Spinning oil for processing regenerated polyester fiber

A technology of recycled polyester and spinning oil, which is applied in the direction of fiber type, fiber treatment, flame retardant fiber, etc. It can solve the problems of easy pilling, dust, poor fiber coating, and large fiber friction, etc., to achieve guaranteed Effects of emulsifying properties, smoothness improvement, and static electricity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

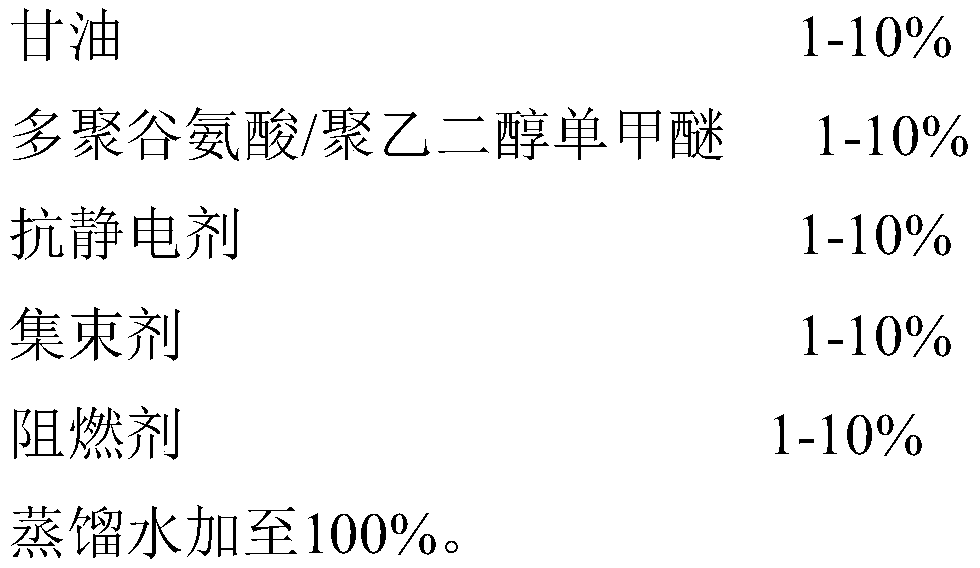

Method used

Image

Examples

Embodiment 1

[0026] Preparation of spinning oil: 4% glycerin, 3% polyglutamic acid / polyethylene glycol monomethyl ether, 5% antistatic agent SN, 3% polyethylene glycol oleate, phosphorus flame retardant Add DDP 3%, distilled water to 100%, mix well.

[0027] Preparation of polyglutamic acid / polyethylene glycol monomethyl ether: 10mmol polyglutamic acid and 10mmol polyethylene glycol monomethyl ether were dissolved in water at room temperature to prepare polyglutamic acid solution and polyethylene glycol Monomethyl ether solution, then add 0.1mmol concentrated sulfuric acid to the polyethylene glycol monomethyl ether solution, mix well, start to add polyglutamic acid solution dropwise, and heat up to reflux state for heat preservation reaction, and continue heat preservation reaction after the dropwise addition is completed After the reaction is completed, it is concentrated under reduced pressure to make a paste. The paste is naturally cooled to room temperature and then sent to a freeze d...

Embodiment 2

[0029] Taking Example 1 as a contrast, Example 2 using polyaluminum sulfate as an antistatic agent is set.

[0030] Preparation of spinning oil: 4% glycerin, 3% polyglutamic acid / polyethylene glycol monomethyl ether, 5% polyaluminum sulfate, 3% polyethylene glycol oleate, phosphorus flame retardant DDP 3%, add distilled water to 100%, mix well.

[0031] Preparation of polyglutamic acid / polyethylene glycol monomethyl ether: 10mmol polyglutamic acid and 10mmol polyethylene glycol monomethyl ether were dissolved in water at room temperature to prepare polyglutamic acid solution and polyethylene glycol Monomethyl ether solution, then add 0.1mmol concentrated sulfuric acid to the polyethylene glycol monomethyl ether solution, mix well, start to add polyglutamic acid solution dropwise, and heat up to reflux state for heat preservation reaction, and continue heat preservation reaction after the dropwise addition is completed After the reaction is completed, it is concentrated under ...

Embodiment 3

[0033] Taking Example 1 as a comparison, Example 3 using a mixture of polydipentaerythritol hexaacrylate and triethanolamine oleic acid soap as a flame retardant was set.

[0034] Preparation of spinning oil: 4% glycerin, 3% polyglutamic acid / polyethylene glycol monomethyl ether, 5% antistatic agent SN, 3% polyethylene glycol oleate, 3% flame retardant , Add distilled water to 100%, mix well.

[0035] The flame retardant is composed of polydipentaerythritol hexaacrylate and triethanolamine oleic acid soap in a mass ratio of 4:1.

[0036] Preparation of polyglutamic acid / polyethylene glycol monomethyl ether: 10mmol polyglutamic acid and 10mmol polyethylene glycol monomethyl ether were dissolved in water at room temperature to prepare polyglutamic acid solution and polyethylene glycol Monomethyl ether solution, then add 0.1mmol concentrated sulfuric acid to the polyethylene glycol monomethyl ether solution, mix well, start to add polyglutamic acid solution dropwise, and heat up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com