Antiskid, wear-resistant and temperature-resistant net belt driving wheel and preparation method thereof

A technology of driving wheels and mesh belts, applied in the direction of conveyor objects, conveyors, transportation and packaging, etc., to achieve excellent anti-skid performance, long service life, and anti-slip effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

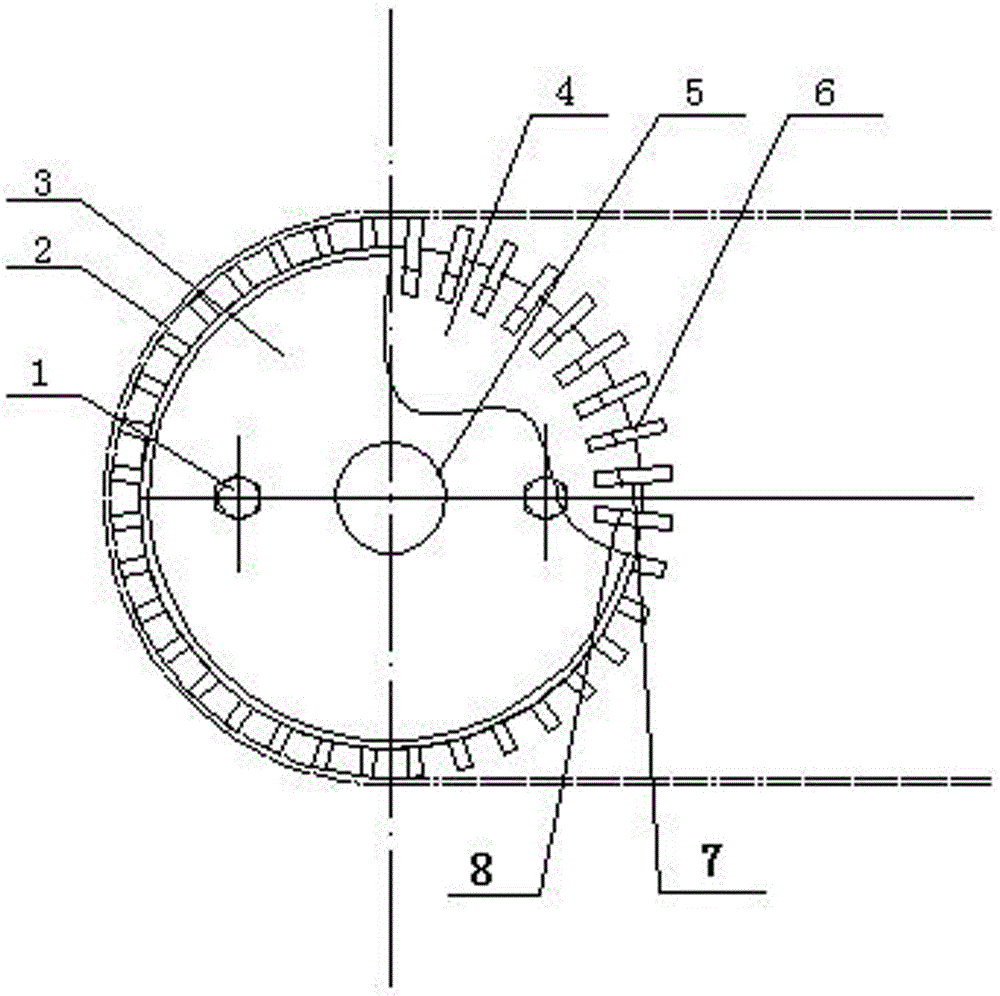

[0018] Such as figure 1 As shown, one embodiment of the anti-slip, wear-resistant and temperature-resistant mesh belt driving wheel of the present invention includes a wheel body 4, and the outer peripheral cylindrical surface of the wheel body 4 offers evenly distributed axial grooves 7, and the groove depth of the axial grooves 7 is greater than 1.25 times the groove width, each axial groove 7 is inlaid with copper flat strips 6; the width of the copper flat strips 6 is 0.1-0.5mm smaller than the groove width, and the exposed height of the copper flat strips is less than 50mm, greater than or equal to the thickness of the copper flat strips, The two ends of the copper flat bar 6 are 10-50mm beyond the two ends of the wheel body 4, and positioning steps 8 are formed at the two ends of the red copper flat bar; Into the groove 7, and the positioning steps 8 at the two ends of the red copper flat strip 6 are provided with a matching positioning ring 3, and are positioned on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com