Method for preparing high alloy steel seamless steel pipe

A seamless steel pipe and high-alloy steel technology, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of aggravated damage and failure of seamless steel pipes, threats to enterprise safety production, casualty accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

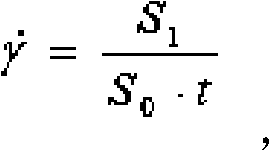

Method used

Image

Examples

Embodiment 1

[0081] Production of high-alloy steel seamless pipes with a size of 244.48×15.11mm

[0082] (1) Ingredients smelting: blast furnace molten iron is used as raw material for steelmaking, which is melted into molten steel by electric arc furnace (EFA). In ladle refining, 11.5kg of CaO refining slag is added per ton of molten steel to adjust the alkalinity of molten steel to 2.6, viscosity to 0.35Pa·s, and melting point to 1560°C. Then use a large circulation tube to blow argon gas and stir strongly. The pressure of argon gas blowing at the bottom is 0.3MPa, and the flow rate is 100-500NL / min. Vacuum cycle degassing treatment is performed to obtain the composition of molten steel for manufacturing high-alloy steel seamless steel pipes by weight percentage For: C: 0.11%, Si: 0.40%, Mn: 0.45%, Cr: 6.5%, Mo: 0.95%, Al: 0.020%, Ni<0.30%, Cu: 0.15%, V: 0.20%, Ti: 0.11 %, Nb: 0.07%, N: 0.04%, Ca<0.0010%, P<0.015%, S<0.003%, and the rest is iron.

[0083] (2) Continuous casting and rol...

Embodiment 2

[0091] Production of high-alloy steel seamless pipes with a size of 244.48×15.11mm

[0092](1) Ingredients smelting: blast furnace molten iron is used as raw material for steelmaking, which is melted into molten steel by electric arc furnace (EFA). In ladle refining, 11.0kg of CaO refining slag is added per ton of molten steel to adjust the alkalinity of molten steel to 2.5, viscosity to 0.32Pa·s, and melting point to 1560°C. Afterwards, a large-scale circulation pipe is used to blow argon gas for strong stirring, the pressure of argon gas blowing at the bottom is 0.3MPa, and the flow rate is 100-500NL / min, and vacuum cycle degassing treatment is carried out to obtain the molten steel composition by weight for manufacturing high-alloy steel seamless steel pipes The percentages are: C: 0.09%, Si: 0.35%, Mn: 0.45%, Cr: 5.2%, Mo: 0.95%, Al: 0.025%, Ni<0.30%, Cu: 0.17%, V: 0.23%, Ti: 0.12%, Nb: 0.081%, N: 0.05%, Ca<0.0011%, P<0.020%, S<0.003%, and the rest is iron.

[0093] (2) ...

Embodiment 3

[0101] Production of high-alloy steel seamless pipes with a size of 244.48×15.11mm

[0102] (1) Ingredients smelting: blast furnace molten iron is used as raw material for steelmaking, which is melted into molten steel by electric arc furnace (EFA). In ladle refining, 11.3kg of CaO refining slag is added per ton of steel to adjust the alkalinity of molten steel to 2.5, viscosity to 0.33Pa·s, and melting point to 1560°C. Afterwards, a large-scale circulation pipe is used to blow argon gas for strong stirring, the pressure of argon gas blowing at the bottom is 0.3MPa, and the flow rate is 100-500NL / min, and vacuum cycle degassing treatment is carried out to obtain the molten steel composition by weight for manufacturing high-alloy steel seamless steel pipes The percentages are: C: 0.10%, Si: 0.35%, Mn: 0.45%, Cr: 7.4%, Mo: 0.95%, Al: 0.025%, Ni<0.25%, Cu: 0.11%, V: 0.21%, Ti: 0.12%, Nb: 0.078%, N: 0.05%, Ca<0.0012%, P<0.020%, S<0.003%, and the rest is iron.

[0103] (2) Contin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| residual stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com