolyte with a certain concentration ratio of calcium to phosphorus. Among them, the concentration of KOH is 0.0891mol / L, NH 4 HF 2 The concentration is 0.1227mol / L, N(CH 2 CH 2 Oh) 3 The volume fraction is 0.5%, C 3 h 8 o 3 The volume fraction is 0.5%, H 2 o 2 The volume fraction is 0.75%;

[0040] The calcium source in the electrolyte used in each group of samples (C 6 h 5 o 7 ) 2 Ca 3 4H 2 O and phosphorus additive Na 3 PO 4 The specific content of is shown in Table 1-1:

[0041] Table 1-1 Composition and content of calcium and phosphorus sources in micro-arc...

Embodiment 2

[0050] Example 2 Preparation of a calcium-phosphorus-rich bioceramic coating on the surface of a magnesium alloy

[0051] Proceed as follows:

[0052] (1) Preparation of electrolyte: add (C 6 h 5 o 7 ) 2 Ca 3 4H 2 O as a calcium source, and adding Na 3 PO 4 As a phosphorus additive, add KOH, NH at the same time 4 HF 2 , N(CH 2 CH 2 Oh) 3 , C 3 h 8 o 3 and H 2 o 2 , to prepare an electrolyte with a certain concentration ratio of calcium to phosphorus. Among them, (C 6 h 5 o 7 ) 2 Ca 3 4H 2 The concentration of O is 0.005mol / L, Na 3 PO 4 The concentration of KOH is 0.005mol / L, the concentration of KOH is 0.0891mol / L, and the concentration of NH 4 HF 2 The concentration is 0.1227mol / L, N(CH 2 CH 2 Oh) 3 The volume fraction is 0.5%, C 3 h 8 o 3 The volume fraction is 0.5%, H 2 o 2 The volume fraction is 0.75%;

[0053] (2) Preparation of base material: Divide the plate into 8×10×12mm by wire cutting 3 Drill holes and tap threads on the small su...

Embodiment 3

[0065] Example 3 Preparation of bioceramic coatings rich in calcium and phosphorus phases on the surface of magnesium alloys

[0066] Proceed as follows:

[0067] (1) Preparation of electrolyte: add (C 6 h 5 o 7 ) 2 Ca 3 4H 2 O as a calcium source, and adding Na 3 PO 4 As a phosphorus additive, add KOH, NH at the same time 4 HF 2 , N(CH 2 CH 2 Oh) 3 , C 3 h 8 o 3 and H 2 o 2 , to prepare an electrolyte with a certain concentration ratio of calcium to phosphorus. Among them, (C 6 h 5 o 7 ) 2 Ca 3 4H 2 O is 0.005mol / L, Na 3 PO 4 is 0.005mol / L, the concentration of KOH is 0.0891mol / L, and the concentration of NH 4 HF 2 The concentration is 0.1227mol / L, N(CH 2 CH 2 Oh) 3 The volume fraction is 0.5%, C 3 h 8 o 3 The volume fraction is 0.5%, H 2 o 2 The volume fraction is 0.75%;

[0068] (2) Preparation of base material: Divide the plate into 8×10×12mm by wire cutting 3 Drill holes and tap threads on the small surface of the cuboid to facilitate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com