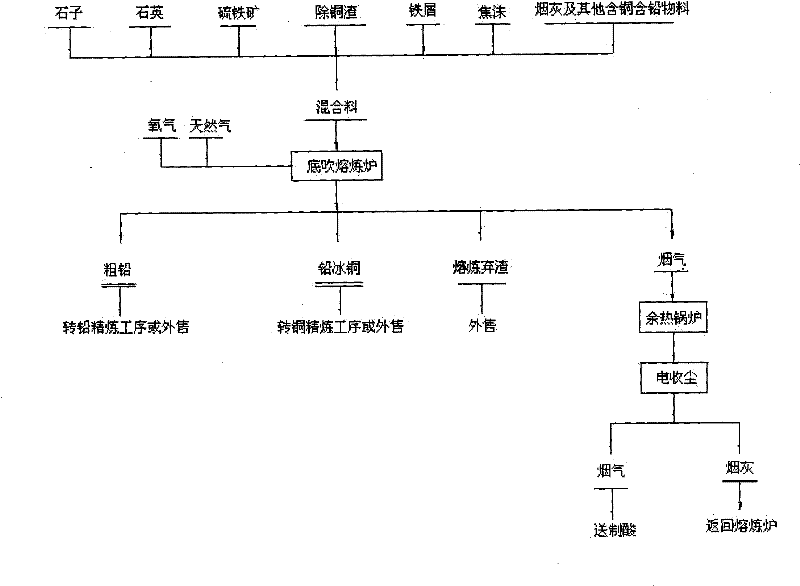

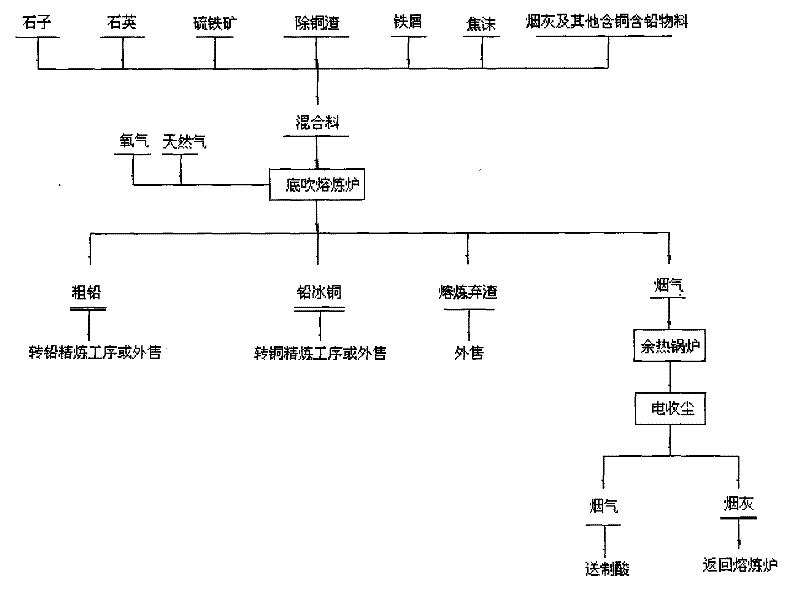

Process for removing copper slag and producing crude lead and lead copper matte by adopting melting treatment in bottom-blowing melting bath and device thereof

A technology of molten pool smelting and lead matte, which is applied in the direction of improving process efficiency, can solve the problems of short service life of furnace lining, large dust pollution, large fluctuation of flue gas volume and flue gas composition, etc., so as to improve production efficiency and improve Heat utilization, effect of improving production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

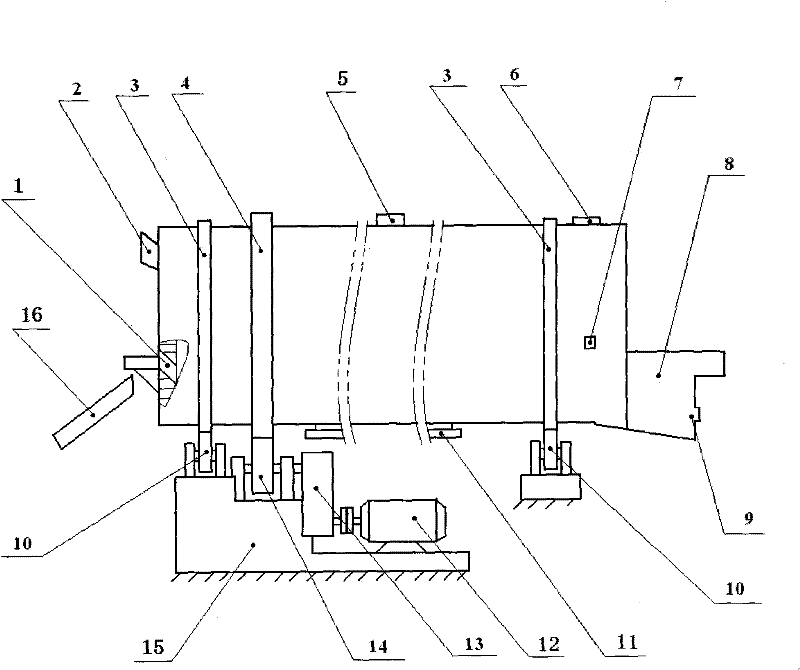

[0033] Such as figure 2 As shown in the schematic diagram of the main structure of the bottom blowing smelting furnace, the structural characteristics of the main process equipment of the bottom blowing smelting furnace are: the bottom blowing molten pool melting furnace (also called the bottom blowing smelting furnace) is a horizontal cylindrical converter, and the furnace body One end is equipped with a rough lead siphon lead release port 8, and a bottom lead port 9 is arranged below the siphon lead release port. The other end of the furnace body is provided with an inclined matte discharge port 1. The matte discharge port is low inside and high outside, and the matte is released through the chute 16 Ingot casting or water quenching, the slag discharge port 7 (slag discharge port 7) can be set on the side of the matte copper discharge port 1, or it can be arranged on the circumference of the furnace cylinder as shown in the figure, and the upper part of the cylinder is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com