Resin-based yawing brake pad for wind-generated generator and preparation method thereof

A technology for wind turbines and brake pads, applied to mechanical equipment, friction linings, etc., which can solve the problems of easy embroidering, damage to the dual disc, and easy generation of howling, etc., to reduce hardness, reduce manufacturing costs, and improve mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The formula description of wind power generator yaw brake pad provided by the invention

[0027] Phenolic resin / nitrile rubber 8, aluminum silicate / KFK fiber 22,

[0028] Aramid fiber 2, Potassium titanate whisker 5,

[0029] Steel fiber 10, copper fiber 5,

[0030] Antimony sulfide 8, graphite 15,

[0032] Modified alumina 7, organic friction powder 2,

[0033] Barite 15.

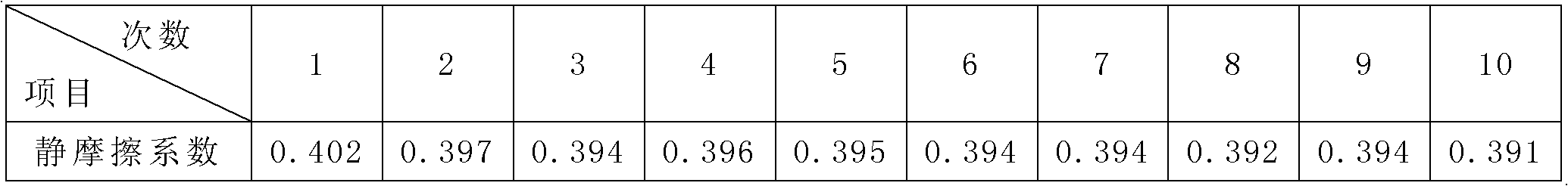

[0034] In this formula system, the friction material uses resin and rubber as the matrix, chromite, pyrite, and modified alumina are used as friction enhancers, antimony sulfide, and flake graphite are used as lubricating components, and steel fibers, copper fibers, and aromatics are added. Alon fibers, potassium titanate whiskers, ceramic fibers and mineral fibers are used as reinforcing phases. In addition to reducing costs, mineral fillers can also stabilize the friction coefficient, adjust the porosity of the material, and improve braking stability.

[0035]...

Embodiment 2

[0050] The formula description of wind power generator yaw brake pad provided by the invention

[0051] Phenolic resin / nitrile rubber 5, aluminum silicate / KFK fiber 25,

[0052] Aramid fiber 1, Potassium titanate whisker 10,

[0053] Steel fiber 20, copper fiber 10,

[0054] Antimony sulfide 3, graphite 6,

[0056] Modified Aluminum Oxide 4, Organic Friction Powder 3,

[0057] Barite 10.

[0058] Description of the preparation process of resin-based yaw brake pads for wind turbines

[0059](1), batching: weigh each component material according to the above ratio;

[0060] (2) Mixing: Put the weighed materials into the high-speed mixer, and the mixing time is 5 minutes;

[0061] (3) Molding: Weigh the mixture according to the model of the brake pad, pour it into the hot pressing mold, and the pressing pressure is 300kgf / cm 2 , the hot-pressing temperature is 200°C, the exhaust is 11 times, and the holding time is 60s / mm;

[0062] (4) Heat...

Embodiment 3

[0065] The formula description of wind power generator yaw brake pad provided by the invention

[0066] Phenolic resin / nitrile rubber 10, aluminum silicate / KFK fiber 15,

[0067] Aramid fiber 2, Potassium titanate whisker 4,

[0068] Steel fiber 10, copper fiber 5,

[0069] Antimony sulfide 3, graphite 16,

[0071] Modified alumina 8, organic friction powder 5,

[0072] Barite 20.

[0073] Description of the preparation process of resin-based yaw brake pads for wind turbines

[0074] (1), batching: weigh each component material according to the above ratio;

[0075] (2) Mixing: Put the weighed materials into the high-speed mixer, and the mixing time is 4 minutes;

[0076] (3) Molding: Weigh the mixture according to the model of the brake pad, pour it into the hot pressing mold, and the pressing pressure is 280kgf / cm 2 , the hot-pressing temperature is 180°C, the exhaust is 12 times, and the holding time is 55s / mm;

[0077] (4) Heat treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com