Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Winding is effective" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

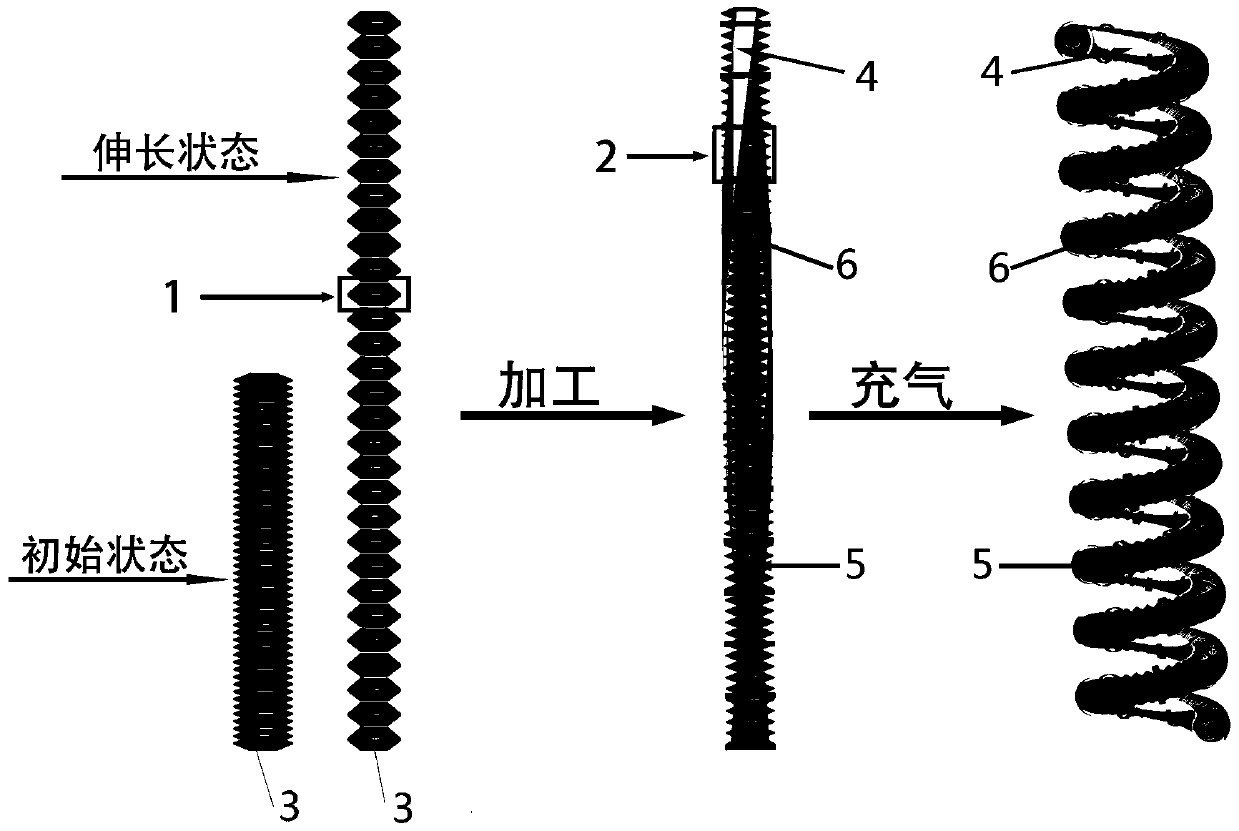

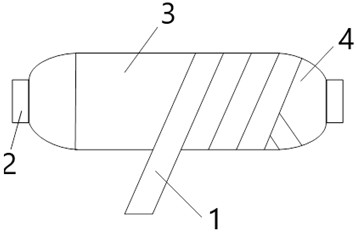

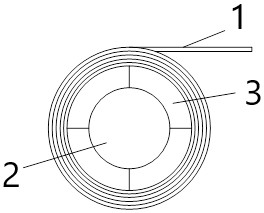

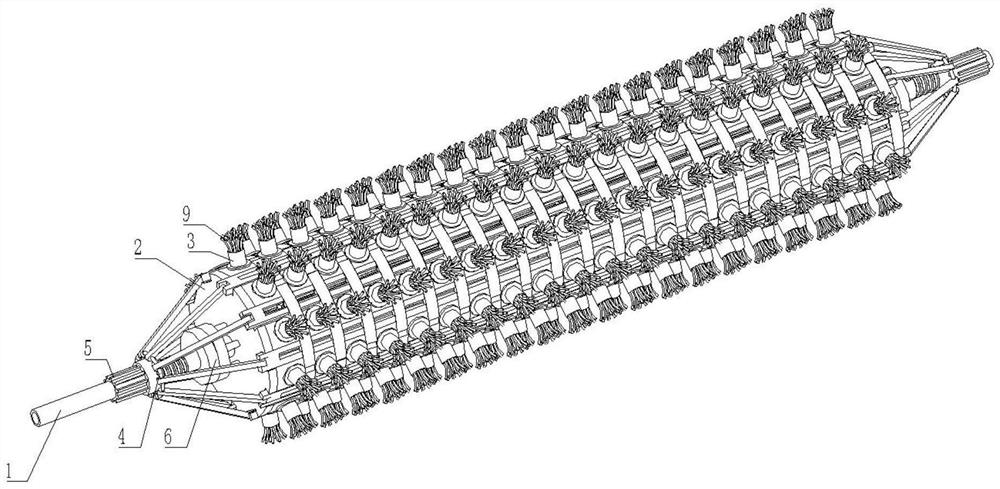

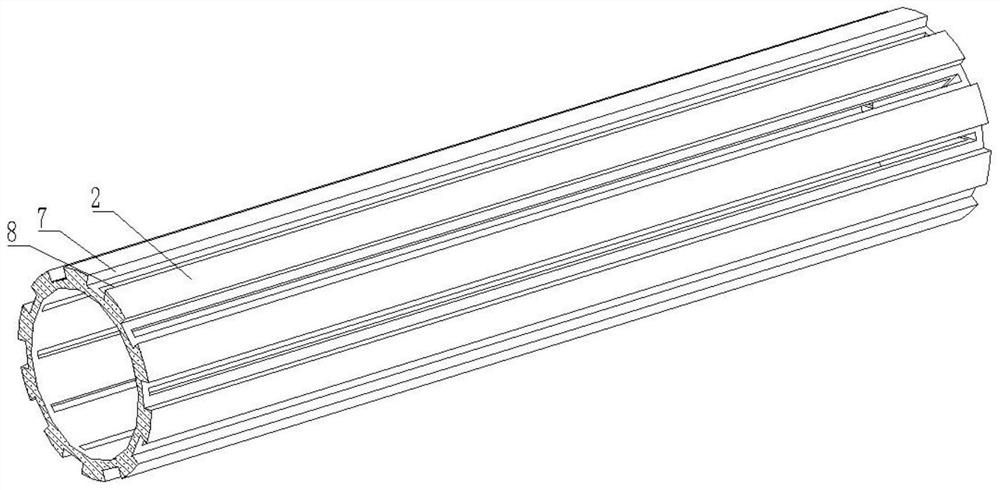

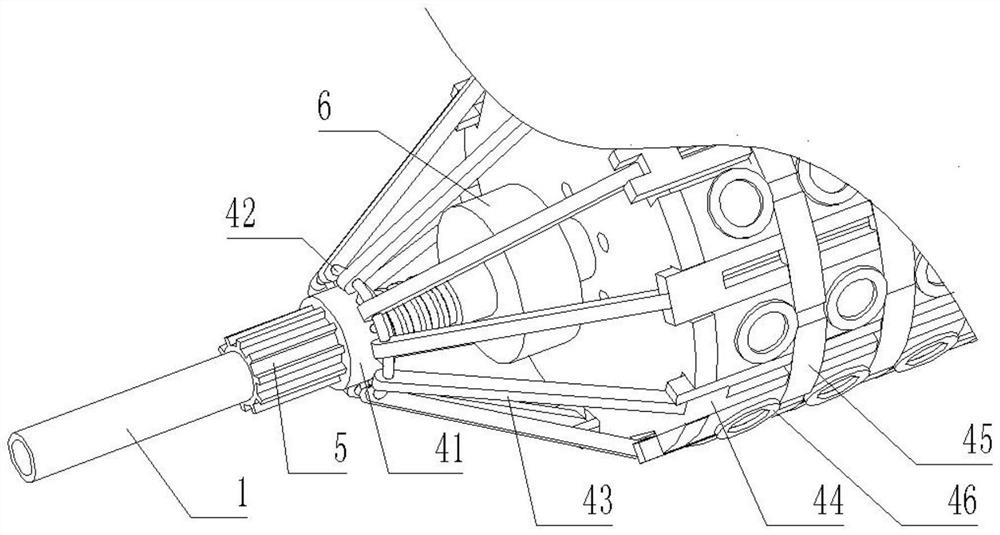

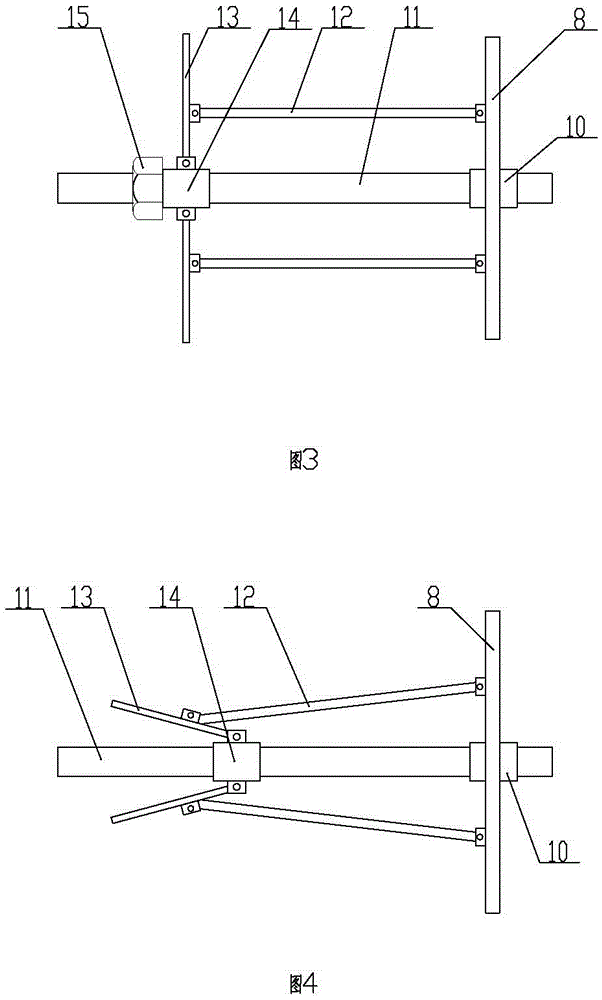

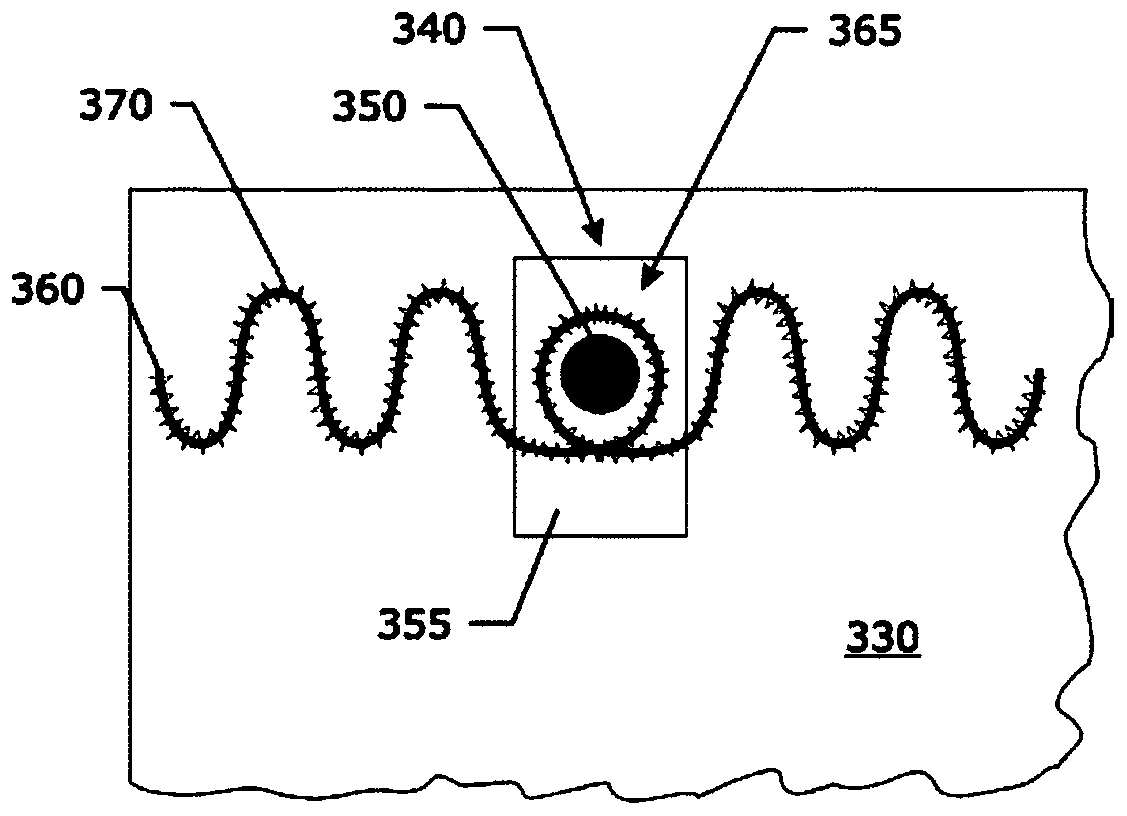

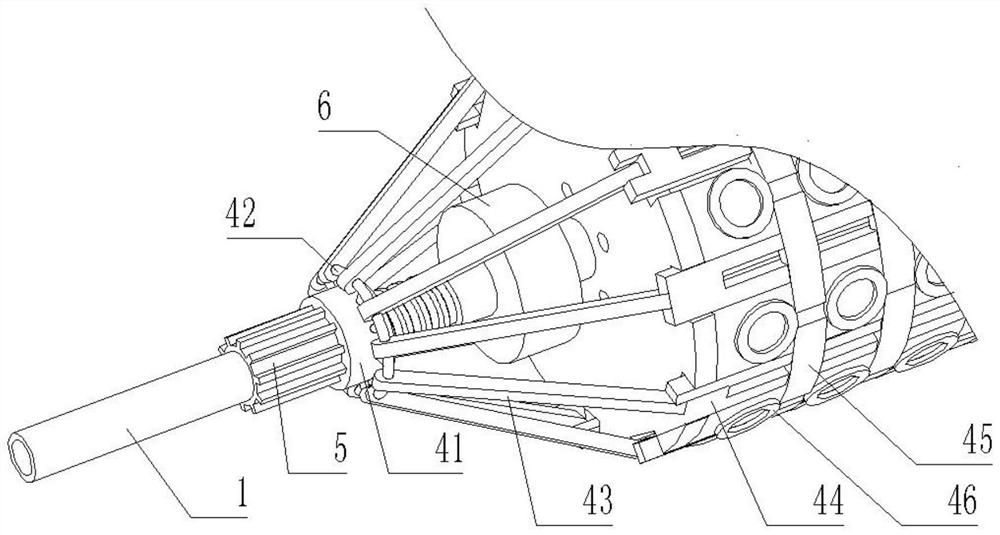

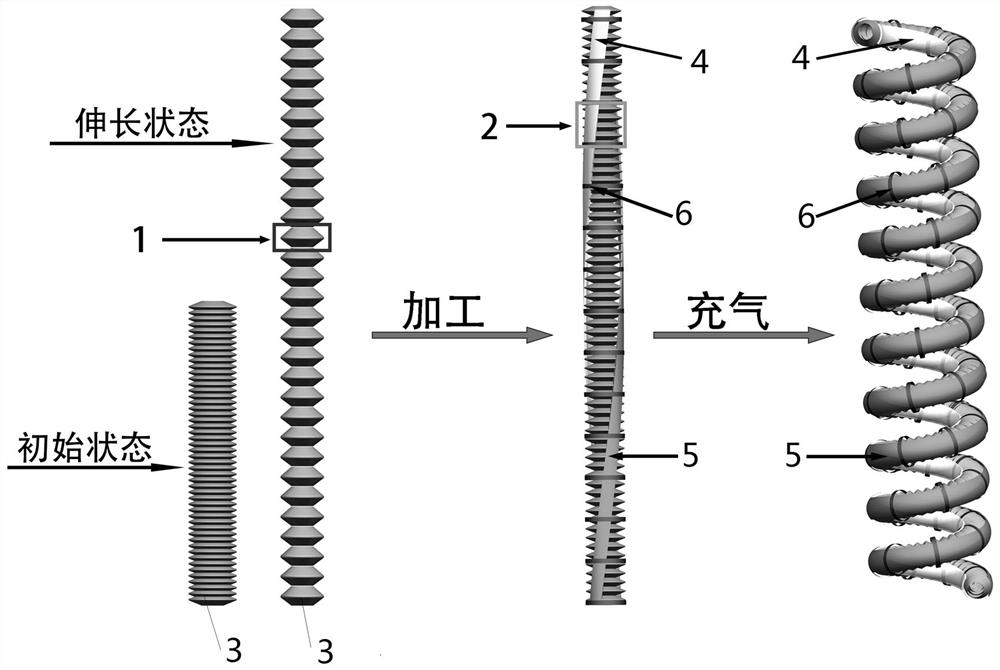

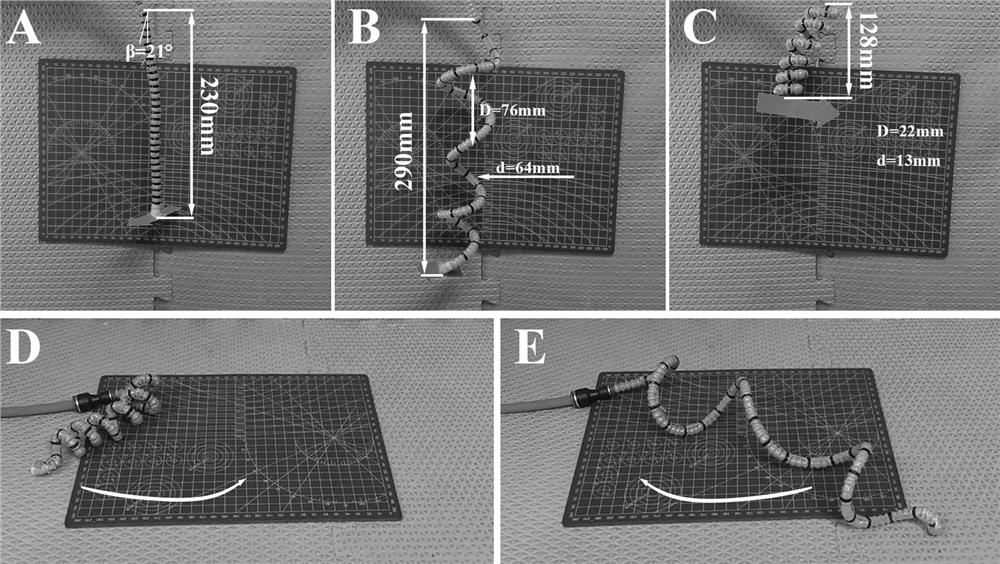

Snakelike wound software actuator

The invention provides a snakelike wound software actuator, which is aimed at solving the problem that a software robot is still in a research stage and needs to be further expanded. The snakelike wound software actuator comprises an elastic corrugated pipe, a strain limiting layer, an elastically stretchable layer, a fixed connecting piece, and an air passage pipe for connection with an air source. The novel snakelike wound actuator provided by the invention covers a wound actuator with the strain limiting layer and a wound actuator without the strain limiting layer. The winding performance of the snakelike wound actuator with the strain limiting layer is determined by depending on the strain limiting layer and the elastically stretchable layer; the snakelike wound actuator with the strain limiting layer can wind a long and thin rod rapidly and efficiently; and with the increase of inflation pressure, the snakelike wound actuator winds an object more tightly and can lift a 1.3kg object. The wound actuator without the strain limiting layer is relatively light and soft; the winding manner of the actuator is determined only by depending on the fixed orientation of the elastically stretchable layer; and the wound actuator without the strain limiting layer can also wind and lift the object.

Owner:SOUTHWEAT UNIV OF SCI & TECH

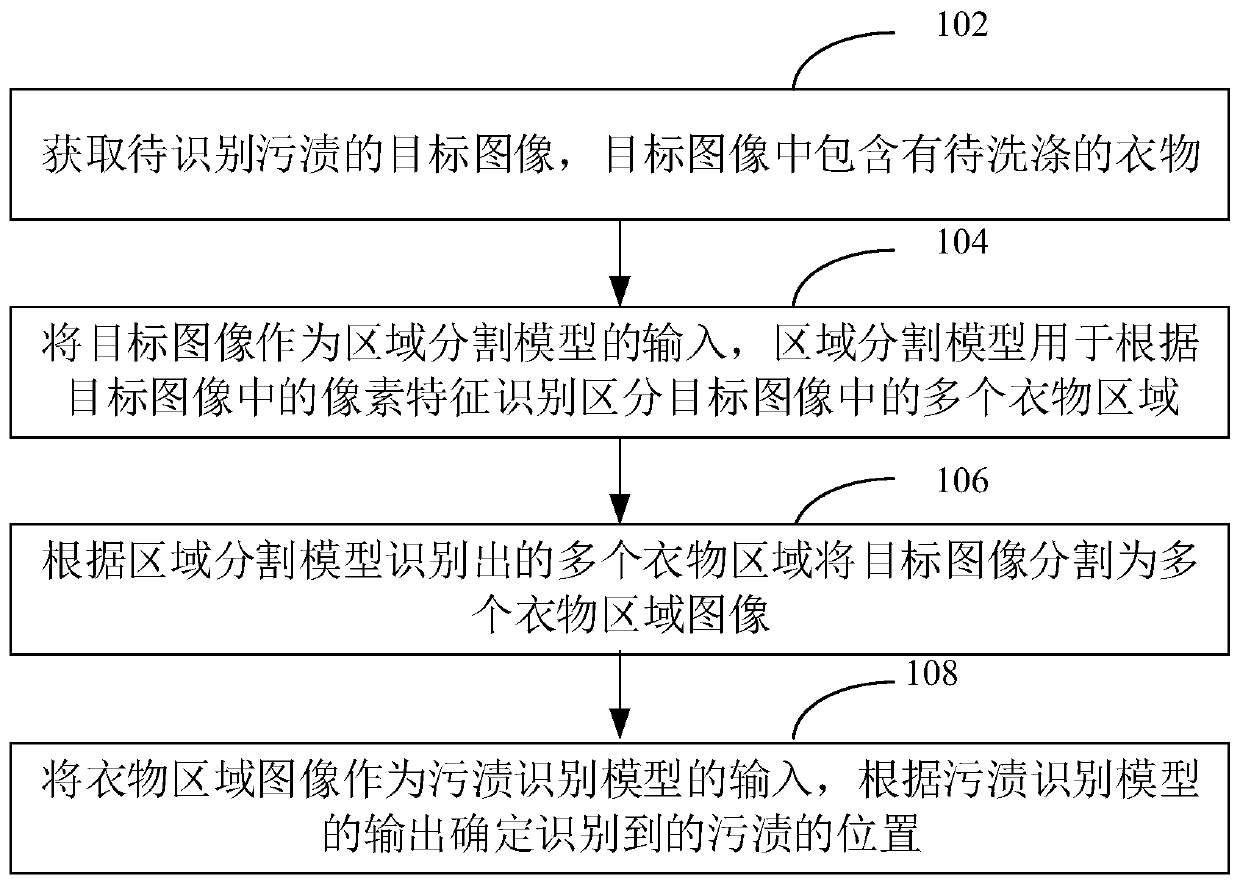

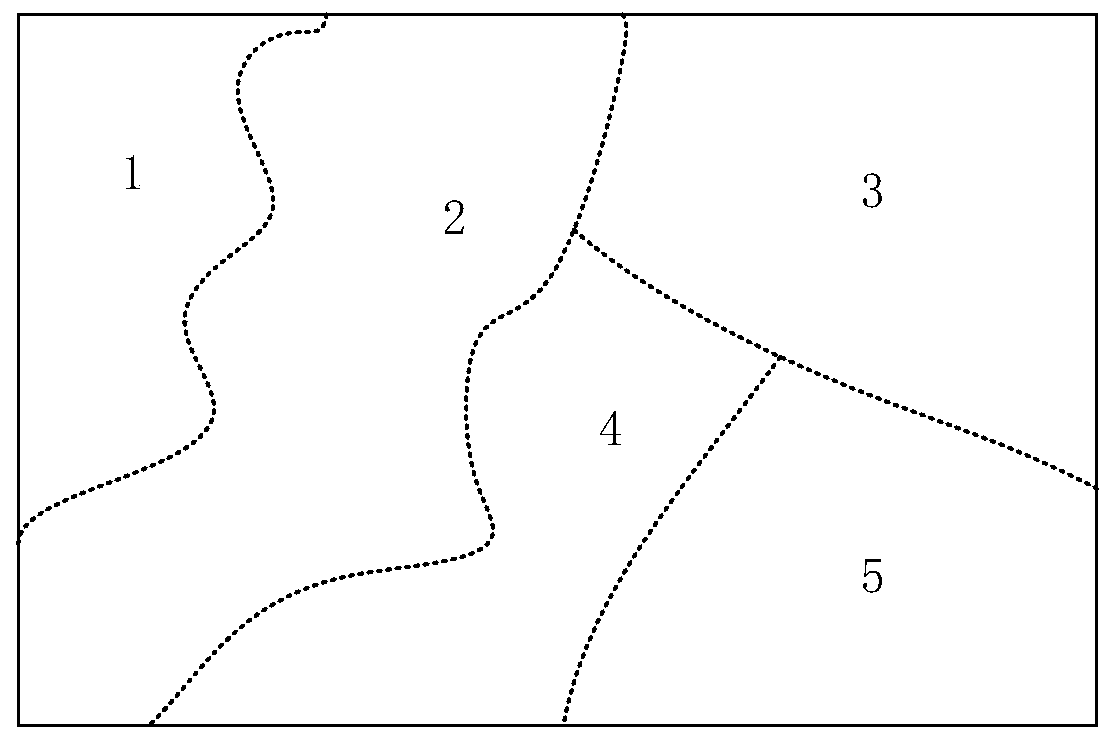

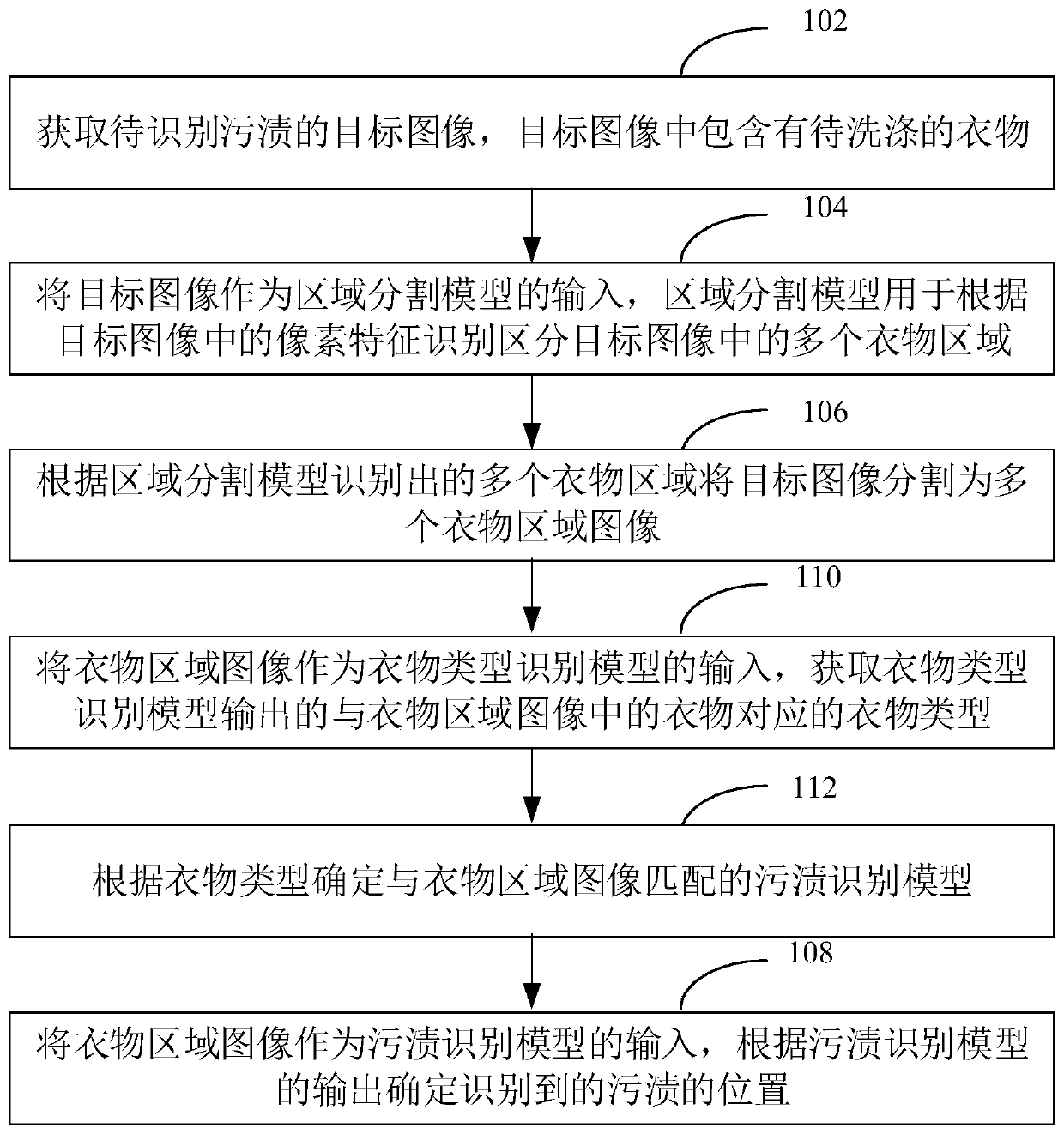

Clothing stain identification method and device, washing machine and storage medium

ActiveCN110004664AEfficient identificationWinding is effectiveOther washing machinesControl devices for washing apparatusIdentification deviceFeature recognition

The invention relates to a clothing stain identification method. The clothing stain identification method includes: acquiring a target image of a stain to be identified, wherein the target image contains clothing to be washed; inputting the target image as a region segmentation model which is used for distinguishing multiple clothing regions according to pixel feature identification in the targetimage; segmenting the target image into multiple clothing region images according to the clothing regions identified by the region segmentation model; inputting the clothing region images as a stain identification model, and determining the location of the identified stain according to the output of the stain identification model. The invention further provides a clothing stain identification device, a washing machine, a storage medium and a method for washing clothing stains.

Owner:深圳数联天下智能科技有限公司

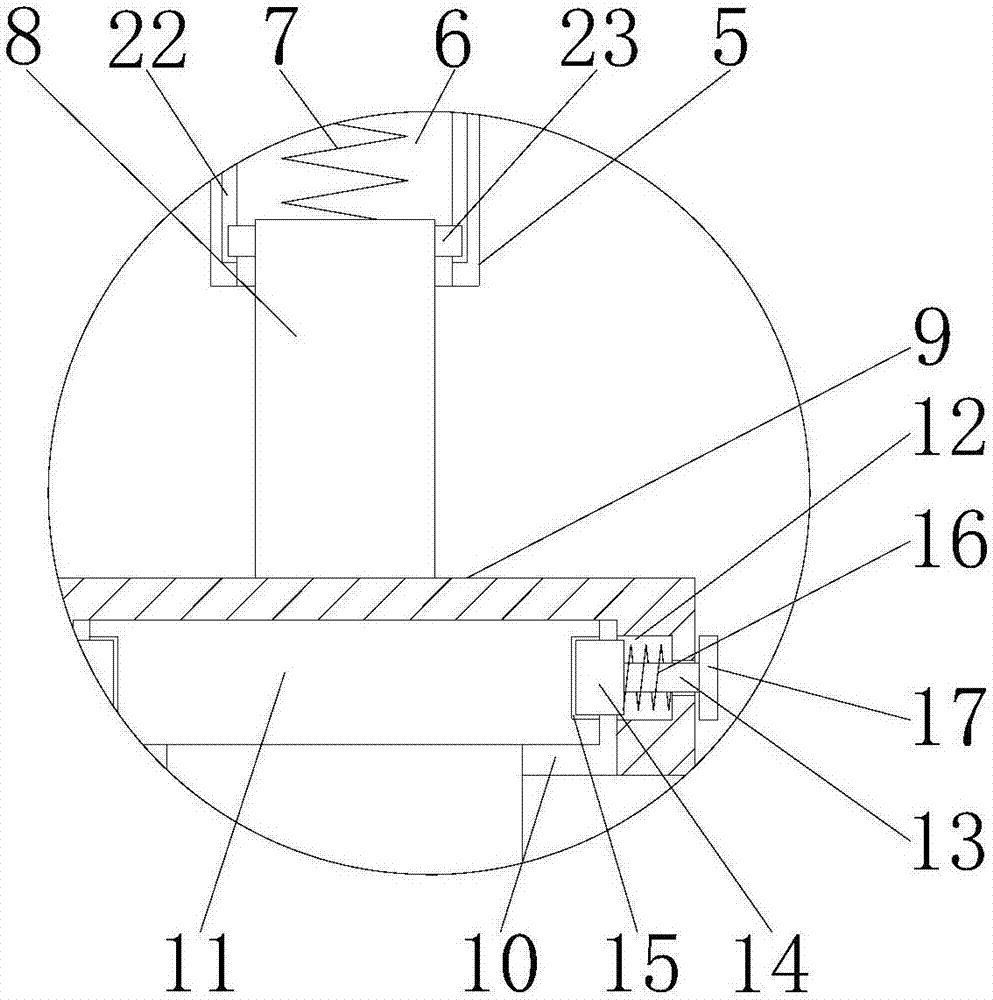

Winding device for enameled wire

ActiveCN107512622AAchieve the effect of rotationTo achieve the mobile effectFilament handlingEngineering

Owner:明光久智知识产权管理有限公司

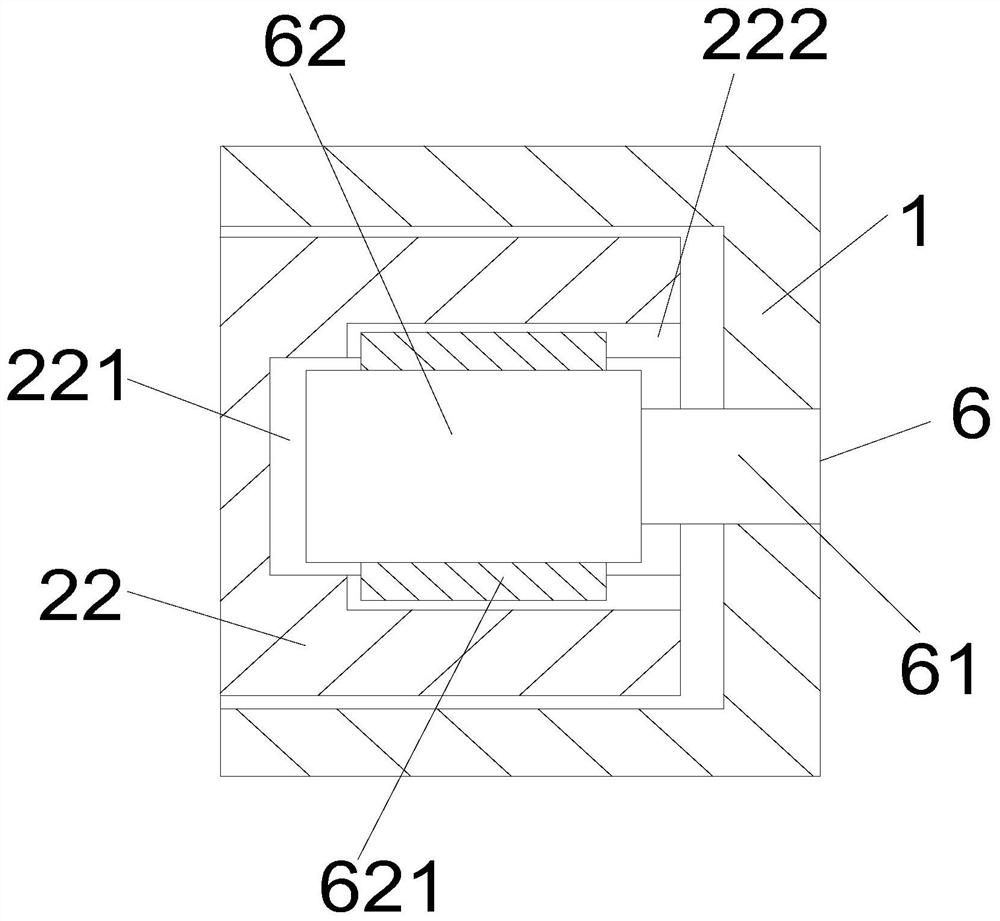

Winding device for fabric processing

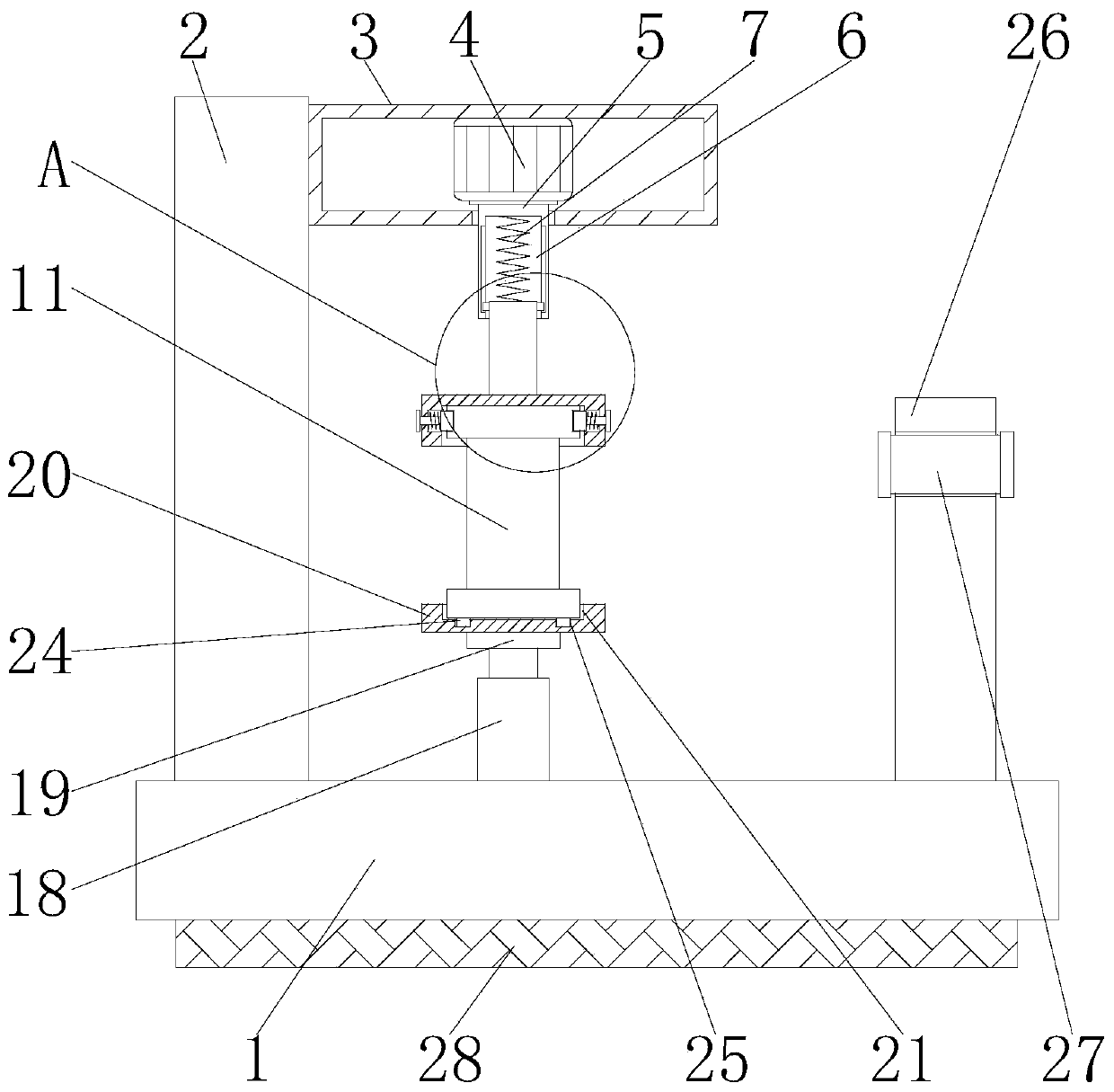

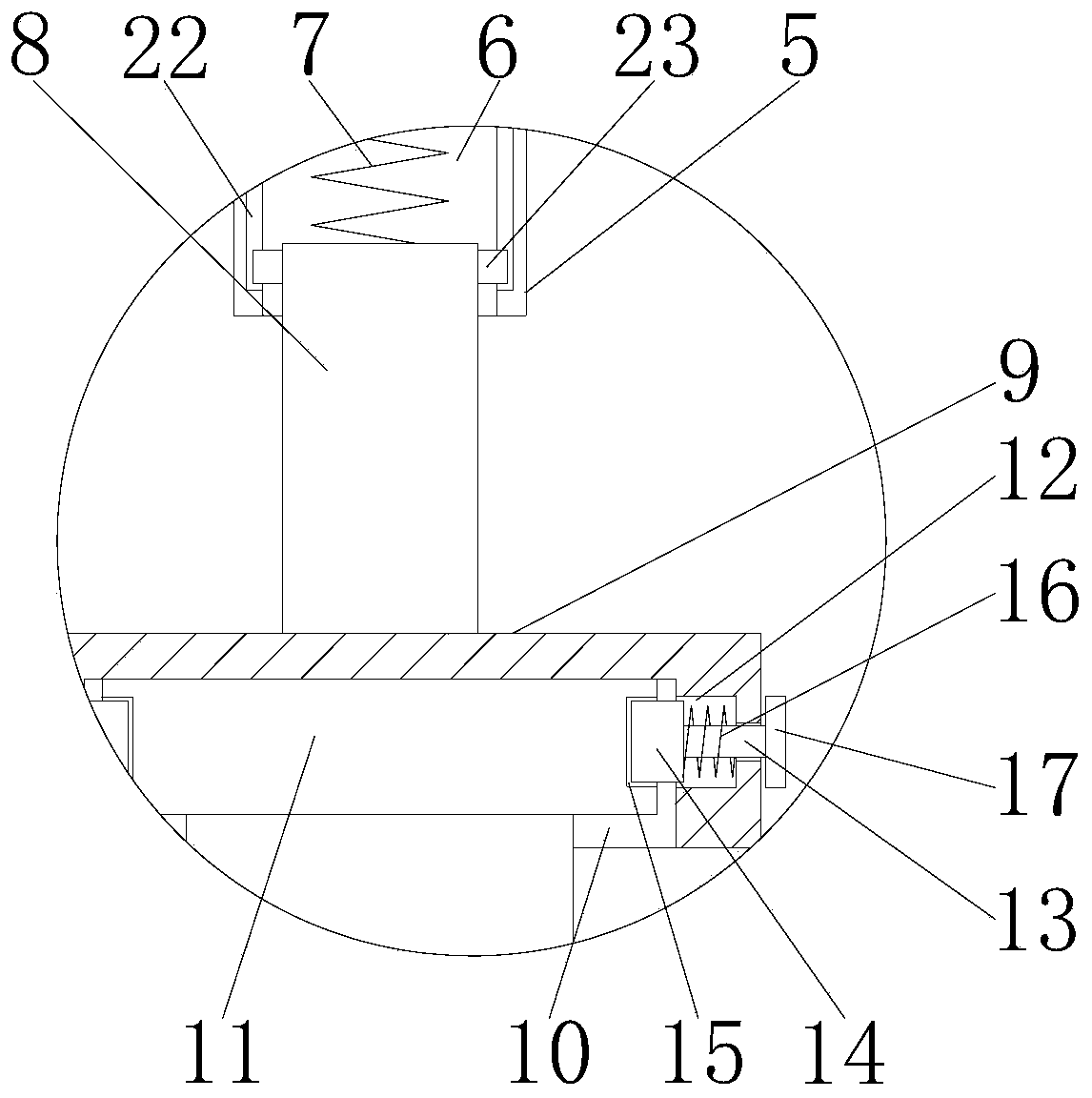

The invention discloses a winding device for fabric processing. The winding device comprises a bottom plate. Two sets of mounting supports are arranged above the bottom plate. A guide roller is arranged on one set of mounting support, and a winding roller is arranged on the other set of mounting support. One end of the winding roller is connected with a rotating disc. A motor is fixed to the bottom plate through screws, and an output shaft of the motor is connected with a drive disc through a coupling. A stand column is vertically arranged on the side, away from the guide roller, of the winding roller. One side of the stand column is horizontally connected with a top plate. Two sets of lifting rods are arranged on the top plate. The bottoms of the lifting rods are connected with a first press roller. The first press roller is arranged over the winding roller. The tops of the two sets of lifting rods are connected with a limiting plate. Telescopic air cylinders are connected between thelimiting plate and the top plate. The winding device is simple in structure and reasonable in design, fabric can be fast wound and can be effectively rolled to be flat, the fabric is wound more tightly, and fabric winding loosening is effectively avoided.

Owner:马道道

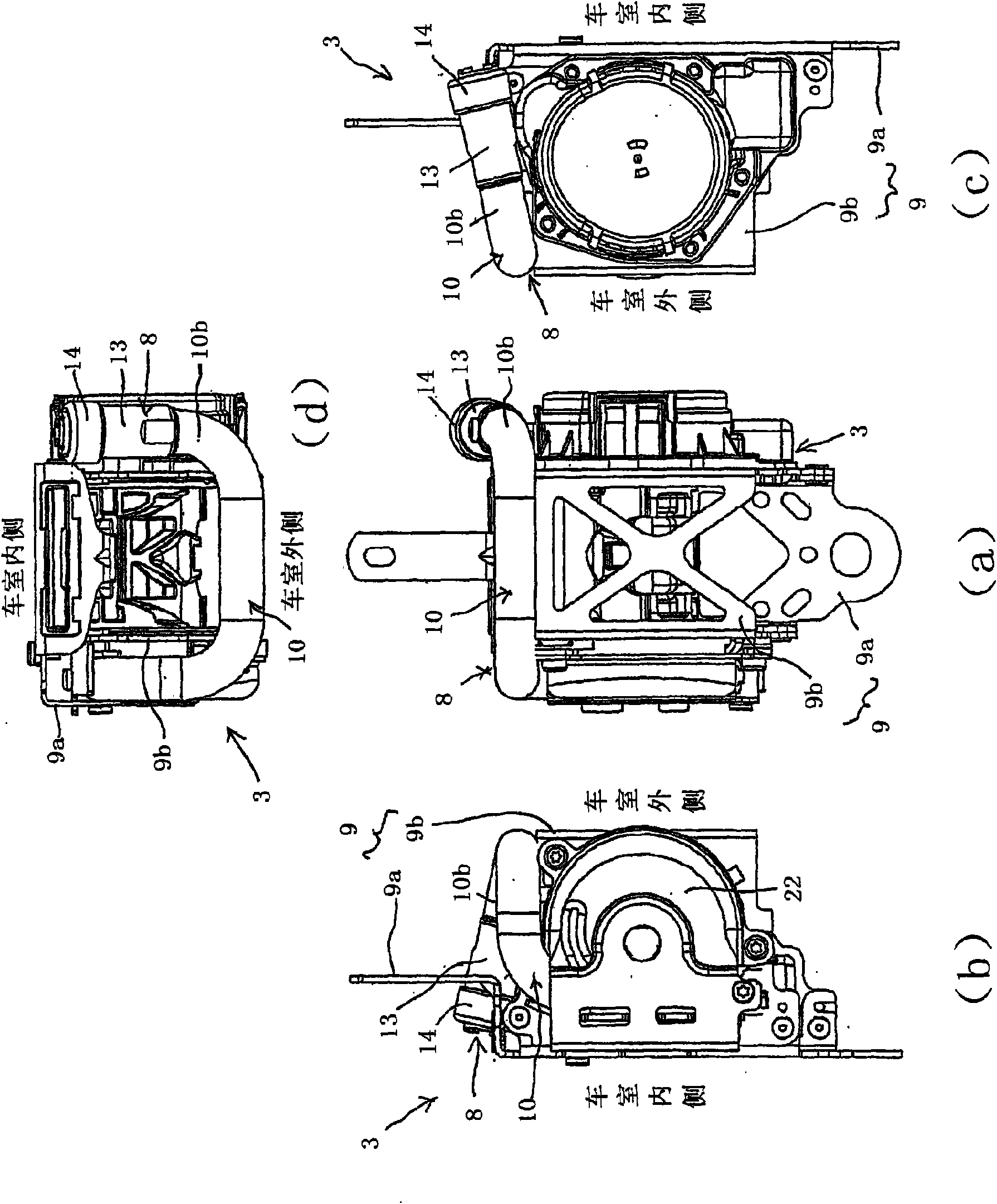

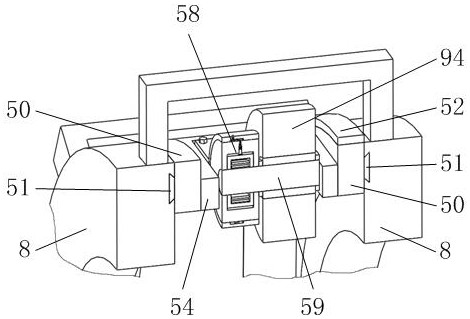

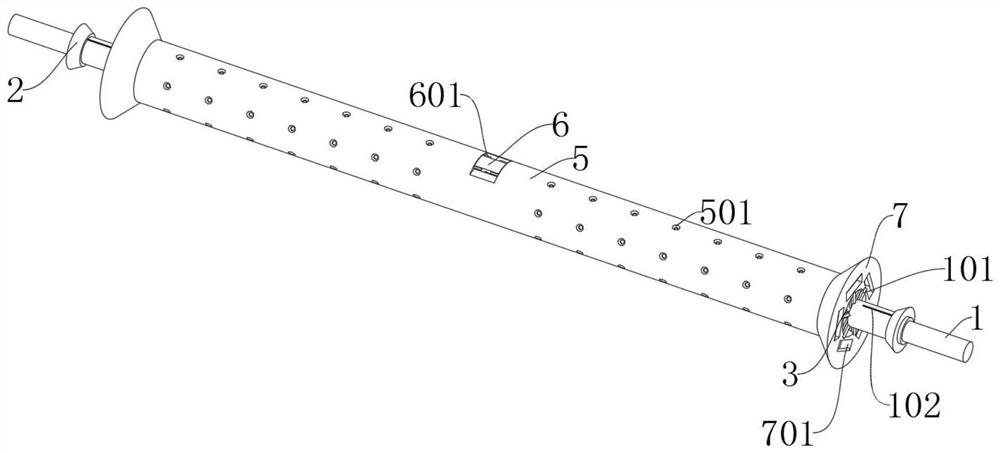

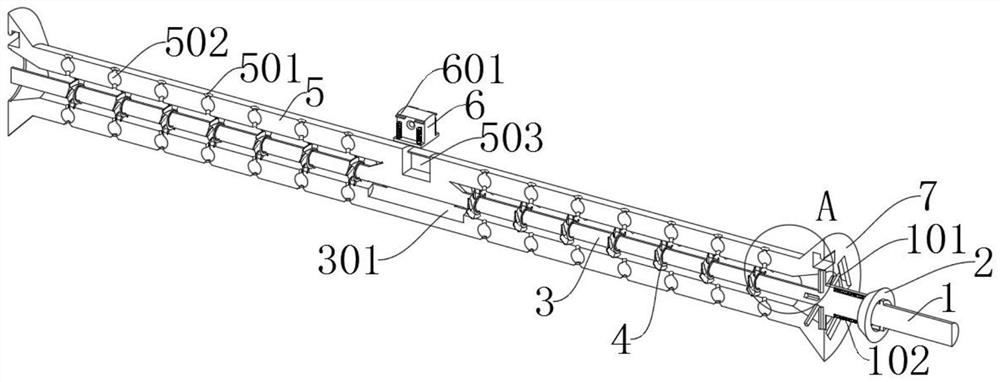

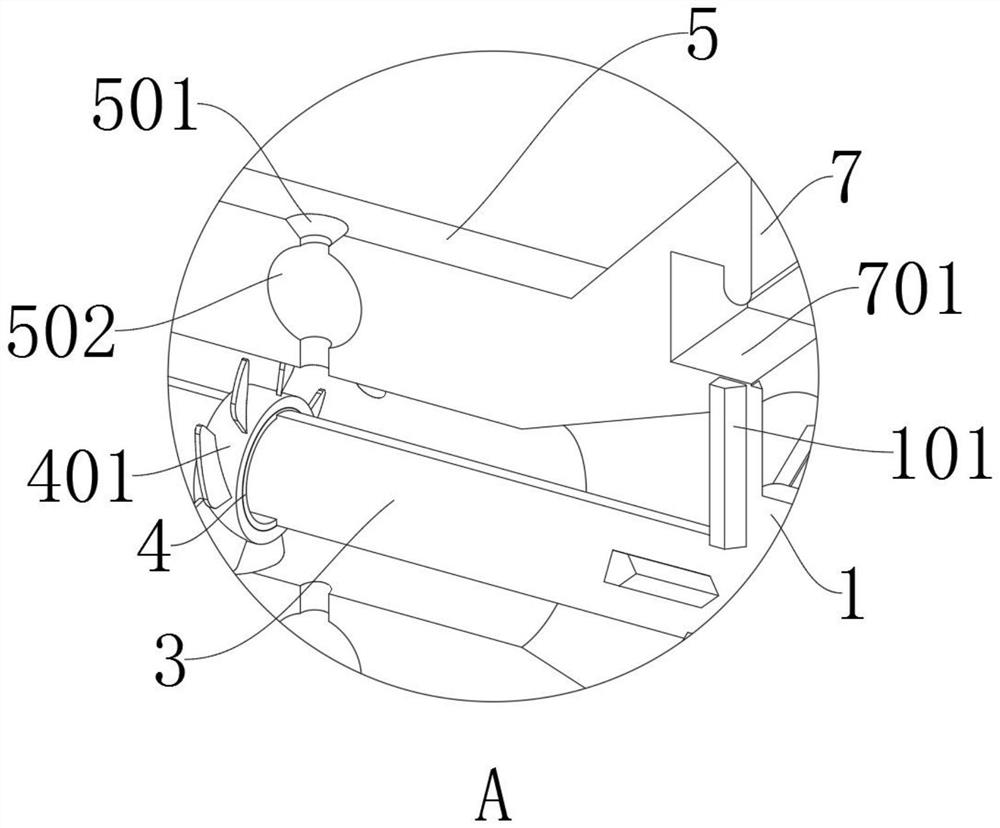

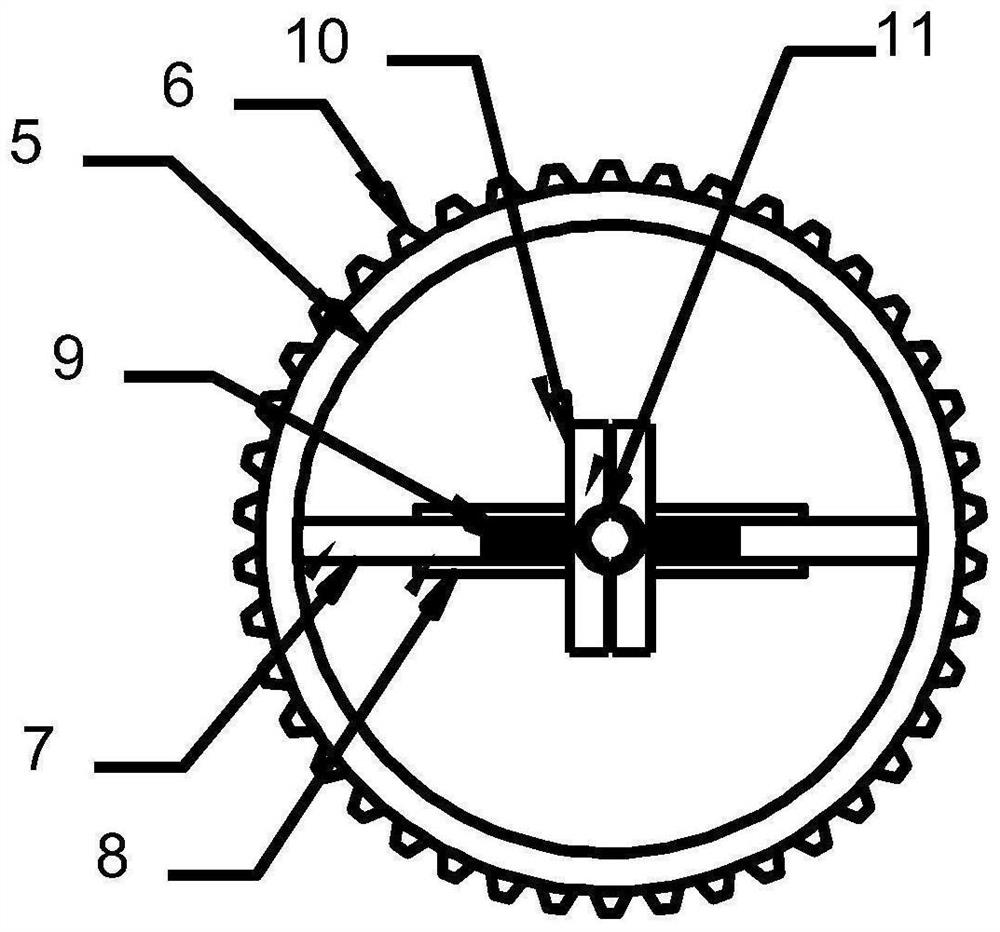

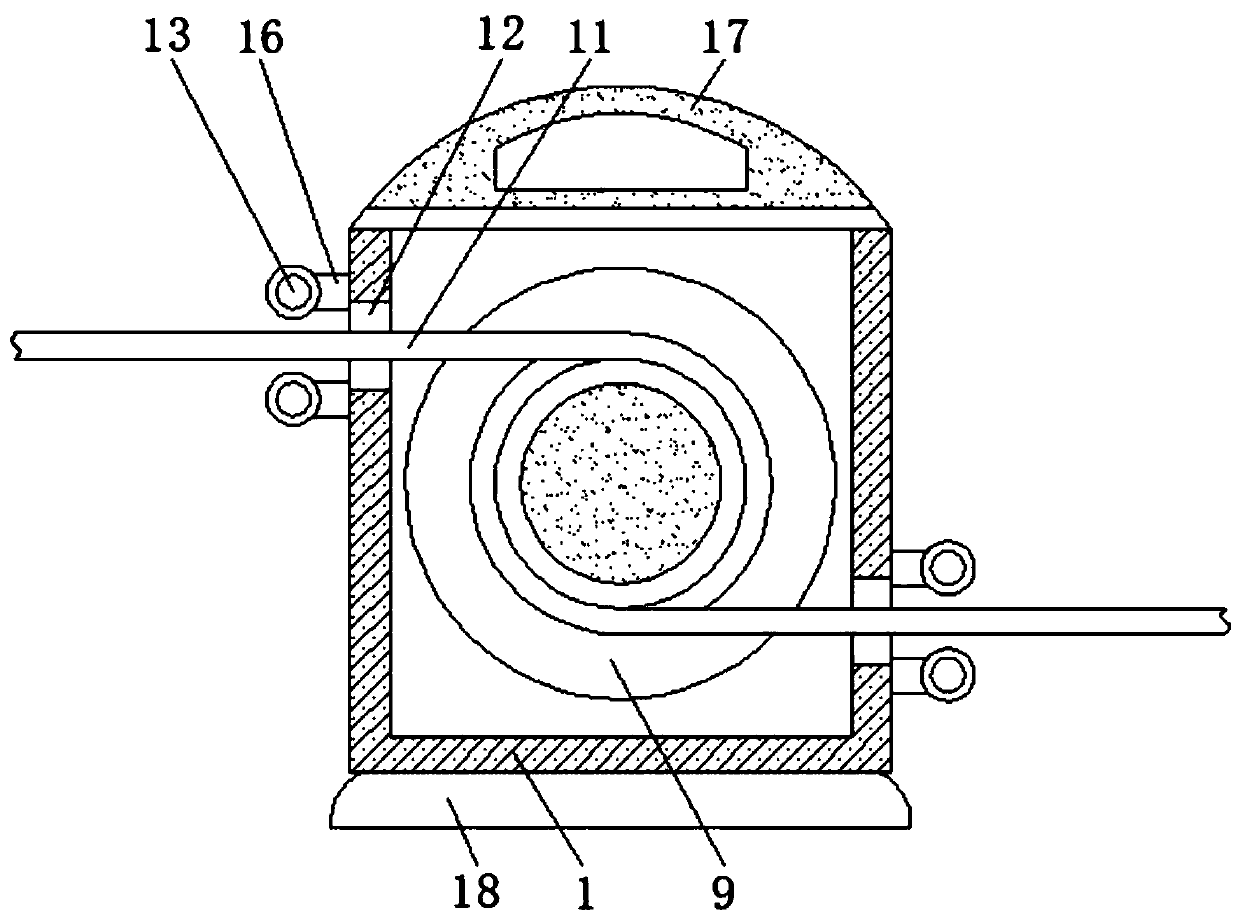

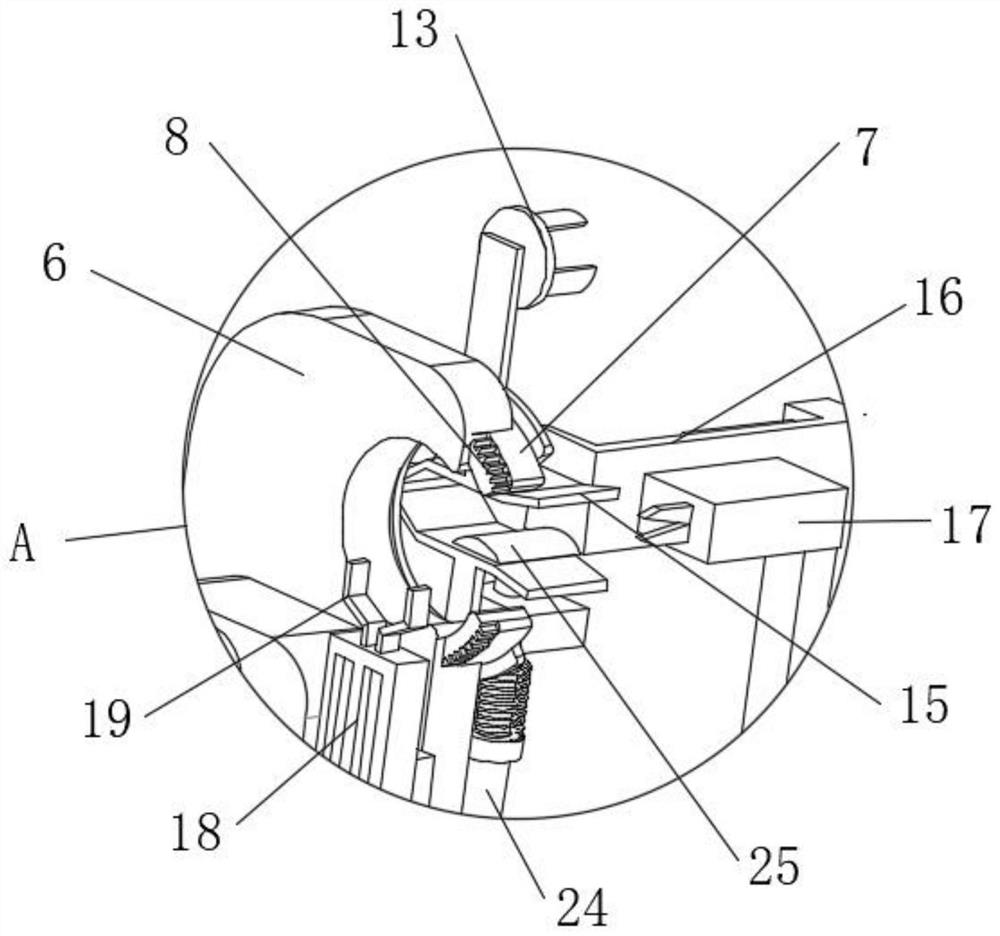

Pretensioner, seatbelt retractor and seatbelt device

The present invention relates to a pretensioner, a seatbelt retractor and a seatbelt device. In order to provide a compact and less expensive pretensioner (8) for improving the work assembly efficiency while effectively transmitting the pressing force of plural force transmission members (12) to a ring gear (16), plural balls (12a) inside a pipe (10) are pressed under the pressure of gas from a gas generator (14) in an emergency. The first ball (12a) presses a lever (17), and the balls (12a) other than the first ball (12a) sequentially press subsequent levers (18) such that the ring gear (16)rotates to move rightward. Internal teeth (16a) of the ring gear (16) are meshed with external teeth (20a) of a pinion (20) attached to a rotary shaft (19) at a side of a spool. The pinion (20) then rotates to allow the spool to retract a seatbelt. The first ball (12a) abuts on a ball stopper portion (10d) of the pipe (10) to stop the rest of the balls (12a) such that most of the balls (12a) are located in a circular movement path.

Owner:JOYSON SAFETY SYST JAPAN GK

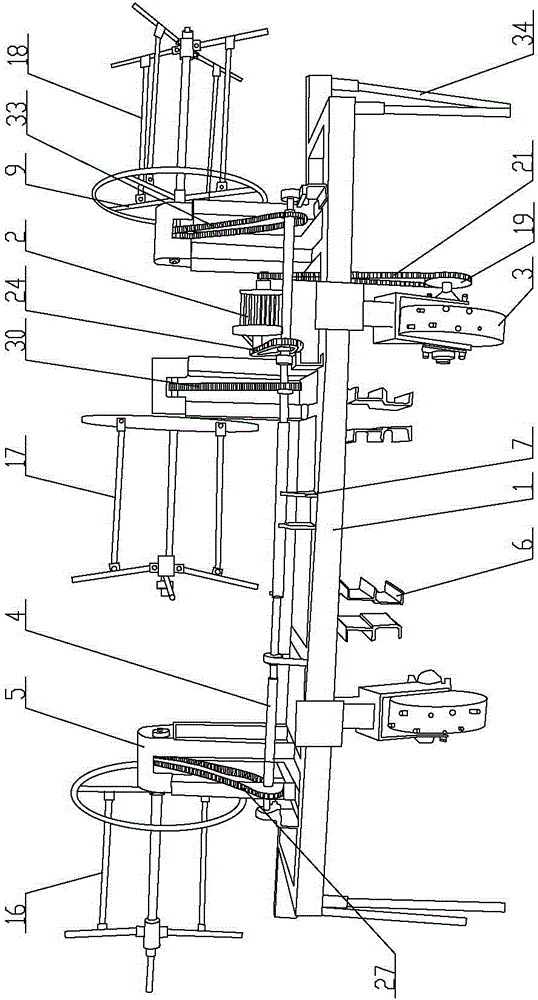

Device for automatically recycling drip irrigation tape

The invention relates to the technical field of agricultural machinery, in particular to a device for automatically recycling a drip irrigation tape. The device for automatically recycling the drip irrigation tape comprises a stander and a stepless gearbox, wherein travelling wheels are mounted at a lower side of the stander in a fixed manner, a transmission shaft is mounted at top of the stander along a left- right direction, a roller is mounted above the stander through a bearing block, the stepless gearbox is mounted above the stander in a fixed manner, a rotating shaft of each travelling wheel is connected to a power input end of the stepless gearbox through a first transmission mechanism, a power output end of the stepless gearbox is connected to a power input end of the transmission shaft through a second transmission mechanism, and a power output end of the transmission shaft is connected to a power input end of the roller through a third transmission mechanism. According to the invention, as the stepless gearbox is mounted, a transmission ratio of the stepless gearbox can be regulated according to operational requirements to ensure a more uniform recycling speed of the drip irrigation tape and an appropriate and uniform tension for the drip irrigation tape, so that the drip irrigation tape is prevented from being broken easily, and moreover the continuity and stability of automatically recycling the drip irrigation tap can be ensured.

Owner:新疆千里良驹农业科技有限公司

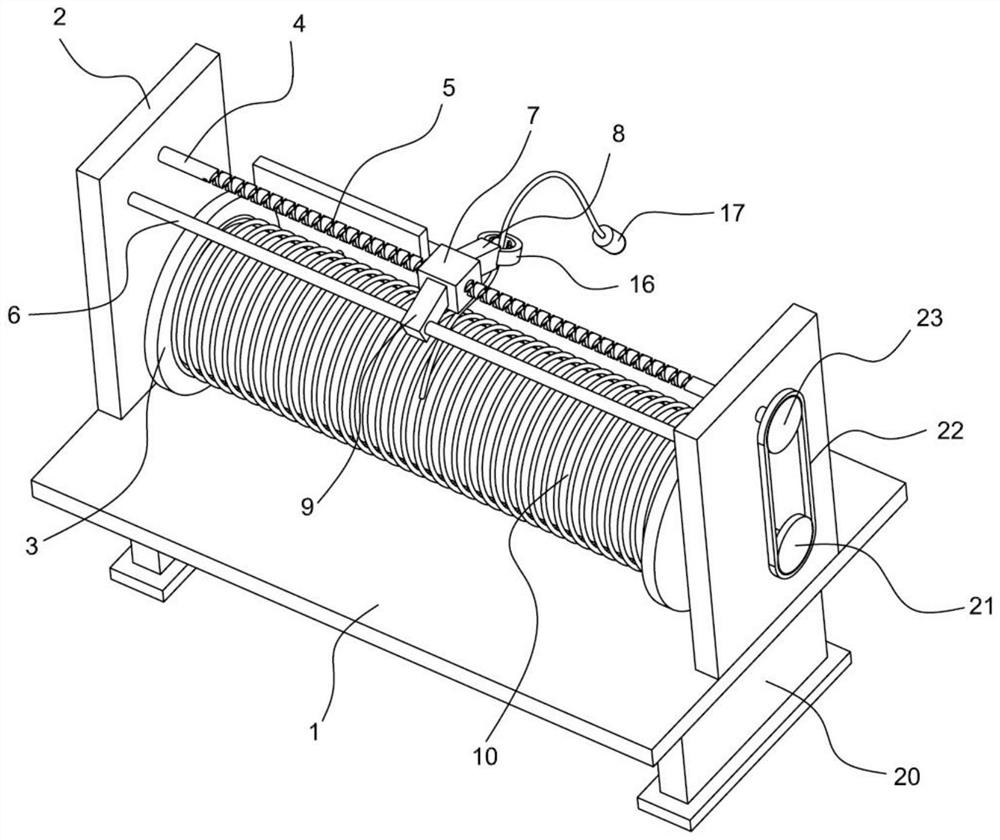

Winding processing machine for heat preservation belt for petroleum conveying pipeline

ActiveCN111532909AAffect heat preservation processing efficiencyEasy to processHollow article cleaningThermodynamicsHeat conservation

The invention relates to a winding processing machine for a heat preservation belt for a petroleum conveying pipeline. The winding processing machine comprises a bottom plate, supporting frames and awinding device, wherein the supporting frames are symmetrically arranged at the upper end of the bottom plate, the winding device is arranged between the supporting frames, and the winding device is arranged in the middle part of the upper end of the bottom plate. The winding processing machine for the heat preservation belt for the petroleum conveying pipeline can solve the problems that the heatpreservation processing efficiency of a pipeline is affected by low manual operation efficiency and high labor intensity caused by the fact that the heat preservation belt is usually wound around thepetroleum pipeline manually when an existing petroleum conveying pipeline is subjected to heat preservation processing, and the heat preservation effect of the pipeline is affected by the fact that the heat preservation belt is prone to fall due to poor adhesion effect caused by the fact that the inner side face of the heat preservation belt cannot be rapidly coated with a glue solution and the pipeline cannot be rapidly cleaned generally when the existing petroleum conveying pipeline is subjected to heat preservation processing.

Owner:峰特(浙江)新材料有限公司

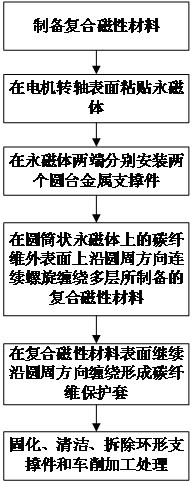

High-speed permanent magnet synchronous motor composite rotor spiral winding preparation method

ActiveCN111835161AReduce concentrated stressWinding is effectiveManufacturing stator/rotor bodiesCoils manufactureAutomotive engineeringMagnetic powder

The invention belongs to the field of motor rotor manufacturing, and particularly relates to a high-speed permanent magnet synchronous motor composite rotor spiral winding preparation method which comprises the following steps: preparing a composite magnetic material; adhering the inner surface of the permanent magnet to the surface of the motor spindle; connecting and mounting circular truncatedcone metal supporting pieces at two ends of the permanent magnet; continuously and spirally winding multiple layers of prepared composite magnetic materials on the outer surface of the carbon fiber ofthe permanent magnet in the circumferential direction, and applying a pre-tightening force in the winding process; and after winding of the composite magnetic material is completed, continuously performing winding at the surface of the composite magnetic material to form a carbon fiber protective sleeve, then performing curing, cleaning, circular truncated cone metal supporting piece dismountingand turning treatment sequentially, and preparing the composite rotor. In the spiral winding process, it can be guaranteed that each layer of magnetic powder adhesive film is evenly distributed, particularly, the problem of interlayer continuous winding can be solved, and the problem that due to continuous winding, the end of the rotating shaft is wrinkled in a winding mode or time is wasted in the cutting and re-winding process is fundamentally solved.

Owner:BEIHANG UNIV +1

Air conditioner pipeline winding device

ActiveCN111891789AEffective self-windingImprove winding efficiencyCastorsWebs handlingDrive wheelElectric drive

Owner:HANGZHOU FUYANG HONGXIANG TECH SERVICES CO LTD

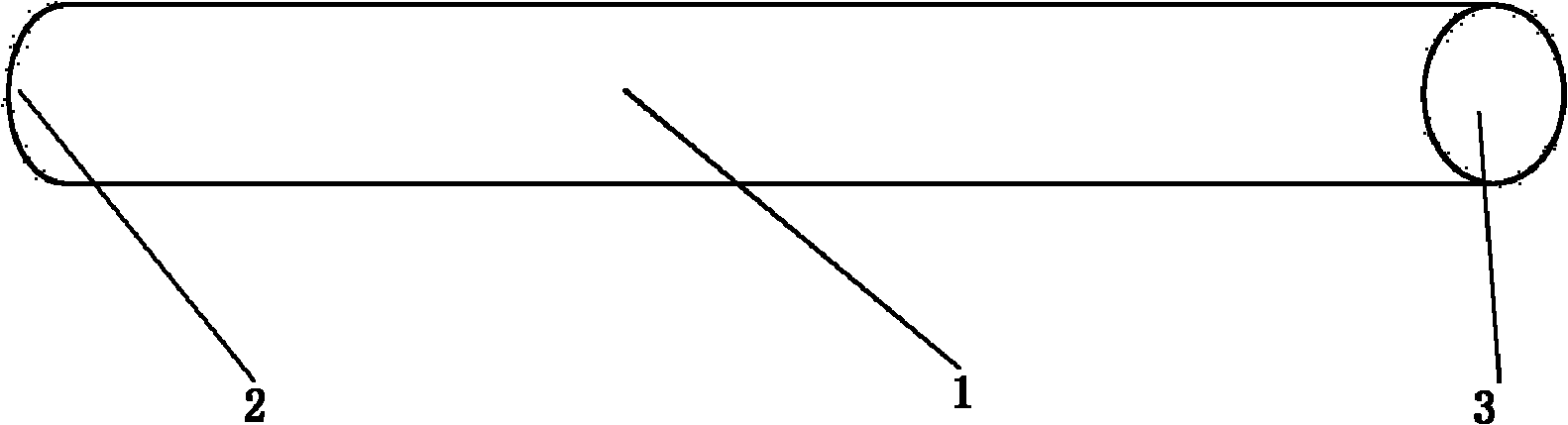

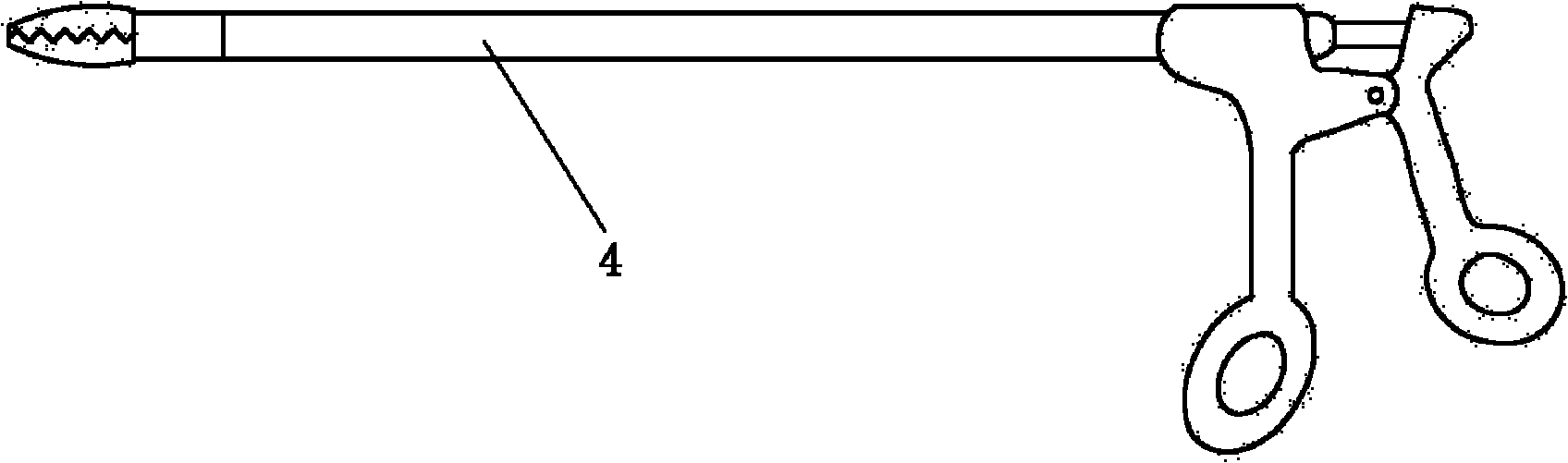

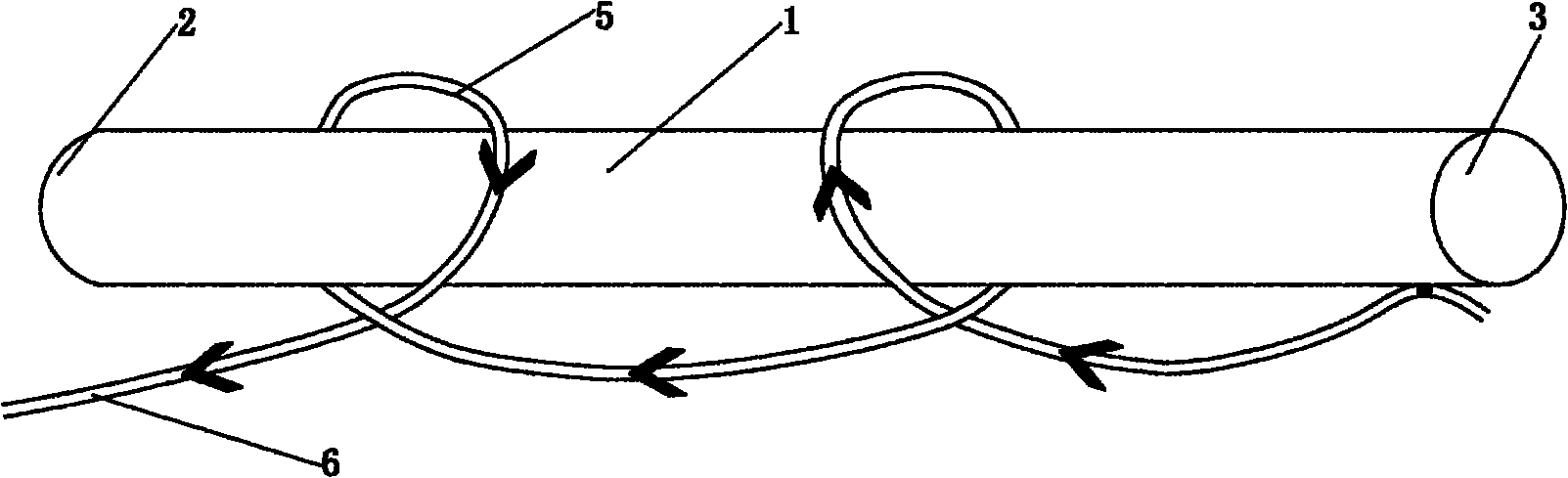

Cord strapping method

ActiveCN102120500ASimple and efficient operationSimple structureBundling machine detailsHollow cylinderKnot tying

The invention discloses a cord strapping and knot tying method, which comprises the following steps: pre-winding multiple cord knots on a support in the shape of a hollow cylinder or other shapes by various required strapping methods and knot tying methods, and placing the cord knots on the object parts needing to be strapped. The free end of the cord is wound around an object needing to be strapped and pulled back by a nipper or other devices passing through the inside of the support so that the free end of the cord and the nipper pass through the centers of multiple cord knots pre-wound on the surface of the support in the shape of a hollow cylinder or other shapes; a pair of pushing tongs or a pushing rod pushes the multiple cord knots pre-wound on the support one by one along the knot tying direction of the cord knots so that the cord knots are wound and knotted with the free end of the cord wound around the strapped object; and the core knots are pushed to the object needing to be strapped and firmly tied to realize an effective strapping and knot tying effect.

Owner:苏红 +1

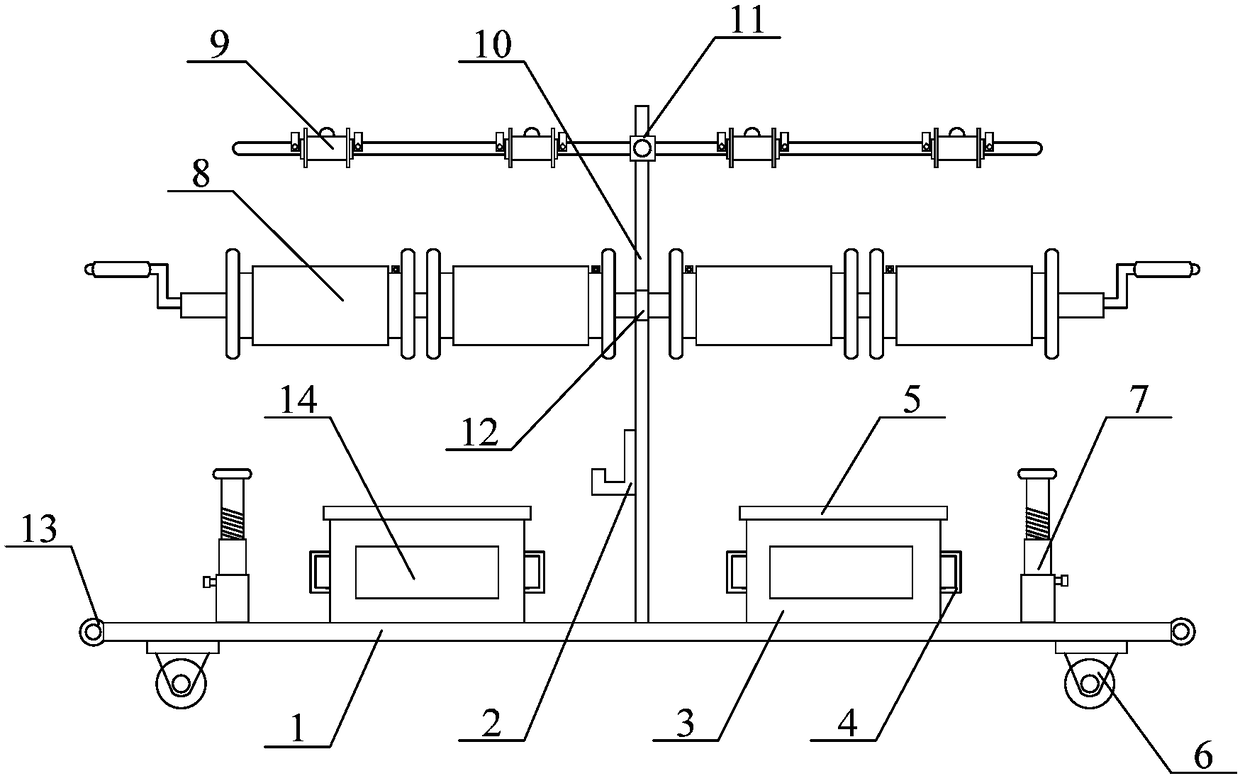

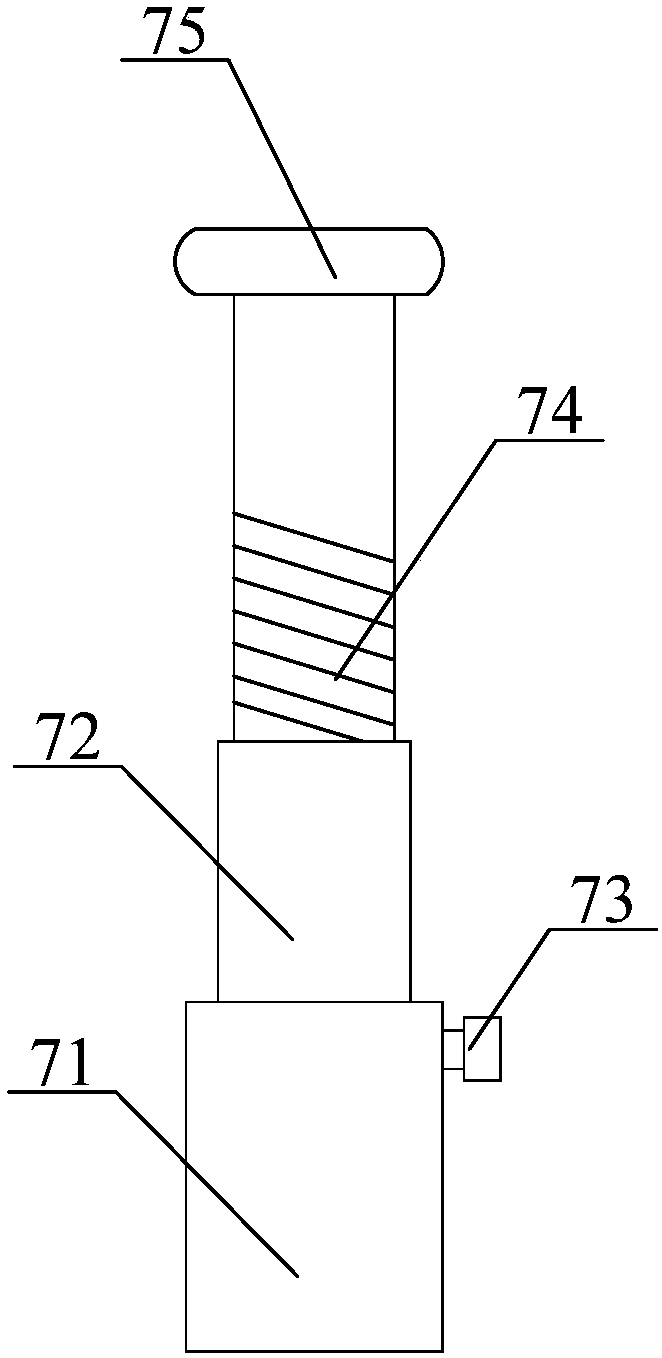

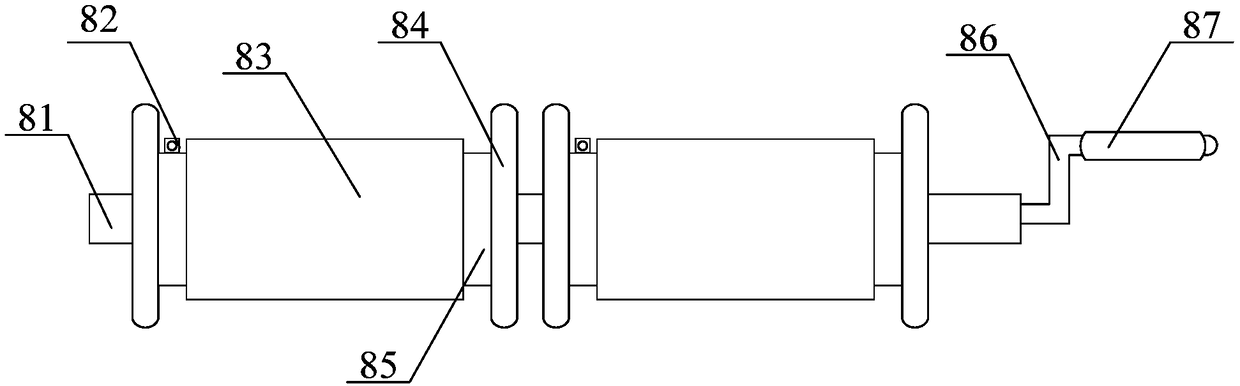

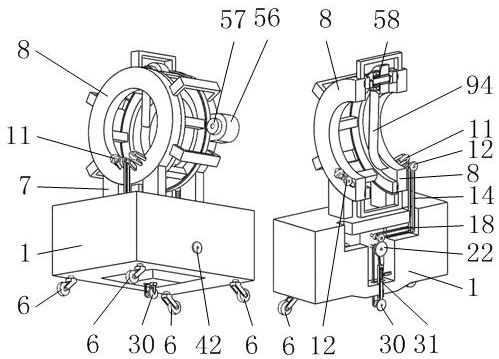

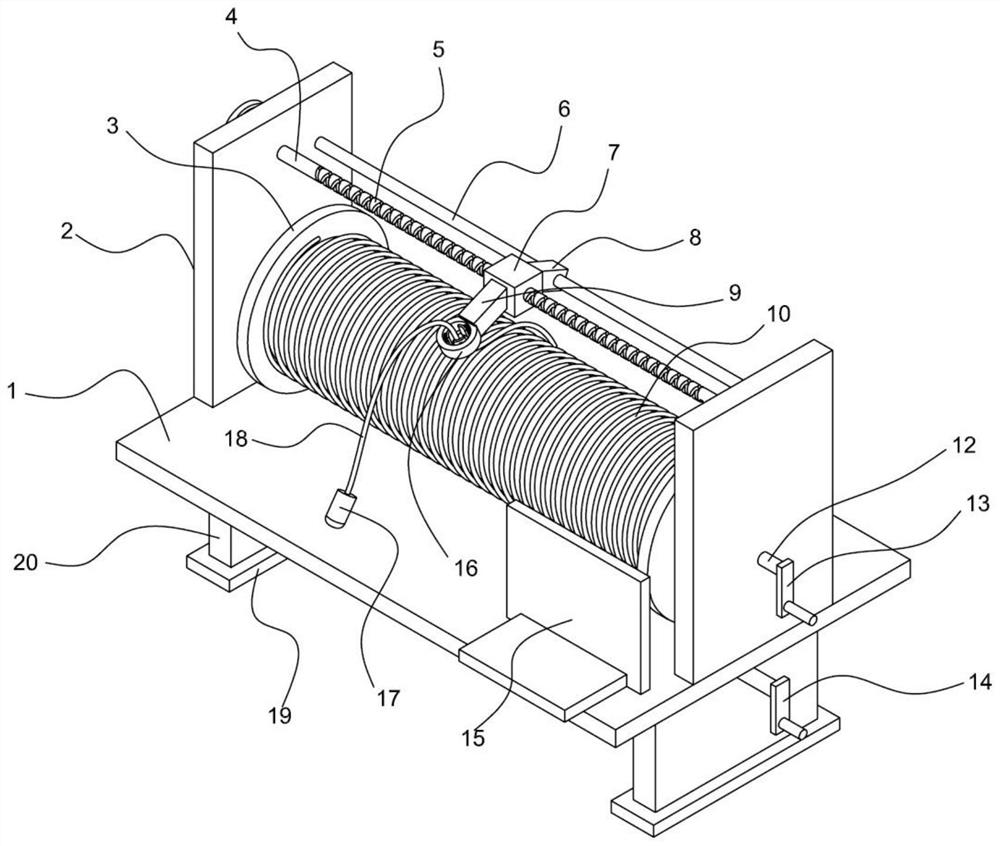

Winding device for multistrand metal wire

The invention discloses a winding device for a multistrand metal wire. The winding device structurally comprises a bottom plate, a hanging hook, placement boxes, handles, protective covers, universalwheels, a telescopic adjustable metal wire placement rod structure, a rotatable disassembling winding structure, an anti-falling metal wire placement rod structure, a supporting rod, a fixed block, abearing, pulling rings and paster; the hanging hook is welded to the lower part of the left side of the supporting rod; the placement boxes are respectively placed at the left side and the right sideof the upper part of the bottom plate; the handles are respectively connected to the middle parts of the left sides and the middle parts of the right sides of the placement boxes through screws. According to the universal wheels, the arrangement of grey glue universal wheels with brake pads are specifically adopted, which is beneficial to the convenient and fast movement of the winding device, andthe convenience is increased; through the arrangement of a winding rotating shaft, a primary separation blade, a main winding shaft sleeve, a secondary winding reel, a hollow winding plate and a secondary separation blade, the situation that the metal wire is accidentally entangled during winding is prevented.

Owner:ZHANGJIAGANG CITY GUANGCHUAN ELECTRONICS

Textile fiber cleaning roller

ActiveCN112359575AImprove cleaning qualityExtended service lifeMechanical cleaningPressure cleaningTextile fiberTextile technology

The invention relates to the technical field of textile, and discloses a textile fiber cleaning roller. The textile fiber cleaning roller comprises a rotating pipe, a fixing mechanism is arranged on the surface of the rotating pipe, a cleaning mechanism is arranged on the surface of the fixing mechanism, a rolling sleeve is arranged on the surface of the cleaning mechanism, a plurality of steel wire columns are fixedly connected to the surface of the rolling sleeve, a plurality of cleaning steel wires are fixedly connected to the tops of the steel wire columns, a washing mechanism is arrangedon the surface of the fixing mechanism, and the washing mechanism is located on the right side of the cleaning mechanism. According to the textile fiber cleaning roller, rotation of a rotating sleeveis controlled, threaded sleeves on the two sides move relatively, a cleaning plate is opened and enlarged under the action of a plurality of connecting strips, fiber filaments left on the rolling sleeve are opened, the cleaning roller is cleaned, so that the cleaning roller cleans textile fibers more effectively, the cleaning quality of the cleaning roller is improved, the service life of the cleaning roller is prolonged, manual cleaning is not needed, and operation is easy, convenient and rapid.

Owner:ZHEJIANG MEILAIYA TEXTILE

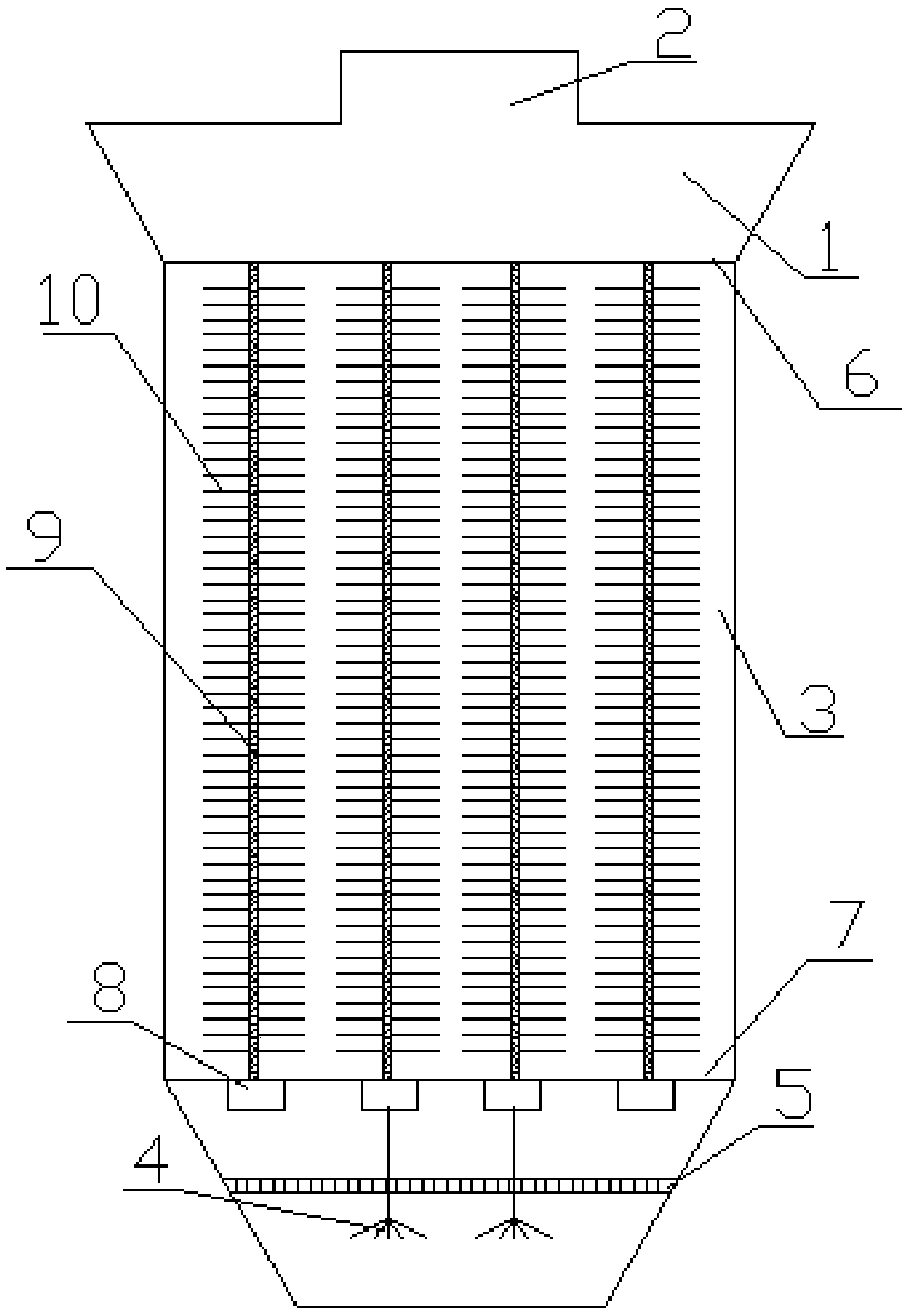

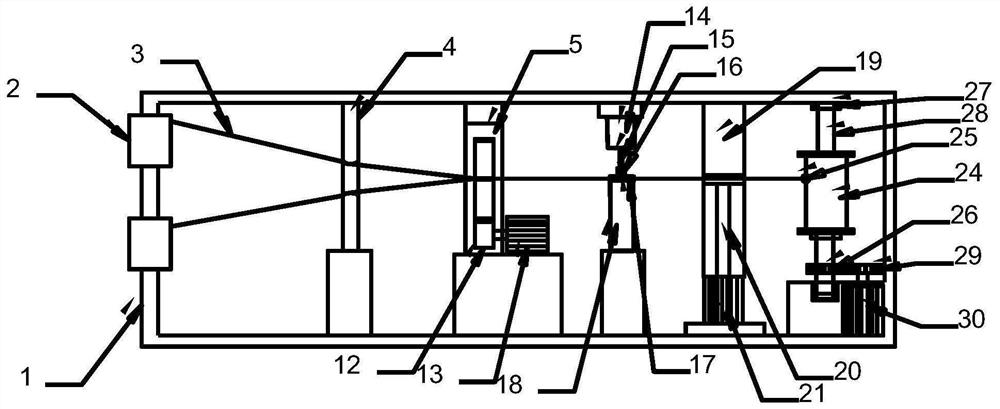

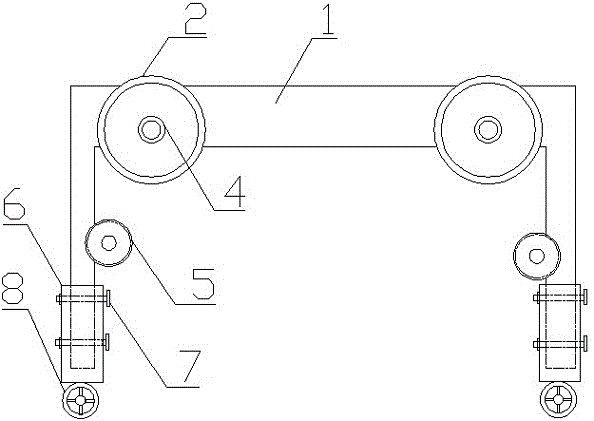

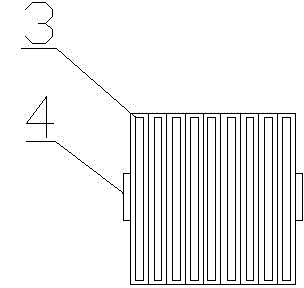

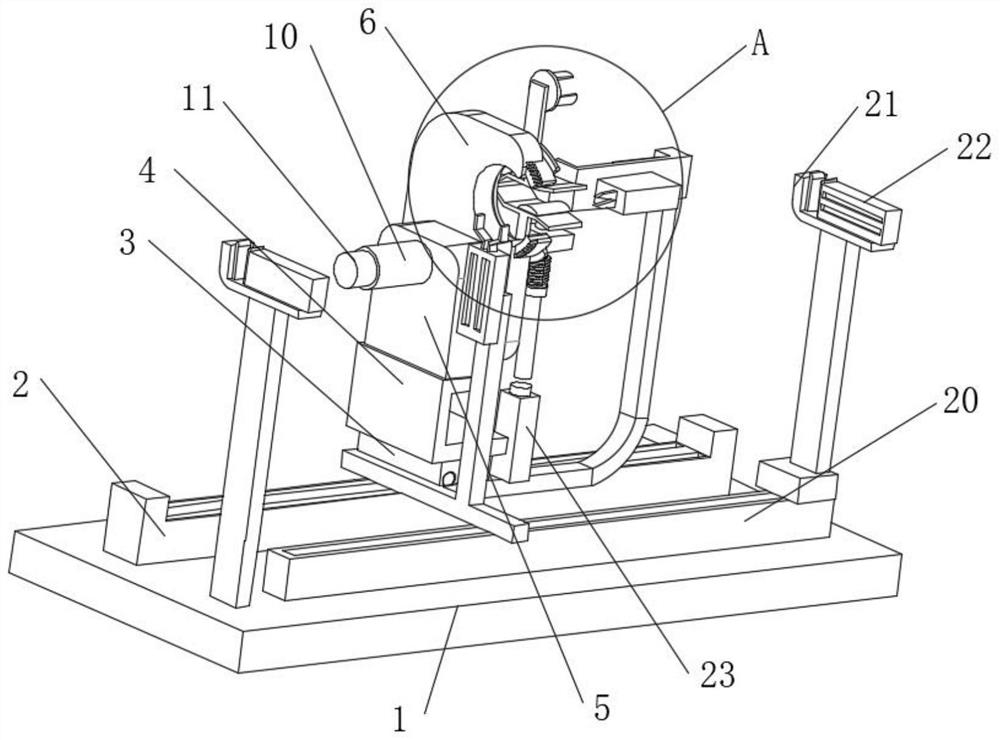

Device for collecting dust

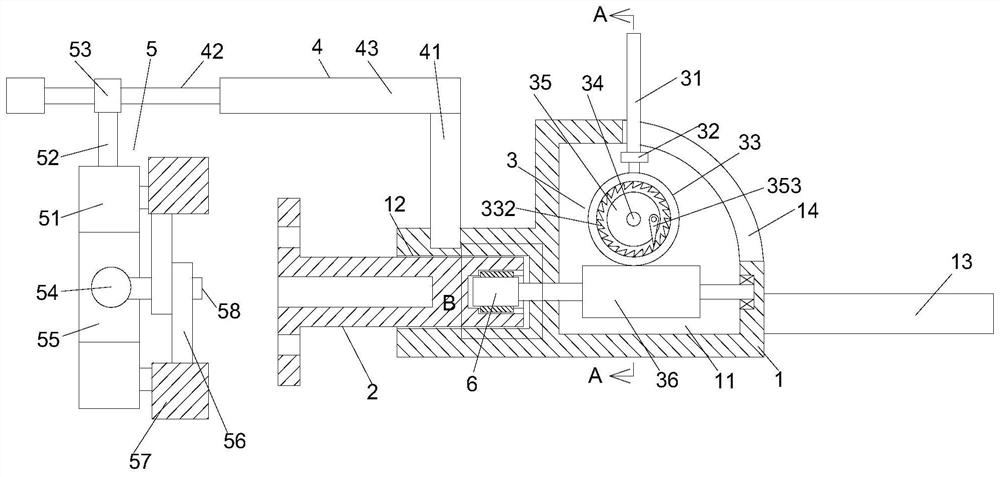

PendingCN109529507AWinding is effectiveAvoid flyingCombination devicesDirt cleaningFiberMechanical engineering

The invention discloses a device for collecting dust. The device for collecting dust comprises a feeding section, a fiber winding section, a settling section and an air-blowing section which are successively connected with each other from top to bottom; the feeding section at least comprises a frame (1) and an embedding part (2); the interior of the frame (1) is hollow; the embedding part (2) is arranged on the upper surface of the frame (1); the fiber winding section comprises a barrel (3) and at least one winding hairbrush; the barrel (3) is connected with the frame (1); the winding hairbrush is vertically arranged in the barrel (3); the winding hairbrush is rotatably arranged; the settling section at least comprises a spraying unit capable of spraying water; at least one fan (4) is arranged in the air-blowing section; an air blowing direction of the fan (4) is opposite to the settling section. The device is capable of achieving the effects of further collecting fibrous dust and reducing environmental pollution and harm to human body.

Owner:江西众安职业卫生技术服务有限公司

Silk thread winding roller for textile machinery

The invention provides a silk thread winding roller for textile machinery, and relates to the technical field of winding rollers. The problems that when an existing textile silk thread winding rolleris used, silk threads cannot be assisted in ventilation and cannot be kept dry, and heat dissipation and ventilation cannot be conducted when the silk threads are wound in a damp or high temperature state are solved. The silk thread winding roller comprises a main body and an ejector block; the main body is of a cylindrical structure with a convex middle part; and the ejector block sleeves the outer side of the main body, a guide rod of the ejector block is inserted into a guide groove, and the side edge of the guide rod is connected with the interior of the guide groove. A rotating roller isused for directly winding the silk threads, so that the silk threads can be wound in a rotating mode after the rotating roller is installed, when the silk threads are wound, if the silk threads are damp or high in temperature, wind passes through the interior of the rotating roller and then makes contact with the silk threads through inner holes and outer holes, the wind can assist in heat dissipation or ventilation of the silk threads, and then the silk threads can be kept dry, and use of the silk threads is not affected.

Owner:芜湖腾飞信息科技有限公司

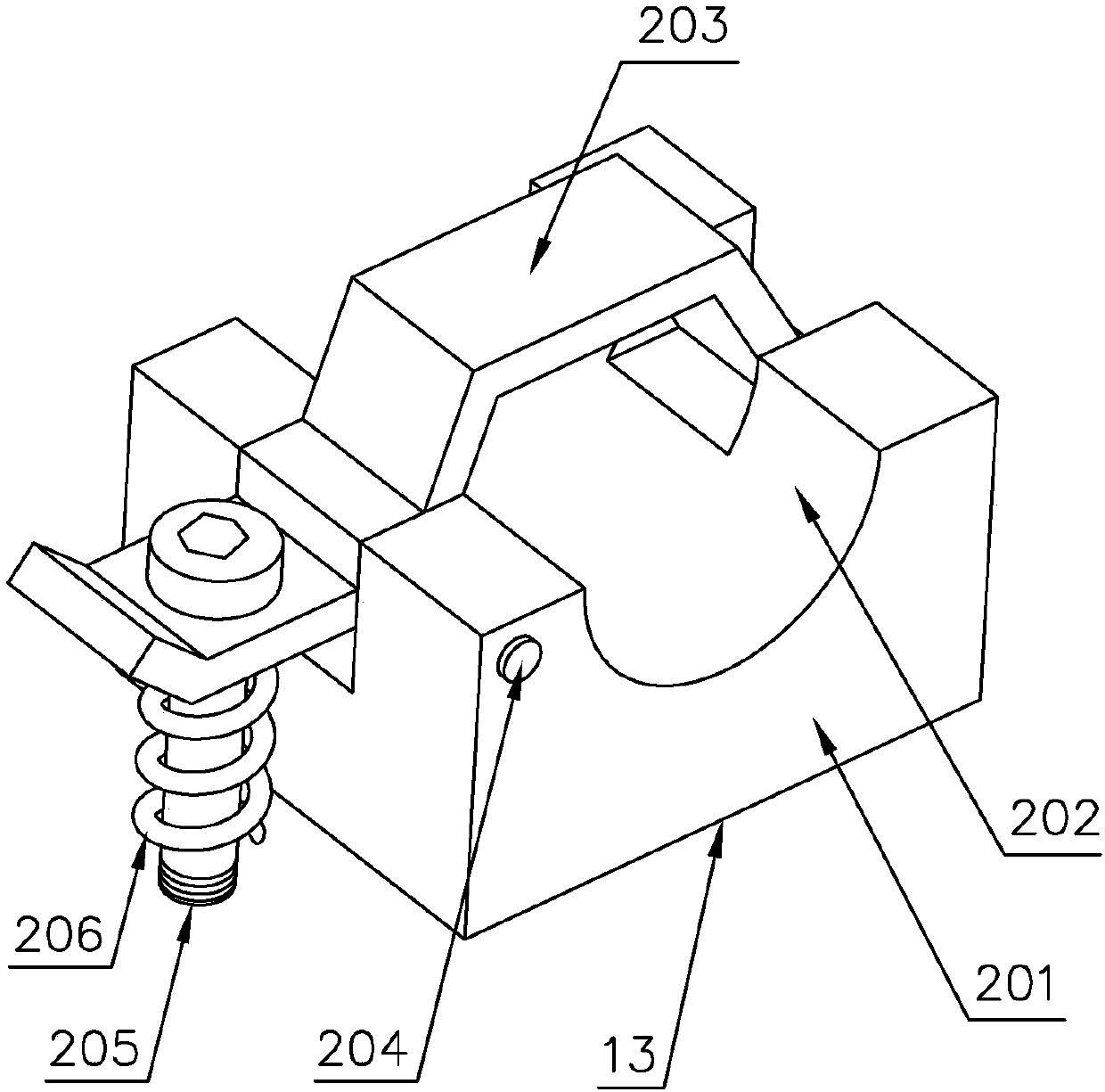

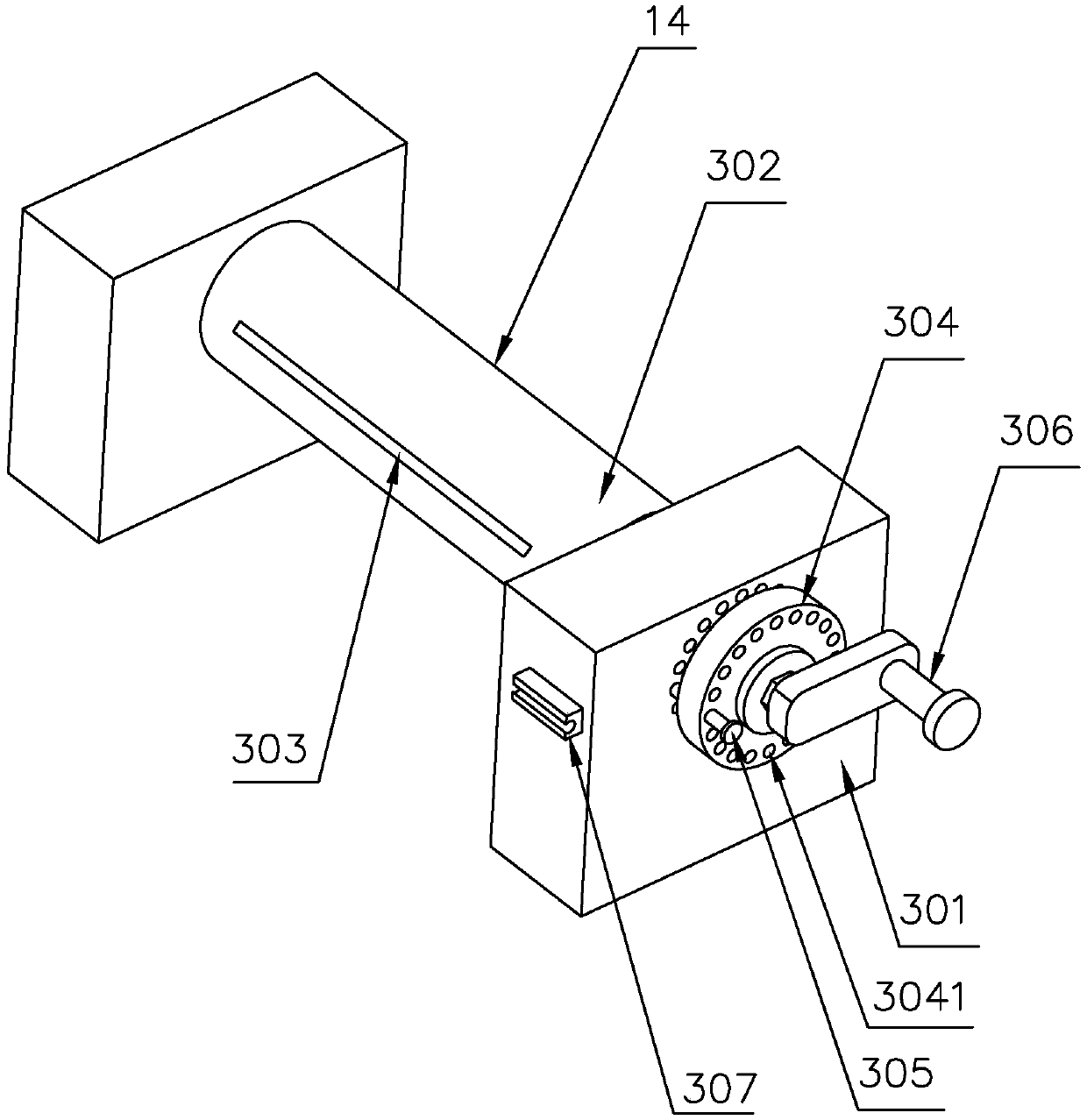

Multi-purpose cuff for nurse in clinical nursing

InactiveCN107890402AWinding is effectiveEasy accessNursing accommodationBandagesEngineeringConductor Coil

The invention discloses a multifunctional wristband for nurses in clinical nursing, which comprises a restraint belt, a fixing seat, a clamping device, and a winding device. Velcro is provided on the restraint belt, and a fixation seat is provided on one side of the restraint belt. , the fixed seat is provided with a clamping device, and one side of the clamping device is provided with a winding device, and the clamping device includes a clamping seat, an arc groove, a block, a pin shaft, a screw, and a spring. There is an arc groove on the seat, and one end of the block is fixed and limited by a screw, and a spring is arranged on the outside of the screw; the winding device includes a support seat, a winding shaft, a runner, a pin, and a handle. A winding shaft is provided, a running wheel is provided at the shaft end of the winding shaft, and a handle is provided on one side of the running wheel. In the present invention, a clamping device and a winding device are arranged on the wrist guard body, so that the needle tube can be stuck on the clamping device when injecting medicine, so as to free hands to complete the disinfection work.

Owner:倪萍

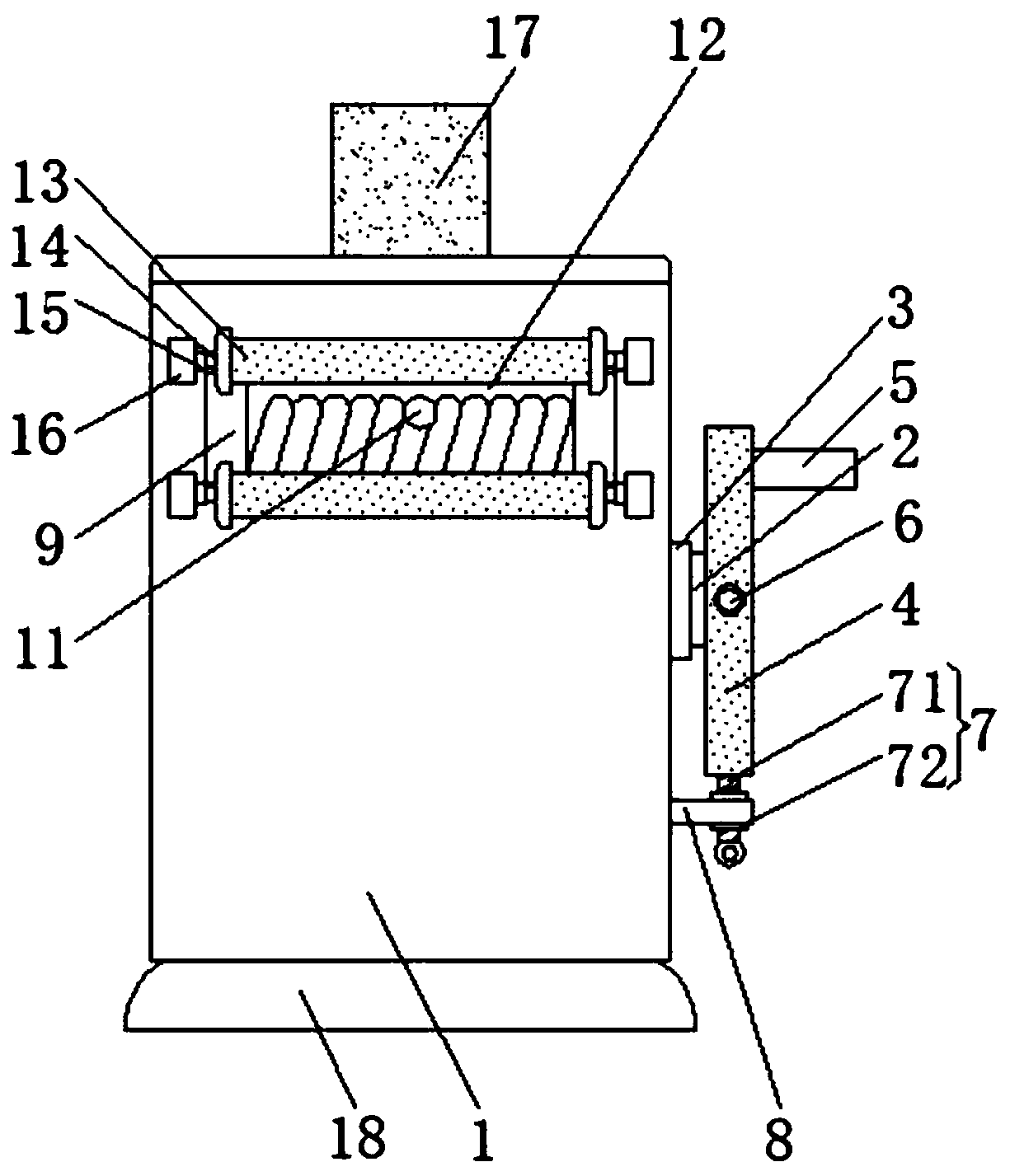

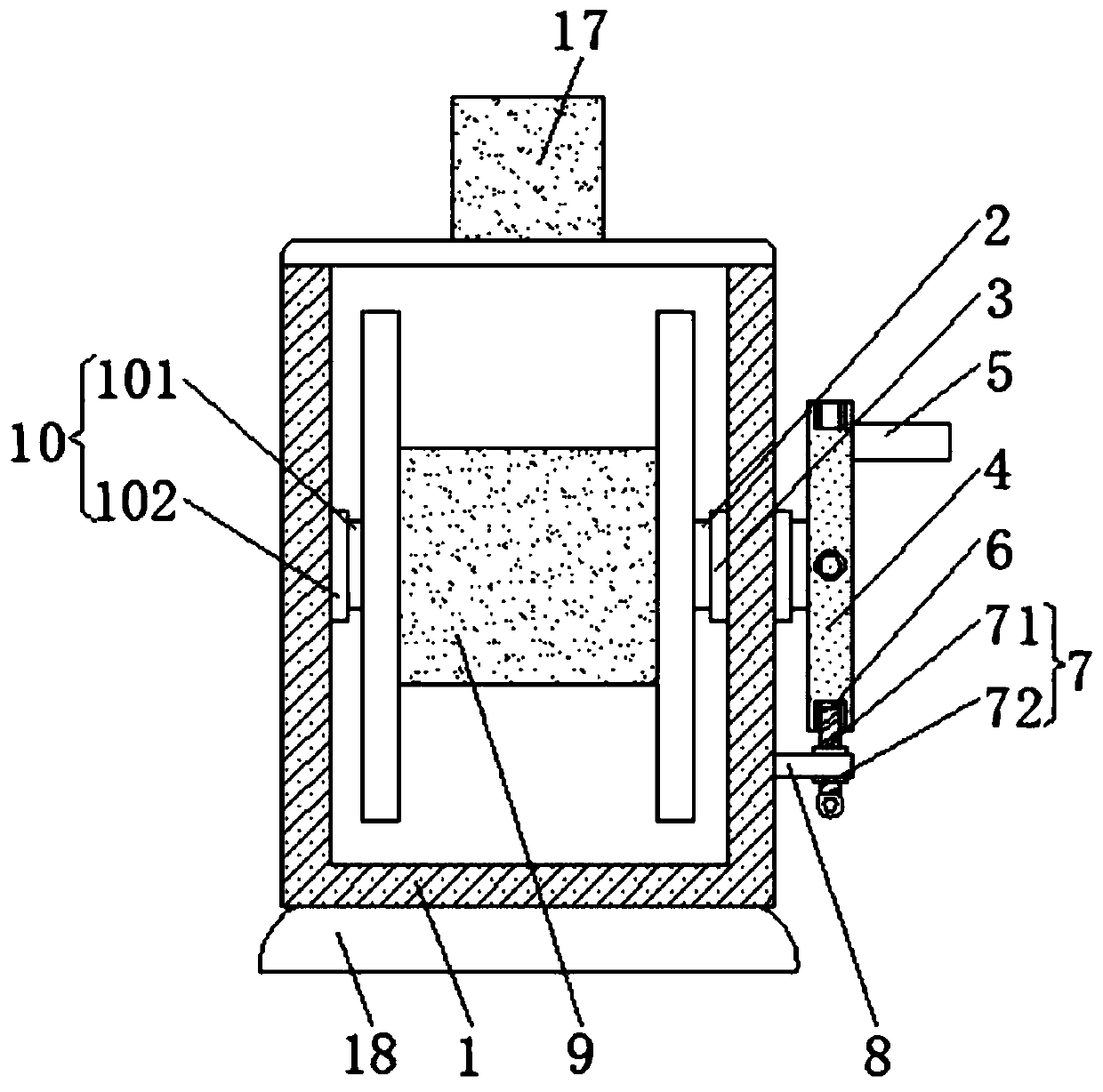

A winding processing machine for thermal insulation belt of oil transportation pipeline

ActiveCN111532909BEasy to processEasy to useHollow article cleaningThermal insulationPipe insulation

The invention relates to a winding processing machine for heat preservation belts of oil pipelines, which comprises a bottom plate, a support frame and a winding device. The top of the bottom plate is symmetrically installed with a support frame, and a winding device is arranged between the support frames. The winding device is installed in the middle of the top of the bottom plate. . The present invention can solve the problem that when the existing petroleum pipelines are heat-preserved, the heat-insulation belts are usually manually wound on the petroleum pipelines. During thermal insulation processing, it is usually not possible to quickly clean the pipeline, and it is not possible to quickly apply glue to the inner surface of the thermal insulation tape, resulting in poor adhesion of the thermal insulation tape, prone to falling off, and affecting the thermal insulation effect of the pipeline, etc. problem.

Owner:峰特(浙江)新材料有限公司

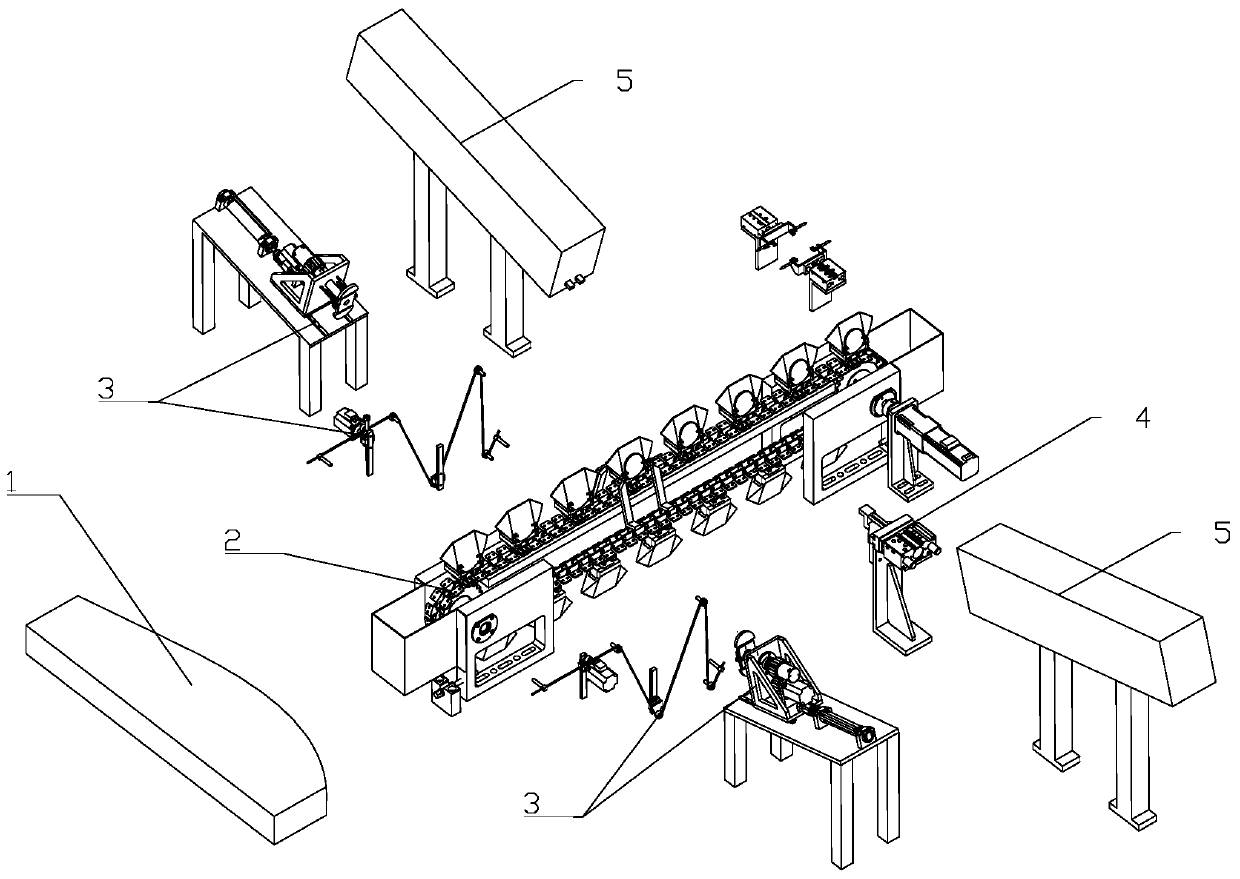

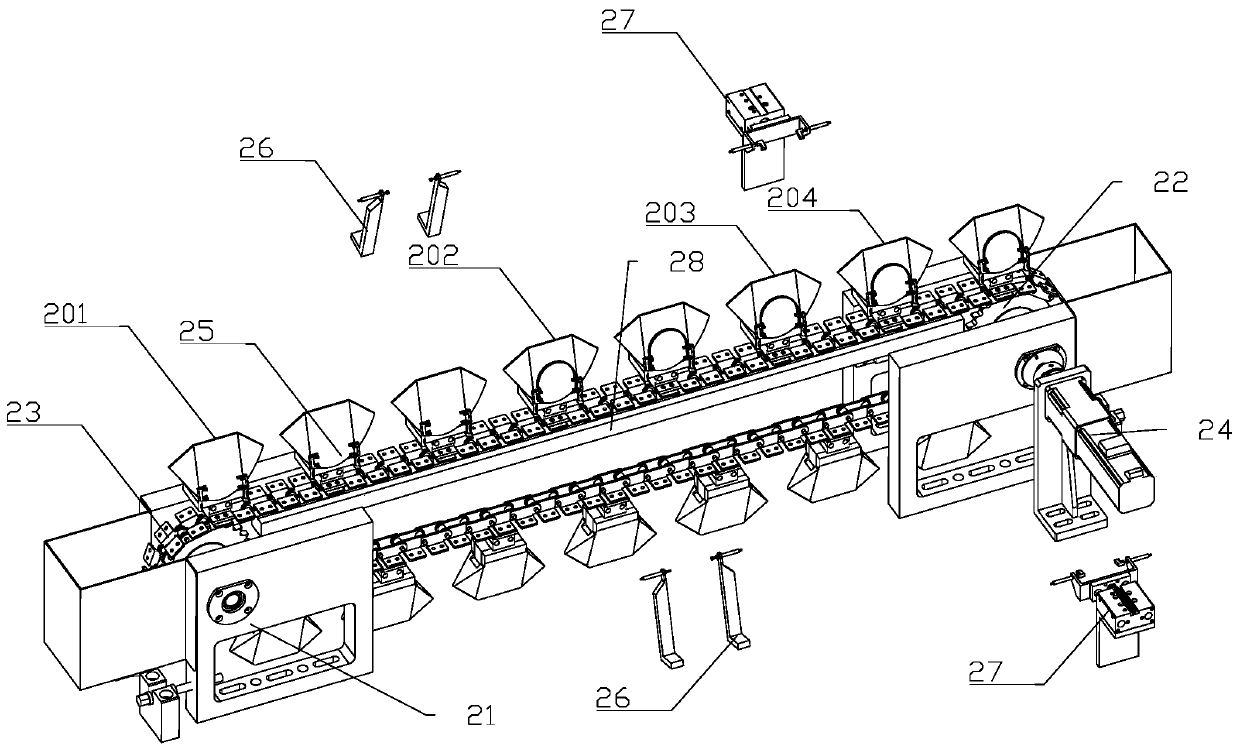

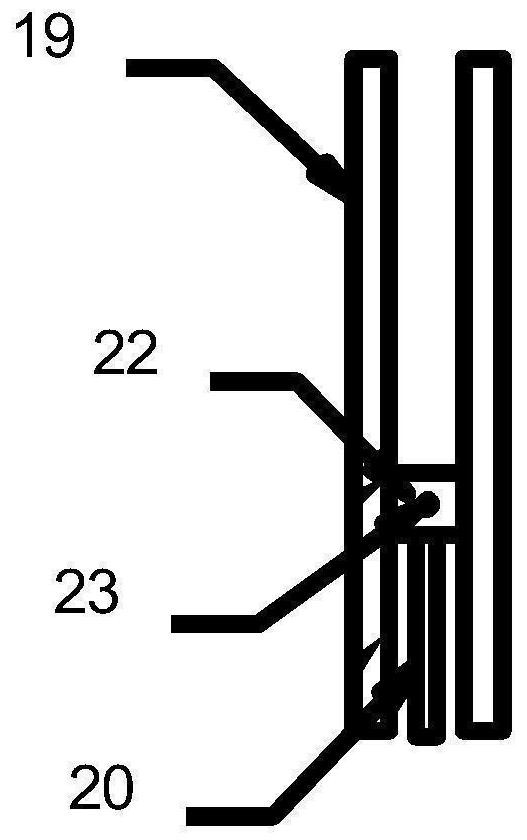

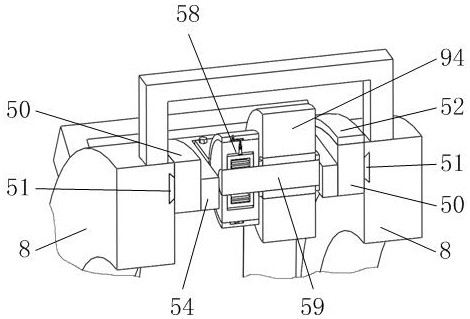

Ear belt feeding device and method for cup-shaped mask production

InactiveCN111493431AAvoid shakingAchieving force balanceMetal working apparatusProtective garmentElectric machineGear wheel

The invention relates to the technical field of mask machines. The invention discloses an ear belt feeding device for cup-shaped mask production. The ear belt feeding device comprises a feeding assembly, an installation frame, a moving frame, a moving air cylinder, a rotating motor, a rotating shaft, a gear set, a winding disc, a rope clamping assembly and a rope cutting assembly. The feeding assembly is used for sending out the ear belt rope; the movable frame is movably connected to the installation platform through a sliding rail, the movable air cylinder is arranged on the installation frame, and the telescopic end of the movable air cylinder is connected with the movable frame. The rotating motor is installed on the moving frame, and the rotating shaft is hinged to the moving frame. The center of the winding disc is fixed at the shaft end of the rotating shaft; the rope clamping assembly and the rope cutting assembly are installed on the winding disc. The device has the advantagesof rotary ear band winding, compact structure, high band winding efficiency, simultaneous processing of two sides of the cup-shaped mask and small nailing impact force.

Owner:徐新建

Automatic recovery device for drip irrigation belt

The invention relates to the technical field of agricultural machinery, in particular to a device for automatically recycling a drip irrigation tape. The device for automatically recycling the drip irrigation tape comprises a stander and a stepless gearbox, wherein travelling wheels are mounted at a lower side of the stander in a fixed manner, a transmission shaft is mounted at top of the stander along a left- right direction, a roller is mounted above the stander through a bearing block, the stepless gearbox is mounted above the stander in a fixed manner, a rotating shaft of each travelling wheel is connected to a power input end of the stepless gearbox through a first transmission mechanism, a power output end of the stepless gearbox is connected to a power input end of the transmission shaft through a second transmission mechanism, and a power output end of the transmission shaft is connected to a power input end of the roller through a third transmission mechanism. According to the invention, as the stepless gearbox is mounted, a transmission ratio of the stepless gearbox can be regulated according to operational requirements to ensure a more uniform recycling speed of the drip irrigation tape and an appropriate and uniform tension for the drip irrigation tape, so that the drip irrigation tape is prevented from being broken easily, and moreover the continuity and stability of automatically recycling the drip irrigation tap can be ensured.

Owner:新疆千里良驹农业科技有限公司

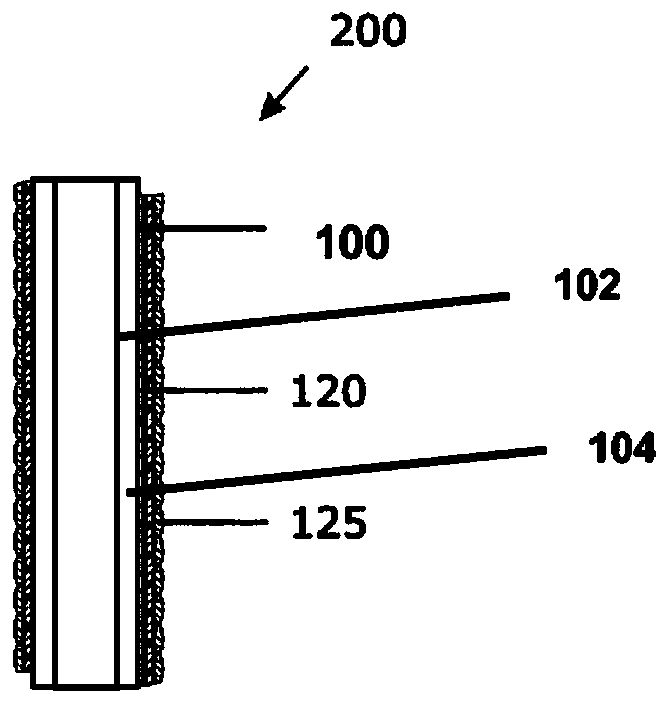

RFID tag

PendingCN110537190AReduce troubleComfortable to wearConductive materialRecord carriers used with machinesEmbedded systemElectrical and Electronics engineering

The RFID tag comprises a transponder chip and an antenna. The antenna is coupled to the transponder chip. The antenna comprises a metal wire or a strand of metal wires. The metal wire(s) comprise(s) acore-sheath structure. The metal wire or the metal wires comprise(s) a core out of a first metal; and a sheath layer. The core is over its full circumference surrounded by the sheath layer out of stainless steel. The first metal has electrical conductivity higher than stainless steel.

Owner:NV BEKAERT SA

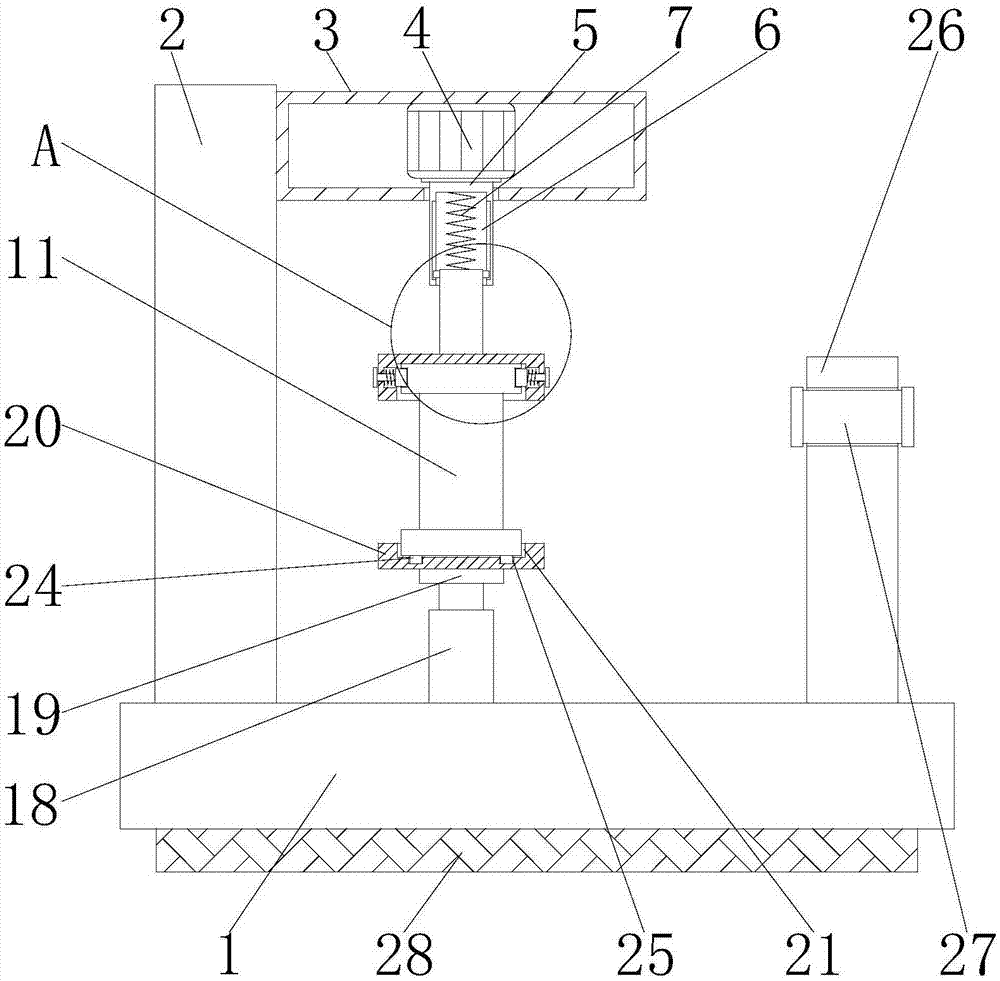

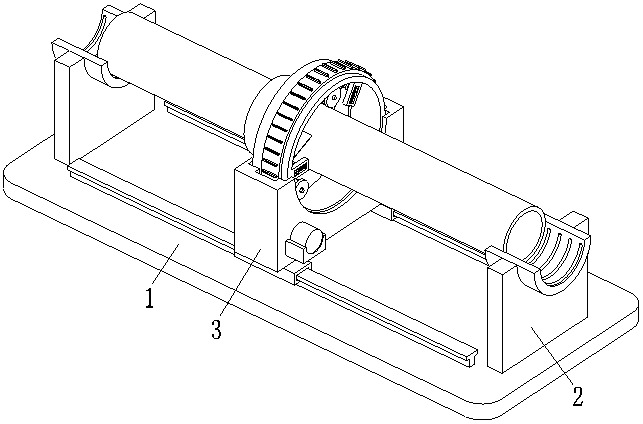

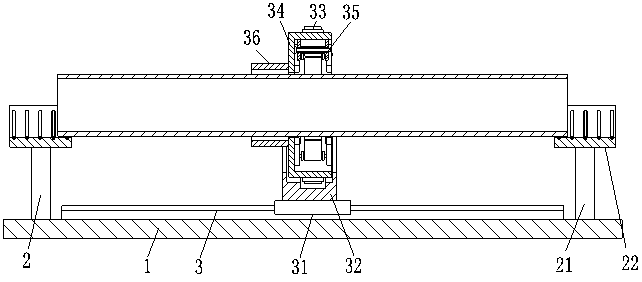

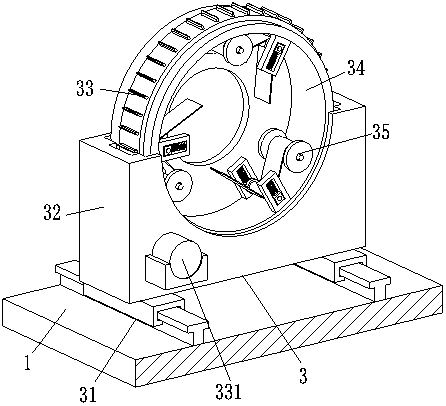

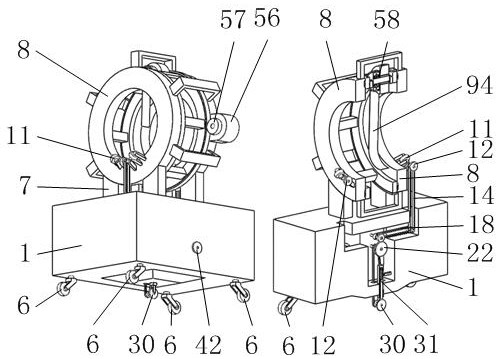

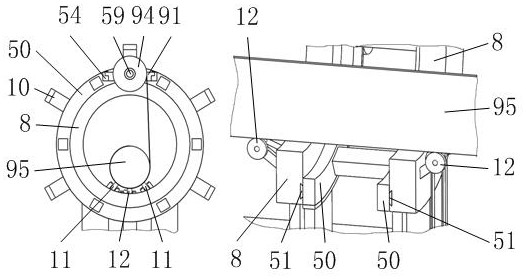

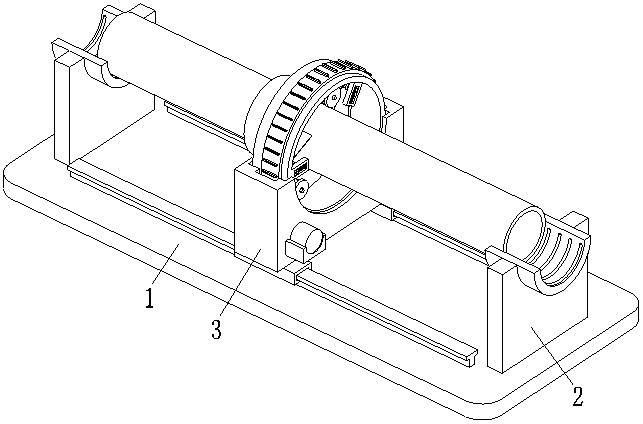

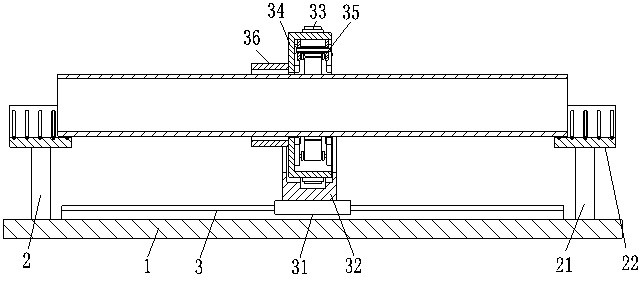

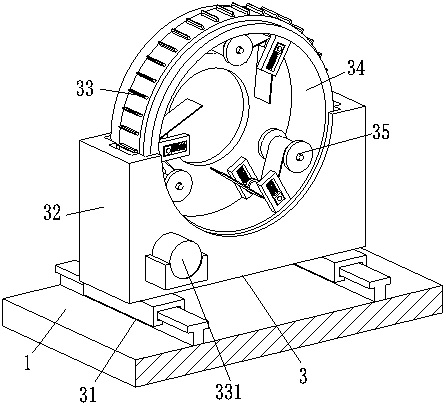

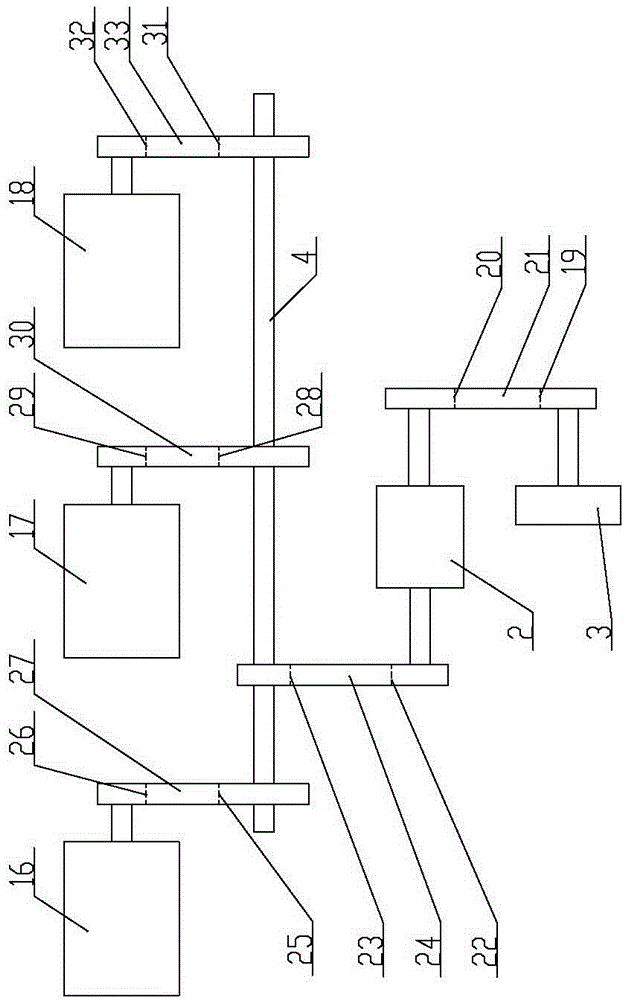

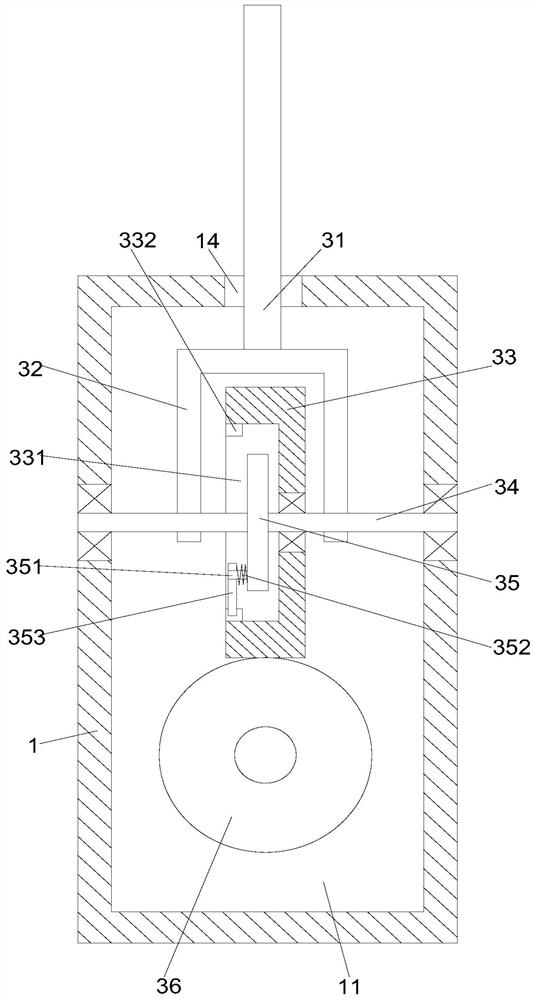

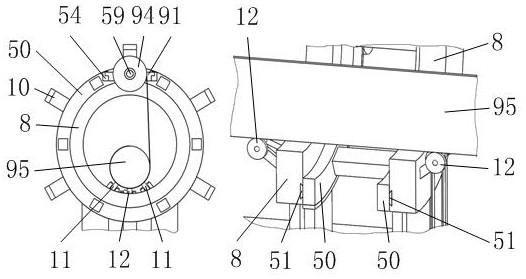

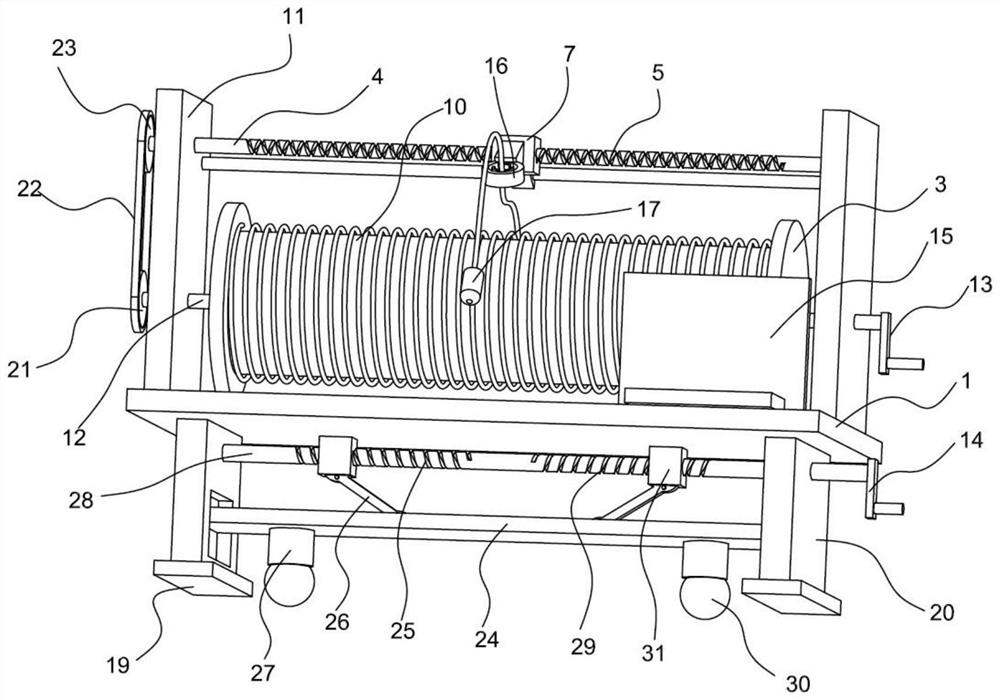

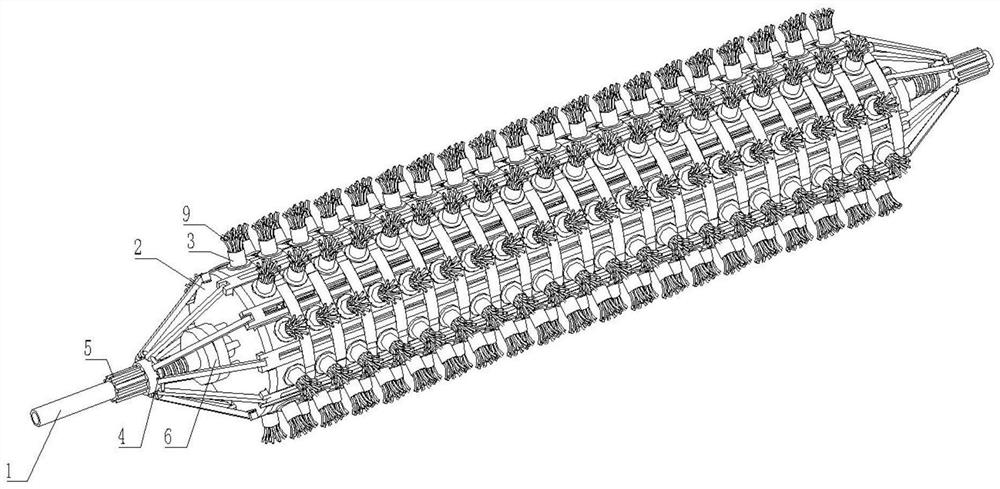

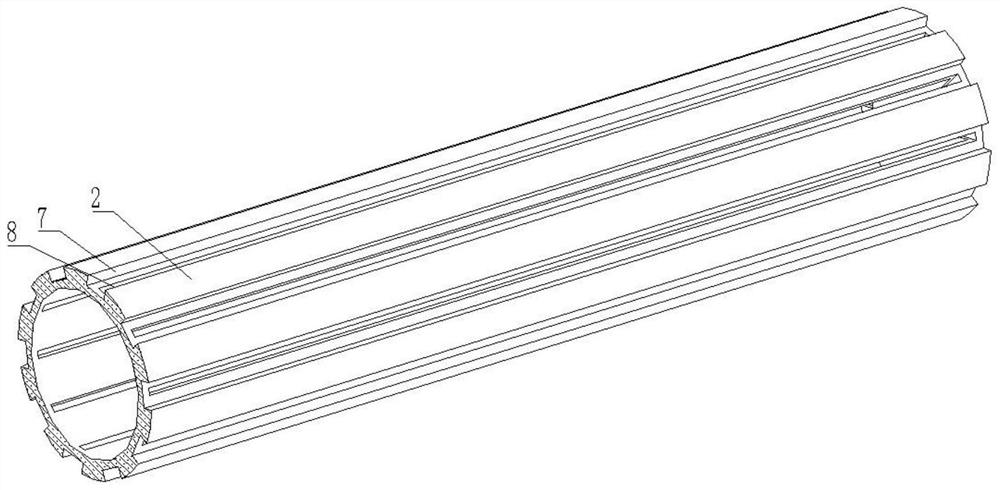

A multi-strand wire core winding mechanism

ActiveCN110828067BEasy windingWinding is effectiveCable/conductor manufactureWinding machineGear wheel

The invention discloses a multi-strand wire core winding mechanism, which includes a frame, a winding ring and a drum. A winding ring is arranged inside the frame, a gear ring is installed outside the winding ring, and a A long rod, the top of the long rod is connected to a spring, and a cylinder is installed on the outside of the spring, and the cylinder is connected to a pressure plate, and a rubber pad is installed on the pressure plate; the outer bottom of the gear ring is connected to the first gear, and the first gear is installed on the first motor on the front shaft. A hydraulic press is installed on the upper right side of the winding ring, a connecting rod is installed at the front end of the hydraulic press, a first crimping groove is installed at the bottom of the connecting rod, a fixing plate is arranged under the first crimping groove, and a second crimping groove is arranged on the top of the fixing plate . The invention has reasonable structure and simple operation, can effectively wind multiple wire cores, and can also prevent the wire cores that are closer to the source of rotation from receiving greater torsion during the twisting process, resulting in excessive twisting of the wire cores Fracture improves the efficiency of wire core processing.

Owner:东莞市安焕电子有限公司

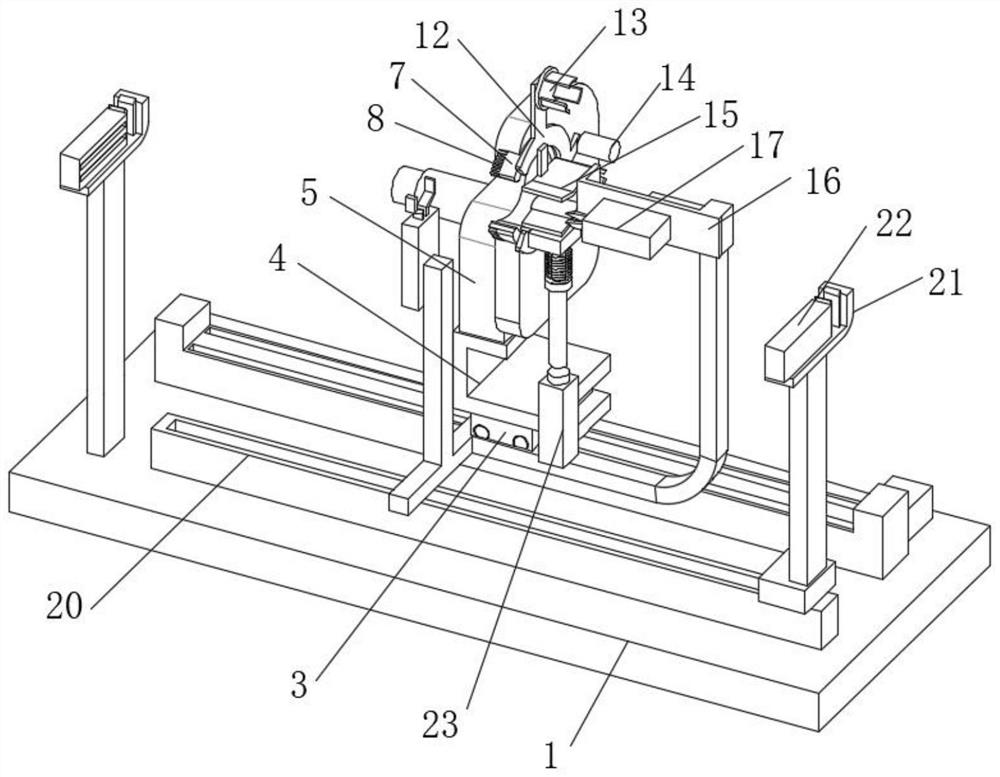

Automatic peeling wiring tool

ActiveCN112217081AImprove efficiencyQuality improvementLine/current collector detailsApparatus for removing/armouring cablesPower cableButt joint

The invention relates to the technical field of power cables, and discloses an automatic stripping wiring tool, which comprises a driving box body, a driving cavity, a butt joint groove, a connector lug, a driving mechanism, a steering piece, a clamping and fixing mechanism and a connecting piece, the butt-joint groove is formed in the left end of the driving box body, an opening of the butt-jointgroove faces leftwards, the driving cavity is located on the right side of the butt-joint groove, and a guide sliding groove is formed in the upper right portion of the driving cavity. The connectingpiece is movably connected between the driving cavity and the butt joint groove, the connector lug is located in the butt joint groove, and the connector lug is detachably connected with the left endof the connecting piece; the driving mechanism is located in the driving cavity and connected to the right end of the connecting piece. The steering piece is located at the upper end of the butt joint groove and movably connected with the driving box body. The clamping and fixing mechanism is located on the left side of the driving box body and movably connected with the steering piece. The problems that in the prior art, a wiring tool has certain limitation in the wiring process, unnecessary trouble is brought to wiring personnel, the wiring efficiency and the wiring quality are influenced,and potential safety hazards exist are solved.

Owner:山东津达线缆有限公司

Intelligent frequency control wiring hardness device based on environmental perception

PendingCN111332865AEfficient storageNot easy to knotFilament handlingEnvironmental resource managementEnvironmental perception

The invention discloses an intelligent frequency control wiring hardness device based on environmental perception and relates to the technical field of environmental perception. The intelligent frequency control wiring hardness device comprises a storage box. A first bearing is connected to the front surface of the storage box in a clamping manner, a first rotating shaft is connected in the firstbearing in a sleeved manner, one end of the front surface of the first rotating shaft is fixedly connected to a turnplate, and a handle is arranged on the front surface of the turnplate. Based on theintelligent frequency control wiring hardness device based on environmental perception, by arranging the handle, the turnplate, a threaded rod, a threaded cap, a groove, a winding roller, the first rotating shaft and a through hole, the winding roller can wind a wiring harness body and then staff rotates the threaded rod forward, so that the threaded rod moves upward under action of threaded connection to the threaded cap, and the threaded rod is located in the groove, so that the turnplate does not rotate and the wiring harness is stored in the storage box effectively without winding the wiring harness body manually by the staff. The wiring harness body is unlikely to tie a knot, so that the service life of the wiring harness is prolonged.

Owner:西安宏泰时频技术有限公司

Electric wire winding device

InactiveCN103818768AImprove work efficiencyWinding is effectiveFilament handlingEngineeringConductor Coil

The invention aims to provide an electric wire winding device which comprises a support. Two parallel wire spools are arranged on the left and the right of the upper side of the support, at least nine separate first guide wheels are overlaid on each wire spool, and a fixing column penetrates the middles of the first guide wheels of each wire spool; second guide wheels are respectively arranged on the left and the right of the lower side of the support. The electric wire winding device has the advantages that electric wires can be wound in a crossed, staggered and non-overlapping manner by the two parallel wire spools, the two wire spools are separated from each other by a certain distance, the first guide wheels are combined with one another to form each wire spool, a guide effect further can be realized by the two second guide wheels, the height of the support can be adjusted, and the electric wire winding device is provided with rollers, so that the electric wires can be effectively wound by the integral device according to actual conditions; the integral device can be shifted according to production conditions, accordingly, the work efficiency can be improved, and the electric wire winding device is applicable to production.

Owner:WUHU SHUNCHENG ELECTRONICS

A kind of air conditioning pipeline winding device

ActiveCN111891789BEffective self-windingImprove winding efficiencyCastorsWebs handlingElectricityDrive wheel

Owner:HANGZHOU FUYANG HONGXIANG TECH SERVICES CO LTD

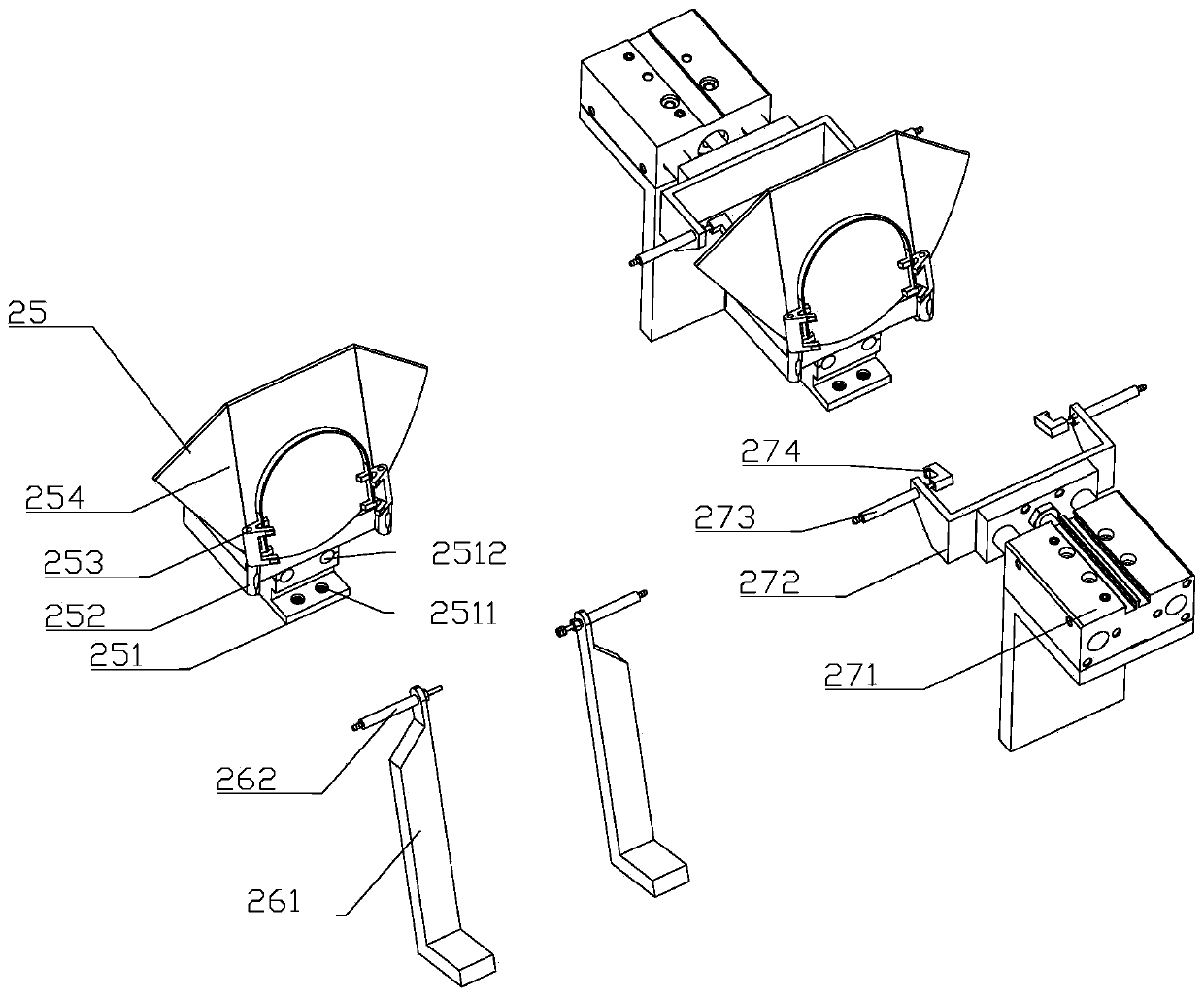

Intelligent high-efficiency full-automatic winding machine

PendingCN113602915AImprove stabilityImprove practicalityManufacturing wire harnessesArticle deliveryWinding machineEngineering

The invention discloses an intelligent high-efficiency full-automatic winding machine comprising a bottom plate. A first pneumatic sliding table and a wire harness positioning device are arranged on the upper surface of the bottom plate, a second pneumatic sliding table is slidably connected to the surface of the first pneumatic sliding table, and an installation base is slidably connected to the surface of the second pneumatic sliding table. A connecting box is fixedly installed on the upper surface of the installation base, a fixed box is fixedly installed on the side face of the connecting box, a circular opening is formed in the surface of the fixed box, a rotating ring is rotationally connected to the inner wall of the circular opening, and a V-shaped gear ring is fixedly installed on one side of the rotating ring. According to the intelligent high-efficiency full-automatic winding machine, the fixed box is arranged, the circular opening is formed in the surface of the fixed box, and therefore the winding machine can perform adhesive tape winding on a wire harness at any position during working, and meanwhile, by arranging the V-shaped gear ring, a Hall sensor installation groove and a magnet installation hole, the rotating speed and the rotating position of the V-shaped gear ring can be monitored in real time.

Owner:重庆中电手自动化科技有限公司

Environment-friendly underground water pollution detection device

PendingCN114674606AReasonable structureInnovative designWithdrawing sample devicesTesting waterDrive shaftEngineering

The invention relates to the technical field of groundwater pollution detection, and discloses an environment-friendly groundwater pollution detection device which comprises a fixed base, supporting frames are installed on the two sides of the upper end of the fixed base, a driven shaft is rotatably installed between the supporting frames, and a moving block is connected to the driven shaft through an arranged reciprocating thread area. One end of the driven shaft penetrates through the supporting frames and is connected with a driving shaft through a belt wheel part, the driving shaft is rotationally arranged between the supporting frames, a winding roller is fixedly installed on the driving shaft located between the supporting frames, a steel wire rope is connected to the winding roller in a winding mode, the steel wire rope penetrates through the limiting assembly, and the tail of the steel wire rope is connected with a detection bottle; and a moving mechanism is mounted on the fixed base. According to the steel wire rope detection device, the limiting assembly can move left and right, orderly winding of the steel wire rope during winding and unwinding is finally achieved, meanwhile, effective movement and stable supporting of the whole detection device are ensured, and the detection reliability of the detection device is further improved.

Owner:河南省自然资源监测院 +1

A textile fiber cleaning roller

ActiveCN112359575BImprove cleaning qualityExtended service lifeMechanical cleaningPressure cleaningTextile fiberTextile technology

Owner:ZHEJIANG MEILAIYA TEXTILE

Snake-like winding soft actuator

This application provides a snake-like winding soft actuator, which aims to solve the problem that the soft robot is still in the research stage and needs to be further expanded. It includes an elastic bellows, a strain-limiting layer, an elastic expansion layer, a fixed connector, and an air pipe for connecting with an air source. The present application provides a novel serpentine winding actuator, which includes two types: a winding actuator with a strain-limiting layer and a winding actuator without a strain-limiting layer. The serpentine winding actuator with strain-limiting layer relies on the strain-limiting layer and the elastic stretch layer to determine the winding performance, and can quickly and efficiently wind the slender rod tightly. As the inflation pressure increases, the serpentine winding actuator will wind tighter and can lift 1.3kg objects. The winding actuator without the strain-limiting layer is lighter and softer, and only depends on the fixed direction of the elastic stretching layer to determine the winding method of the actuator, which can also wind and lift objects.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Winding device for enameled wire

ActiveCN107512622BAchieve the effect of rotationTo achieve the mobile effectFilament handlingElectric machineStructural engineering

Owner:明光久智知识产权管理有限公司

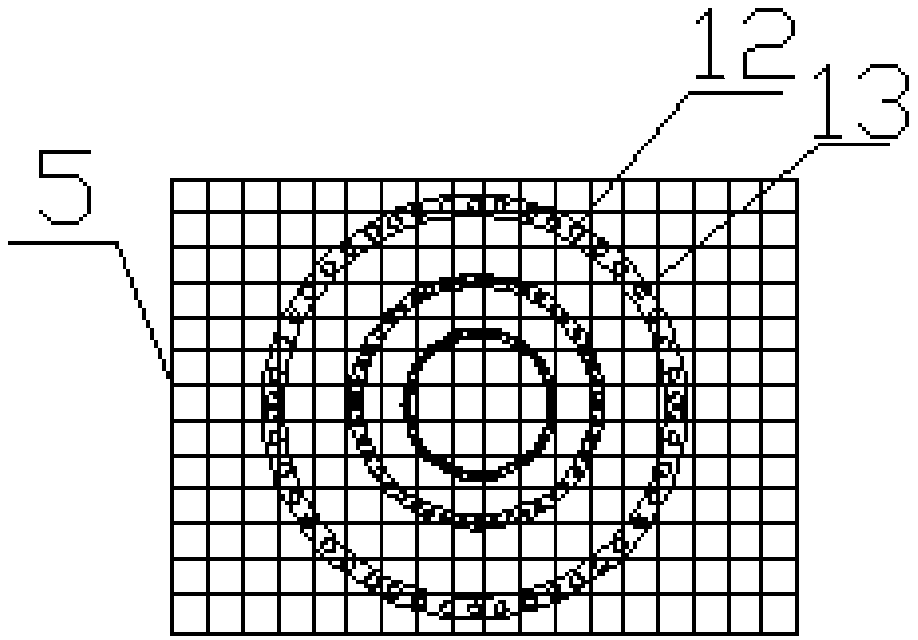

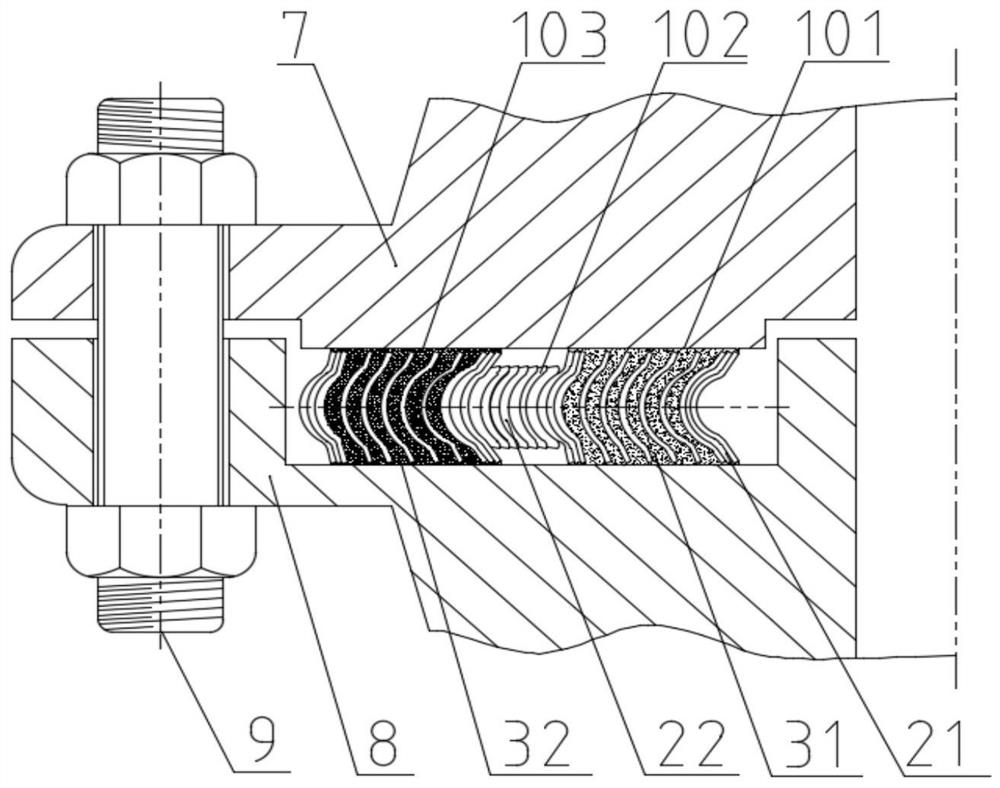

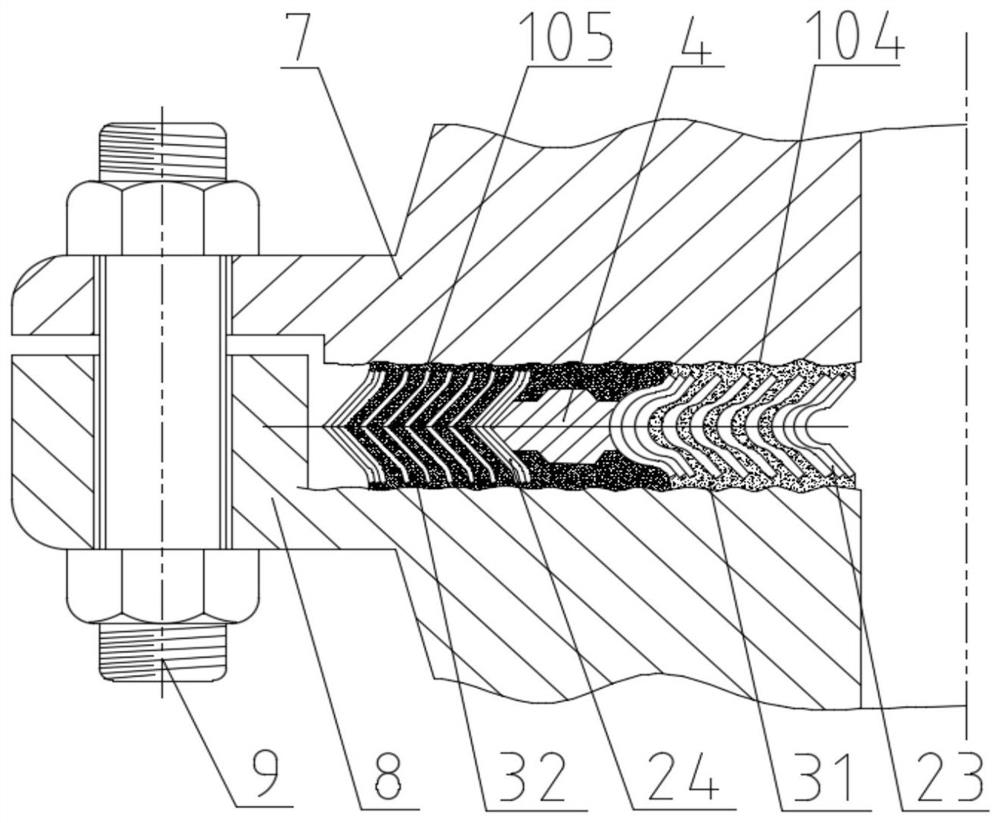

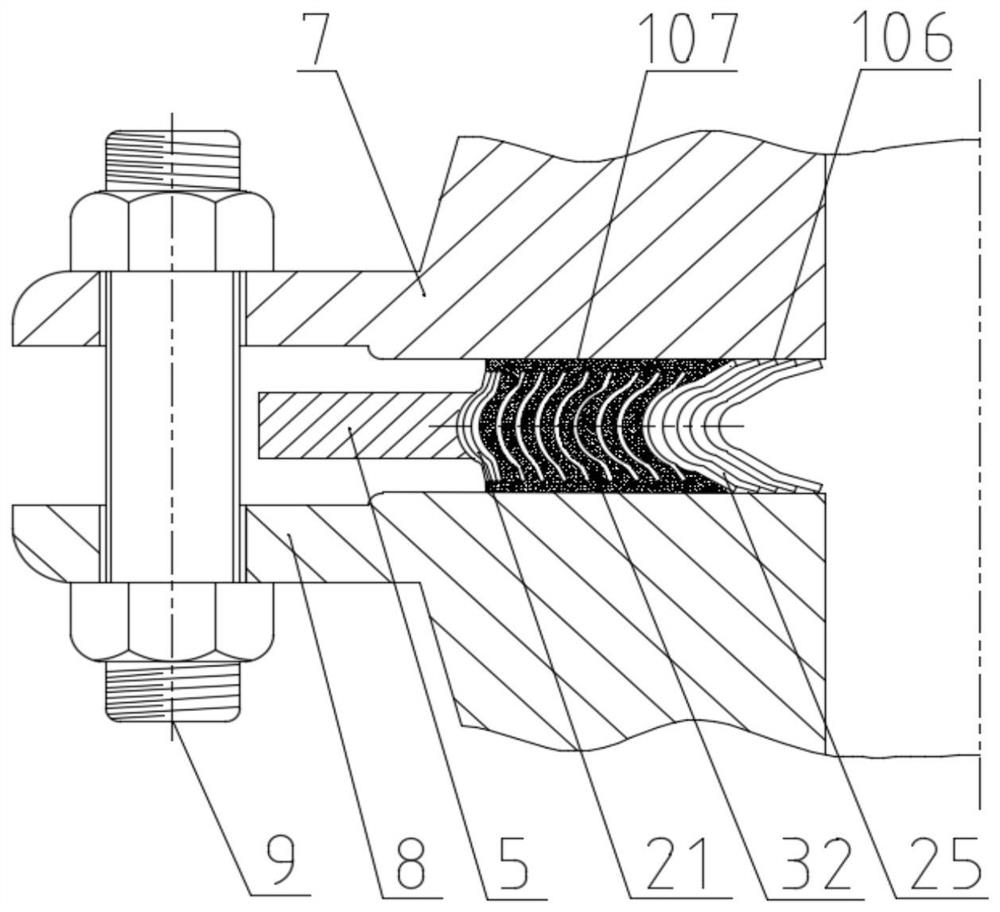

Fishbone-shaped winding type gasket

PendingCN113623396APrevent crushingImprove stress resistanceEngine sealsFlanged jointsStructural engineeringSteel belt

The invention discloses a fishbone-shaped winding type gasket in the field of winding type gaskets. The fishbone-shaped winding type gasket comprises a plurality of winding parts which are different in radius and are concentrically arranged, each winding part comprises a plurality of elastic metal belts which are tightly wound into a ring shape in the circumferential direction, the center of each elastic metal belt is bent, the inclined faces of the two sides of each elastic metal belt incline towards the medium pressure direction, and each inclined face is provided with at least one bent part. According to the fishbone-shaped winding type gasket, a sealing interface formed by the plurality of winding parts is more uniform in stress and higher in sealing safety and reliability, the plurality of winding parts can share pressure and better bear higher pressure and impact fluctuation, a steel belt with multiple bending points or bent faces is adopted for winding, stress concentration is not prone to being generated, the secondary compression and springback performance can be provided, and the compression and springback variables are greatly improved.

Owner:ENVIRONMENTAL GASKET COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com