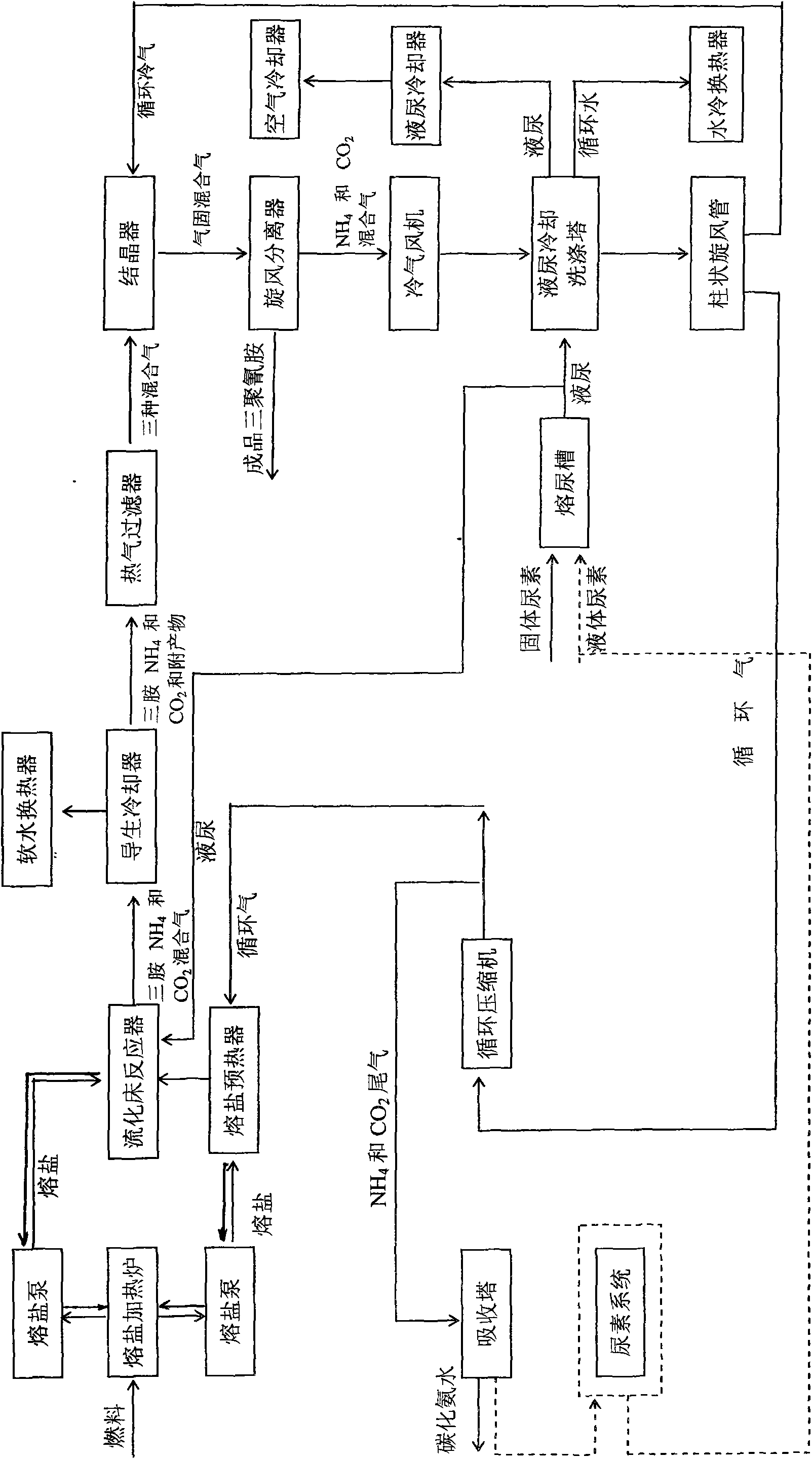

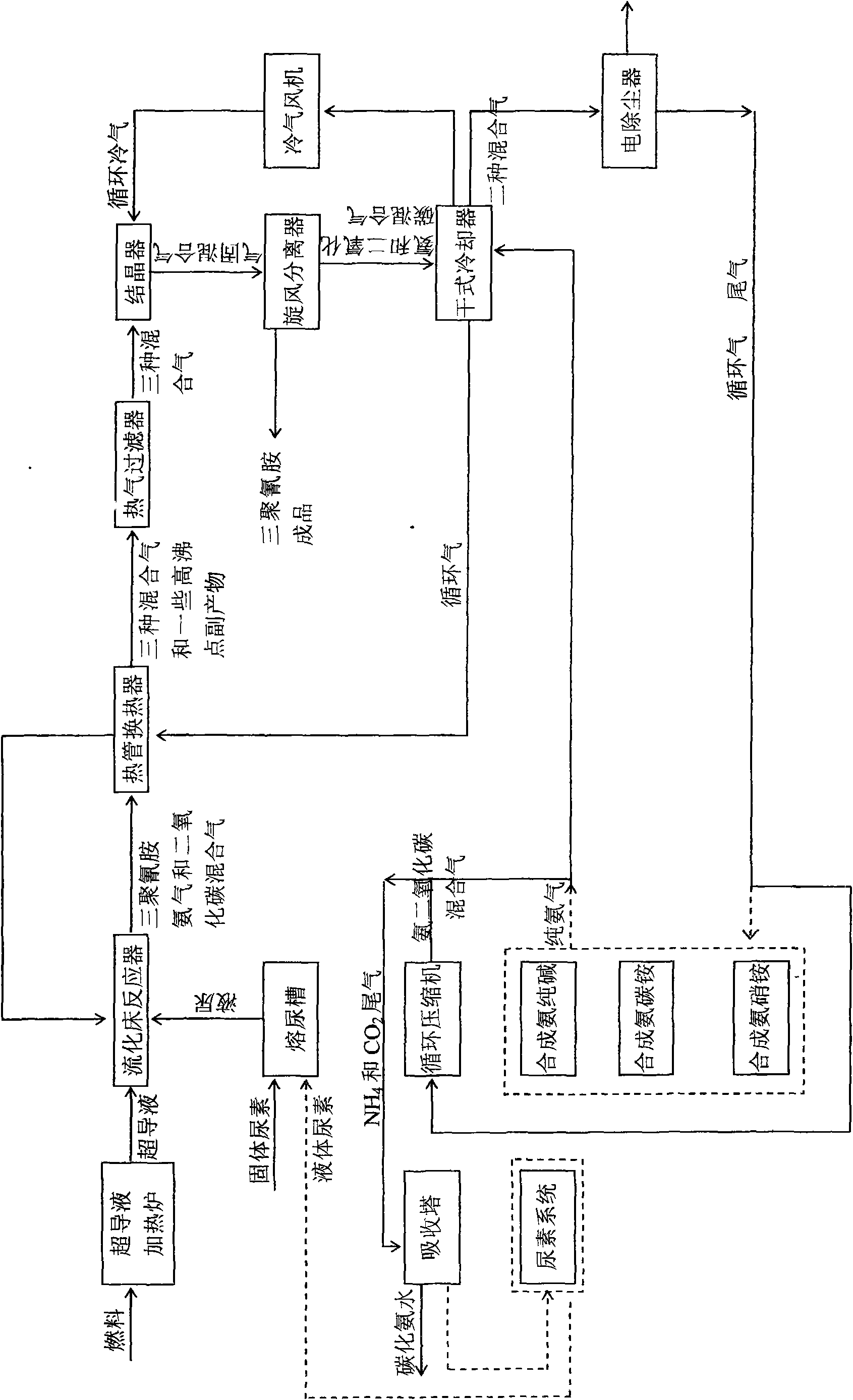

Energy-saving technology for producing melamine by one-step method

A melamine and process technology, which is applied in the energy-saving production process of melamine, can solve the problems that waste heat cannot be recycled by the system, high power operation costs, and large heat loss, etc., to achieve continuous and automatic production, saving investment and operating costs , The effect of low investment and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1, the fluidized working gas of the fluidized bed is the mixed gas of ammonia and carbon dioxide provided by the circulating compressor.

[0037] The first step: the production of melamine

[0038] (1) Melt solid urea into liquid urine at about 135°C in the urine melting tank or send the liquid urine drawn from the urea system into the fluidized bed reactor for normal or low pressure reaction under the catalysis of silica gel, and the reaction gauge pressure Choose within the range of 20-1000Kpa, and control the temperature within the range of 380-398°C;

[0039] The above-mentioned fluidized bed reactor is heated by a superconducting liquid heating furnace, and the heating temperature of the furnace is required to be controlled within the range of 400-450°C;

[0040] (2) Fill the system with ammonia gas as the initial circulating working gas. Under the action of ammonia gas, liquid urine decomposes and reacts in the fluidized bed reactor to generate gaseous...

Embodiment 2

[0044] Embodiment 2, the fluidized bed fluidized working gas is the pure ammonia working gas provided by the synthetic ammonia section of the synthetic ammonia soda ash plant or the synthetic ammonia ammonium bicarbonate plant or the synthetic ammonia ammonium nitrate plant.

[0045] The process route of embodiment two and embodiment one is basically the same, the difference is: the one, when melamine is made, the pure ammonia gas provided by the synthetic ammonia workshop section of synthetic ammonia soda ash plant or synthetic ammonia ammonium bicarbonate plant or synthetic ammonia ammonium nitrate plant is used as working gas, the table The pressure is about 100-300Kpa; the second is that the mixed tail gas of purified ammonia and carbon dioxide enters the synthetic ammonia soda ash plant or the synthetic ammonia ammonium bicarbonate plant or the synthetic ammonia ammonium nitrate plant to provide raw materials for recycling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com