Seal film for solar cell module and solar cell module utilizing the same

A technology of solar cells and sealing films, which is applied in household seals, applications, circuits, etc., can solve the problems of electrical insulation of sealing films, lower gas barrier properties, and lower gas barrier properties of gas barrier layers, and improve output power reduction , Good balance of heat resistance, and the effect of suppressing changes over time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0196] (1) Aggregation of PPS

[0197] Add 32 kg (250 mol, including 40% by mass of crystal water) of sodium sulfide, 100 g of sodium hydroxide, 36.1 kg (250 mol) of sodium benzoate, and 79.2 kg of N-methyl-2-pyrrolidone (hereinafter referred to as NMP) into the autoclave , while stirring, the temperature was slowly raised to 205° C., and 7.0 liters of distilled liquid containing 6.9 kg of water were removed. 37.5 kg (255 mol) and 20 kg of NMP were added to the remaining mixture, and it polymerized at 250 degreeC for 5 hours. The obtained reaction product was alternately washed 8 times with hot water using ion-exchanged water and NMP, and dried at 80° C. for 24 hours with a vacuum dryer. The melt viscosity of the obtained PPS powder polymer was 4100 poise, the glass transition temperature was 90°C, and the melting point was 285°C.

[0198] (2) Preparation of PPS resin composition

[0199] After adding 1% calcium carbonate powder with an average particle diameter of 1 μm to ...

Embodiment 2

[0217] A PPS film was produced by the same method as in Example 1, and the heat treatment temperature after stretching was set to 260°C, and the post-annealing temperature was set to 150°C. The thus obtained film having a thickness of 25 μm was designated as PPS-F-2. The orientation degree OF of this film was 0.39 in the edge direction and 0.42 in the terminal direction.

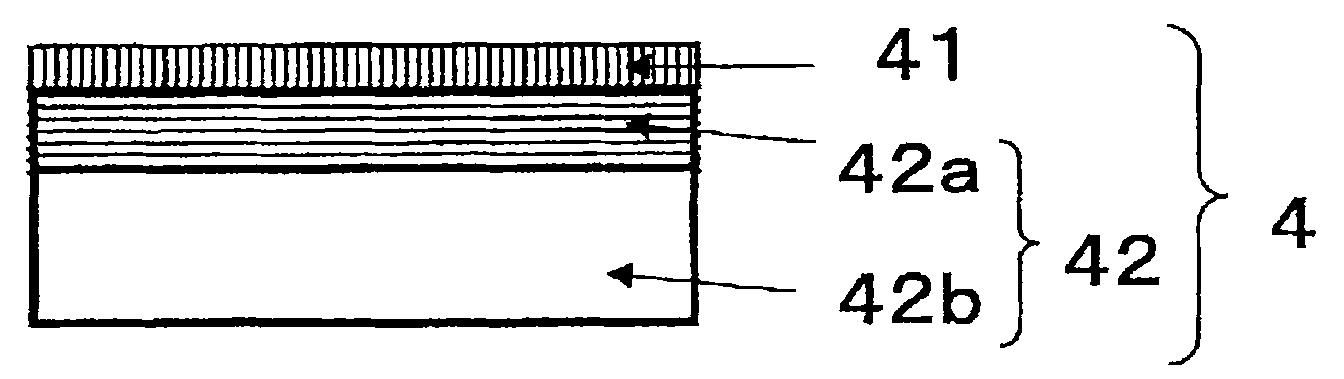

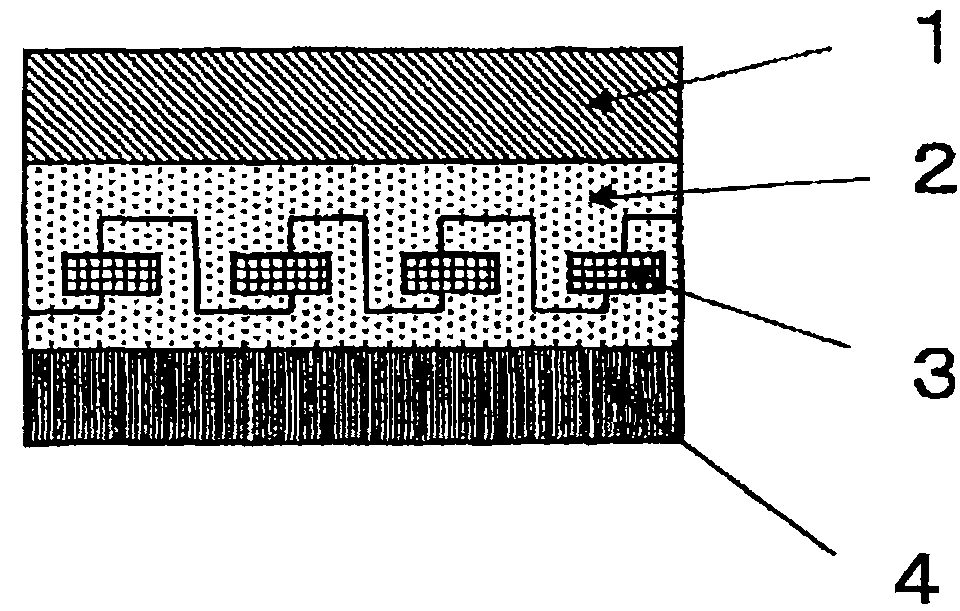

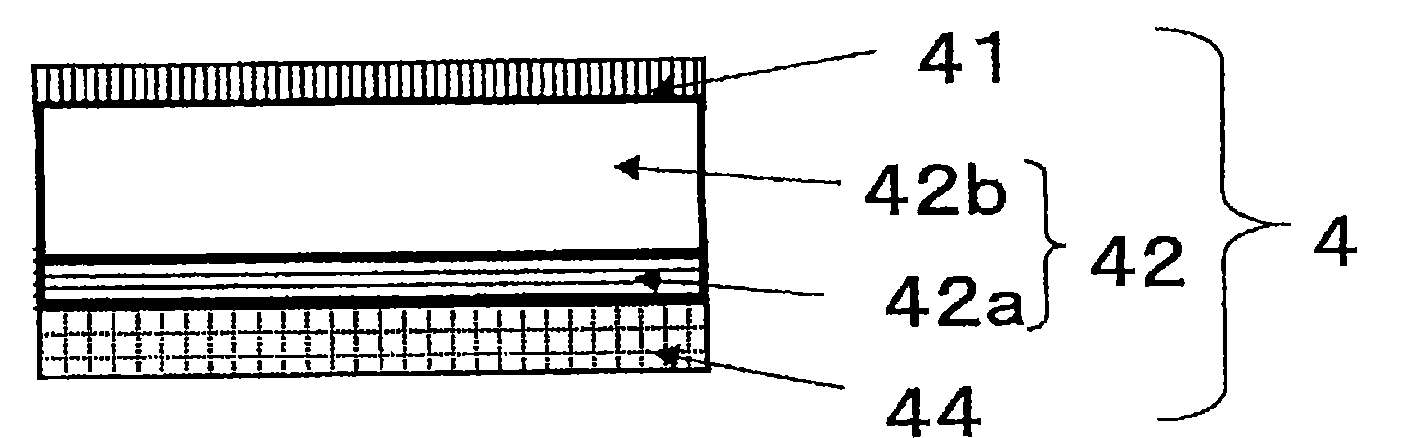

[0218] On the other hand, the PET film was manufactured in the same manner as PET-F-1 of Example 1, and the post-annealing temperature was set to 150°C. The obtained film with a thickness of 100 μm was designated as PET-F-2. The above-mentioned PPS-F-2 and PET-F-2 were laminated into a three-layer structure of PPS-F-2 / PET-F-2 / PPS-F-2 by the method of Example 1 to form a resin film layer. Then, a gas barrier layer-1 was laminated on one surface of the resin film layer by the same method as in Example 1 to obtain a sealing film (as sealing film-2). The water vapor transmission rate of the film is 0.5g / m 2 ...

Embodiment 3

[0220] A PPS film was prepared by the method of Example 1, the heat treatment temperature was set to 260° C., and the relaxation rate in the width direction in the same tenter was set to 12%. The degree of orientation OF of this film was 0.32 in the edge direction and 0.36 in the terminal direction. In addition, the post-annealing treatment was performed using the method of Example 1 at a temperature of 150° C. for one minute. The obtained film with a thickness of 25 μm was designated as PPS-F-3. On the other hand, the stretch ratio of the PET film in the longitudinal direction and the width direction was set to 3.5 times, and the heat treatment conditions and post-annealing treatment were carried out under the conditions of Example 1 to obtain a PET film with a thickness of 100 μm. This film was called PET-F-3.

[0221] The PPS-F-3 and PET-F-1 were laminated in three layers under the same lamination structure and conditions as in Example 1, and then the gas barrier layer-1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com