Interdigital type piezoelectric fibre composite material, preparation method and application thereof

A technology of piezoelectric fibers and composite materials, which is used in the selection of materials for piezoelectric devices or electrostrictive devices, the manufacture/assembly of piezoelectric/electrostrictive devices, and the selection of device materials. Component research and other issues, to achieve the effect of significant sensing performance, small fiber diameter, and sensitive voltage response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

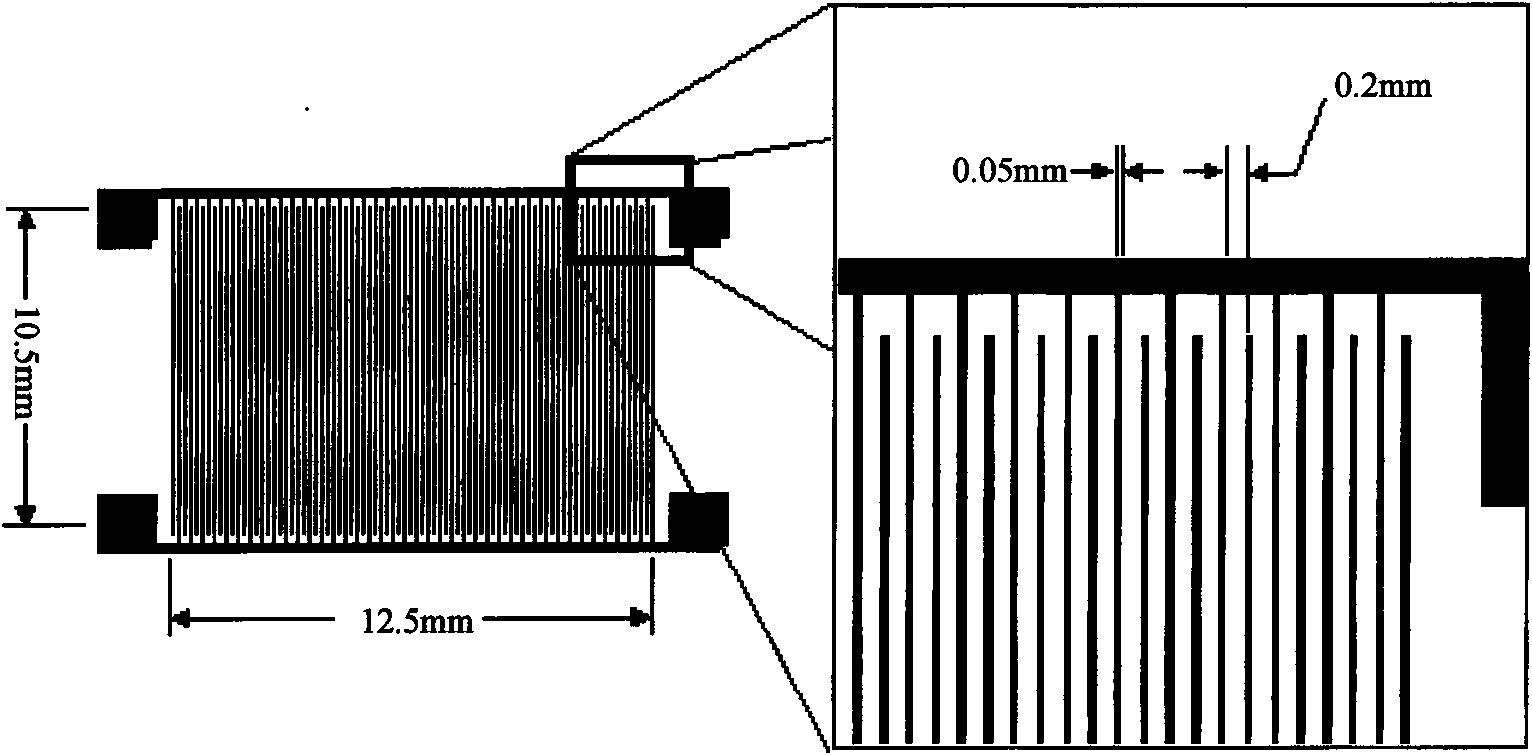

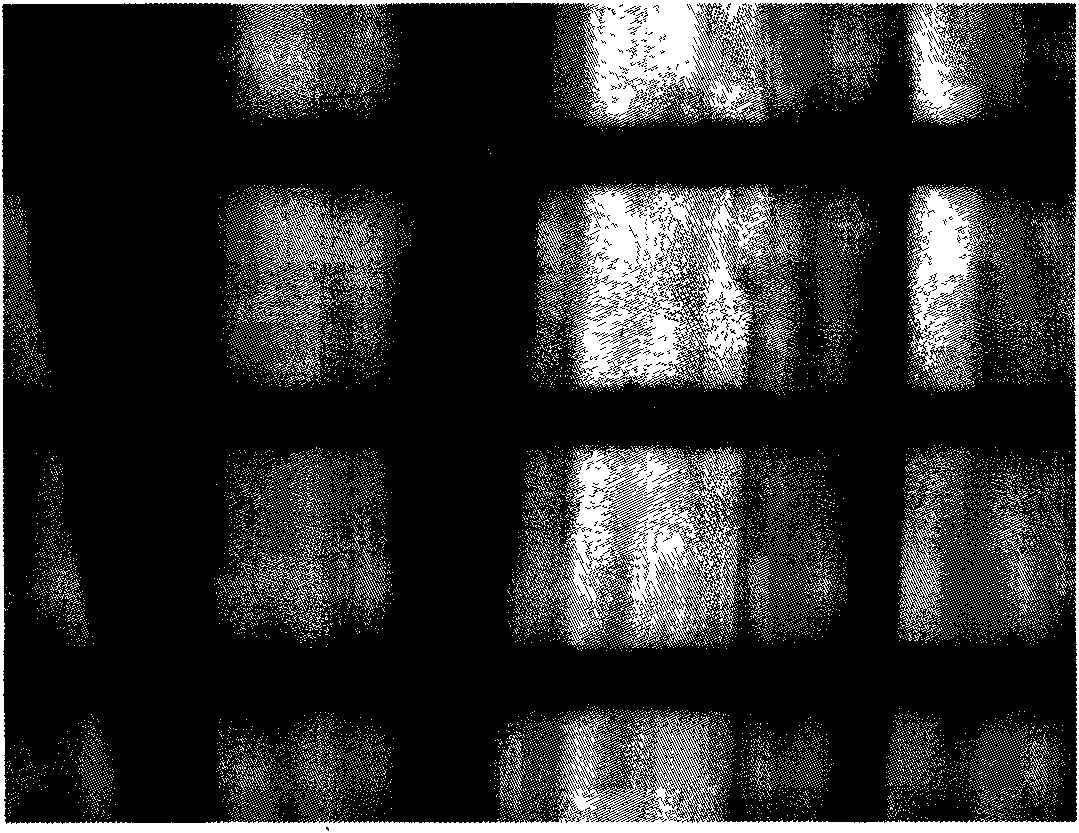

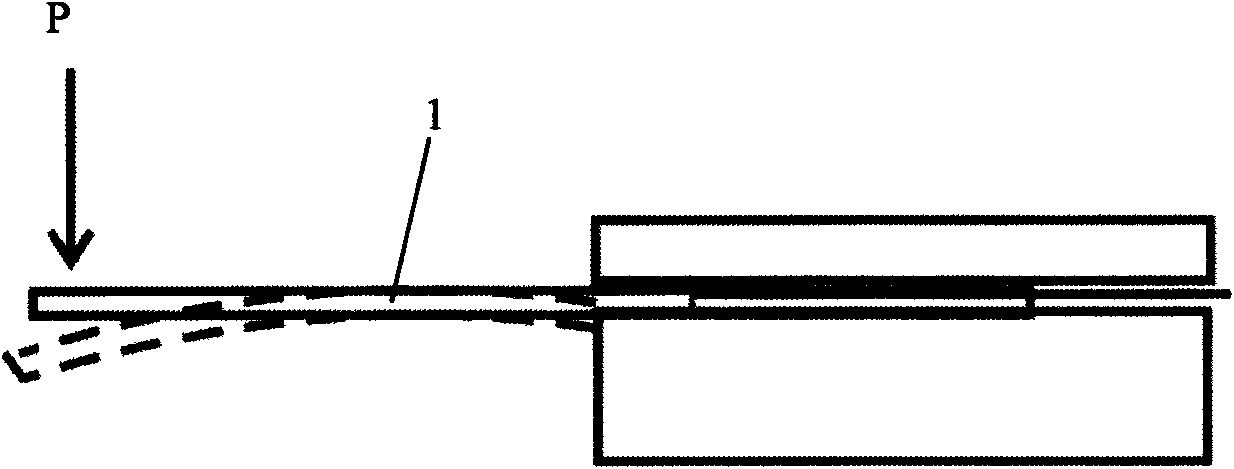

[0039] Example 1: Piezoelectric lead zirconate titanate PZT fibers were prepared by sol-gel method and continuous spinning technology, and ferroelectric tetragonal phase ceramic fibers were obtained after heat treatment. The PZT ceramic fibers had a dense structure and a diameter of less than 50 μm. The PZT ceramic fibers are arranged in the mold, and the prepared epoxy resin is poured around the PZT ceramic fibers and cured. Different numbers of PZT ceramic fibers were arranged to obtain piezoelectric fiber composites with different fiber volume fractions. The mass ratio of epoxy resin and hardener in Example 1 is 100:32, and the fiber volume fraction is 30%. After weighing and stirring evenly, place it in a vacuum oven to remove air bubbles by vacuuming at room temperature. The piezoelectric fiber composite material After curing, it comes out of the mold and has a thin and long sheet shape. Grind the cured sample into a thin slice of about 0.3-0.4mm with sandpaper, and poli...

Embodiment 2

[0042] Example 2: Piezoelectric lead zirconate titanate PZT fibers were prepared by sol-gel method and continuous spinning technology. The PZT fibers were heat-treated at 1000° C. for 1 hour, and the fiber structure was compact and the diameter was less than 50 μm. The PZT ceramic fibers are arranged in the mold, and the prepared epoxy resin is poured around the PZT ceramic fibers and cured. A piezoelectric fiber composite material with a fiber volume fraction of 40% was prepared. After preparing the epoxy resin and stirring it evenly, place it in a vacuum oven at room temperature to evacuate to remove air bubbles. After the piezoelectric fiber composite material is cured, it will come out of the mold and have a thin and long sheet shape. Grind the cured sample into a thin slice of about 0.3mm with sandpaper, and polish it. In the grinding process, first use coarse sandpaper to polish, then use fine sandpaper, and finally polish with 0.5 μm abrasive paste to obtain 1-3 type P...

Embodiment 3

[0044] Example 3: Piezoelectric lead zirconate titanate PZT fibers were prepared by sol-gel method and continuous spinning technology. The PZT fibers were heat-treated at 900° C. for 1 hour, and the fiber structure was dense and the diameter was less than 50 μm. The PZT ceramic fibers are arranged in the mold, and the prepared silicone resin is poured around the PZT ceramic fibers and cured. A piezoelectric fiber composite material with a fiber volume fraction of 50% was prepared. After preparing the silicone resin and stirring it evenly, place it in a vacuum oven at room temperature to evacuate to remove air bubbles. After the piezoelectric fiber composite material is cured, it will come out of the mold and have a thin and long sheet shape. Grind the cured sample into a thin slice of about 0.3mm with sandpaper, and polish it. In the grinding process, first use coarse sandpaper to polish, then use fine sandpaper, and finally polish with 0.5 μm abrasive paste to obtain 1-3 typ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com