Treatment solution for preparing aluminum alloy surface amorphous composite passivation film, preparation method and application

A technology of aluminum alloy surface and treatment solution, which is applied in the coating process of metal materials, etc., can solve the problems of poor solution stability and low film-forming efficiency of chromium-free treatment solution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

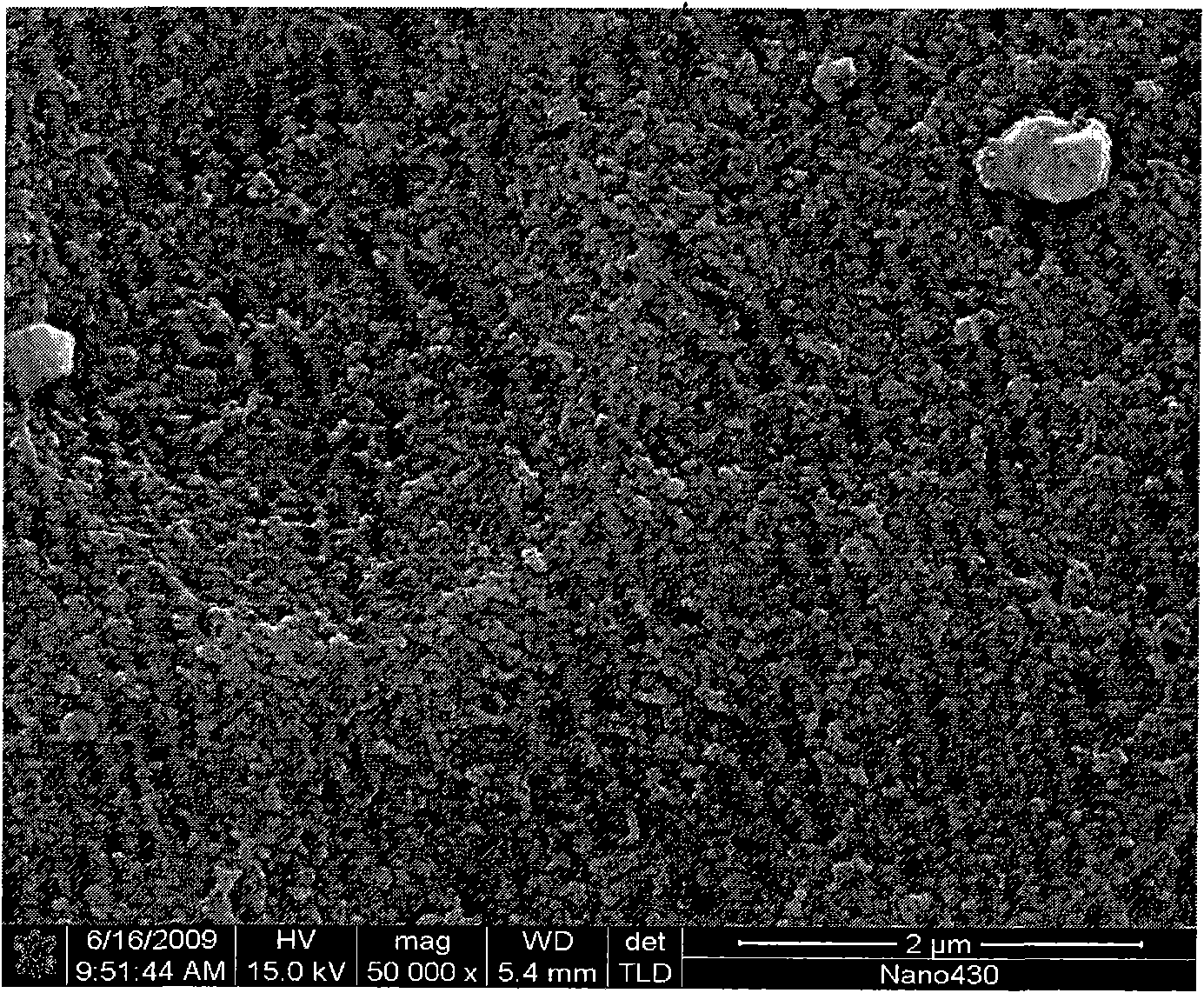

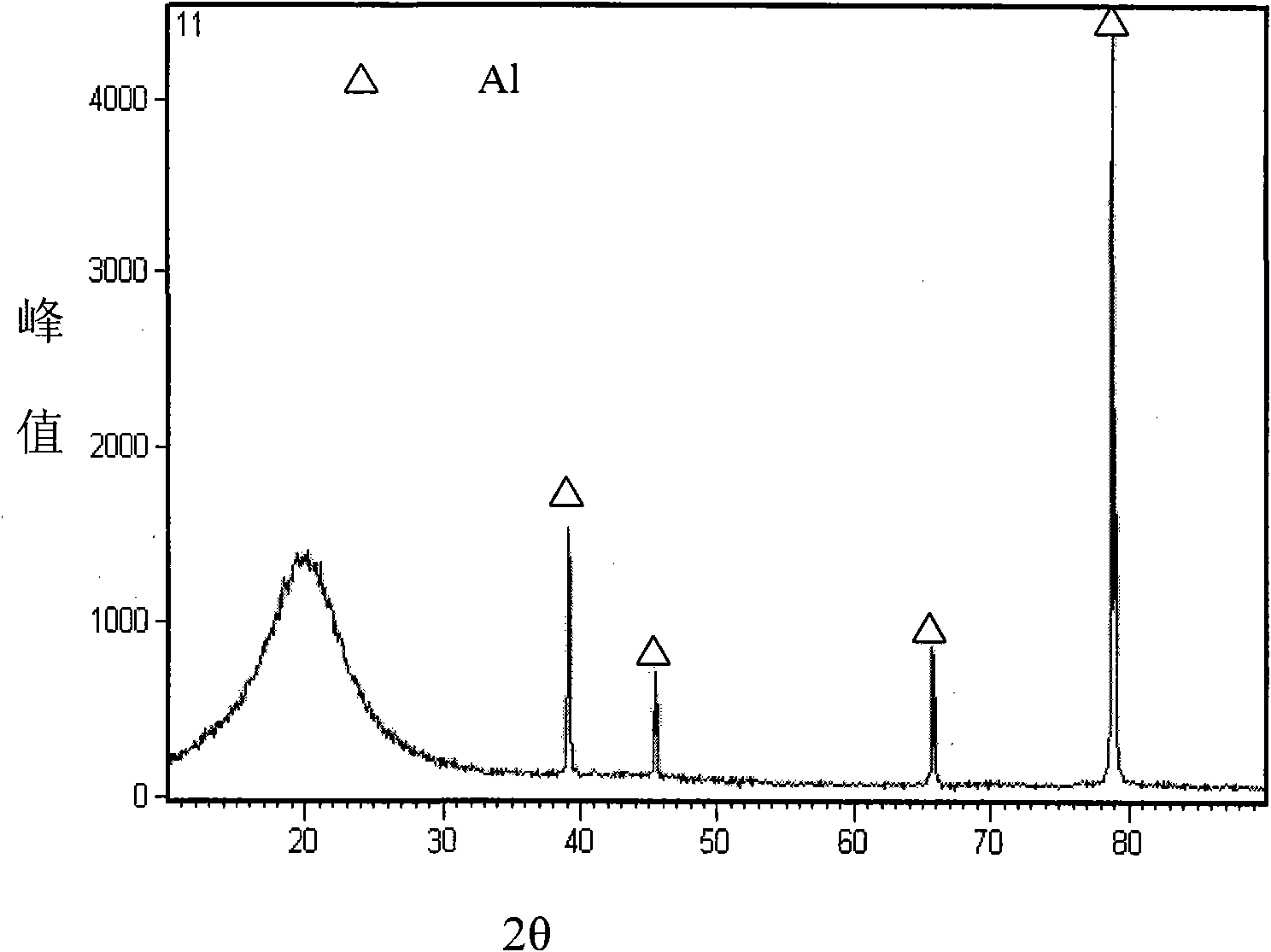

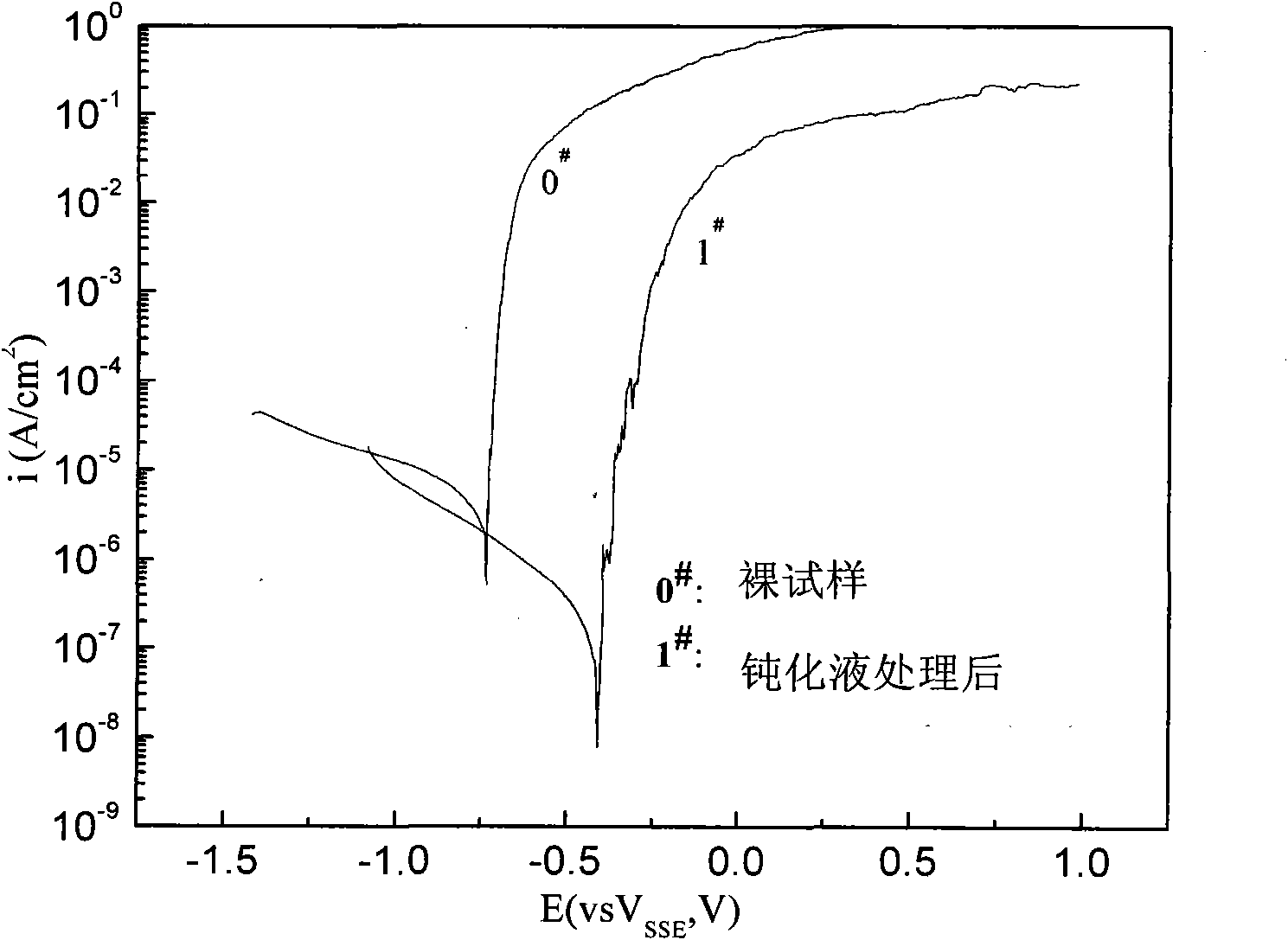

[0075] Example 1: Composite passivation treatment on the surface of 6063 aluminum alloy profiles

[0076] The aluminum alloy surface composite passivation treatment method comprises the following steps:

[0077] (1) Pretreatment

[0078] (a) Take a sample piece from a 6063 large-size aluminum alloy profile, and polish it with SiC water sandpaper until the surface roughness is 10 microns;

[0079] (b) First place the sample at a temperature of 50°C and a concentration of 40g L -1 Sodium hydroxide solution to degrease and degrease for 1 minute, then rinse with deionized water;

[0080] (c) Put the test piece into 15% (weight) dilute nitric acid solution and soak for 1 minute to remove ash, then rinse it with deionized water, and dry it with a hair dryer;

[0081] (d) the test piece is placed into the mixed acid solution (the weight percentage of the mixed acid solution is: 40% H 2 SO 4 , 10%H 3 PO 4 , 3% HF, and the rest are deionized water) for 1 minute, then rinse with de...

Embodiment 2

[0085] Example 2: Composite passivation treatment on the surface of 6063 aluminum alloy profiles

[0086] The processing method of the present embodiment is the same as embodiment 1,

[0087] Composite passivation treatment solution configuration: configure 1000ml composite passivation treatment solution, in which the weight-to-volume ratio concentration of various components in the treatment solution is as follows: cerium nitrate 5g L -1 , sodium bismuthate 3g·L -1 , potassium permanganate 1g·L -1 ; Ammonium bifluoride 0.1g L -1 , composite stabilizer 0.5g·L -1 (wherein boric acid 0.2g·L -1 , acetic acid 0.3g·L -1 ), adjusted to pH 1.8 with dilute nitric acid.

[0088] The aluminum alloy surface composite passivation treatment method is similar to that of Example 1, but the treatment time is slightly longer than that of Example 1, which is 5 minutes. Wherein the treatment solution is prepared and left for 1 hour to start the conversion treatment.

[0089] The film lay...

Embodiment 3

[0090] Example 3: Composite passivation treatment on the surface of 6063 aluminum alloy profiles

[0091] The treatment method of this embodiment is the same as that of Example 1, and the configuration of the composite passivation treatment solution: 1000 ml of the composite passivation treatment solution is configured, wherein the weight-to-volume ratio concentration of various components in the treatment solution is as follows: cerium nitrate 15g L -1 , Sodium bismuthate 10g·L -1 , potassium permanganate 3g·L -1 ; Ammonium bifluoride 0.5g L -1 , composite stabilizer 1.5g L -1 (wherein boric acid 0.5g·L -1 , acetic acid 1g·L -1 ), the pH of the passivation solution is 2.5.

[0092] The aluminum alloy surface composite passivation treatment method is similar to that of Example 1, but the treatment solution is prepared and placed for 15 days before conversion treatment, and the treatment time is 5 minutes.

[0093] After passivating the 6063 aluminum alloy with the passiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com