Method for preparing high temperature superconduction coating conductor buffer layer using polymer auxiliary azotate deposition

A polymer-assisted, high-temperature superconducting technology, applied in the usage of superconducting elements, superconducting/high-conducting conductors, manufacturing/processing of superconducting devices, etc., can solve the complex system, high cost and unsuitable industrial production of physical vapor deposition methods and other problems, to achieve the effect of smooth and compact surface, easy operation and control, and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0026] A kind of specific embodiment of the present invention is:

[0027] A kind of polymer-assisted nitrate deposition prepares the method for high-temperature superconducting coating conductor buffer layer, and its specific method is:

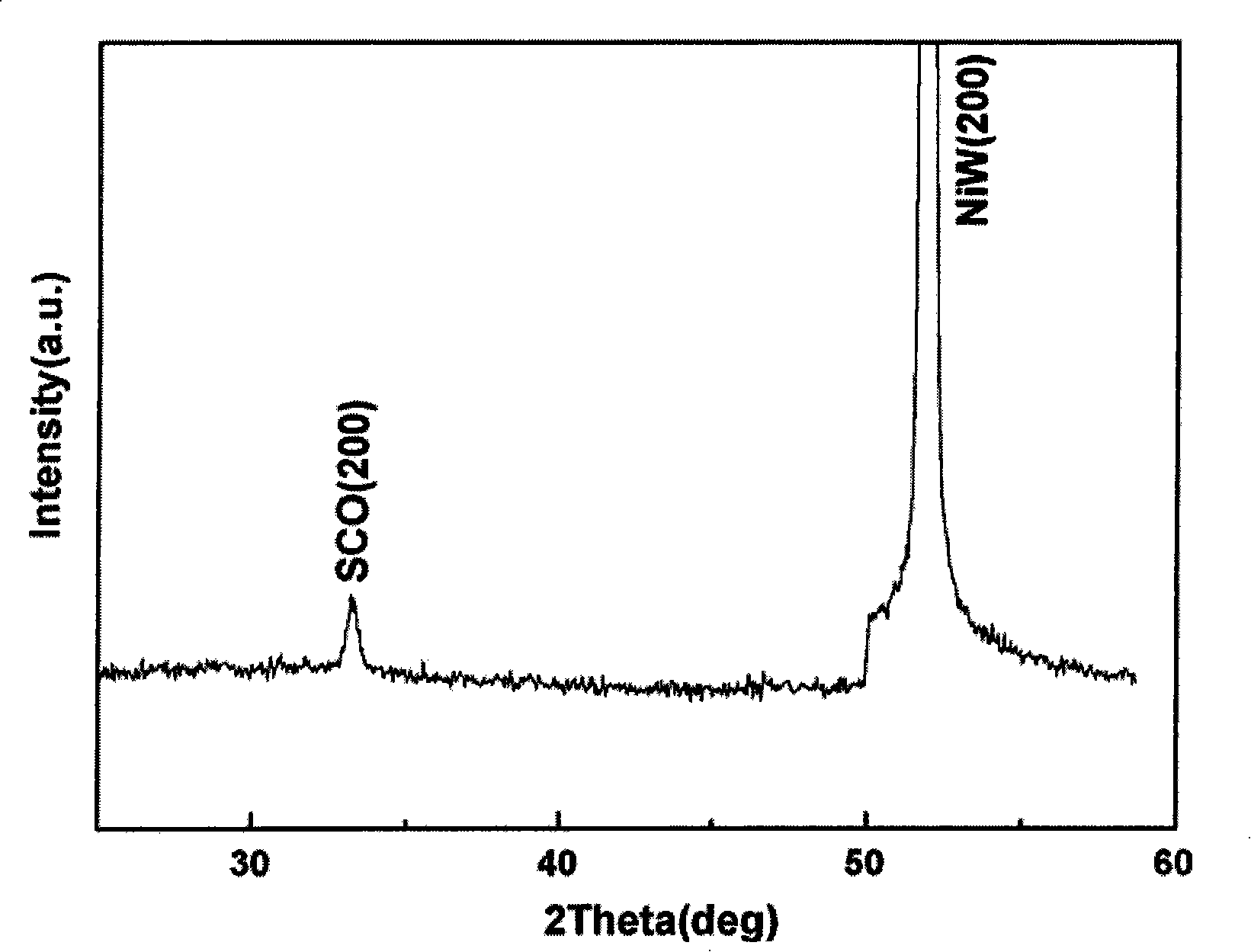

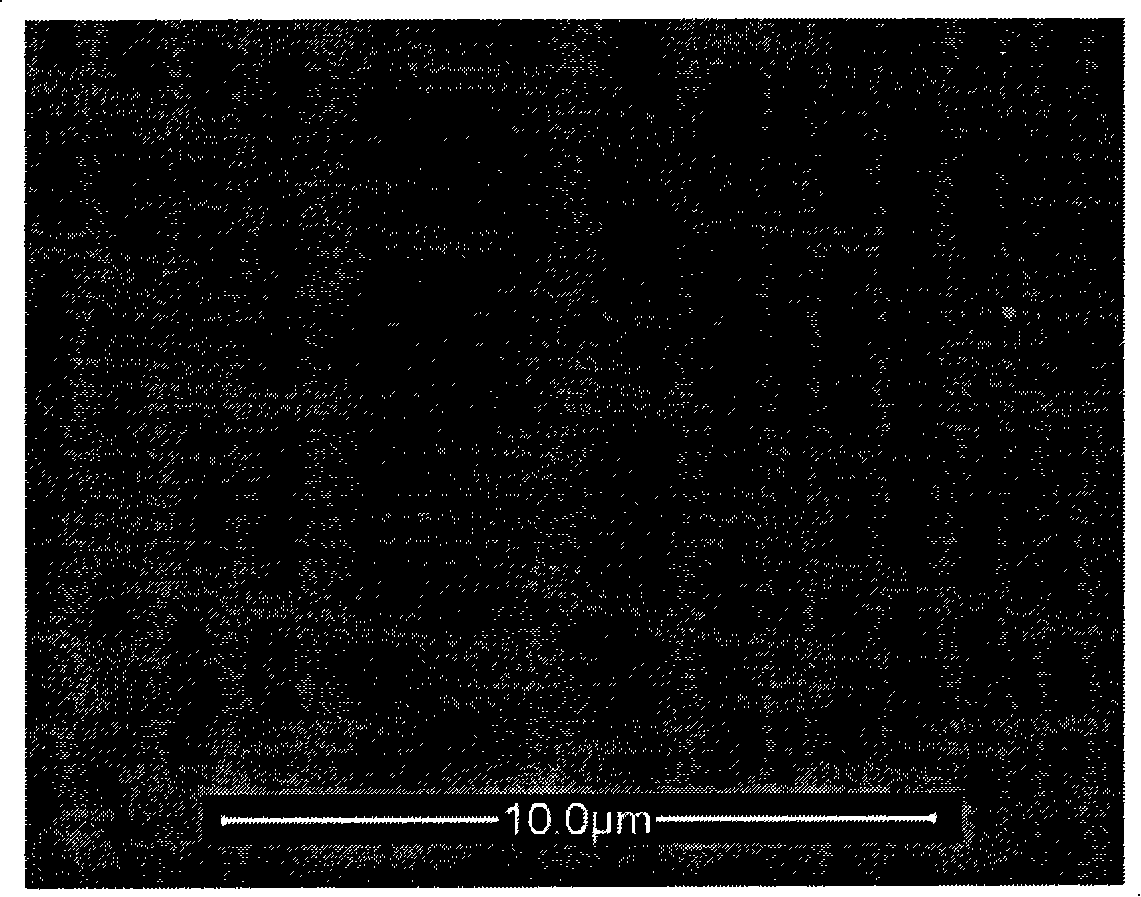

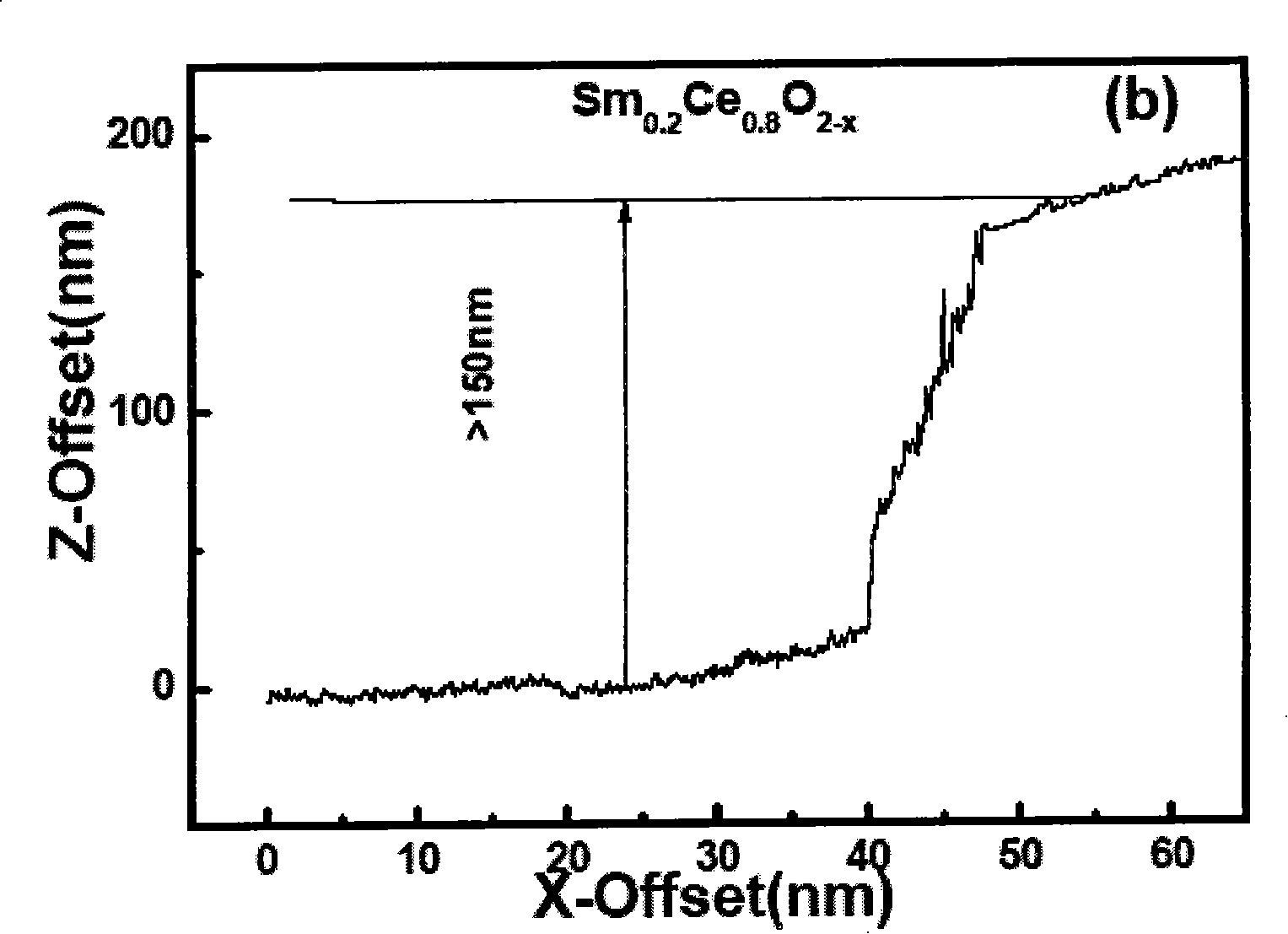

[0028] a, preparation of anhydrous solution: the rare earth nitrate samarium nitrate and cerous nitrate are dissolved in the organic solvent N, N-dimethylformamide (DMF) according to the ratio of cations, namely Sm: Ce=0.2: 0.8, to form anhydrous aqueous solution.

[0029] b. Preparation of colloid: Add polymer material polyacrylic acid (PAA) to the anhydrous solution in step a to form a colloid with good film-forming properties.

[0030] c. Colloid coating and drying: the colloid prepared in step b is coated on the Ni alloy substrate, and then dried at a temperature of 150°C.

[0031] Thermal decomposition treatment before sintering: place the colloid-coated substrate in a sintering furnace, slowly increase the temperature of the furnace ...

Embodiment 2

[0034] The specific approach in this example is:

[0035] a, preparation of anhydrous solution: holmium nitrate and cerous nitrate are dissolved in N, N-dimethylformamide (DMF) according to the ratio of cations, i.e. Ho: Ce=0.01: 0.99, to form an anhydrous solution;

[0036] B, colloid preparation: add polymethacrylic acid (PMAA) in the anhydrous solution of step a, form the good colloid of film-forming property;

[0037] c. Colloid coating and drying: Coat the colloid prepared in step b on the Ni alloy substrate, and then place it at 100°C for drying;

[0038] Thermal decomposition treatment before sintering: place the colloid-coated substrate in a sintering furnace, slowly increase the temperature of the furnace from room temperature to 200°C, and increase it to 280°C at a speed of 0.1°C / min, and keep it warm for 15 minutes .

[0039] d. Sintering phase formation: put the thermally decomposed substrate into the sintering furnace, rapidly raise the furnace temperature to 85...

Embodiment 3

[0041] The specific approach in this example is:

[0042] a, preparation of anhydrous solution: zirconium nitrate and cerous nitrate are dissolved in N,N-dimethylformamide (DMF) according to the ratio of cations, namely Zr: Ce=0.5:0.5, to form an anhydrous solution;

[0043] B, colloid preparation: add polyacrylic acid (PAA) in the anhydrous solution of a step, form the good colloid of film-forming property;

[0044] c. Colloid coating and drying: Coat the colloid prepared in step b on the Ni alloy substrate, and then dry at 200°C;

[0045] Thermal decomposition treatment before sintering: place the colloid-coated substrate in a sintering furnace, slowly increase the temperature of the furnace from room temperature to 230°C, and increase to 400°C at a rate of 1°C / min, and keep it for 20 minutes.

[0046] d. Sintering phase formation: put the thermally decomposed substrate into the sintering furnace, rapidly raise the furnace temperature to 1150°C at 100°C / min, keep it warm fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com