Textile fiber cleaning roller

A textile fiber and cleaning roller technology, which is applied in the textile field, can solve the problems of difficult cleaning of textile fibers, and achieve the effects of increasing service life, improving cleaning quality, and convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

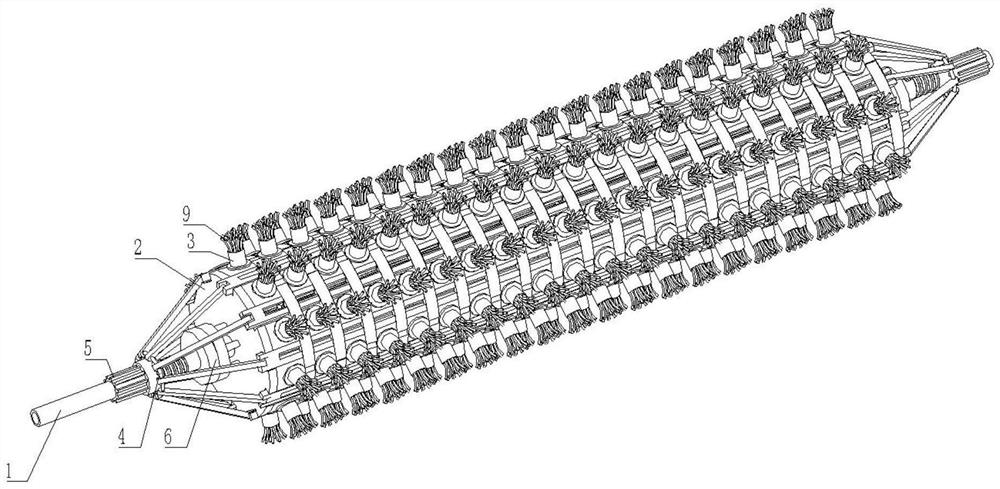

[0031] see Figure 1-6 , a textile fiber cleaning roller, comprising a rotating tube 1, the surface of the rotating tube 1 is provided with a fixing mechanism 5, the surface of the fixing mechanism 5 is provided with a cleaning mechanism 4, the surface of the cleaning mechanism 4 is provided with a roller sleeve 2, the surface of the roller sleeve 2 The surface is fixedly connected with several steel wire columns 3, and the top of the steel wire column 3 is fixedly connected with several cleaning steel wires 9. The surface of the fixing mechanism 5 is provided with a cleaning mechanism 6, and the cleaning mechanism 6 is located on the right side of the cleaning mechanism 4.

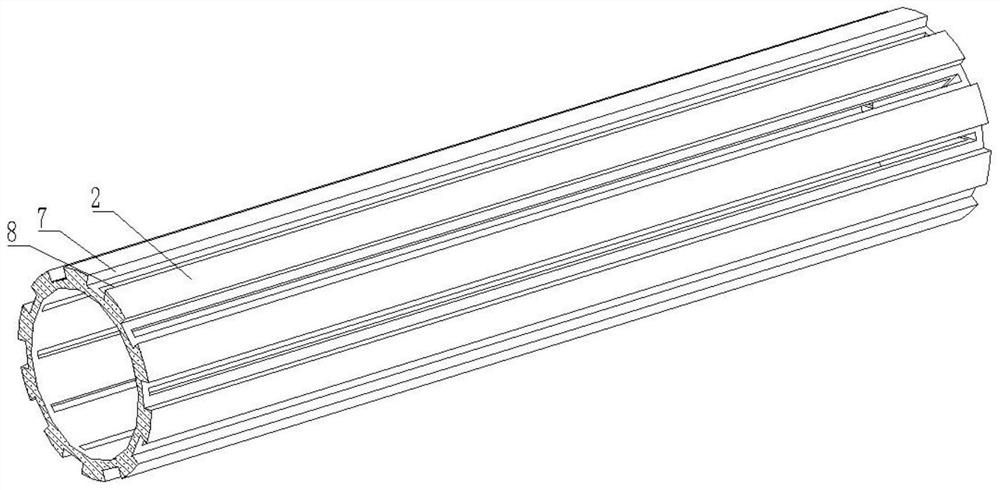

[0032] In this embodiment, the surface of the roller sleeve 2 is provided with several long grooves 7, and the interior of the roller sleeve 2 is provided with several water spray grooves 8, and the several long grooves 7 and the water spray grooves 8 are all centered around the center of the roller sleeve...

Embodiment 2

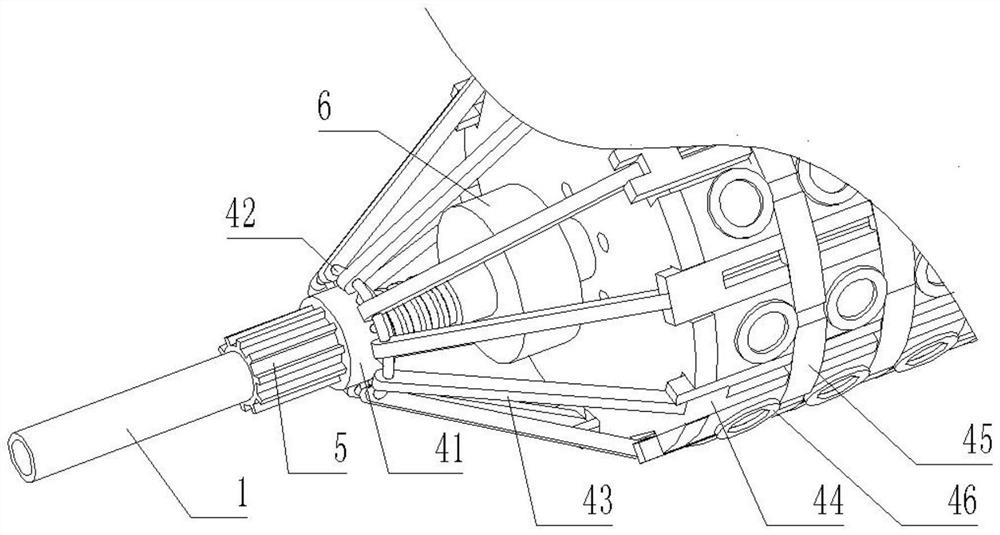

[0042] see Figure 7 , on the basis of Embodiment 1, in this embodiment, the cleaning mechanism 6 includes a water tray 61, and the right side of the water tray 61 is connected with several water pipes 63, and several water pipes 63 are all symmetrical to the center of the water tray 61 The shafts are distributed in a circular array, the surface of the rotating tube 1 is provided with water outlet holes 62, the water outlet holes 62 are located inside the water tray 61, the surface of the water pipe 63 is connected with a connecting pipe 64, and the bottom end of the connecting pipe 64 is fixedly connected with a nozzle 65.

[0043] Inject clean water through the two ends of the rotating tube 1, then enter the inside of the water pipe 63, then enter the inside of the connecting pipe 64 and spray it out from the position of the nozzle 65, and flush the textile fiber cloth with water, making the cleaning process more efficient efficient.

[0044] It is worth mentioning that the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com