Catalyst for dehydrogenation of C16-C19 long chain normal alkanes and preparation method and application thereof

A C16-C19, dehydrogenation catalyst technology, applied in the direction of metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the dehydrogenation of long-chain alkanes, there is no literature Reporting, low stability, unable to meet the requirements of industrial use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] γ-Al 2 o 3 Preparation of vector

[0027] Mix aluminum hydroxide, pseudo-boehmite and kale powder with a weight ratio of 8:1:1 evenly, add 15% nitric acid, stir and extrude into strips with an extruder, and then dry at 120°C for 4 hours , roasted at 650°C for 8 hours, crushed into 18-20 mesh particles, and finally treated with steam at 650°C for 8 hours. The physical and chemical properties of the obtained carrier are: bulk specific gravity 0.68 g / ml, specific surface area 198 m 2 / g, average particle crushing strength 112 N / cm, pore volume 0.61 cm 3 / g, the average pore diameter is 135nm, of which 0~10nm pores account for 38%, and 100~2000nm pores account for 40%.

Embodiment 2

[0029] Catalyst preparation

[0030] Get the Al prepared in Example 1 2 o 3 50ml of the carrier is placed in an incubator, and at the same time, take 4.4ml of chloroplatinic acid aqueous solution containing 0.02g / ml of platinum, 2.4ml of concentrated hydrochloric acid, 4.5ml of stannous chloride aqueous solution containing 0.06g / ml of tin, and 0.06g / ml of iron 0.9 milliliters of ferric chloride aqueous solution, 2.0 milliliters of potassium chloride aqueous solution containing potassium 0.1 g / ml, add deionized water so that the volume of soaking solution is 42 ml. Add the above impregnating solution into an impregnator equipped with a carrier, impregnate evenly and dry, then roast in a muffle furnace at 500°C for 4 hours, then in the roasting furnace with an air flow rate of 200 ml / min and a water flow rate of 40 g / hour, 500 Treat with 30% steam for 4 hours at ℃, stop the water and continue air cooling, and reduce with pure hydrogen (purity>99.9%) with water content less tha...

Embodiment 3

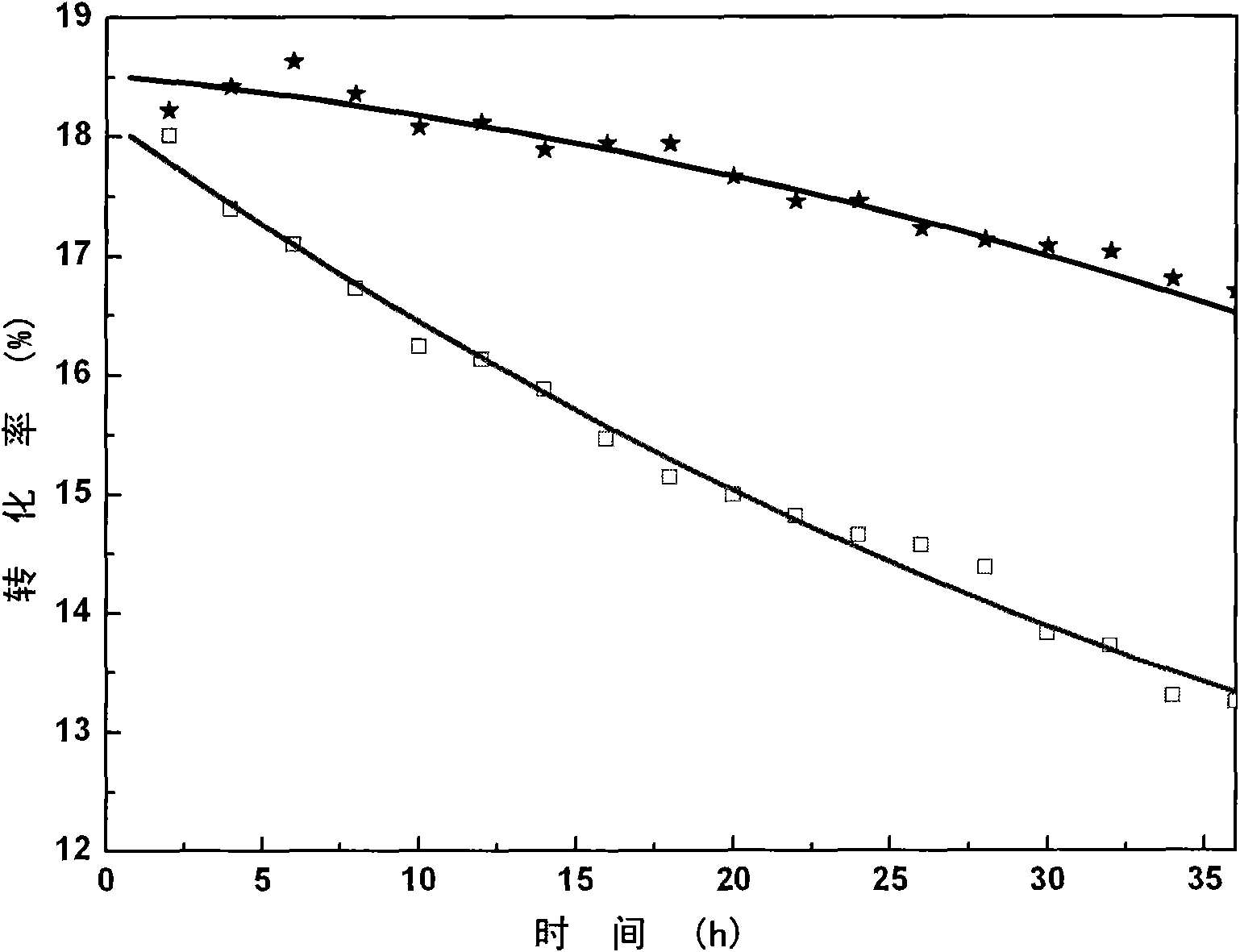

[0035] long chain n-alkanes C 18 Dehydrogenation to Monoolefins

[0036] On the fixed-bed reactor, the catalyst prepared in Example 2 is evaluated for the long-chain alkane dehydrogenation reaction. 18 Alkanes are raw materials, at a pressure of 0.14 MPa (gauge pressure) and a liquid space velocity of 20 -1 , the ratio of hydrogen to hydrocarbon is 600:1 (volume ratio), and the reaction is carried out under the condition of controlling the initial outlet temperature of the catalyst bed at 455° C., and the conversion rate of normal alkanes is calculated by analyzing the dehydrogenation product components. Orthomorphic C 18 For the alkane conversion rate-time curve, see figure 1 (A).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com