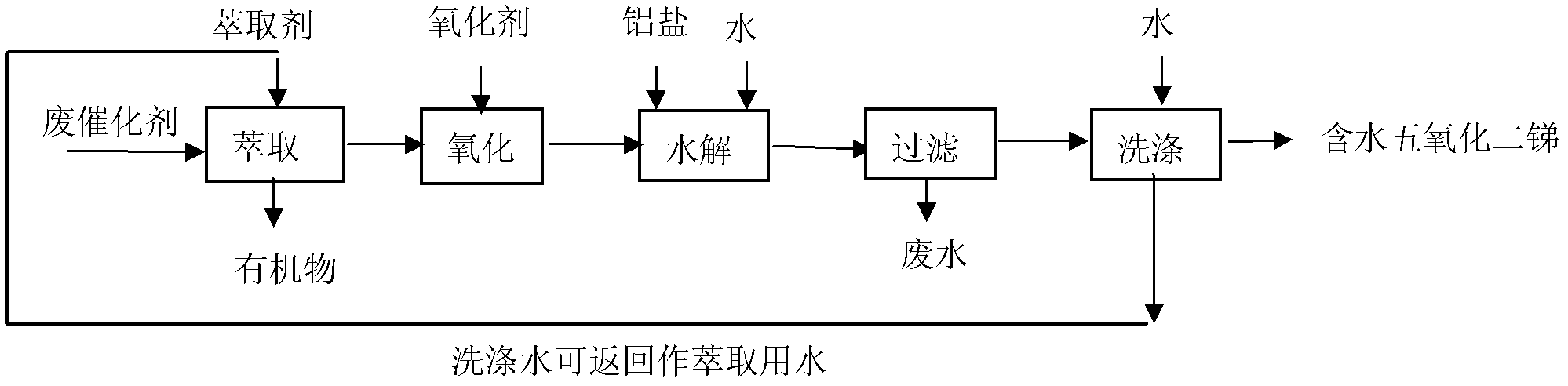

Method for recovering antimony pentoxide from waste antimony pentachloride serving as fluorination catalyst

A technology of antimony pentoxide and fluorination catalyst, which is applied in chemical instruments and methods, improvement of process efficiency, crystal growth, etc. It can solve the problems of high metal antimony activity, high elemental antimony, complex process, etc., and achieve less discharge of three wastes , Reduce the impact, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A) Extraction. Measure 100ml of water into a 500ml flask, slowly add 100ml of spent fluorination catalyst under stirring, and absorb the generated waste gas with water. After the feeding is completed and the stirring is continued for 10 minutes, the stirring is stopped, and the solution is moved to a separatory funnel and left to stand for 30 minutes to separate the upper and lower layers. 3+ 3.61%, Sb 5+ 16.90%;

[0026] B) oxidation. Weigh 100g of the aqueous solution containing antimony ions, according to the chemical reaction formula: Sb 3+ +H 2 o 2 +2H + =Sb 5+ +2H 2 After calculating the theoretical consumption of required 30% hydrogen peroxide, add 30% hydrogen peroxide by 1.2 times of theoretical consumption, and react for 30 minutes to oxidize trivalent antimony into pentavalent antimony to obtain 104.2 g of antimony oxidation solution;

[0027] C) Hydrolysis. Add 2.5ml of 200g / L aluminum trichloride solution to the antimony oxidation solution, add 30...

Embodiment 2

[0029] A) Extraction. Measure 75ml of water into a 500ml flask, slowly add 100ml of spent fluorination catalyst under stirring, and absorb the generated waste gas with water. Stir for 10 minutes after the addition, stop stirring, move the solution to a separatory funnel and let stand for 30 minutes to separate the upper and lower layers. The lower layer is an organic phase, and the upper layer is an aqueous phase. The separation obtains a total of 162.4 g of an aqueous solution containing antimony ions, wherein Sb 3+ 4.10%, Sb 5+ 19.45%;

[0030] B) oxidation. Weigh 100g of the aqueous solution containing antimony ions, according to the chemical reaction formula: Sb 3+ +H 2 o 2 +2H + =Sb 5+ +2H 2 After calculating the theoretical consumption of required 30% hydrogen peroxide, add 30% hydrogen peroxide by 1.1 times of theoretical consumption, and react for 30 minutes to oxidize trivalent antimony into pentavalent antimony to obtain 104.3 g of antimony oxidation solution...

Embodiment 3

[0033] A) Extraction. Measure 150ml of antimony pentoxide washing water into a 500ml flask, slowly add 100ml of spent fluorination catalyst under stirring, and absorb the generated waste gas with water. Stir for another 10 min after feeding, stop stirring, move the solution to a separatory funnel and let stand for 30 min to separate the upper and lower layers. 3+ 2.83%, 13.33%;

[0034] B) oxidation. Weigh 100g of the aqueous solution containing antimony ions, according to the chemical reaction formula: Sb 3+ +H 2 o 2 +2H + =Sb 5+ +2H 2 After calculating the theoretical consumption of required 30% hydrogen peroxide, add 30% hydrogen peroxide by 1.5 times of theoretical consumption, and react for 30 minutes to oxidize trivalent antimony into pentavalent antimony to obtain 104.1 g of antimony oxidation solution;

[0035] C) Hydrolysis. Add 5.0ml of 200g / L aluminum trichloride solution to the antimony oxidation solution, add 200g of water under stirring to hydrolyze the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com