Rapeseed oil distillation deacidification device

A rapeseed oil and deacidification technology, which is applied in the direction of oil/fat refining, fat production, etc., can solve the problems of inconvenient use of the device, no crushing and mixing device, rapeseed affecting the quality of rapeseed oil distillation, etc., so as to improve production. Efficiency, improve processing productivity, and the effect of ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

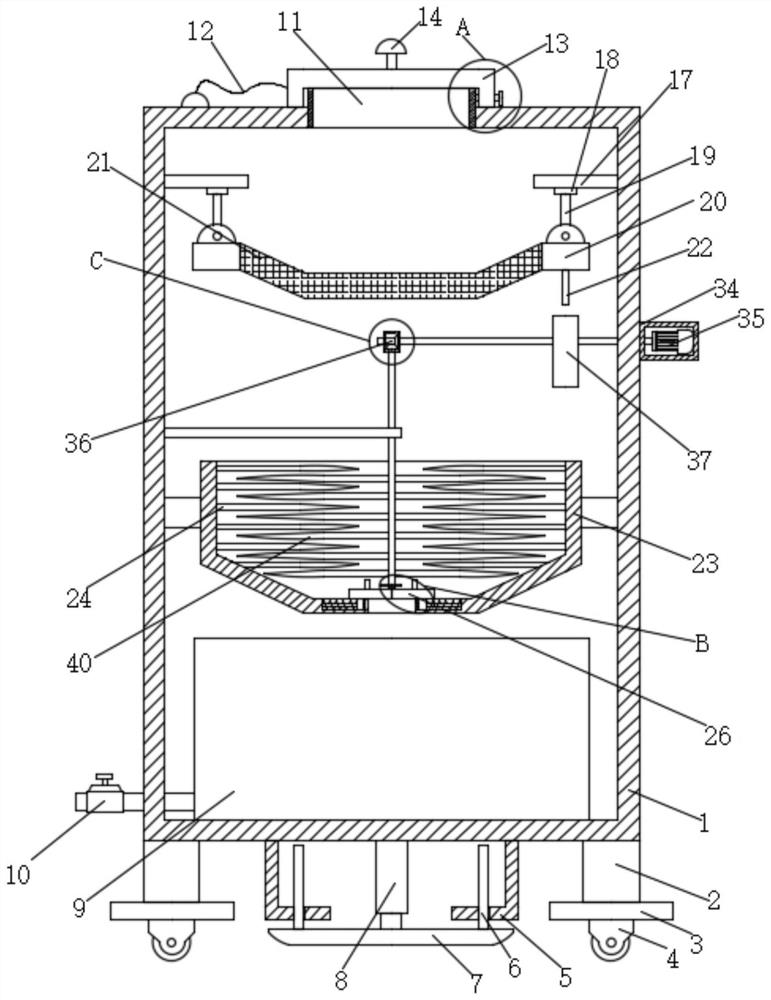

[0029] refer to Figure 1-6 , a rapeseed oil distillation and deacidification device, comprising a box body 1, two vertical plates 2 are symmetrically fixedly installed on the bottom of the box body 1, and a bottom plate 3 is fixedly installed on the bottom of the two vertical plates 2, and the bottom of the two bottom plates 3 A plurality of guide wheels 4 are movably installed at the bottom, and two mounting brackets 5 are symmetrically fixedly installed on the bottom of the box body 1, and slide bars 6 are slidably installed on the two mounting brackets 5, and the bottoms of the two slide bars 6 are fixedly installed with On the same top plate 7, an electric push rod 8 is fixedly installed on the bottom of the box body 1, the output shaft of the electric push rod 8 is fixedly connected with the top plate 7, and a distillation deacidification box 9 is fixedly installed on the inner wall of the bottom of the box body 1. A discharge pipe 10 is fixedly installed on the box 9, a...

Embodiment 2

[0040] refer to Figure 1-6 , a rapeseed oil distillation deacidification device, comprising a box 1, the bottom of the box 1 is symmetrically installed with two vertical plates 2 by welding, the bottom of the two vertical plates 2 are all installed with a bottom plate 3 by welding, the two bottom plates The bottom of 3 is equipped with several guide wheels 4, and the bottom of box body 1 is symmetrically installed with two mounting brackets 5 by welding, and sliding rods 6 are installed on the two mounting brackets 5, and the bottoms of the two sliding rods 6 The same top plate 7 is installed by welding, and the bottom of the box body 1 is installed with an electric push rod 8 by welding. Box 9, the distillation deacidification box 9 is equipped with a discharge pipe 10 by screws, the top of the box body 1 is installed with a feed pipe 11 by welding, and the top of the box body 1 is installed with the bottom end of a fixed rope 12 by welding, and the fixed rope The top of 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com