A kind of cornmeal pretreatment equipment and cornmeal pretreatment process

A technology of pretreatment and cornmeal, applied in the field of food processing, to achieve the effect of simplifying production process, saving energy and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

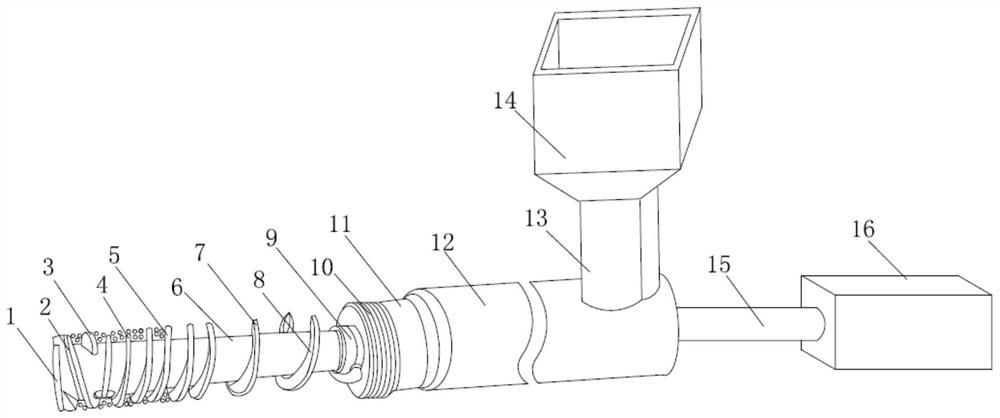

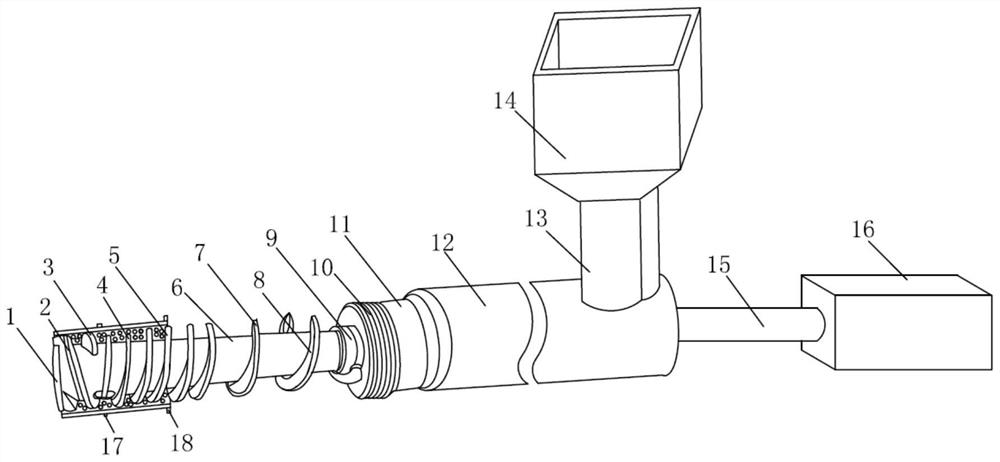

[0031] Such as Figures 1 to 2 As shown, the present invention provides a kind of cornmeal pretreatment equipment, comprises the puffing cylinder 12 that is communicated with the outlet 13 of soaking tank 14 bottoms, and described puffing cylinder 12 is provided with threaded shaft 6, and puffing cylinder 12 is cylindrical structure, The inner cavity 10 is arranged in the cylindrical structure, and the end of the cylindrical structure is provided with a puffing tube shrink tube 11, and the outer side of the puffing tube shrink tube 11 is provided with threads for connecting with other conveying pipelines, and the two ends of the threaded shaft 6 A helical thread group is provided between the threaded shaft end 1 and the threaded shaft end tail 9, the threaded shaft end tail 9 is connected to the output shaft 15 of the motor 16, and the helical thread group includes And the fifth helical thread 8, the fourth helical thread 7, the third helical thread 5 and the second helical th...

Embodiment 2

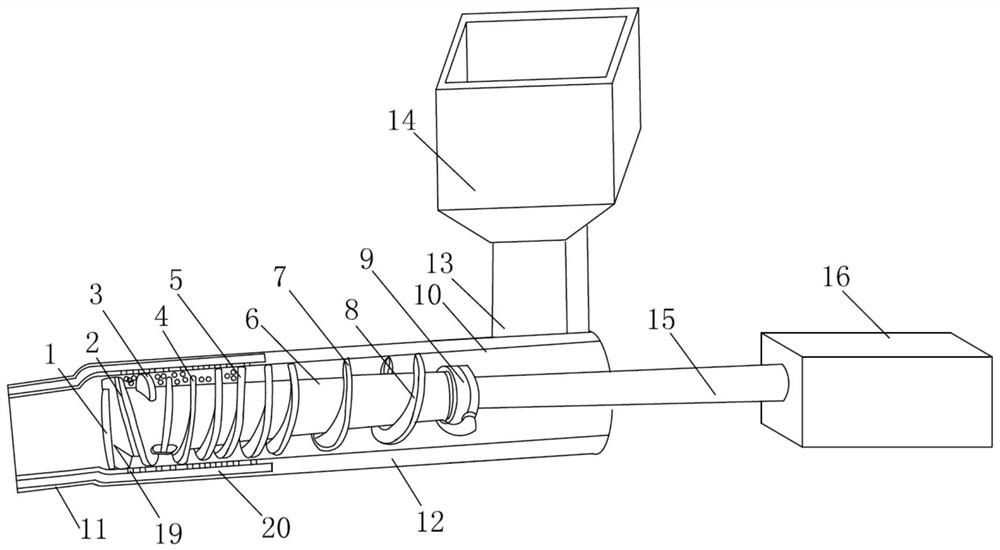

[0035] Such as image 3 As shown, this embodiment has been further improved on the basis of Embodiment 1, and the other structures are the same, and the difference is that in the rice noodle pretreatment equipment provided by the present invention, the preferred structure is in the side wall of the expansion cylinder 12 An expansion channel 20 is provided, and the inner wall of the tube wall of the expansion channel 20 is provided with several through holes, and a gap is provided between the inner wall and the threaded shaft 6 . In a preferred solution, the diameter of the through hole ranges from 0.5 mm to 1.5 mm, and the preferred diameter is 0.5 mm, 0.7 mm, 0.8 mm, 1.0 mm, 1.2 mm or 1.5 mm. Since the puffing channel 20 is provided in this embodiment, The structure of the equipment is simplified, which is beneficial to equipment maintenance.

Embodiment 3

[0037] The present invention also provides using the rice flour pretreatment equipment described in embodiment 1 and embodiment 2 to carry out cornmeal pretreatment process, described cornmeal pretreatment process comprises the following steps:

[0038] Step 1) Pour the selected whole grain corn into the soaking tank 14, add water until the corn that needs to be soaked and puffed is completely submerged, and at the same time control the temperature of the added water, and the temperature range of the controlled water is 15° to 20°;

[0039]Step 2) The water soaked in the corn in step 1) is circulated, and the soaking time is 0.5 days to 3 days, and the puffing treatment is carried out. The soaking time selected in this embodiment is 24 hours;

[0040] Step 3) Treat the corn puffed in step 2) through pretreatment equipment, first turn on the control switch of the motor 16 to energize, and drive the threaded shaft 6 to rotate through the output shaft 15, and soak the threaded sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com