Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Operation positioning is accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

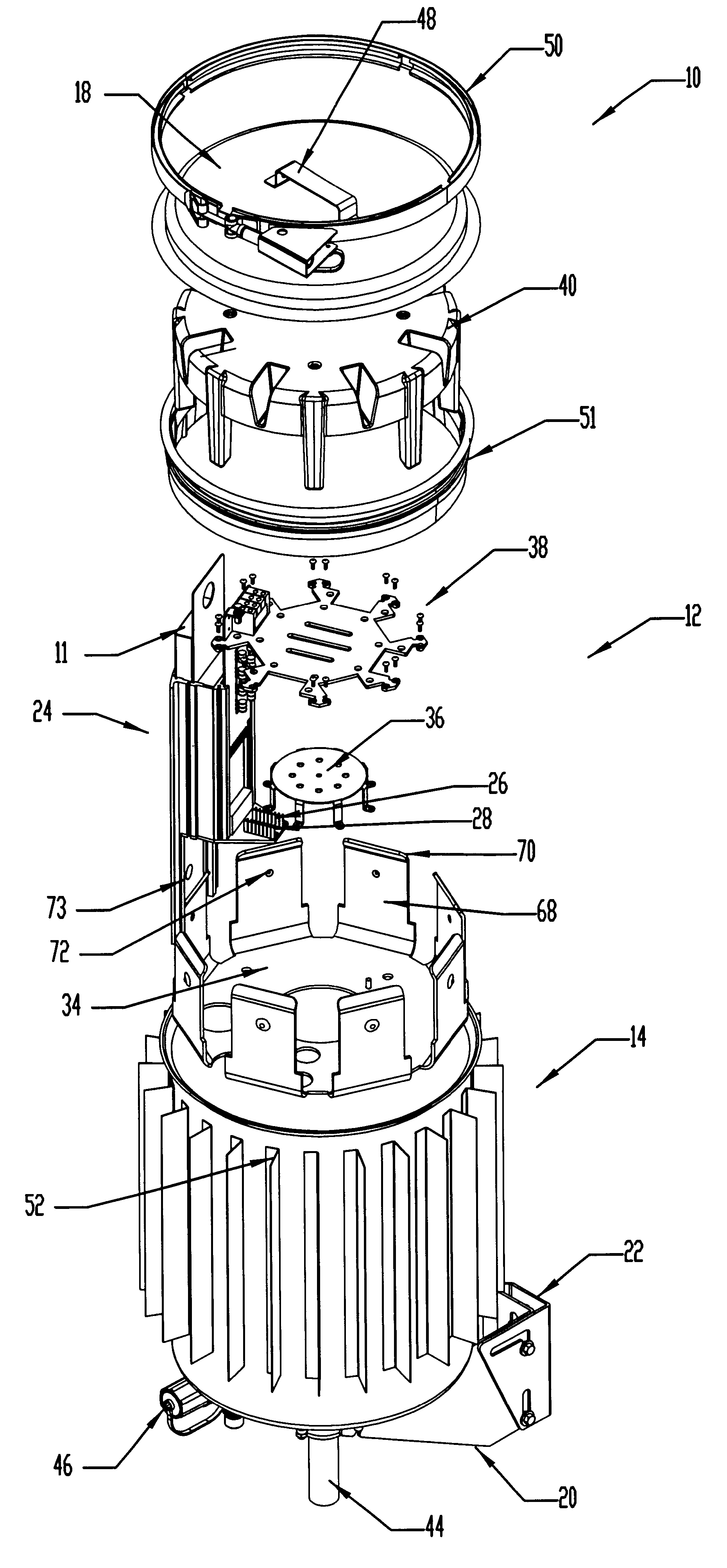

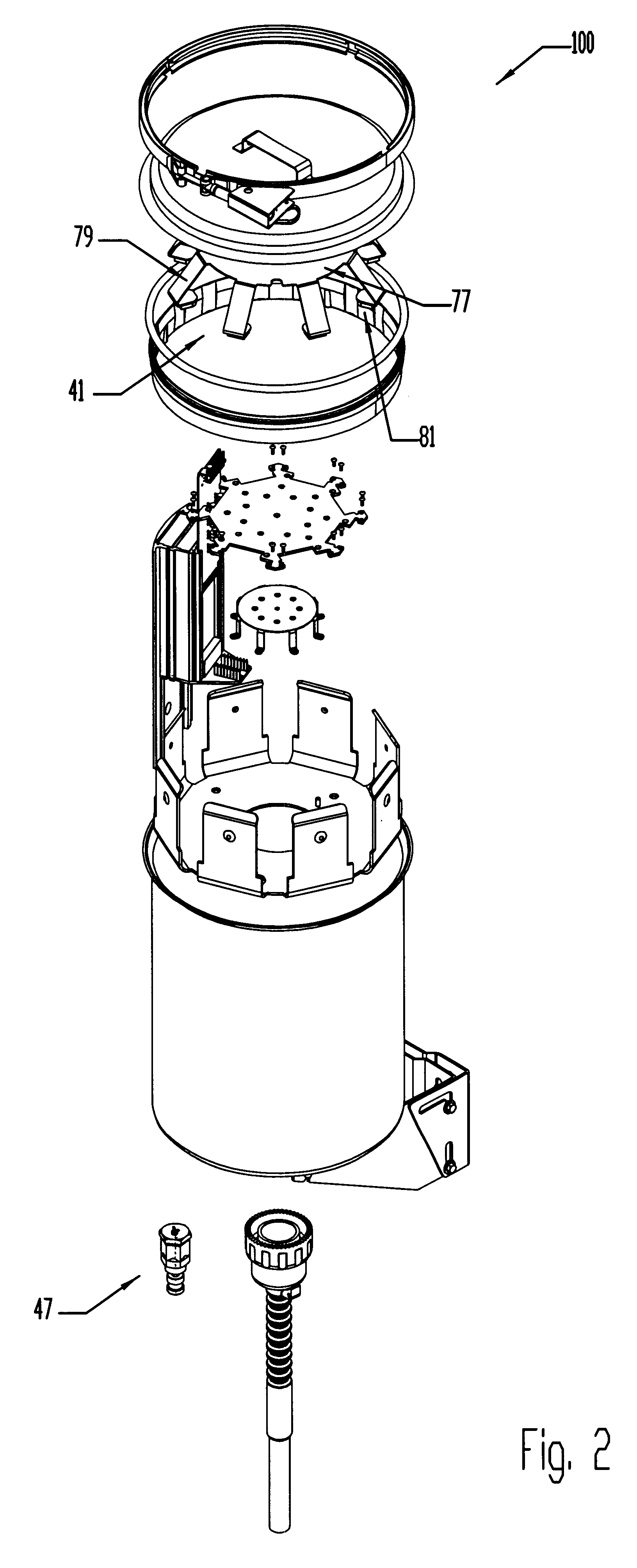

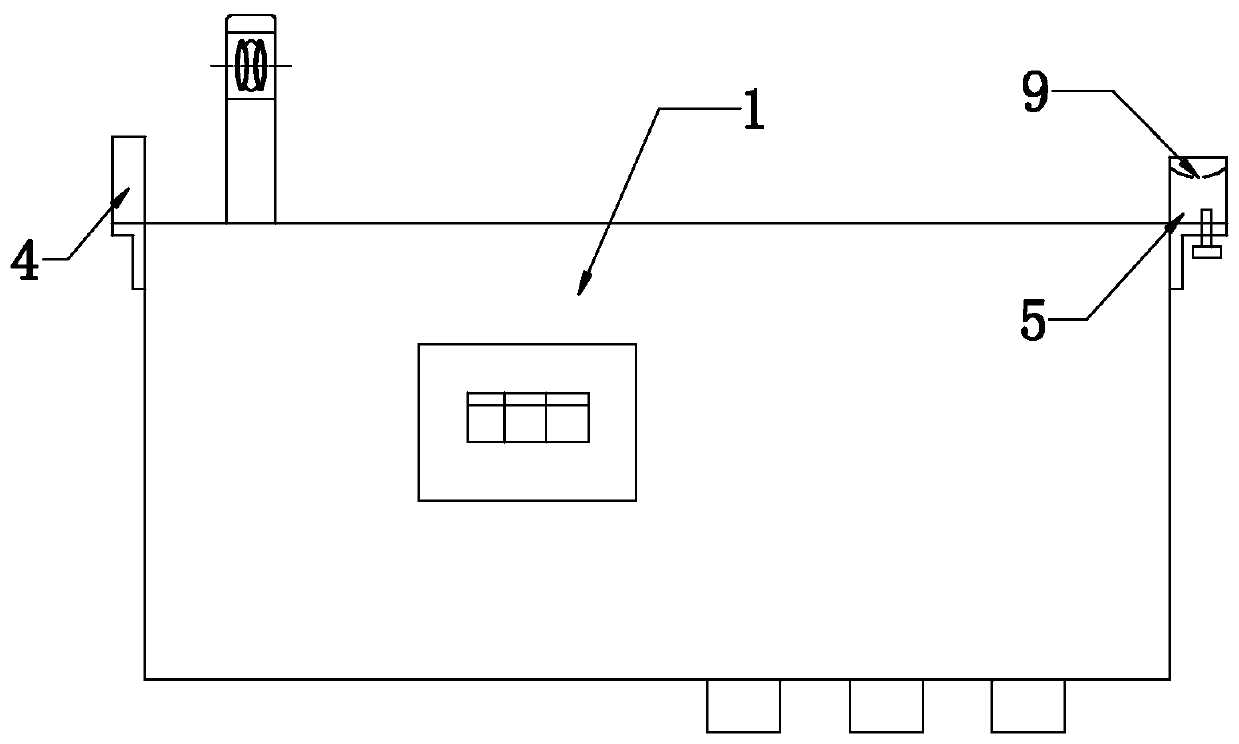

Electronic equipment enclosure

InactiveUS6507494B1Easy accessEasily interfaceEngagement/disengagement of coupling partsNetwork connectorsEngineeringHeat sink

An electronic equipment enclosure (10) for housing electronic equipment (11), and broadly comprising a pivot bracket (22); a plurality of sleeves (24), each being associated with a transmit terminal (26), a receive terminal (28), protective circuitry (30), and test circuitry (32); a spreader plate (38); and a heat sink (40). The pivot bracket (22) allows for tilting an outer housing (12) up to 30° relative to a mounting surface. The separate and distinct transmit and receive terminals (26,28) maintain minimum cross-talk and interference levels. The protective and the test circuitries (30,32) are located on daughter boards adjacent each sleeve (24) so as to be easily accessible. The spreader plate (38) is operable to force the sleeves (24) into direct contact with the interior surface of the outer housing (18). The heat sink (40) is operable to facilitate conductive heat transfer between the sleeves (24) and the lid (18).

Owner:SPECIAL PRODS +1

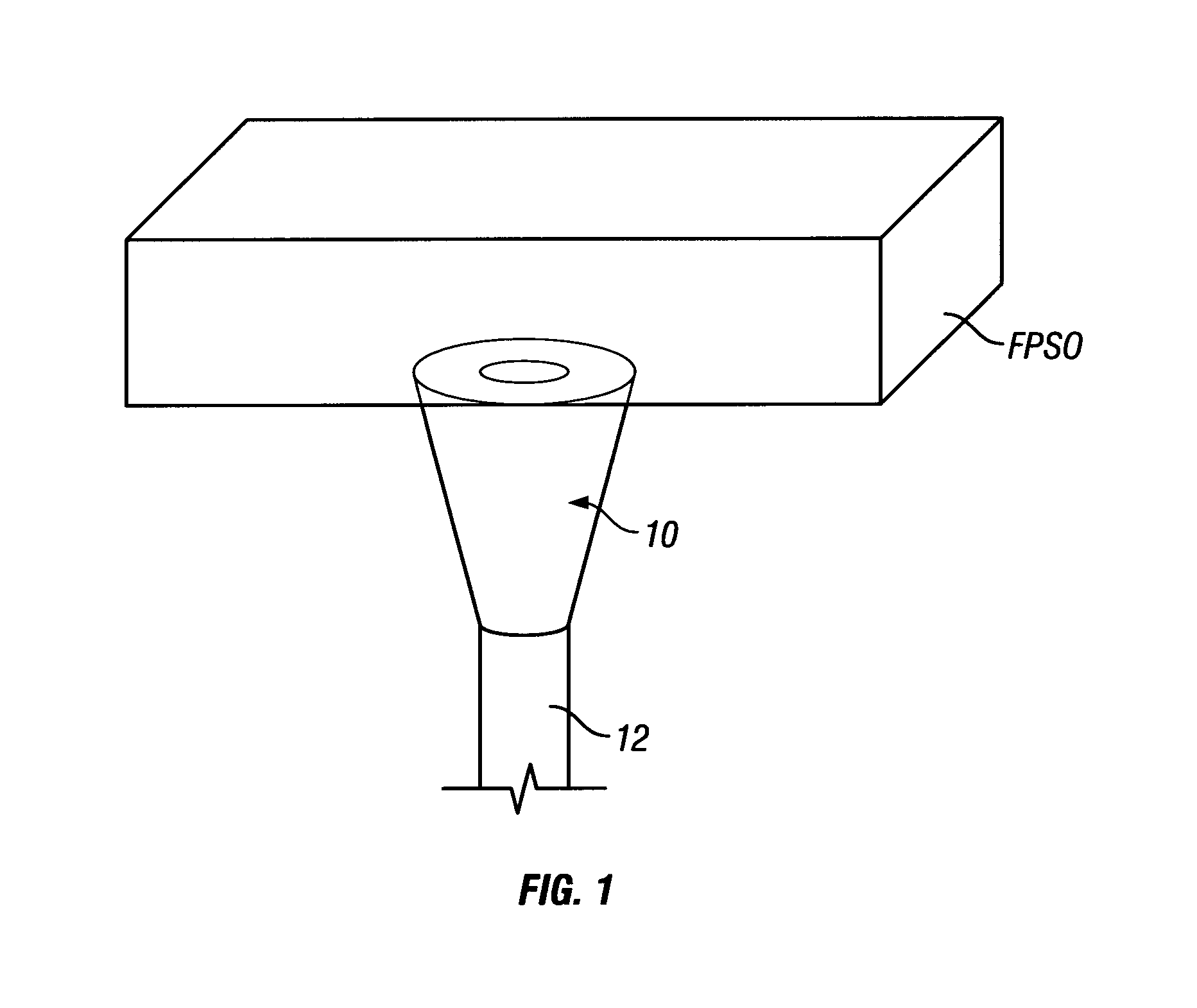

Flexible pipe terminal end-attachment device

ActiveUS20120192982A1Simple structureReduce difficultyDrilling rodsConstructionsStrain sensorBiomedical engineering

A terminal end-attachment device (10) for a flexible pipe (12) comprising an attachment body (14) adapted to receive a terminal end of a flexible pipe (12) and to couple the said flexible pipe to a hydrocarbon production installation structure. The device (10) further comprising a strain sensor (16) coupled to a sensor carrier (18), at least part of the sensor carrier (18) and the strain sensor (16) being at least partially incorporated within the attachment body (14). A method of manufacturing a terminal end-attachment device (10) for a flexible pipe (12) is also provided.

Owner:ONESUBSEA L L C

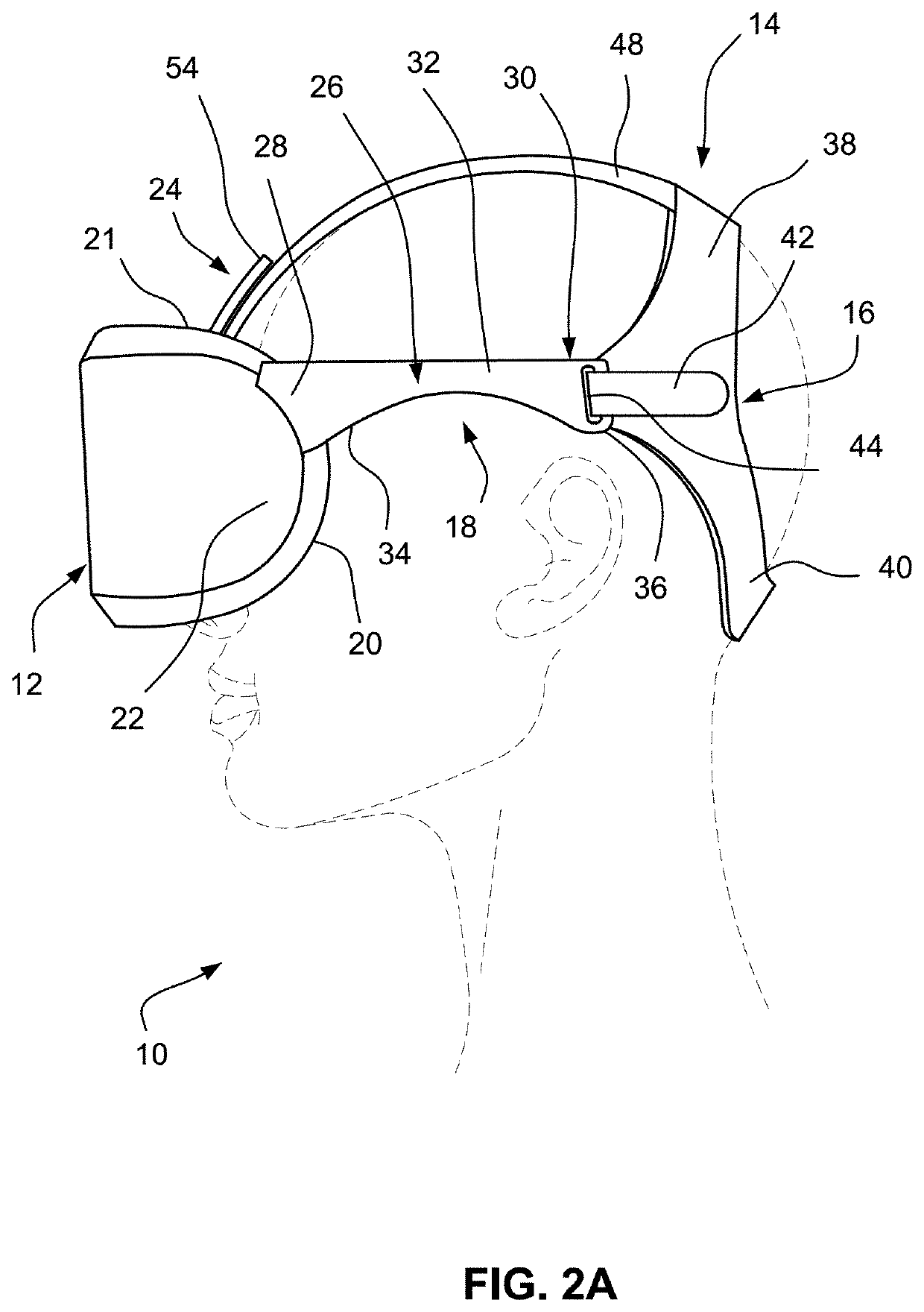

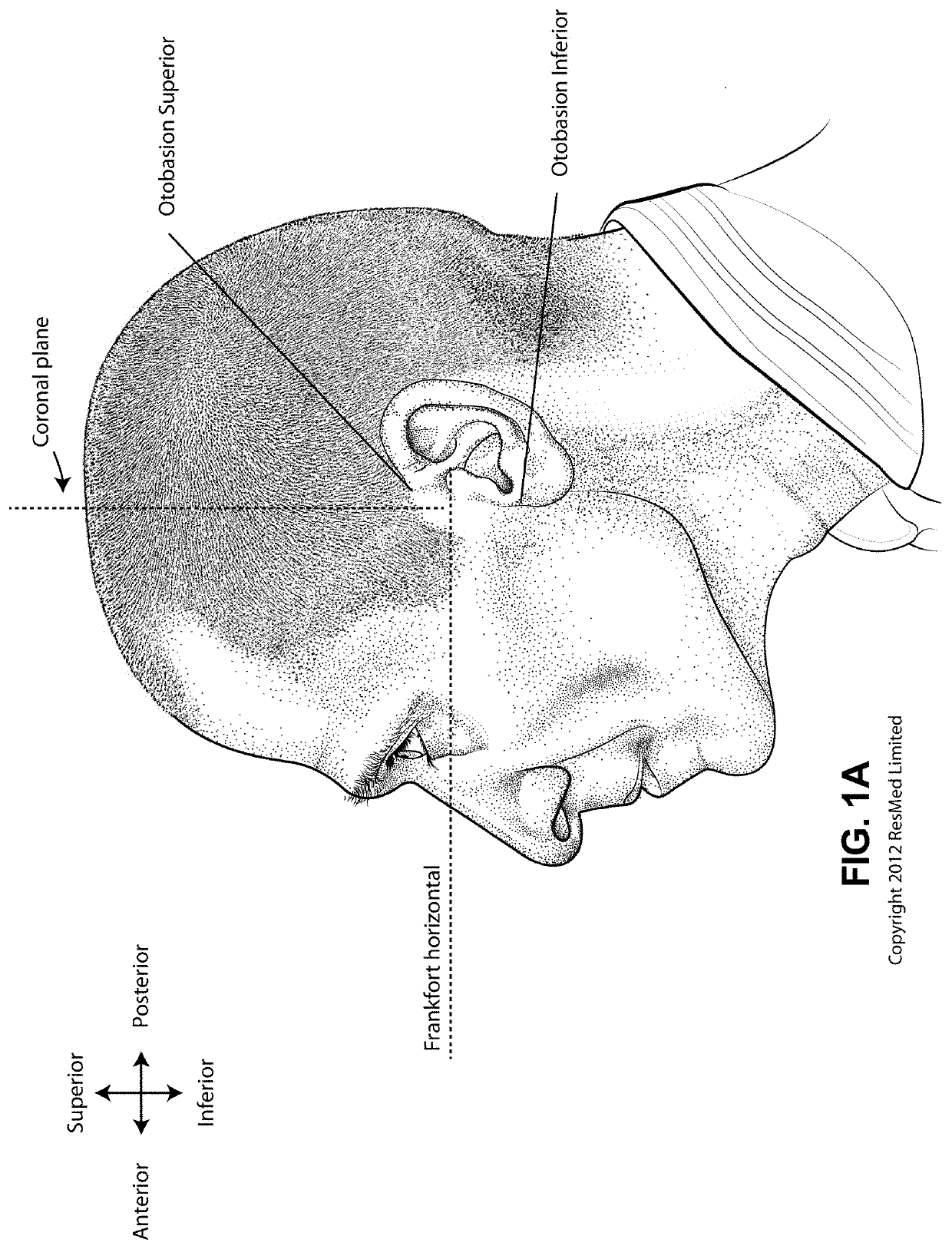

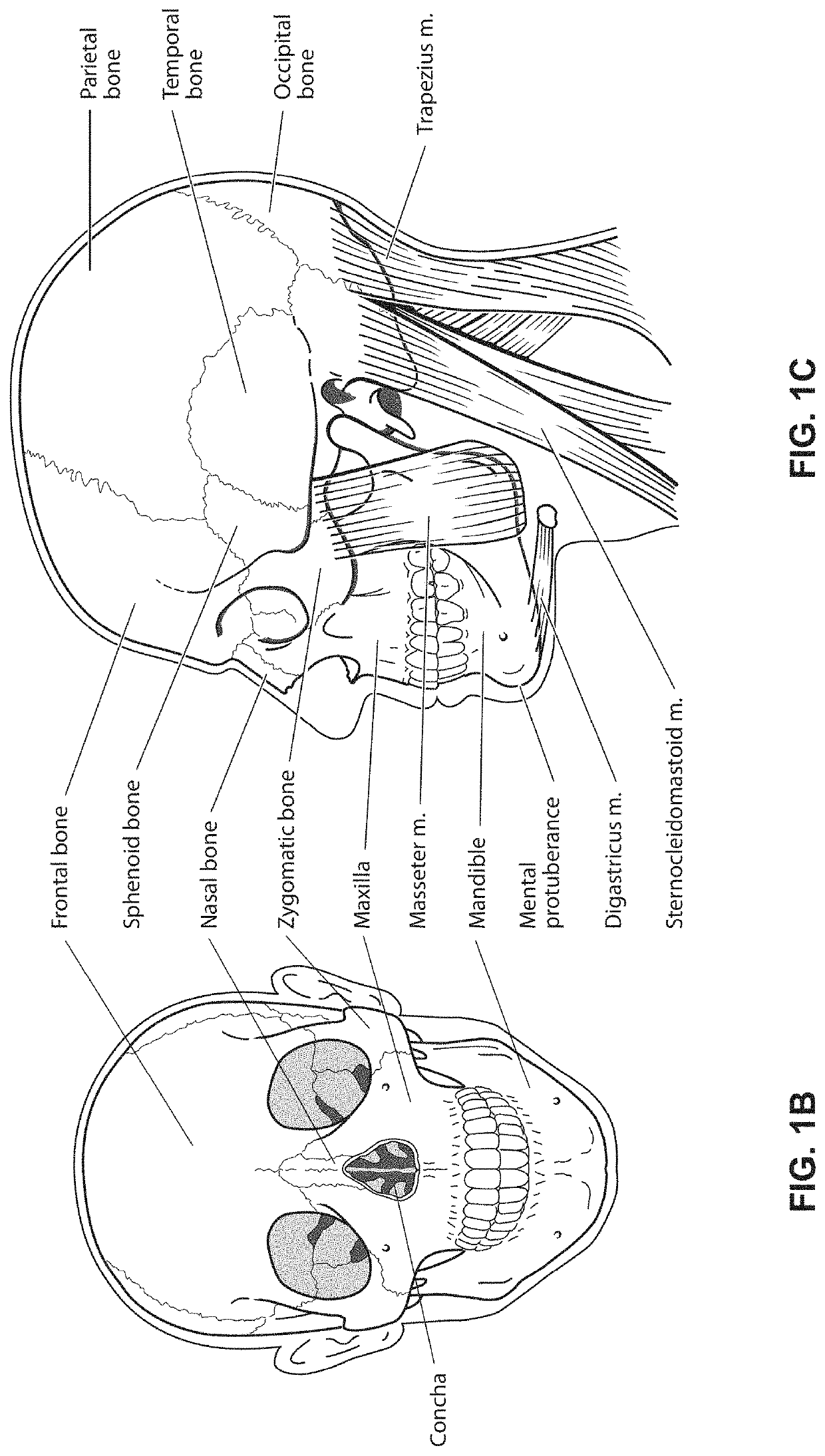

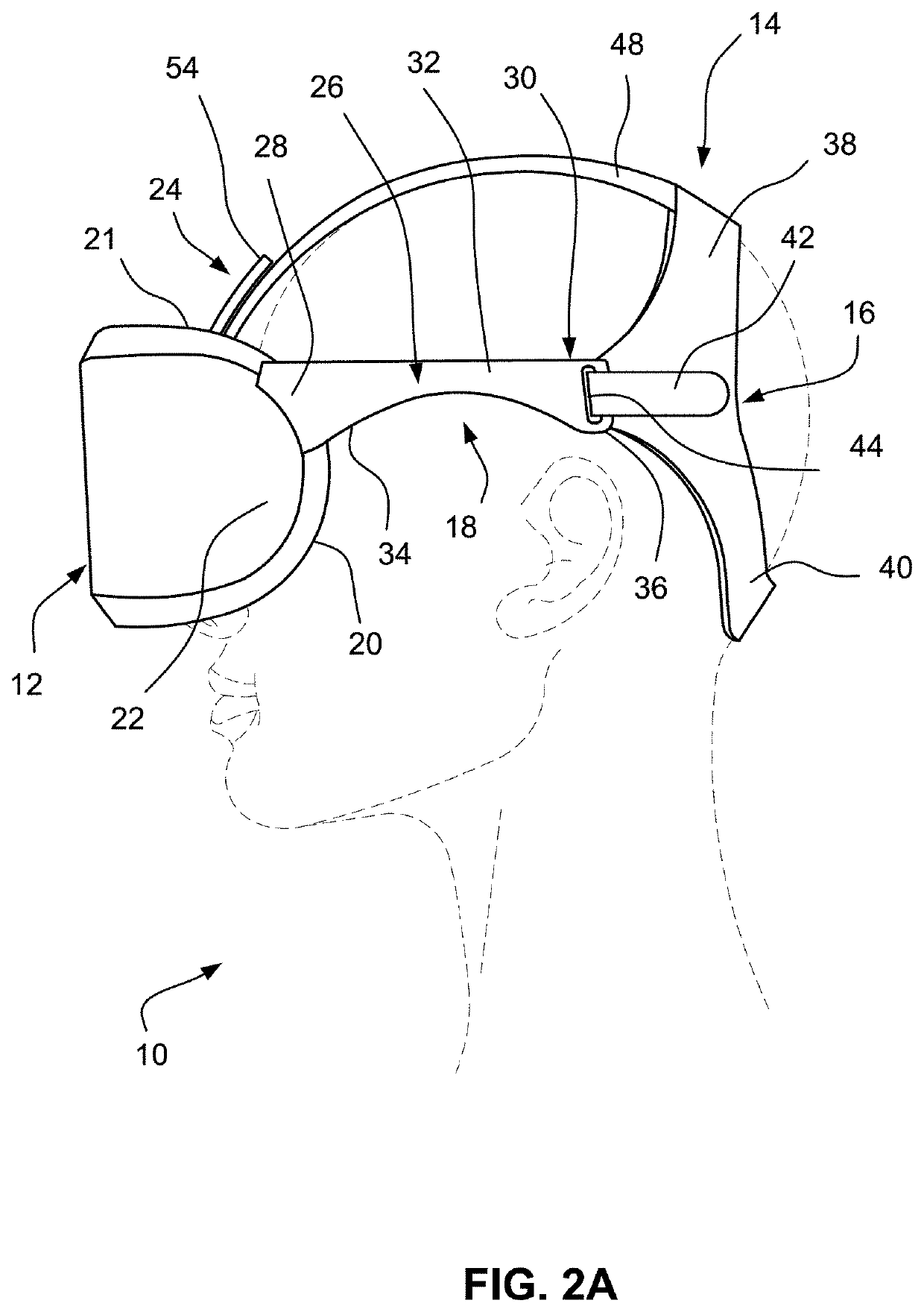

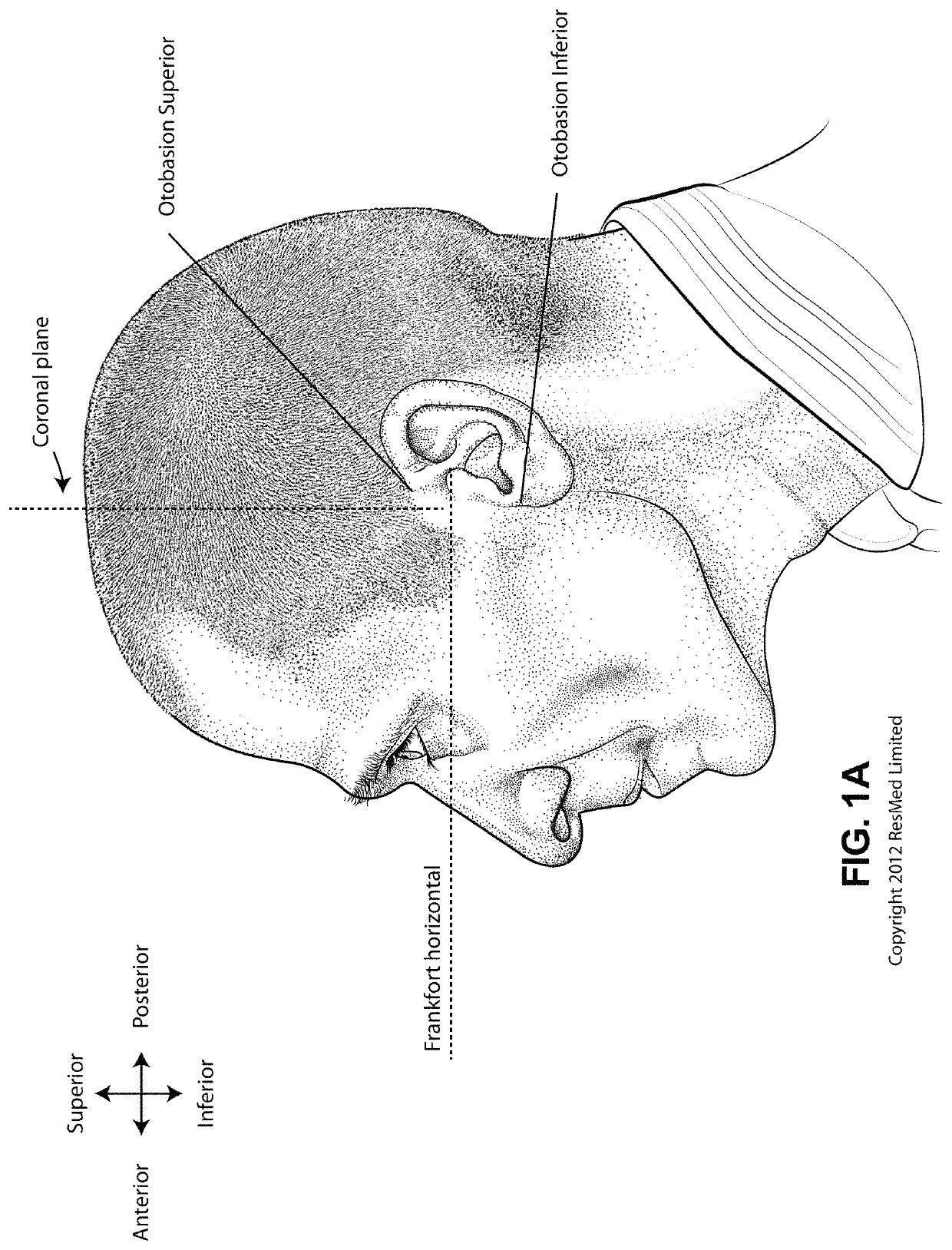

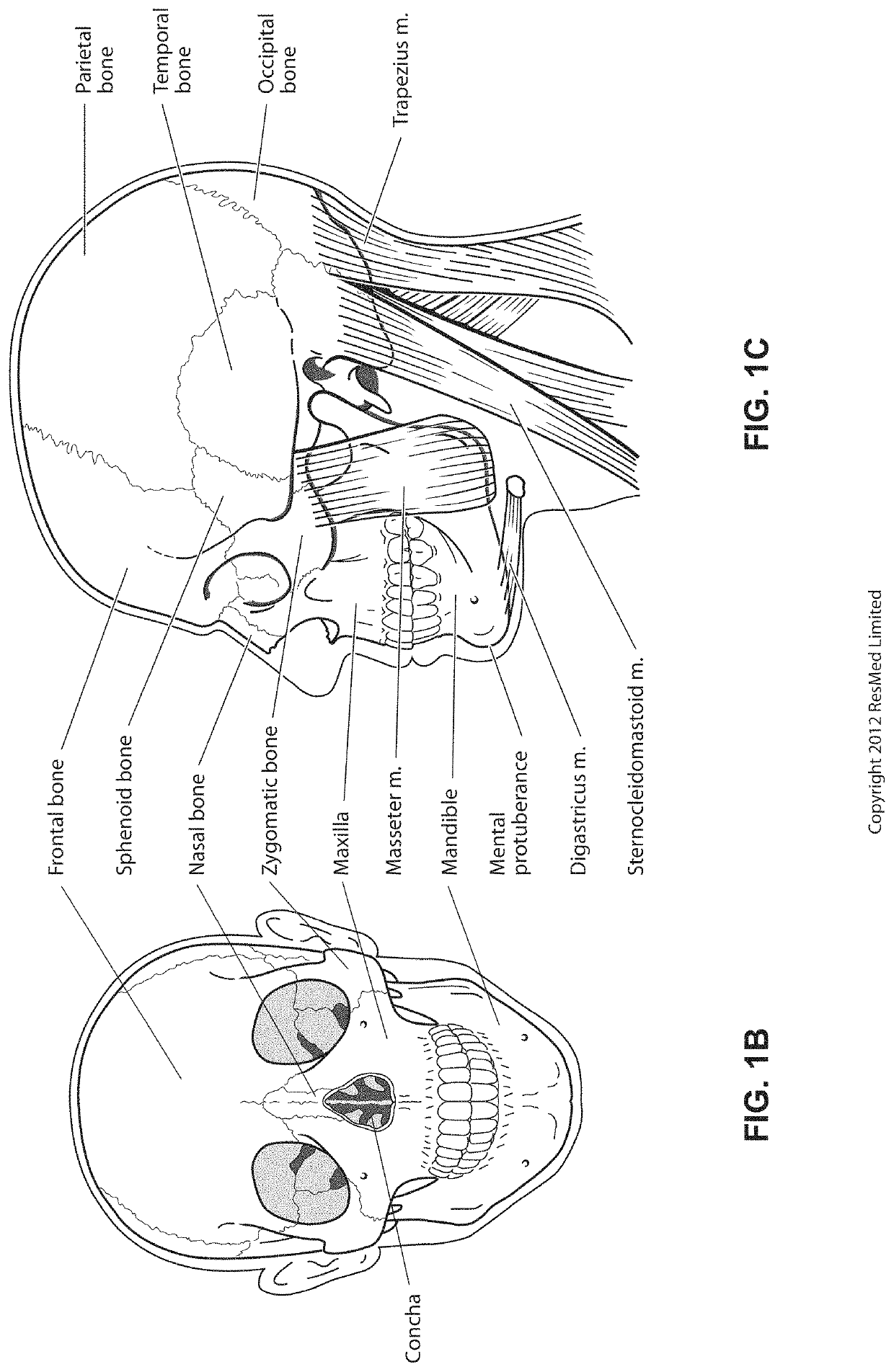

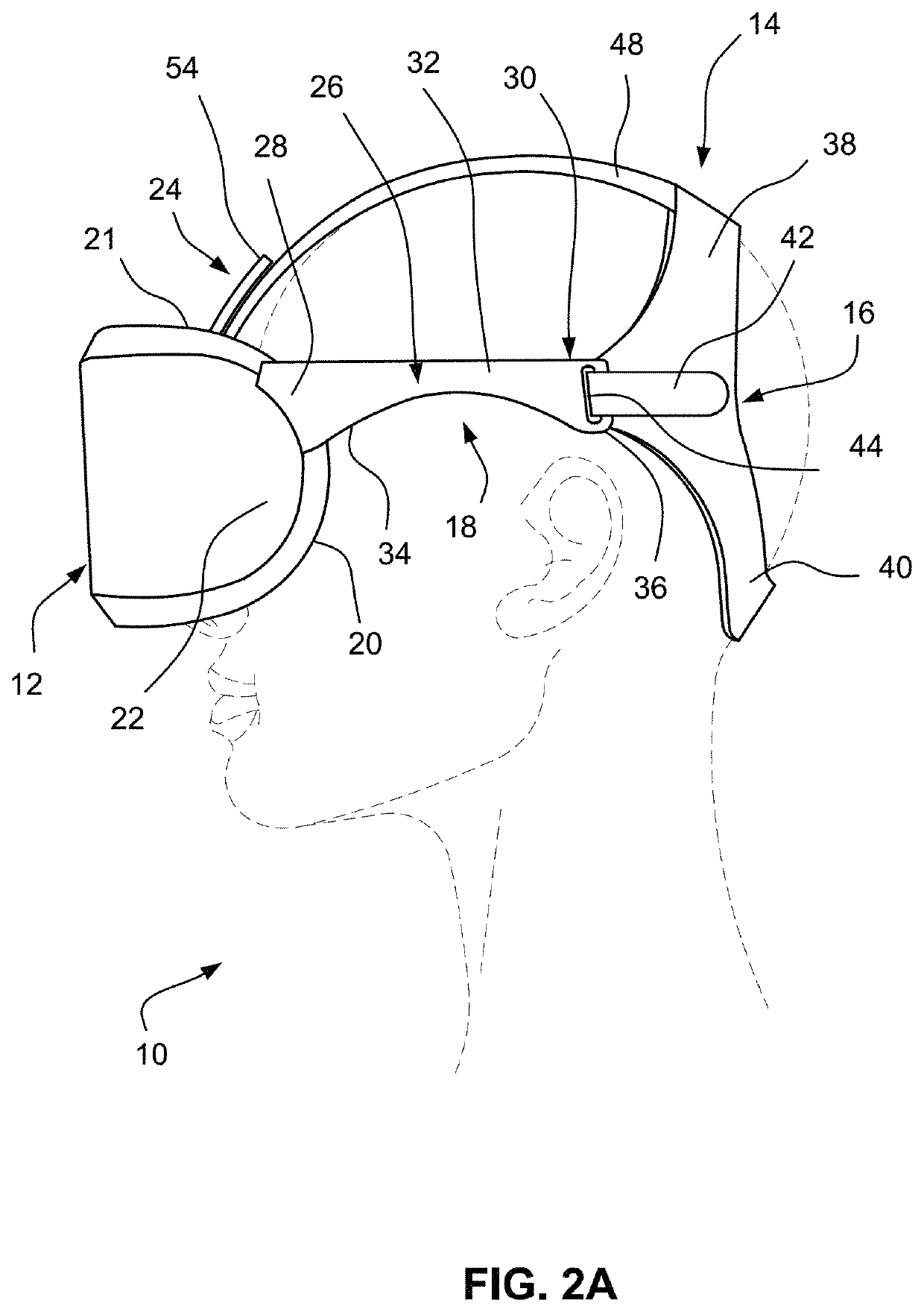

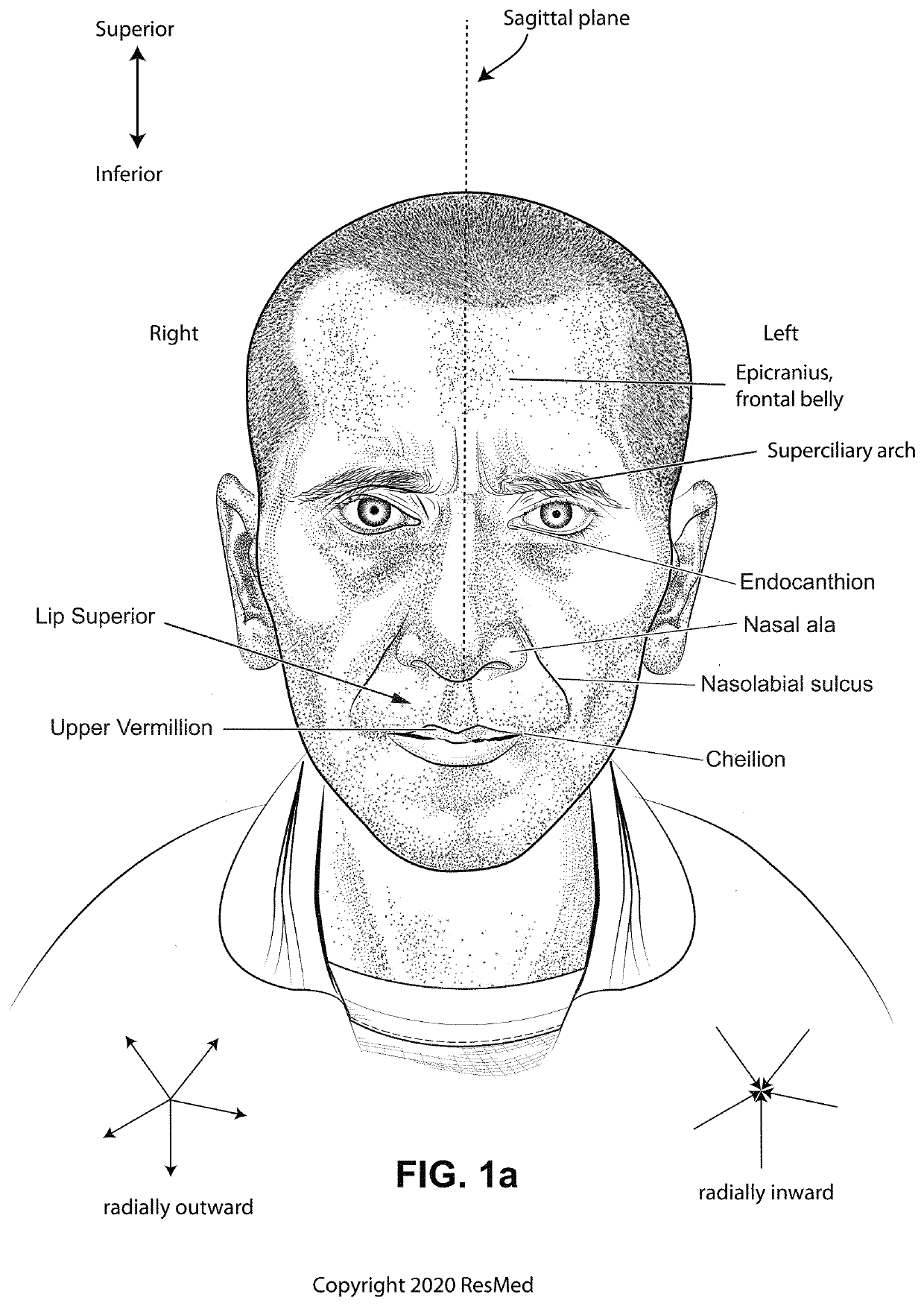

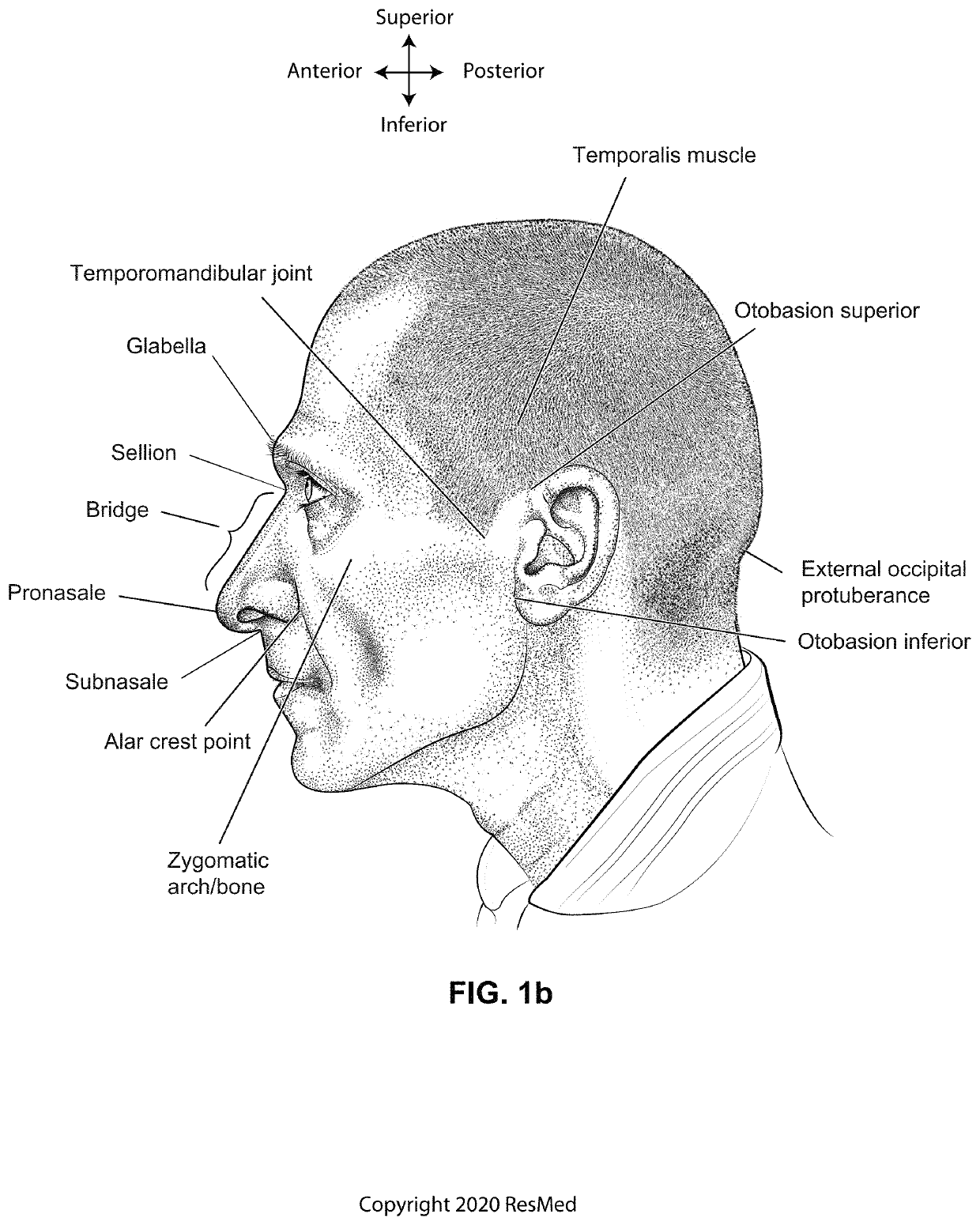

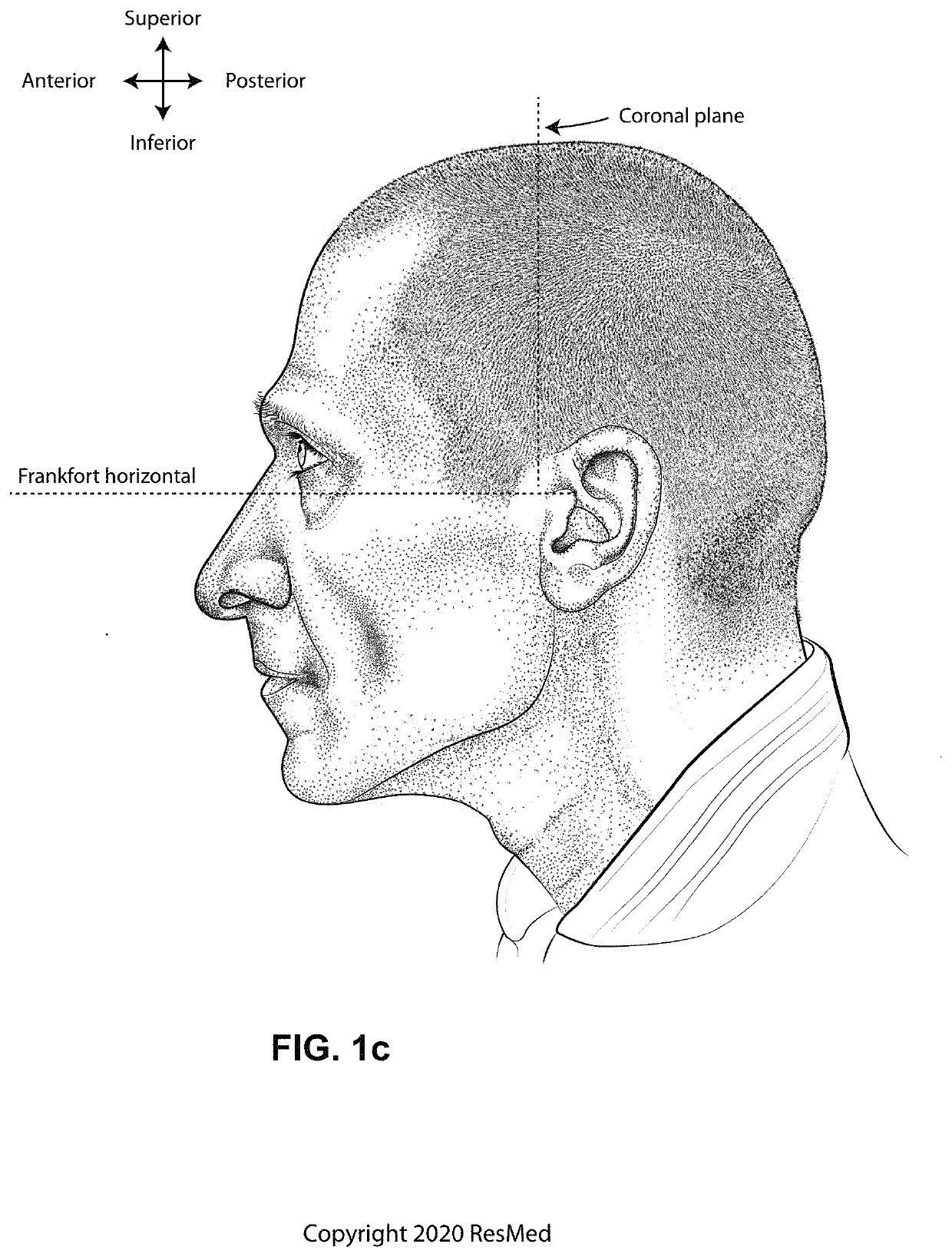

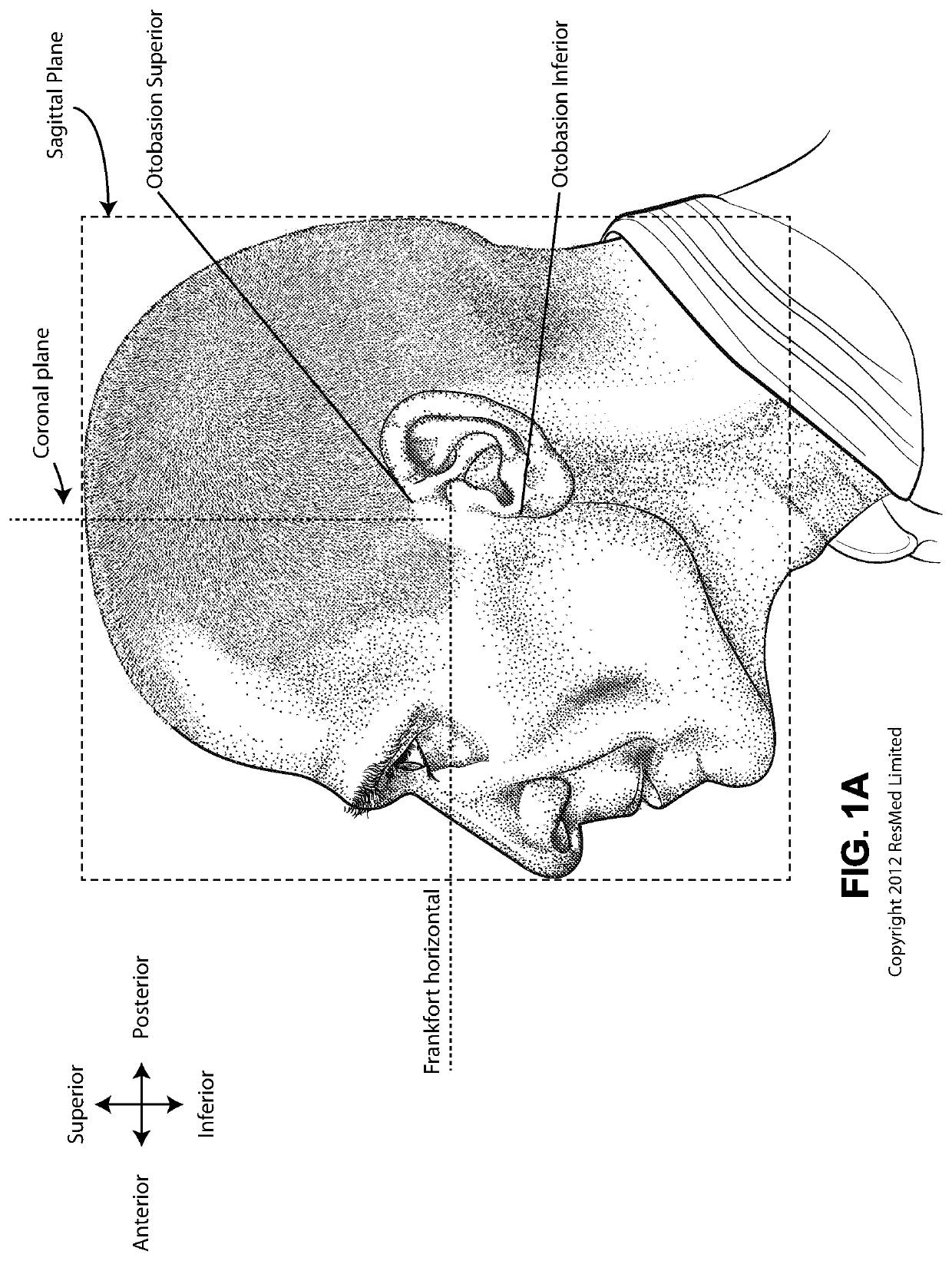

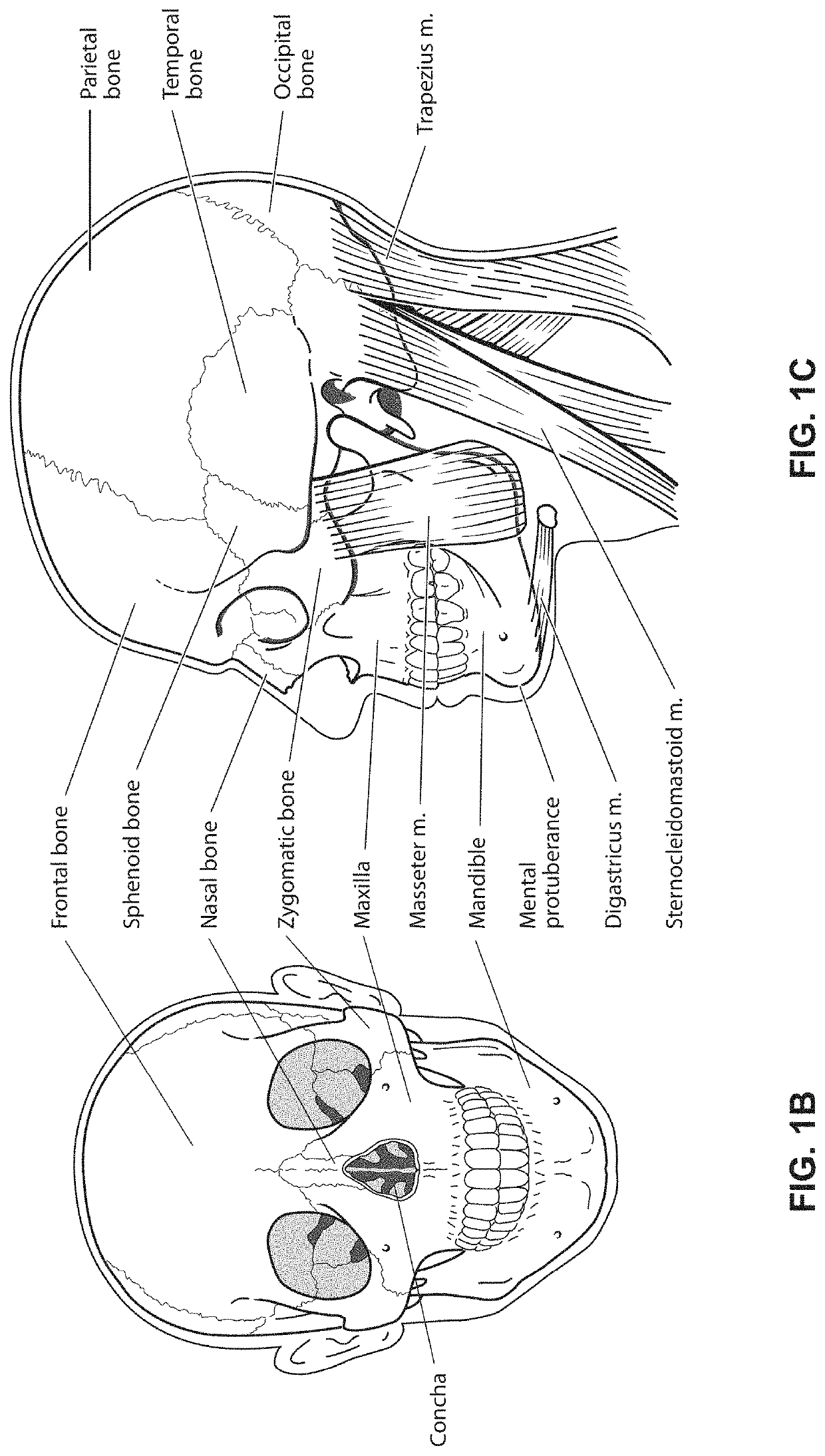

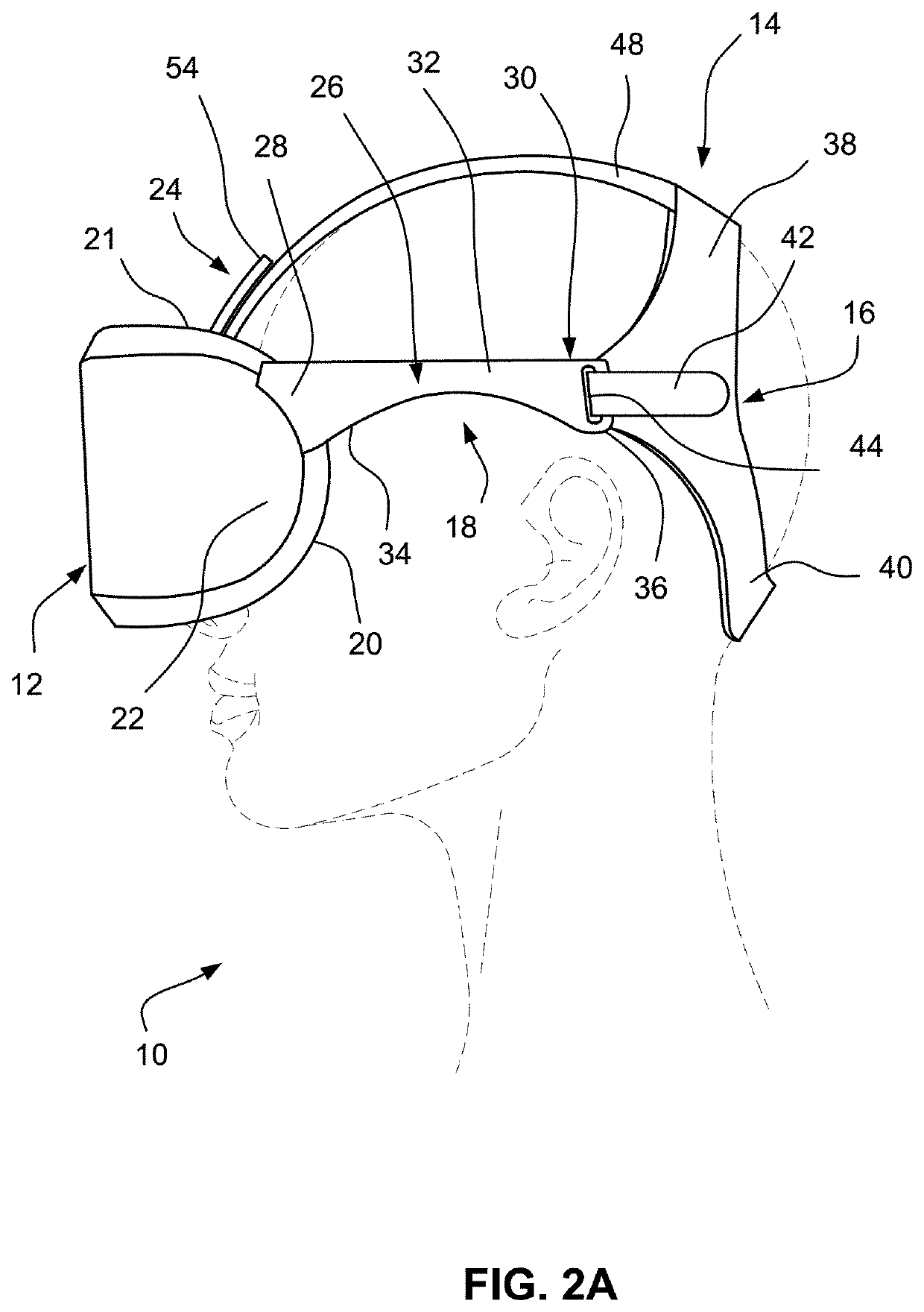

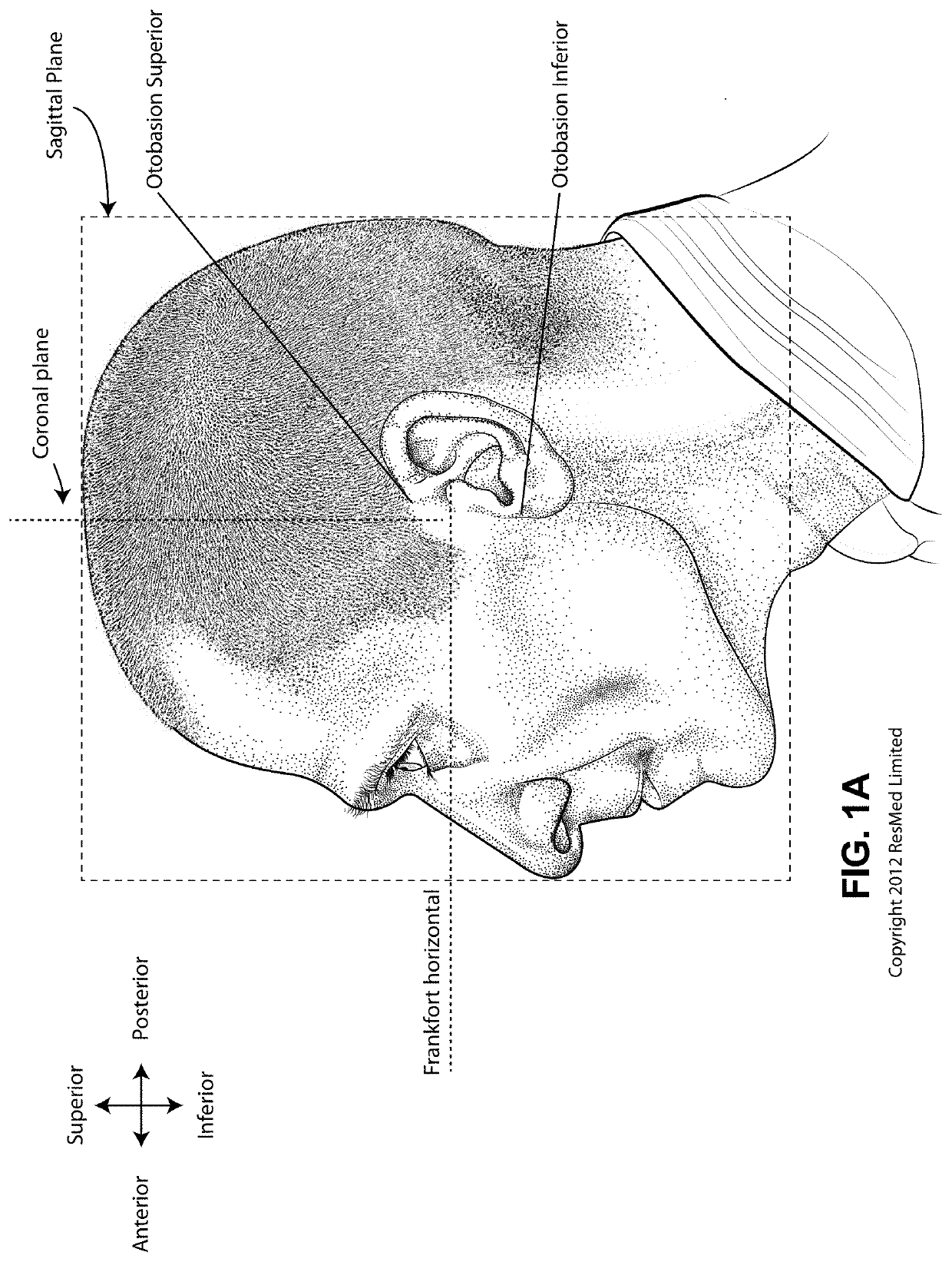

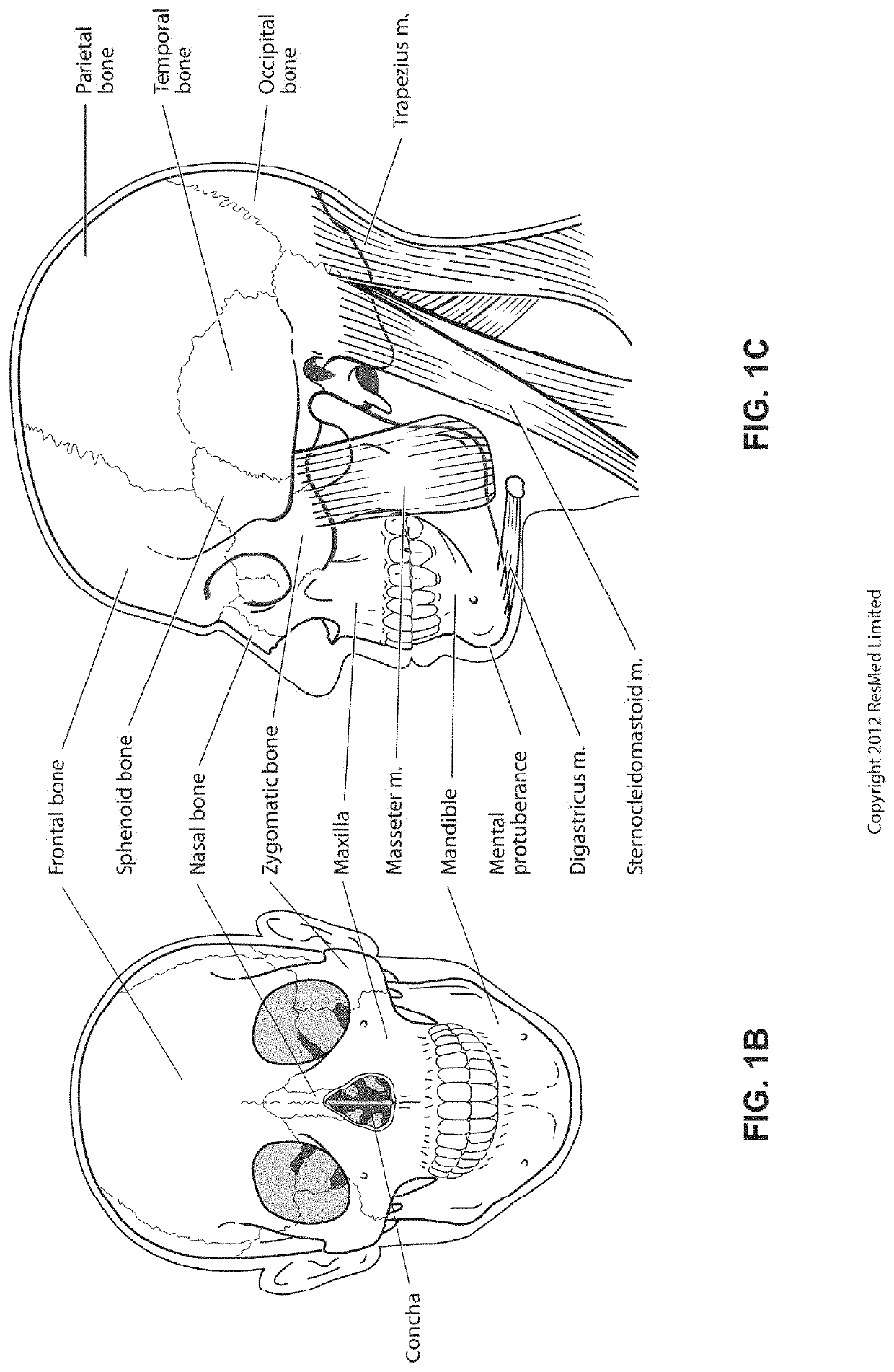

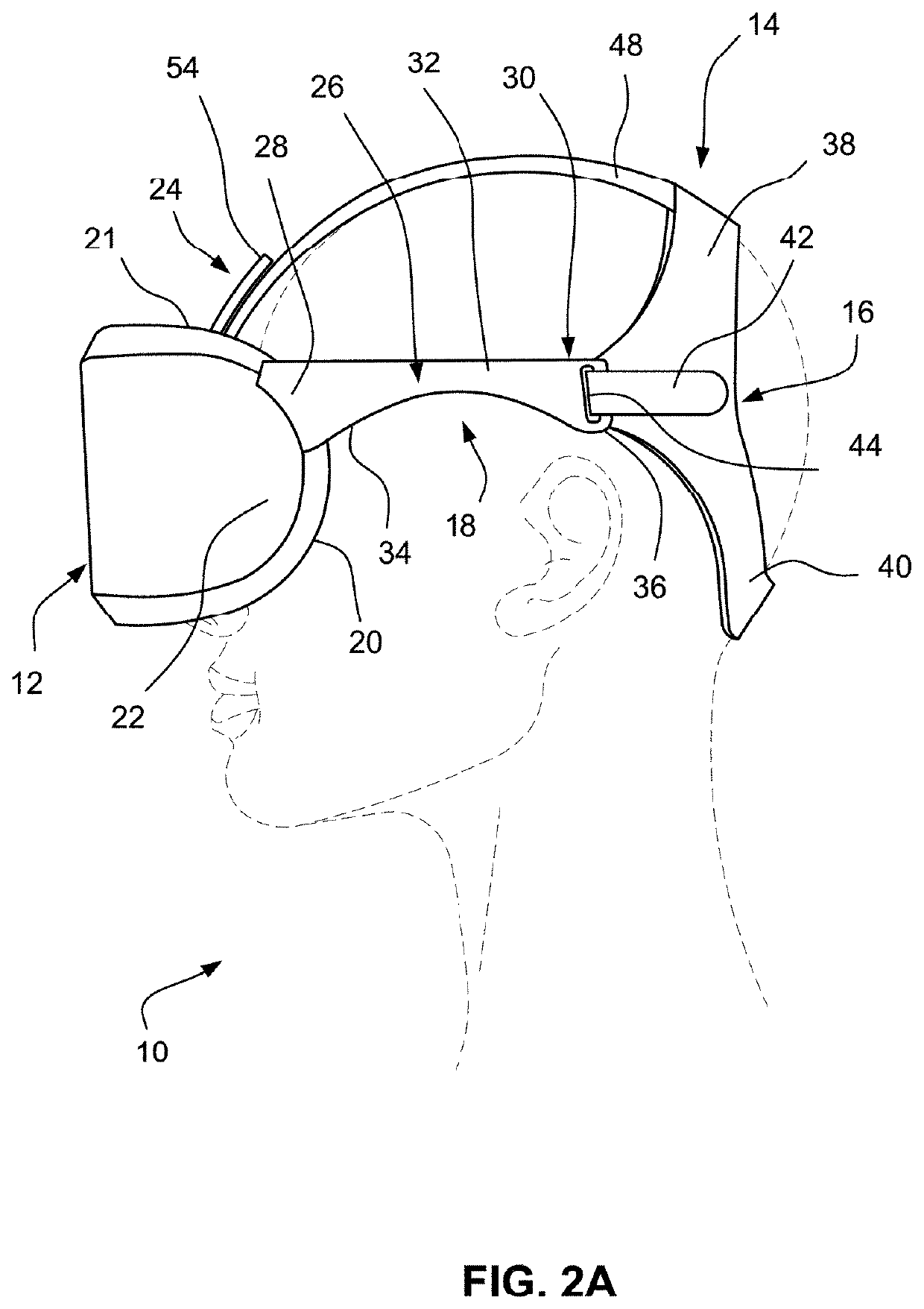

Positioning and stabilising structure and system incorporating same

ActiveUS20210302749A1Relieve pressureImprove the display effectOptical elementsDisplay deviceEngineering

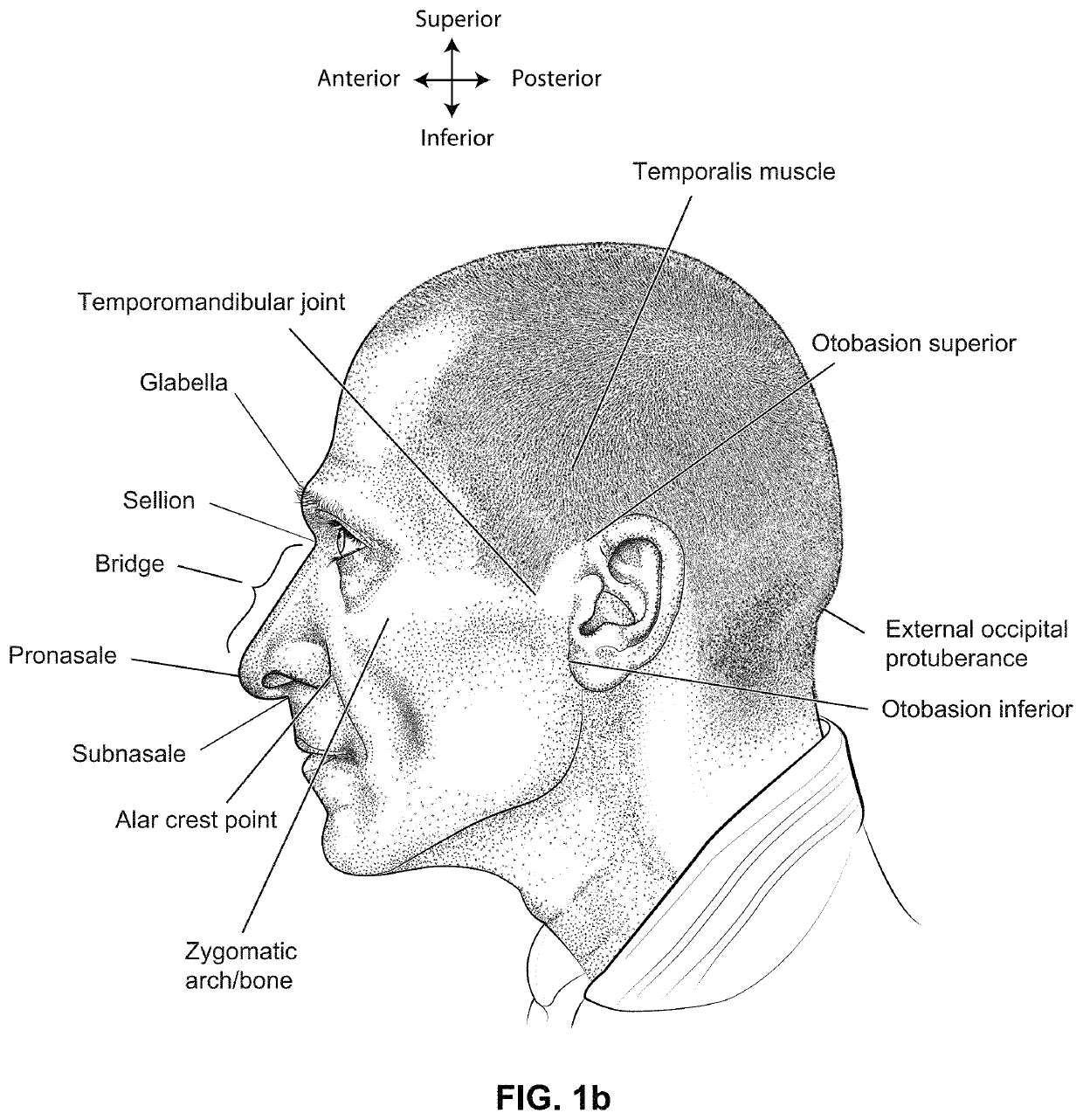

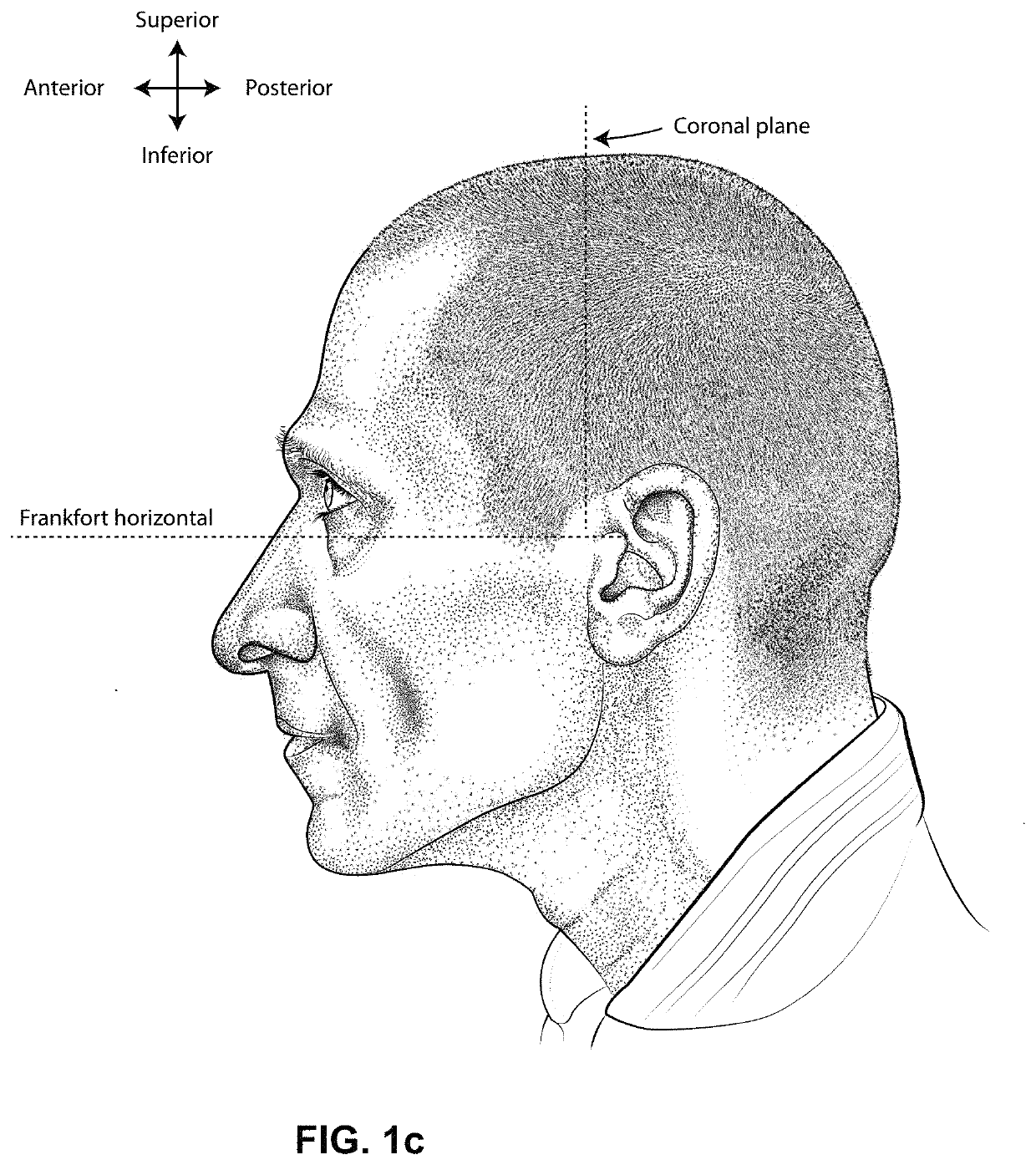

A head-mounted display system includes a head-mounted display unit and a positioning and stabilising structure structured and arranged to hold the head-mounted display unit in an operational position over a user's face in use. The positioning and stabilising structure includes a rear support structure adapted to contact posterior regions of a user's head and opposing temporal connectors structured and arranged to interconnect the rear support structure to the head-mounted display unit, the opposing temporal connectors adapted to be disposed on opposing sides of the user's head and extend along the temporal regions of the user's head. At least the rear support structure comprises a textile material configured to conform to the posterior regions of the user's head.

Owner:RESMED LTD

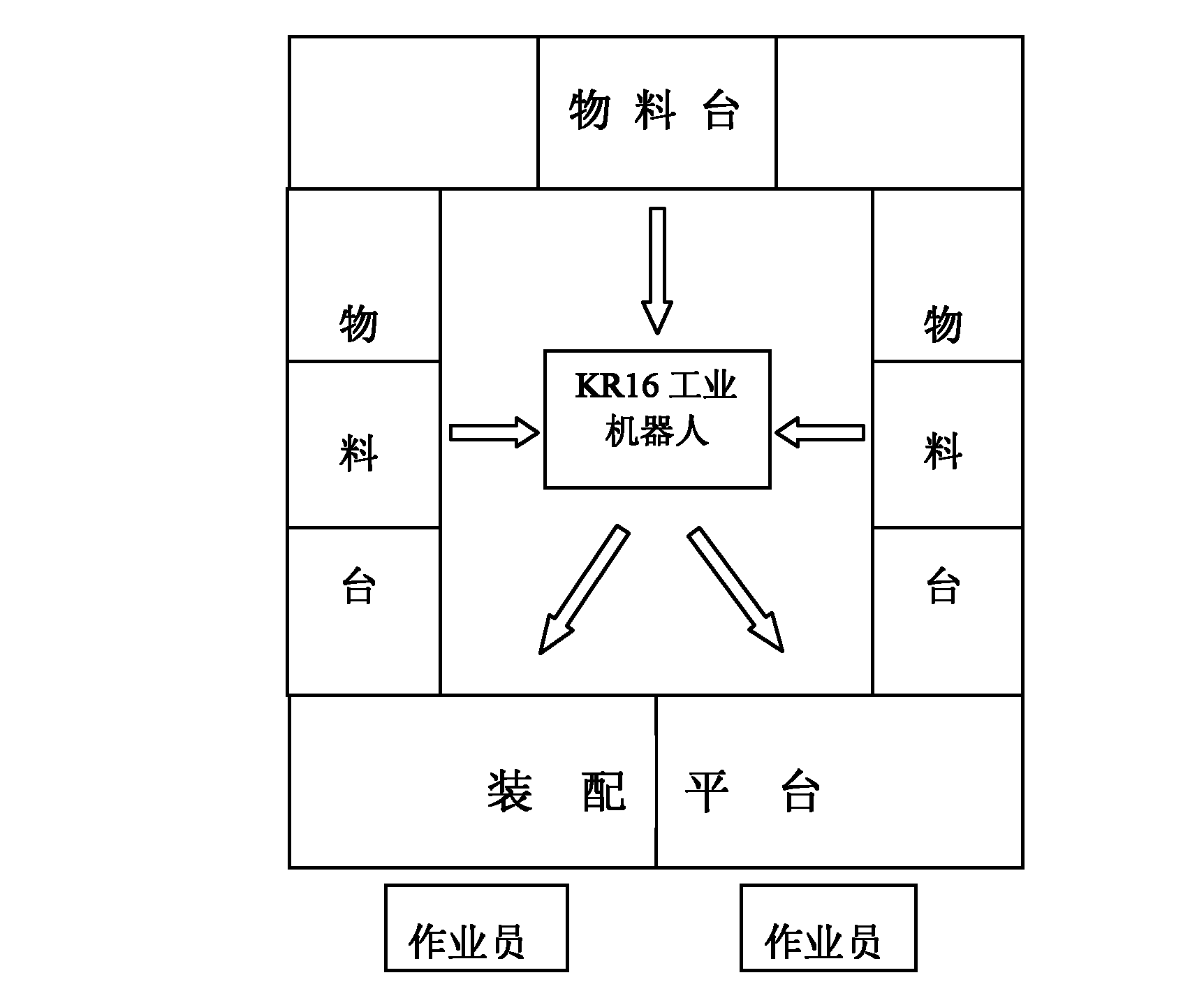

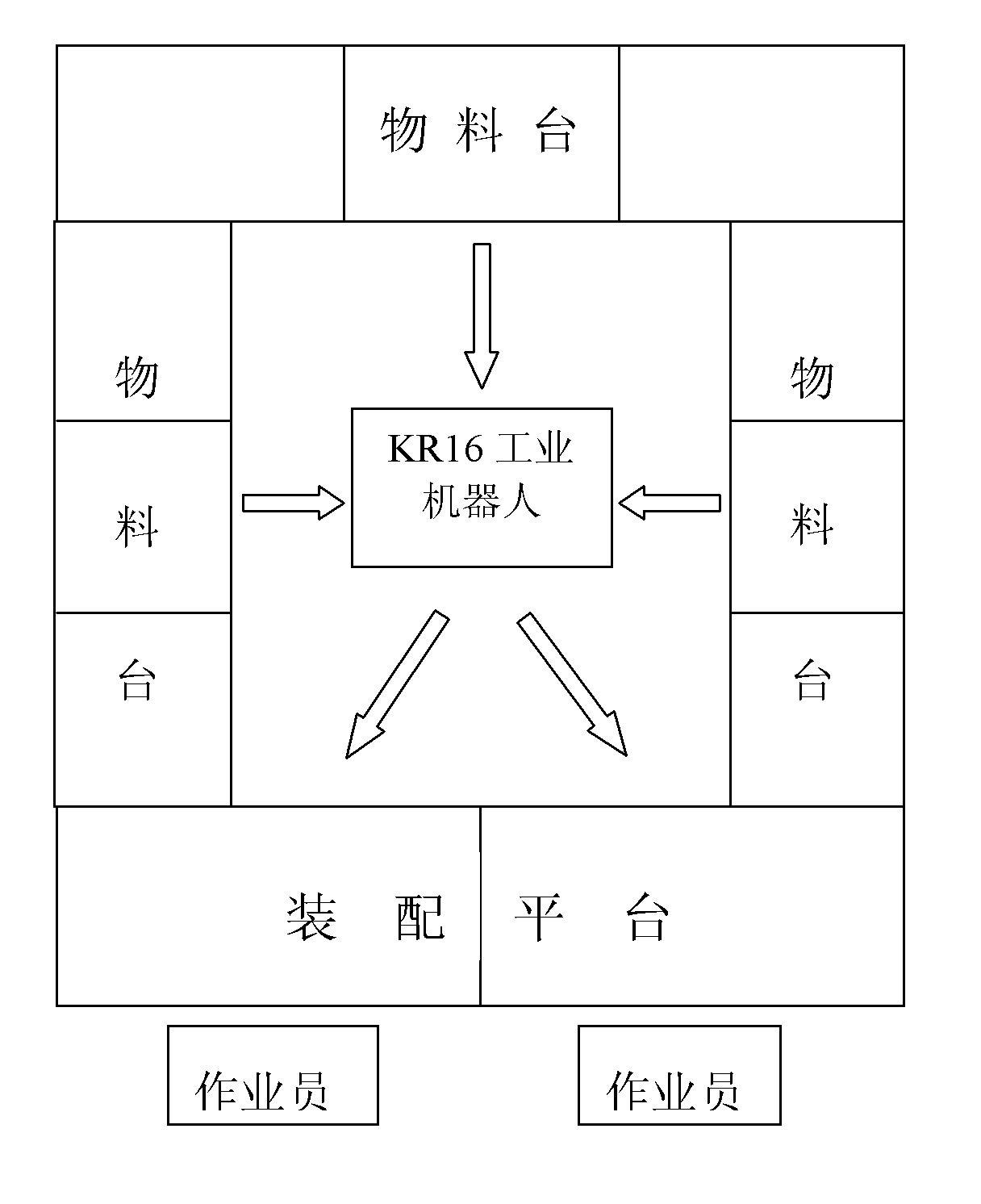

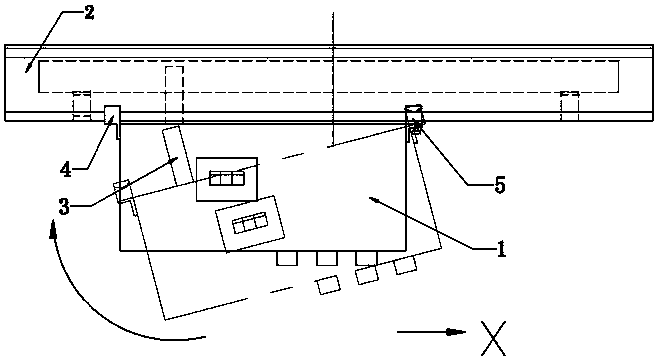

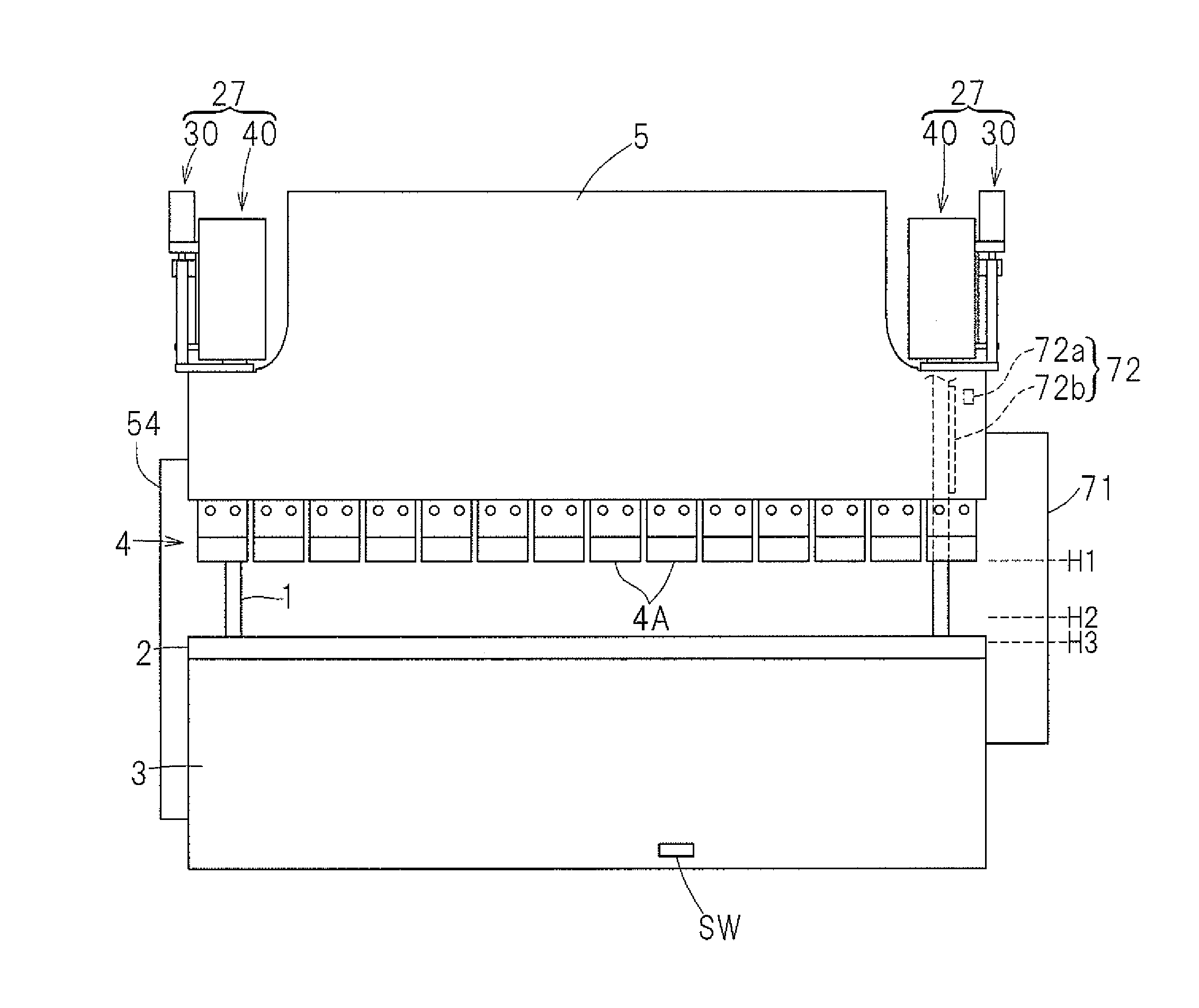

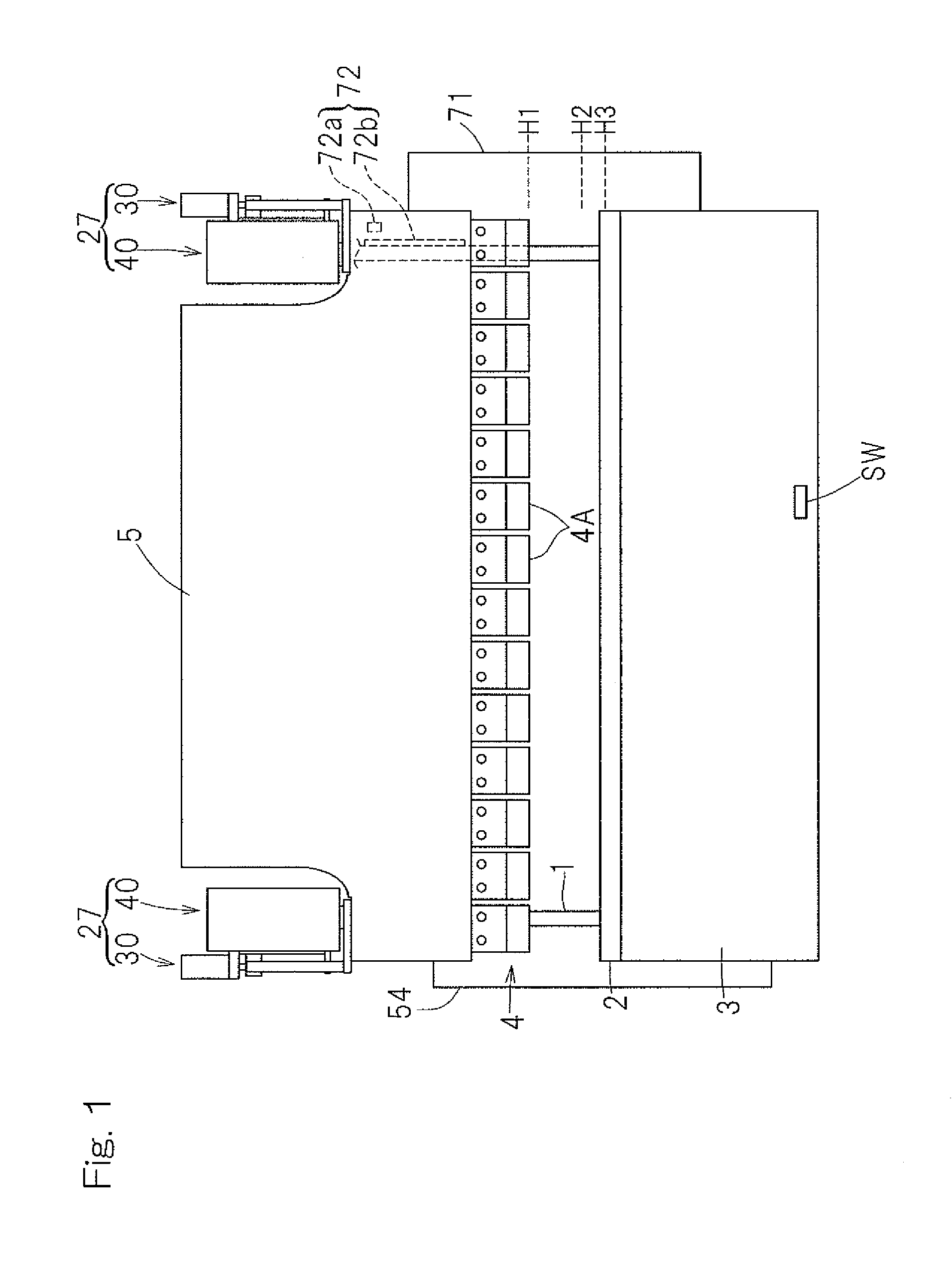

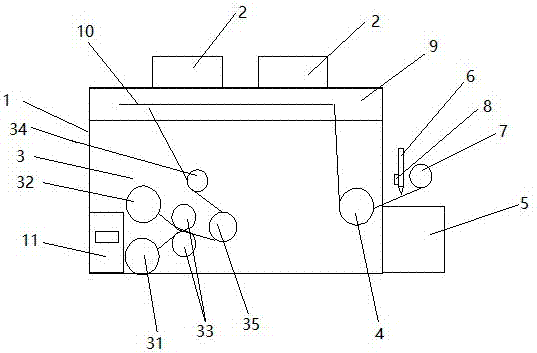

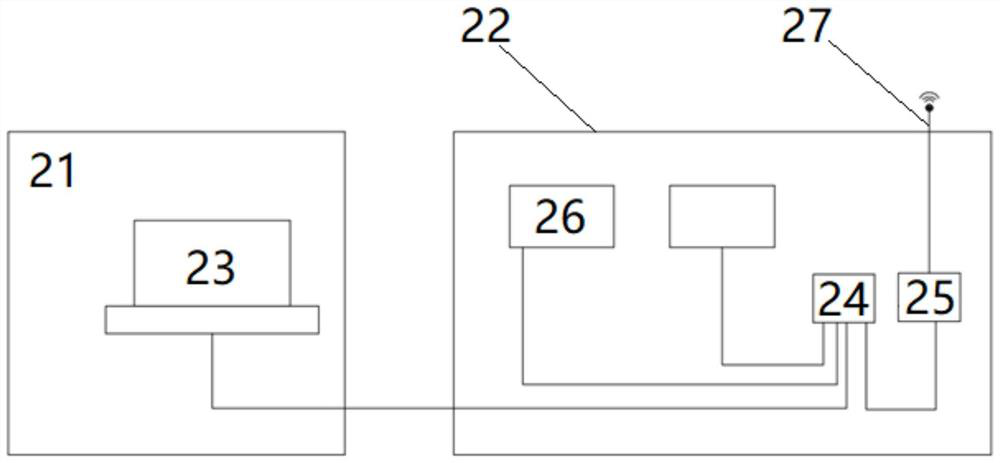

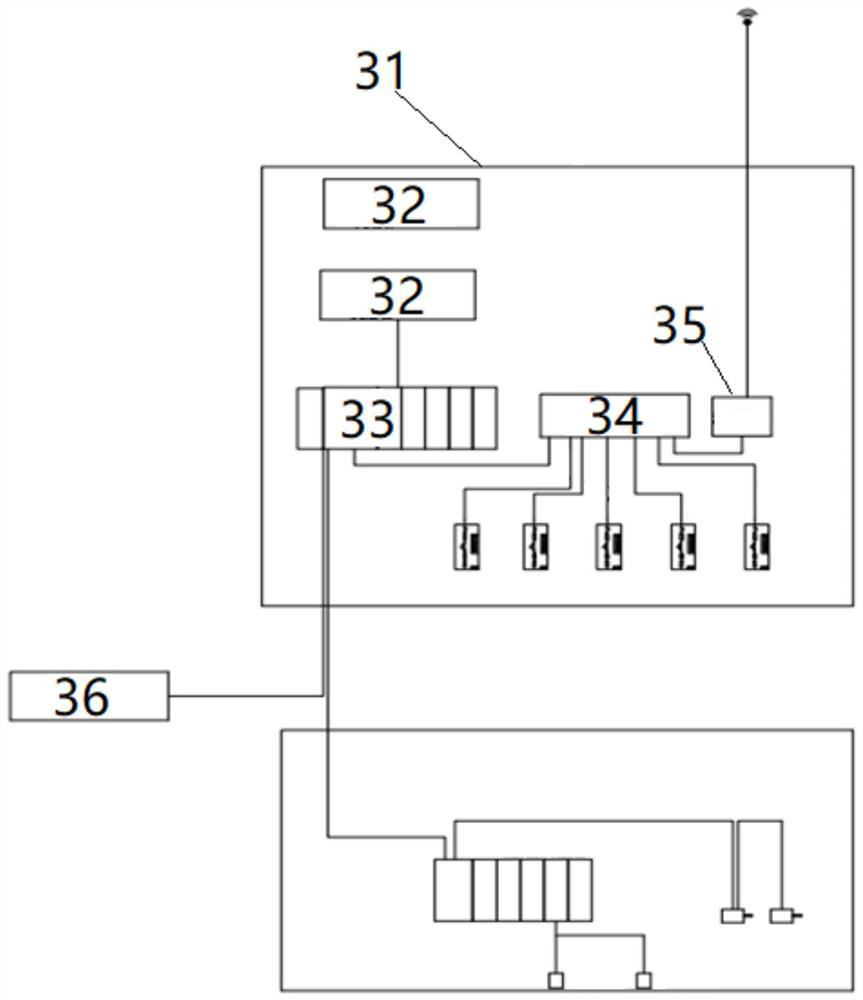

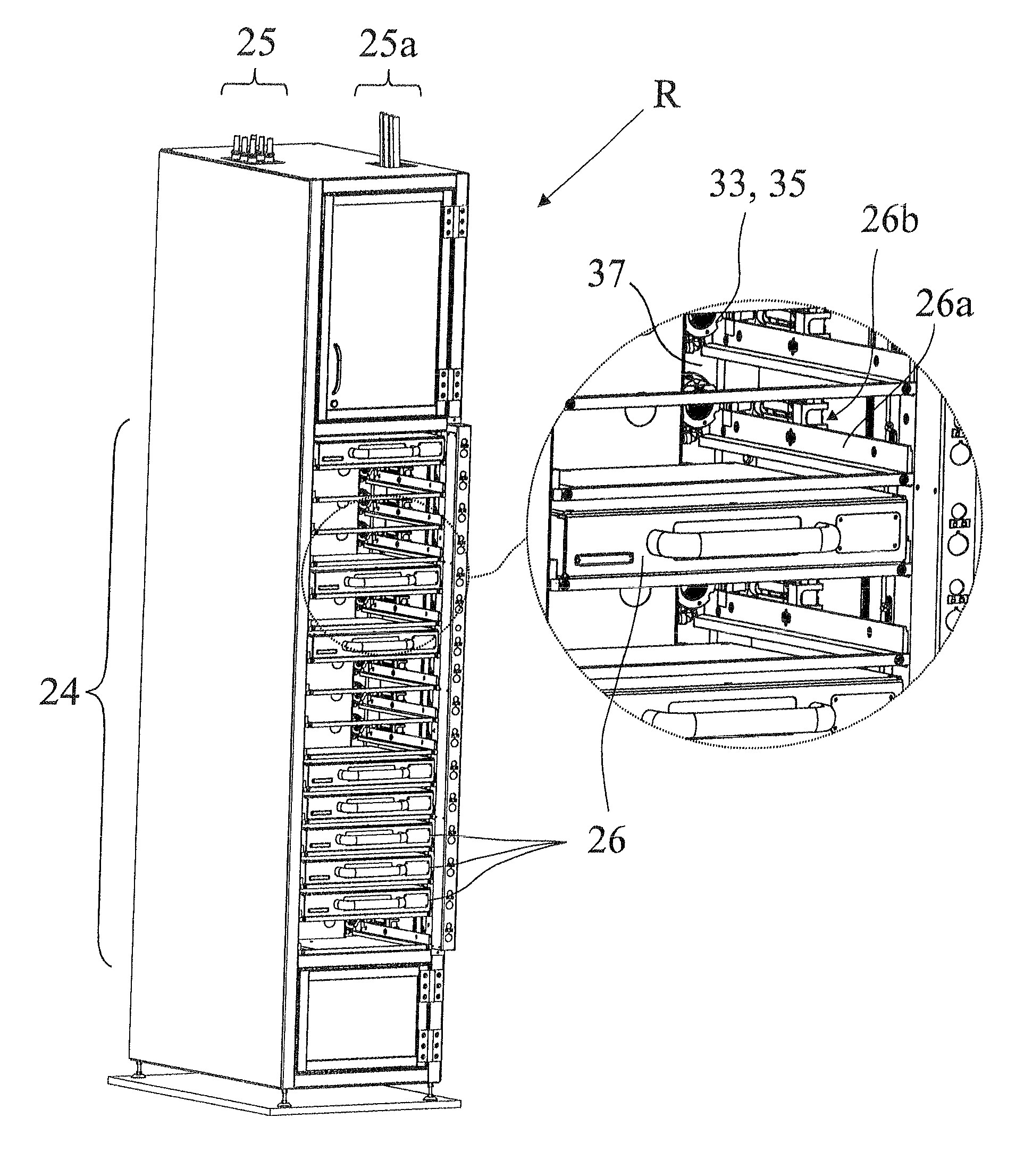

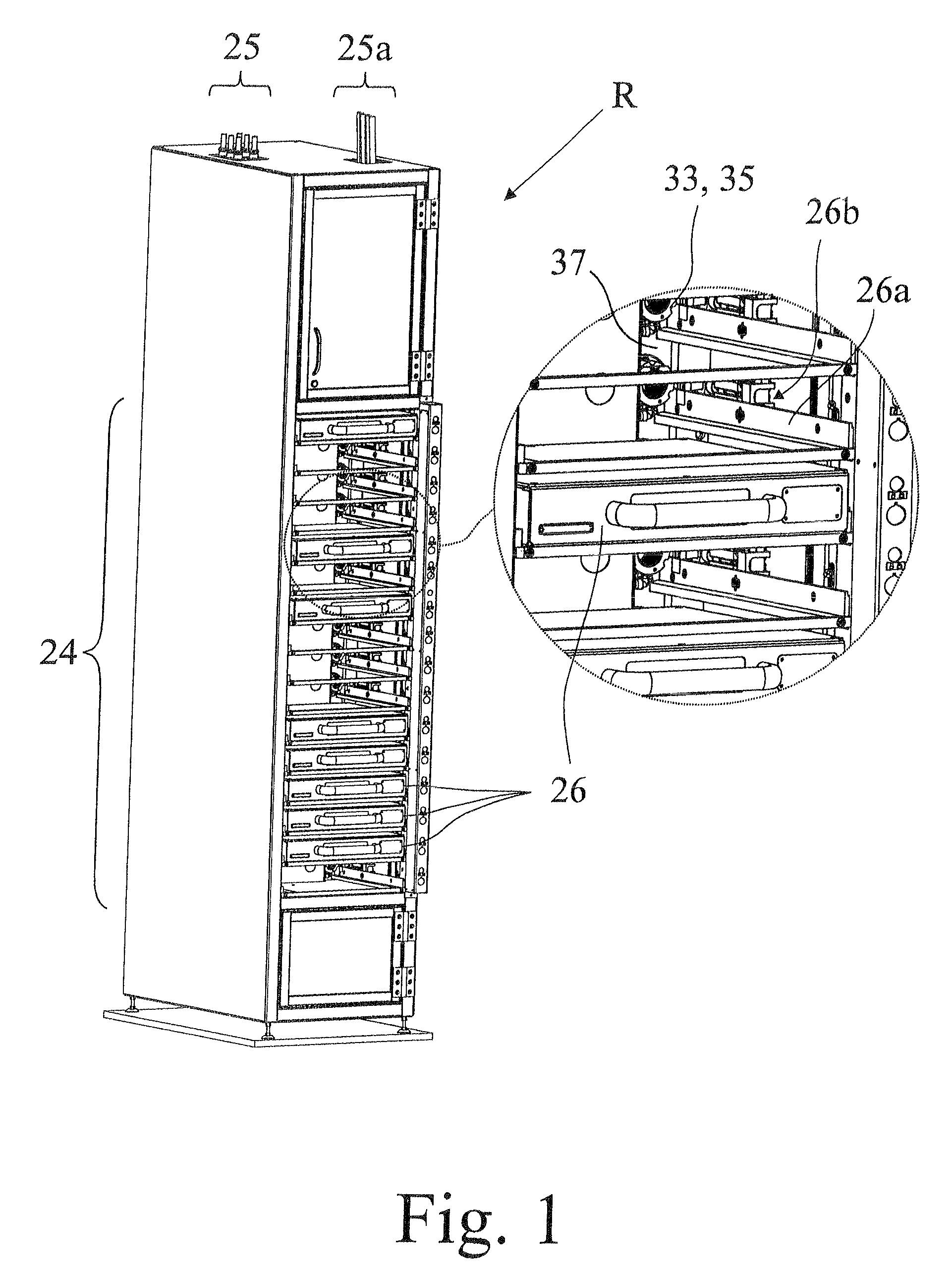

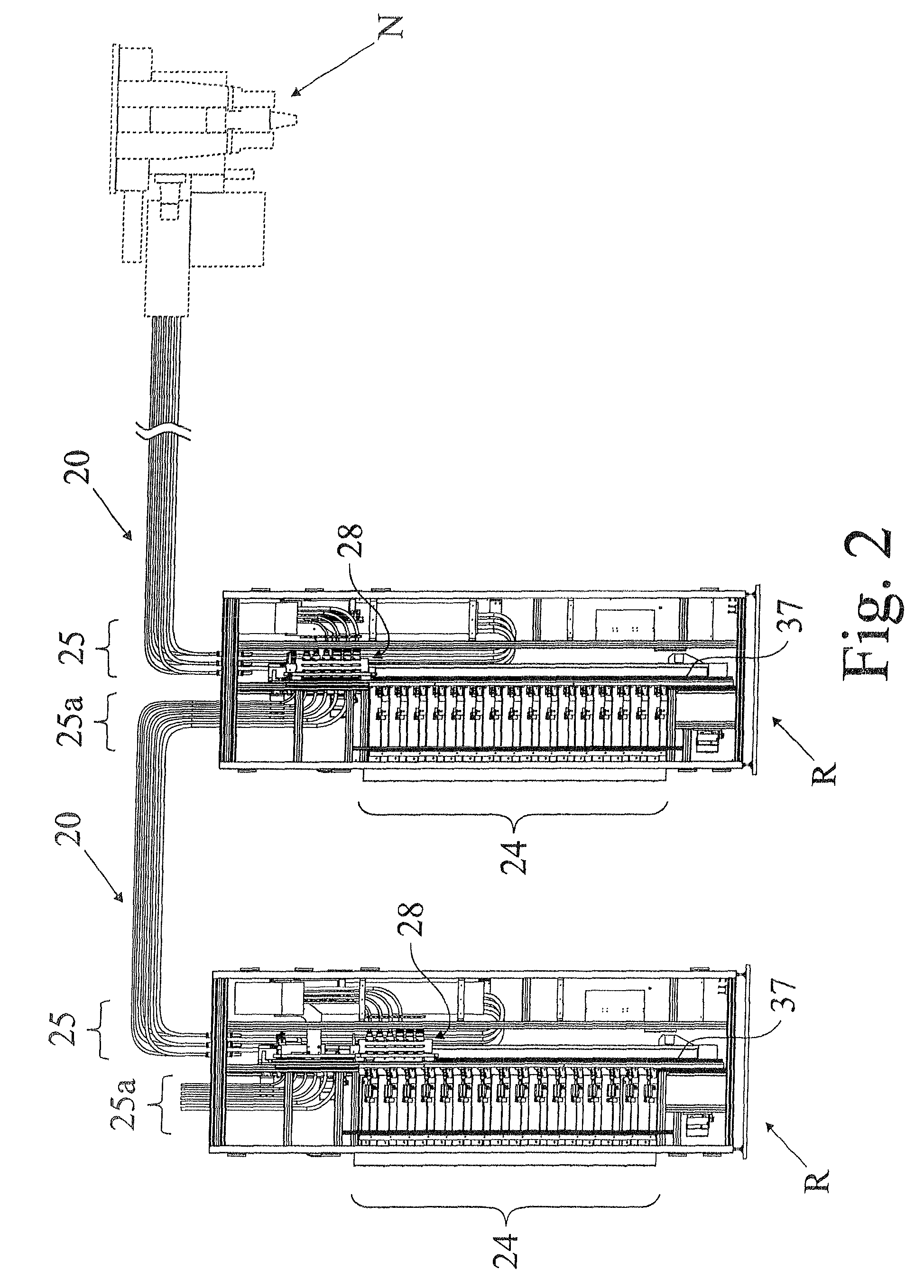

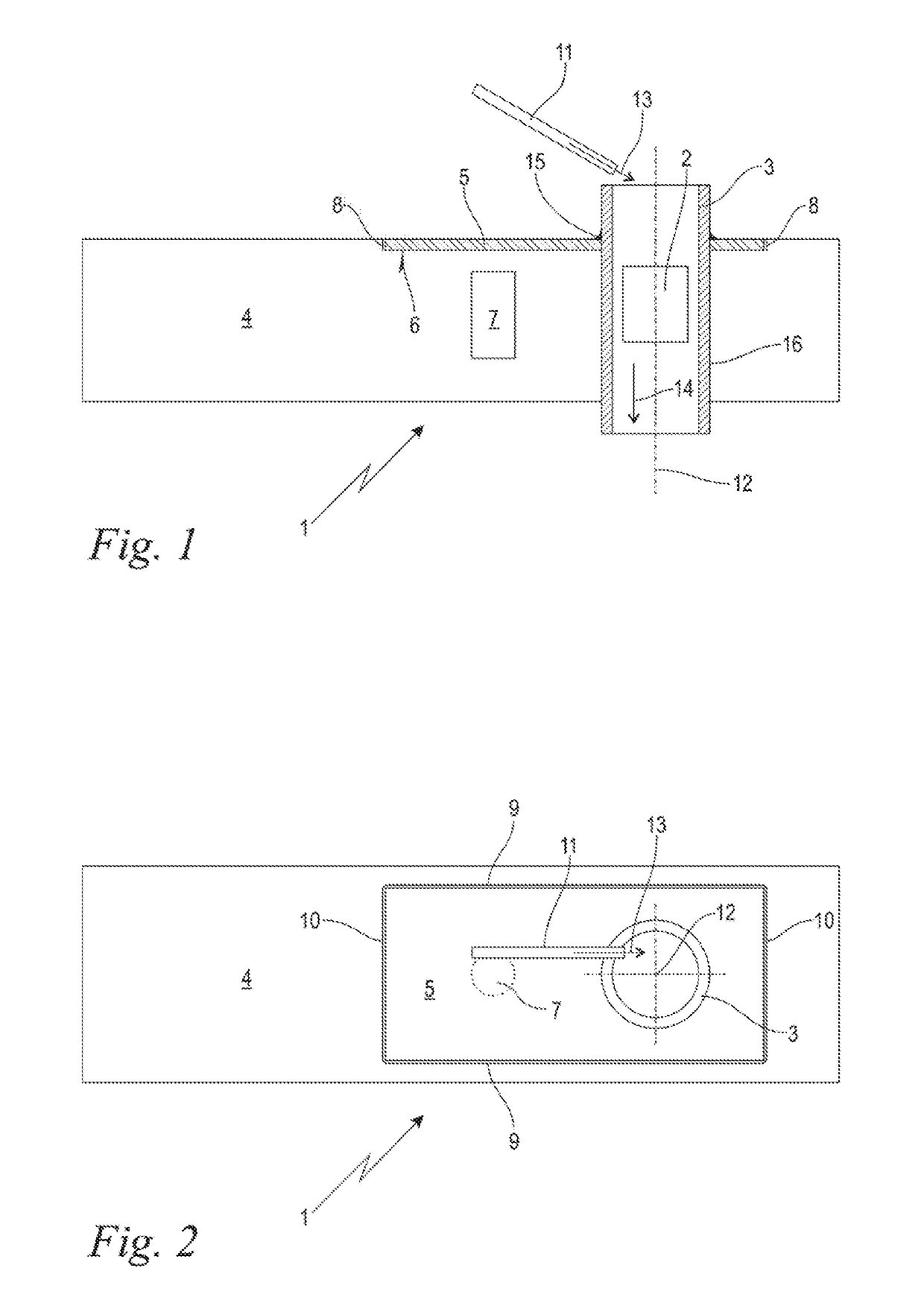

Robot assembly line for LED backlight module

InactiveCN102107355AOperation positioning is accurateWon't scratchProgramme-controlled manipulatorGripping headsProgrammable logic controllerElectrical control

A robot assembly line for an LED (Light Emitting Diode) backlight module relates to the assembly of the LED backlight module. The assembly of the conventional LED backlight is realized through manual operation, the efficiency is low, the accuracy is low, and the problems such as difficult clamping of a rubber frame, film arch, light leakage and the like are easy to occur. The invention is mainly characterized in that an air tube of a robot gripper adopts a vacuum suction manner and comprises eight independent vacuum air passages; the air tube of each assembling platform adopts a vacuum suction manner and comprises four vacuum air passages and three material platforms, each material platform can accommodate three small platforms, and each platform can be adjusted manually so as to position materials; an electrical control device adopts a PLC (Programmable Logic Controller); each colour touch screen is installed on a control cabinet; and each colour touch screen is positioned above each assembling platform respectively. The invention improves the assembling accuracy of parts, reduces the damage of films, improves the assembling efficiency, reduces the manual operation cost, and increases the production volume.

Owner:浙江天乐微电科技股份有限公司

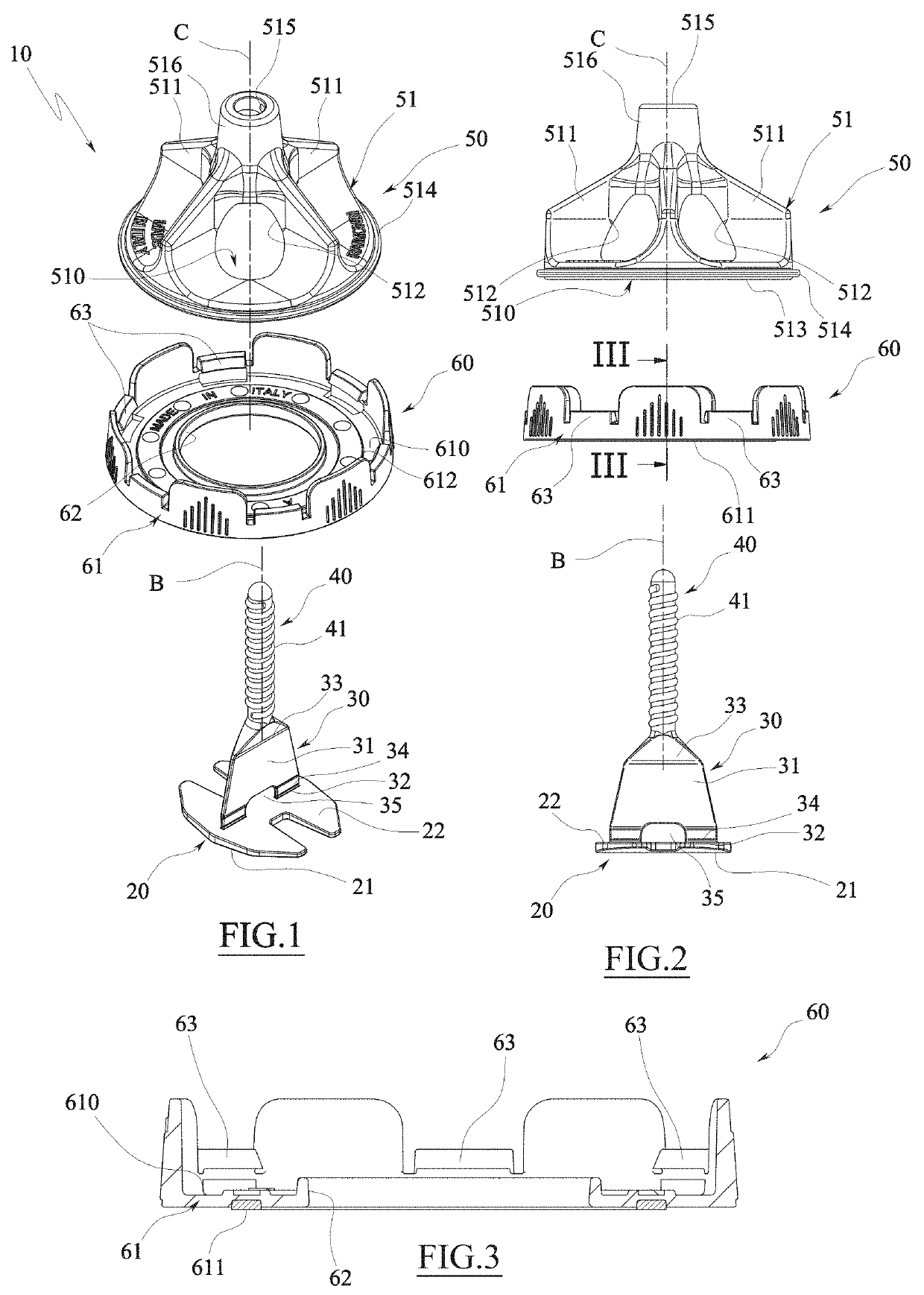

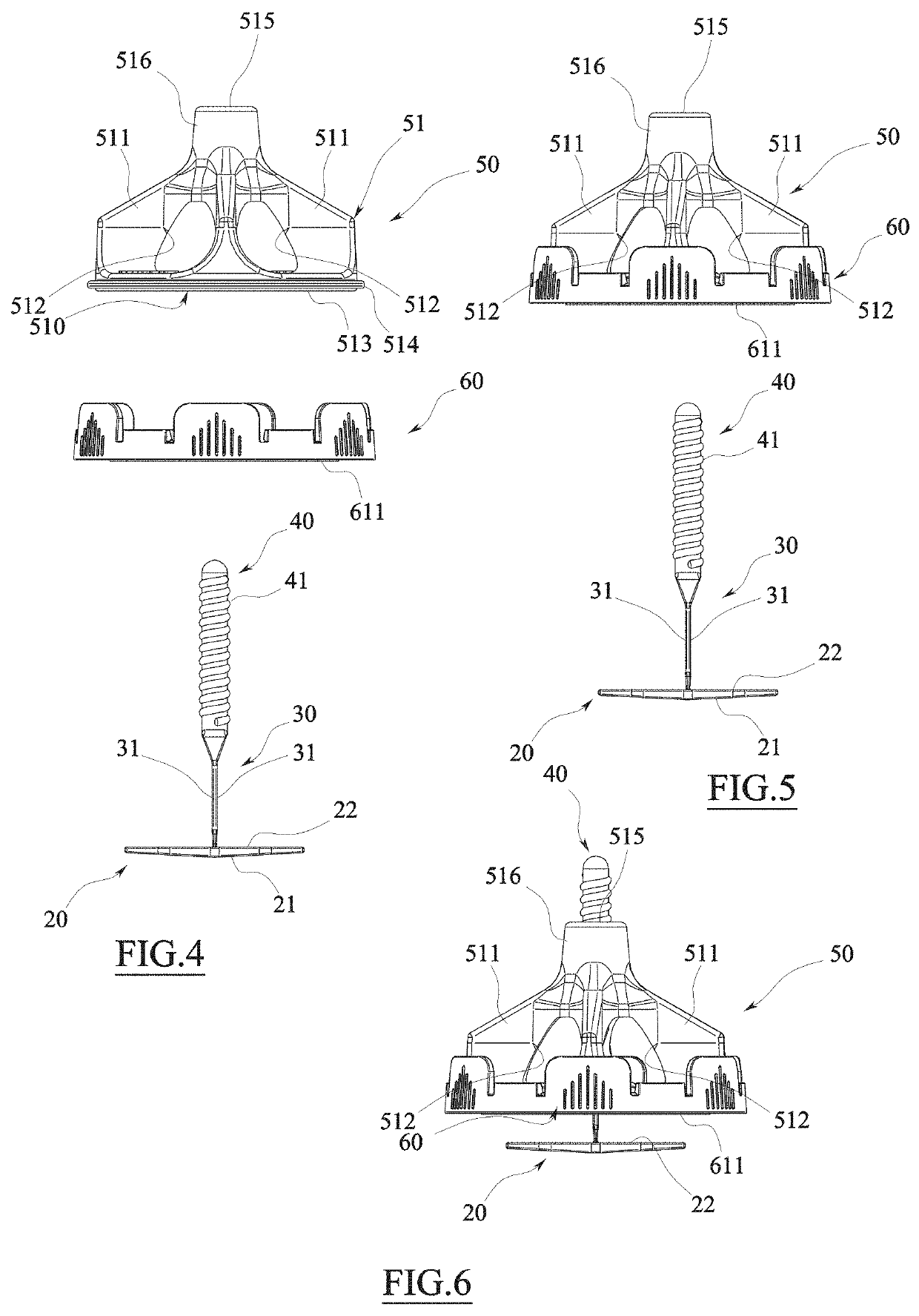

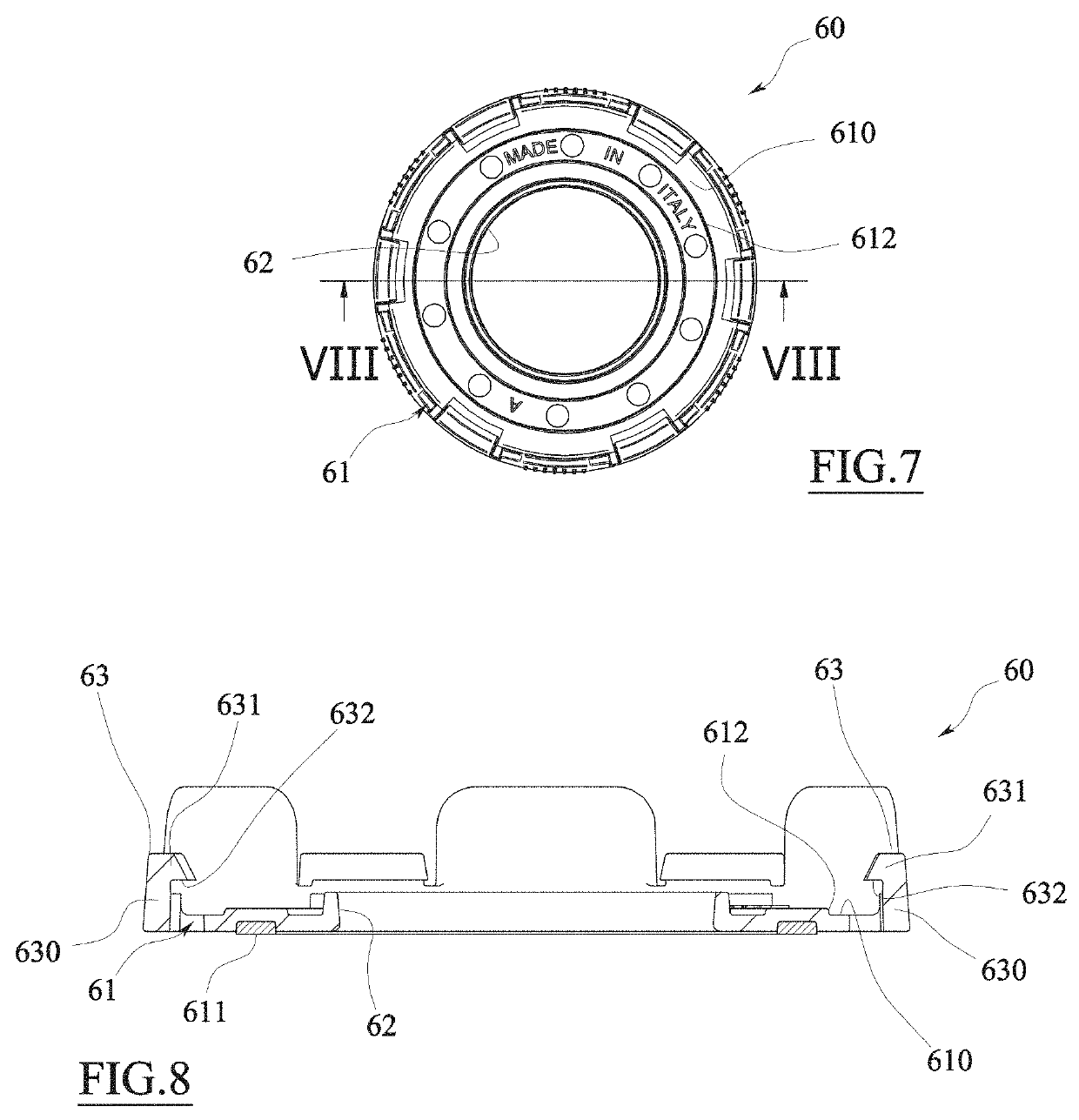

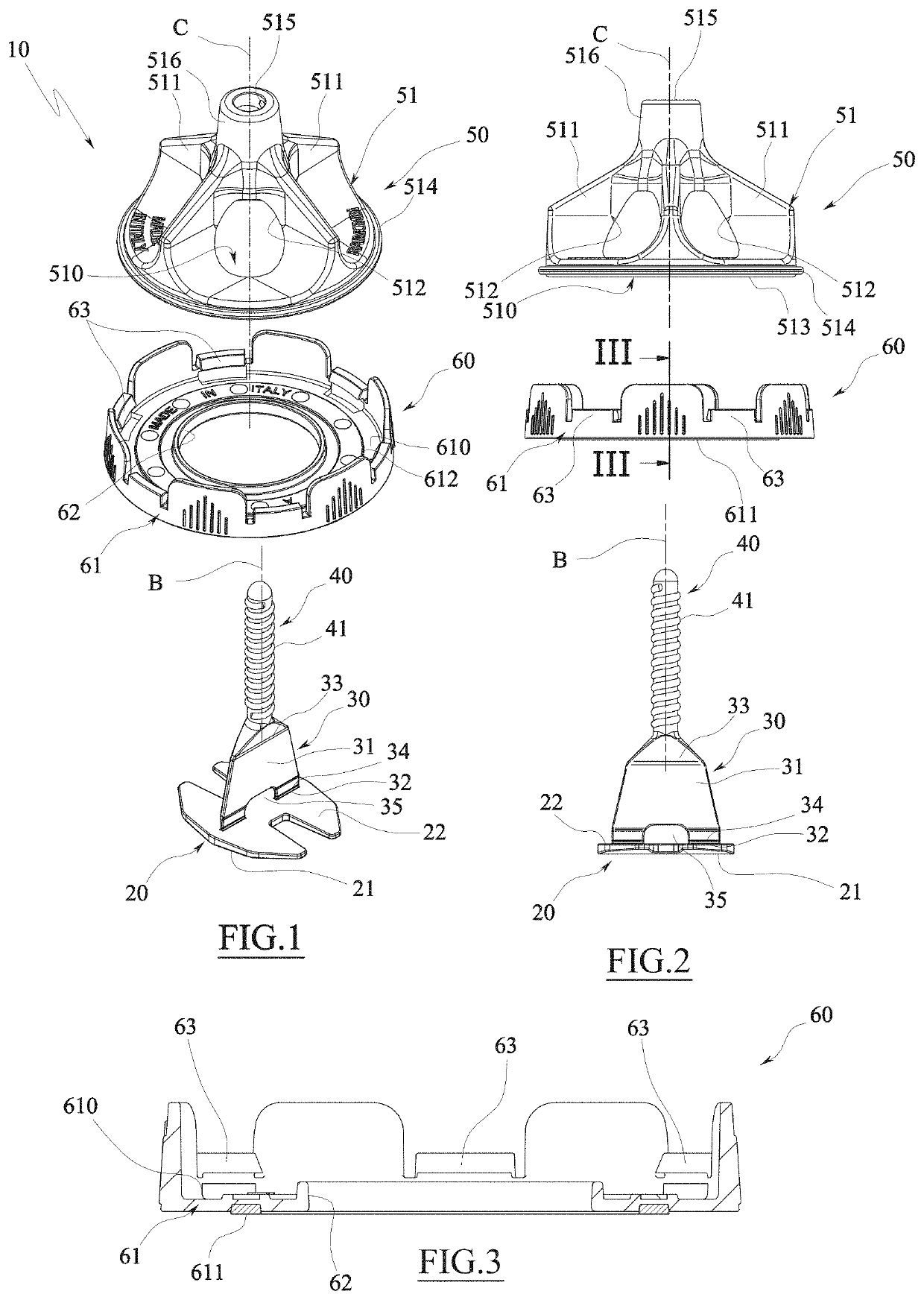

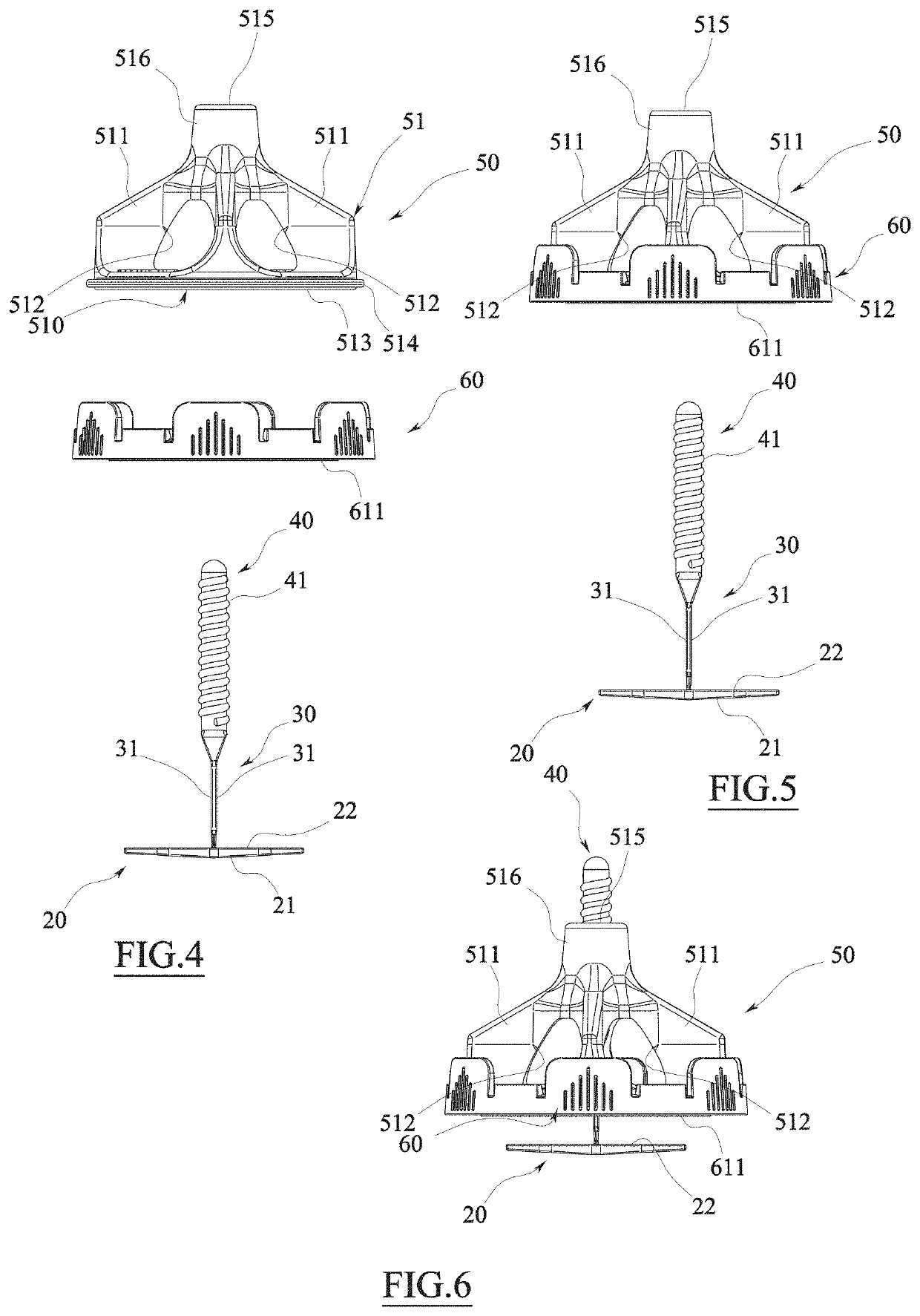

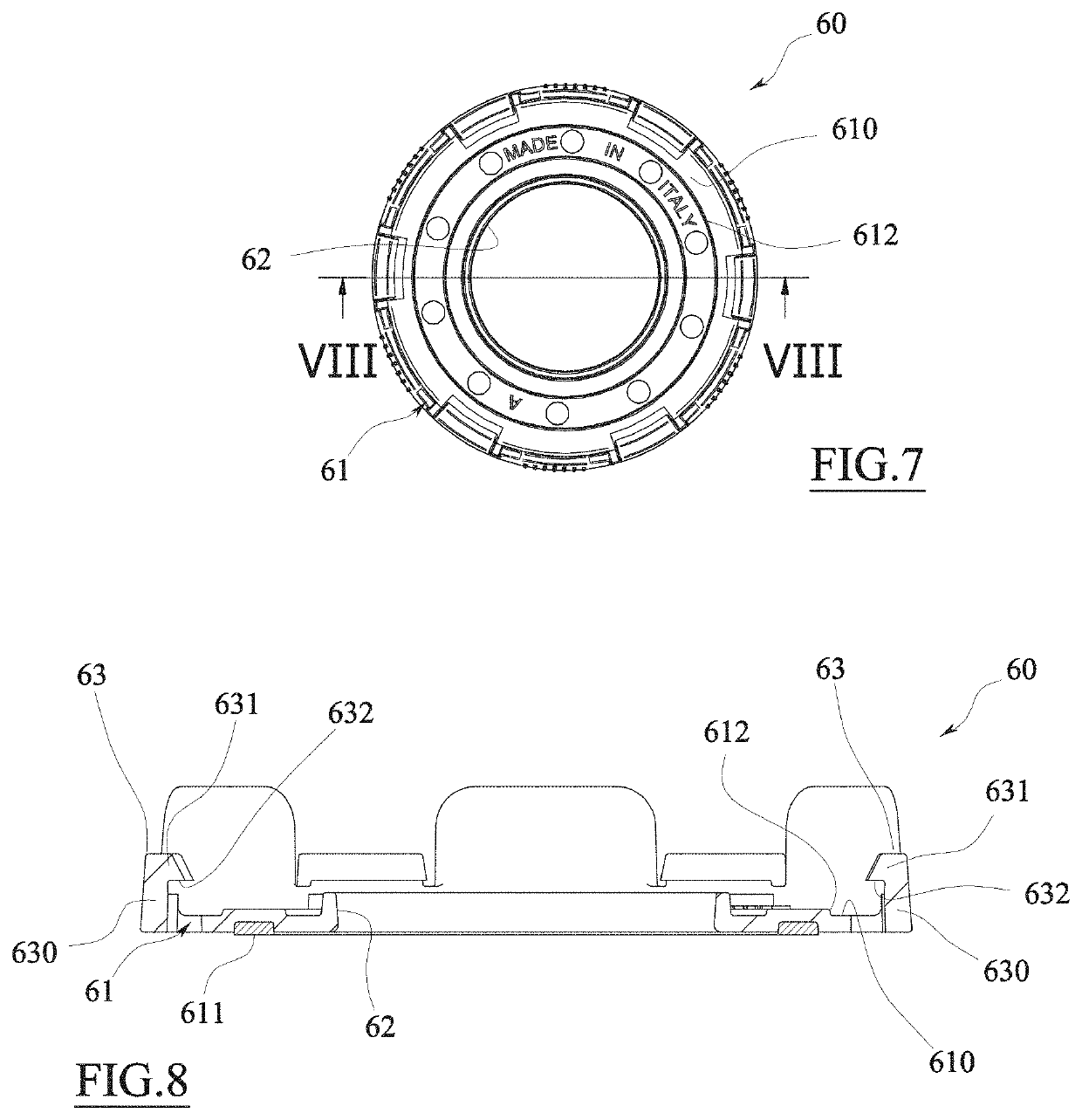

Leveling spacer device

ActiveUS20190345724A1Shorten the timeOperation positioning is accurateFlooringProtection ringSpacer device

A leveling spacer device (10) for laying sheet-like products (P) for the coating of surfaces which comprises:a base (20), which may be positioned at the rear of a laying surface of at least two sheet-like products (P) being adjacent and placed side-by-side relative to a side-by-side direction (A);a separator element (30) rising from said base (20) angled relative thereto and suitable for sliding between the facing side walls of said two sheet-like products (P) placed side by side;a threaded stem (40) rising from the separator element (30) with a screw axis (B) orthogonal to the base (20);a presser (50) that can be screwed onto the threaded stem (40) andan anti-sliding protection ring nut (60) suitable for being interposed between the presser (50) and the base (20), wherein the protection ring nut (60) comprises a first surface (610) facing towards the presser (50) and configured to come into contact therewith and a second opposing surface (611) facing towards the base (20), wherein the second surface (611) has a sliding friction coefficient greater than a sliding friction coefficient of the first surface (610).

Owner:RAIMONDI

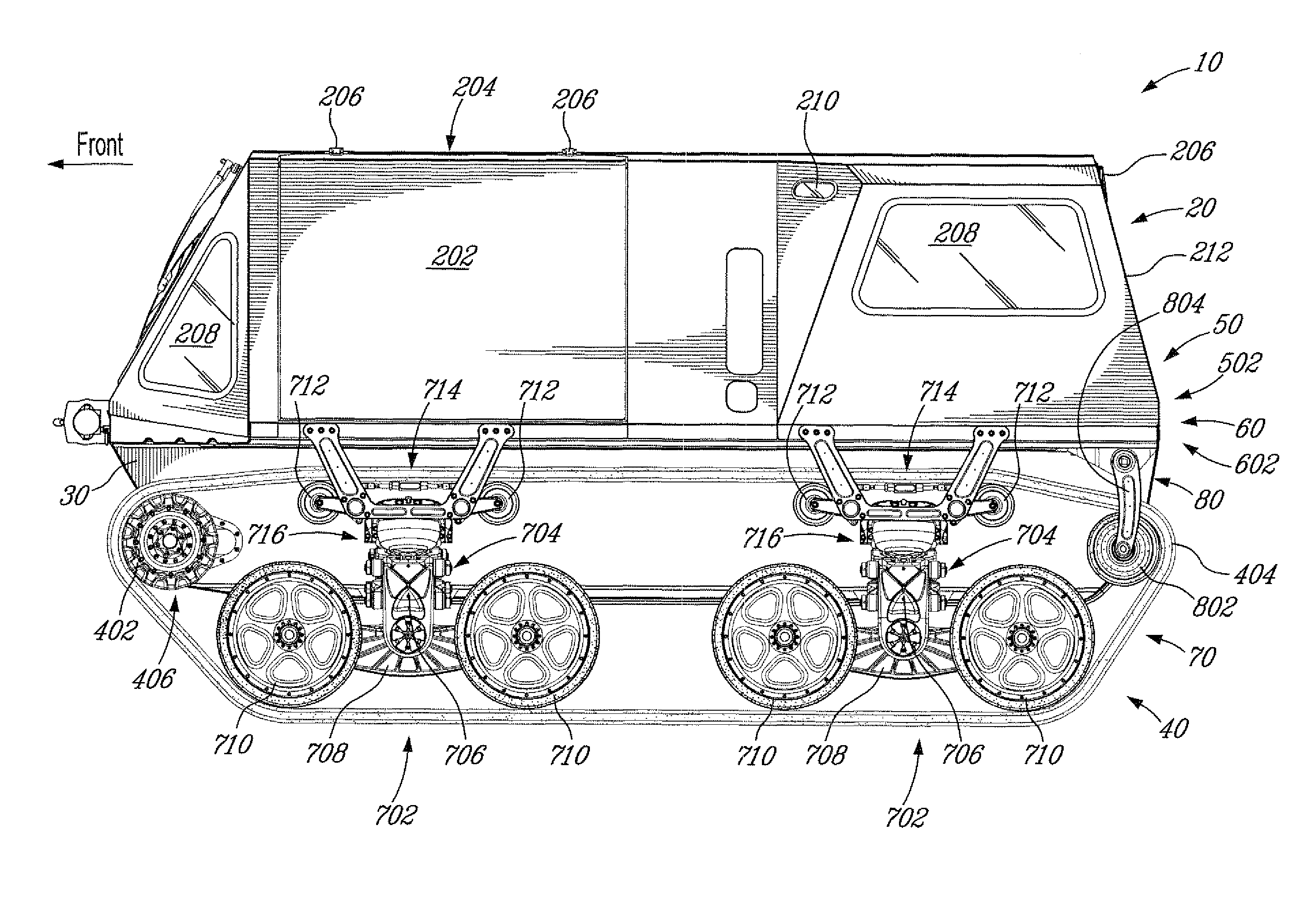

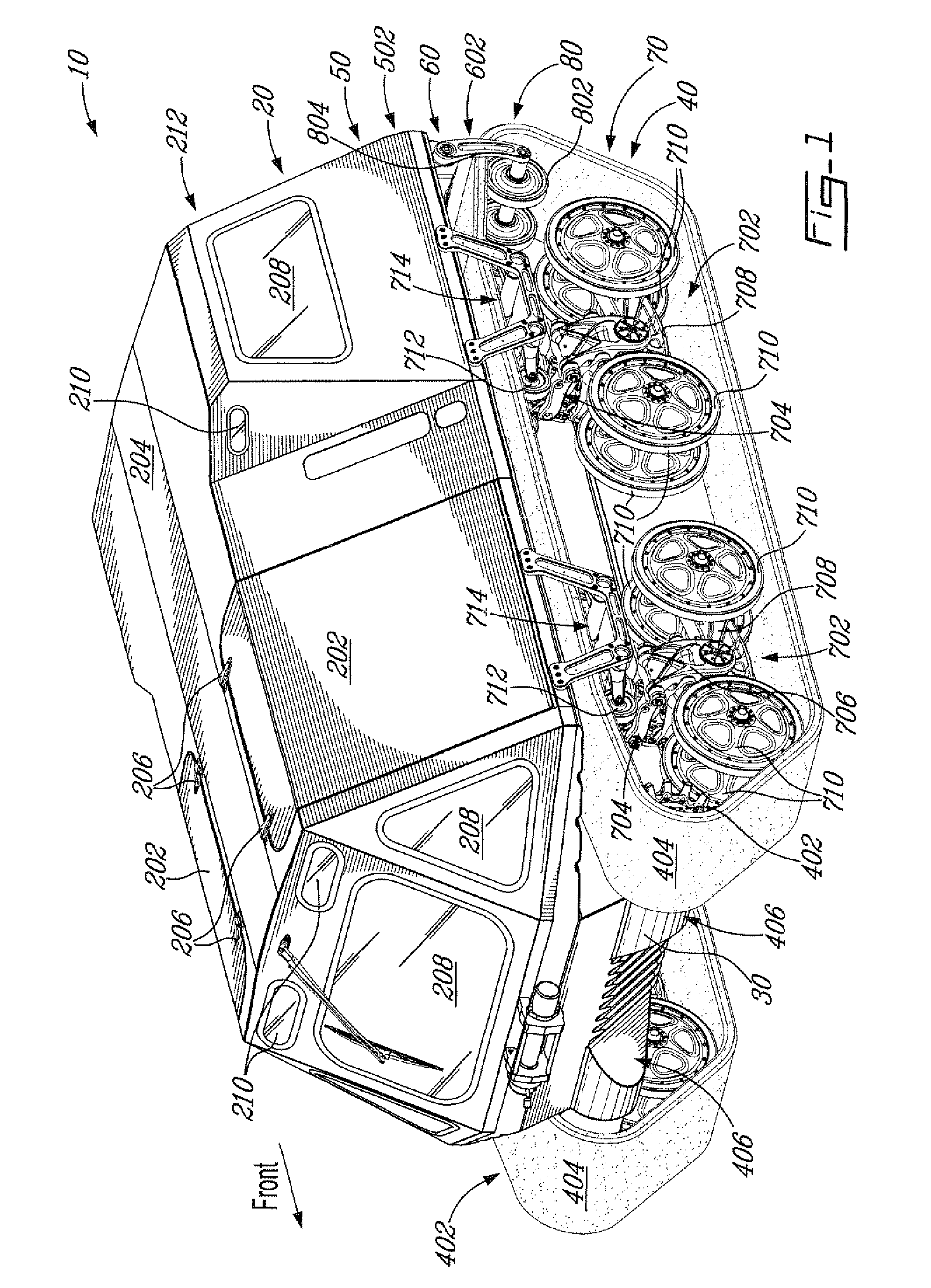

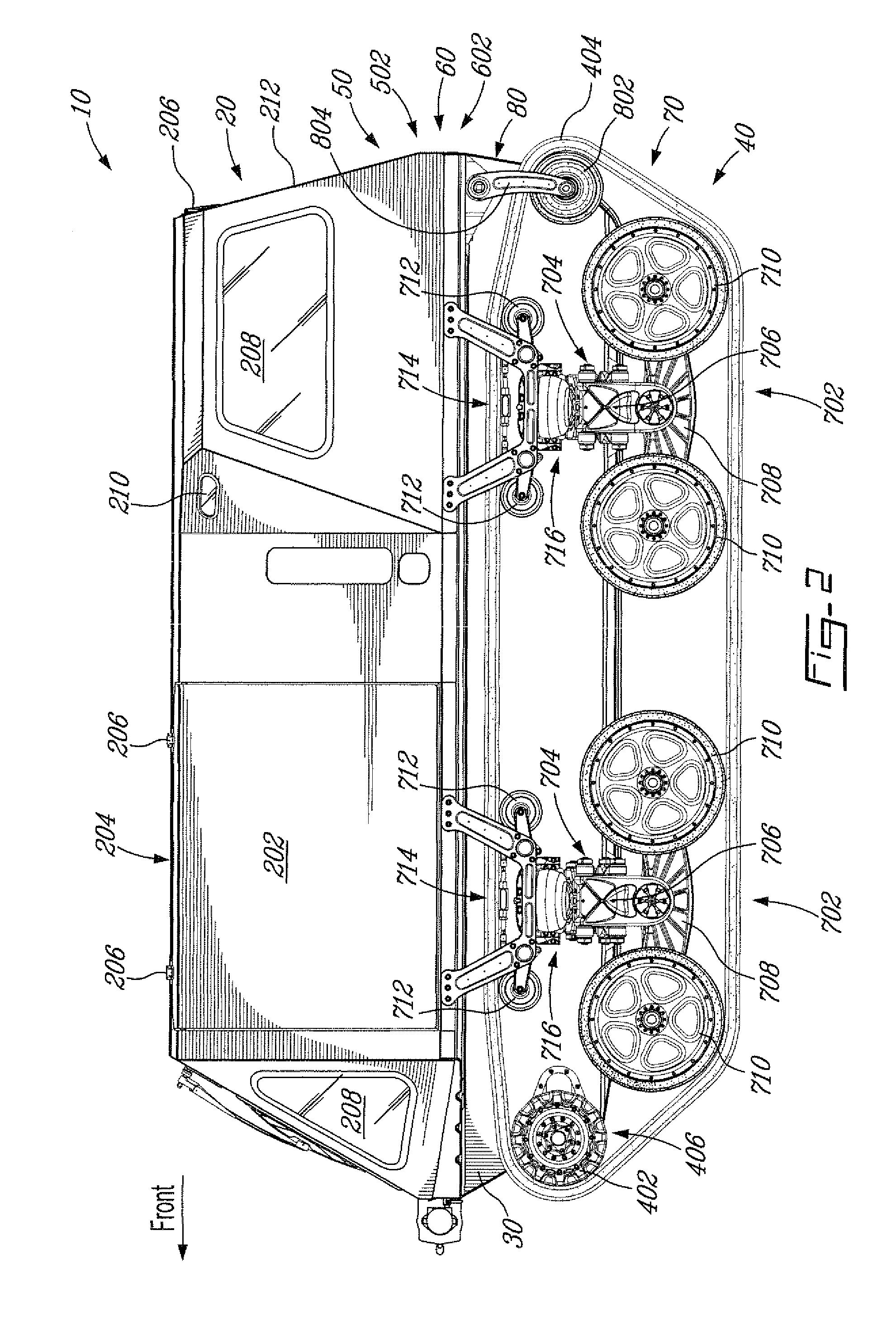

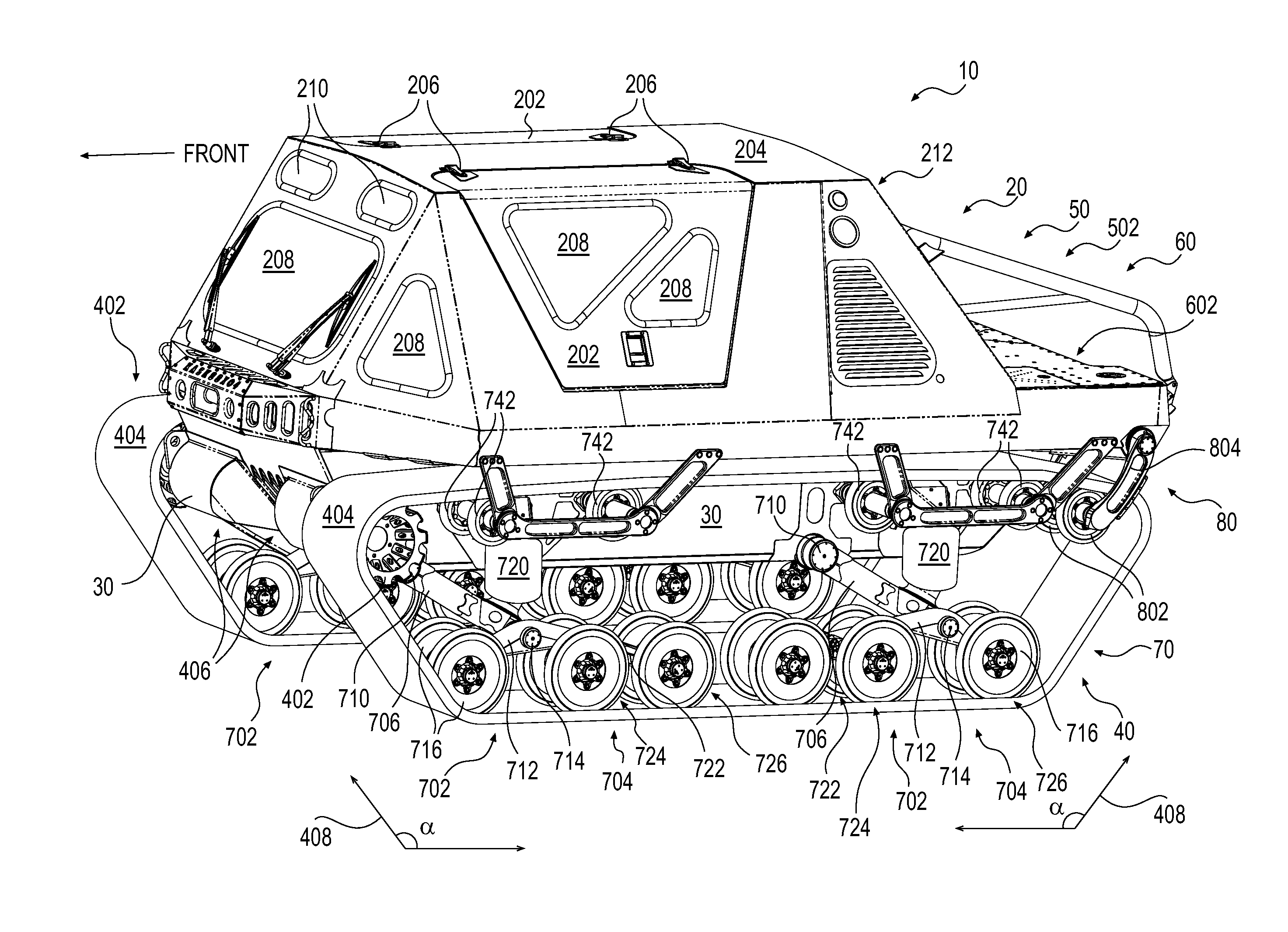

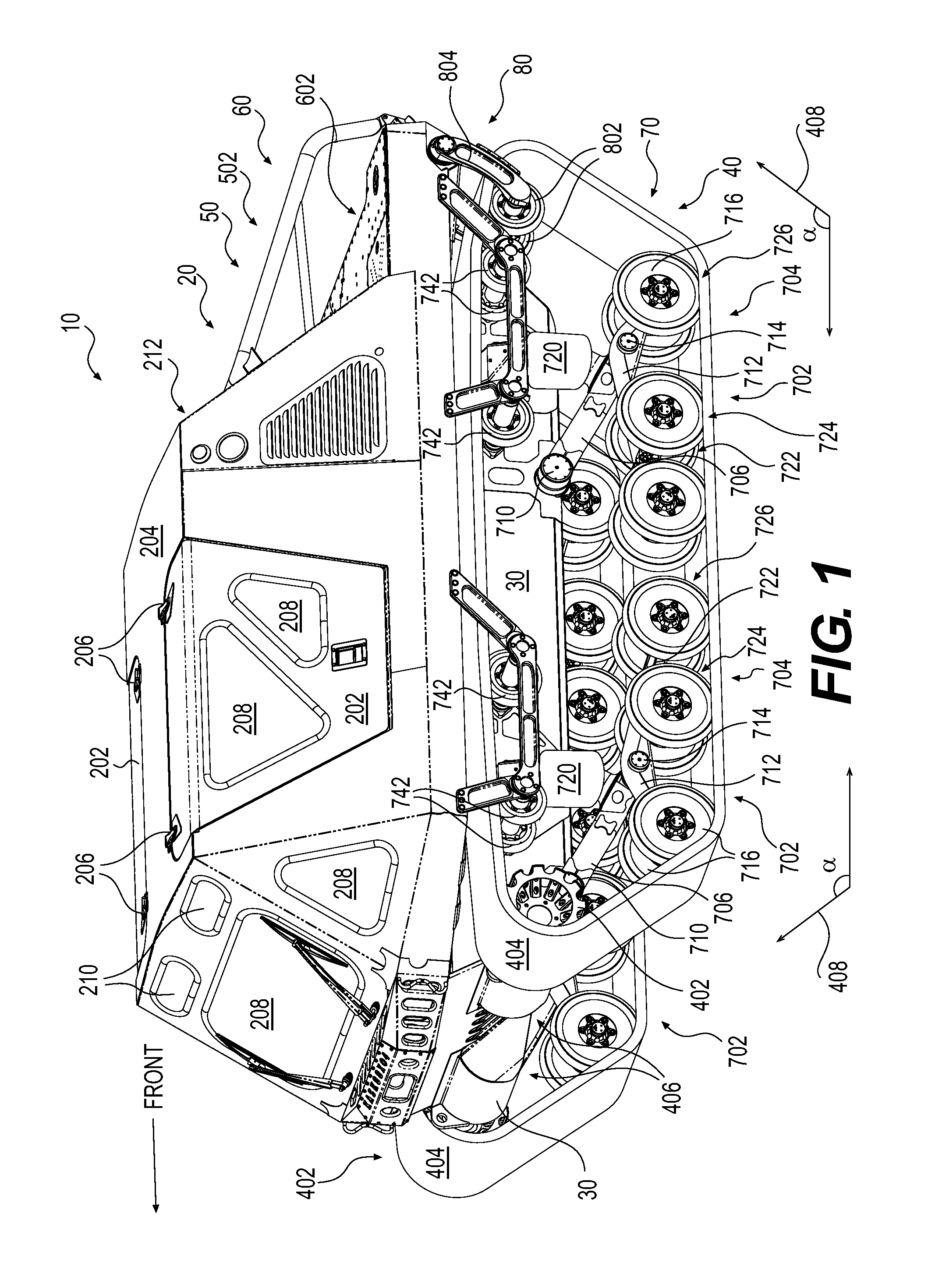

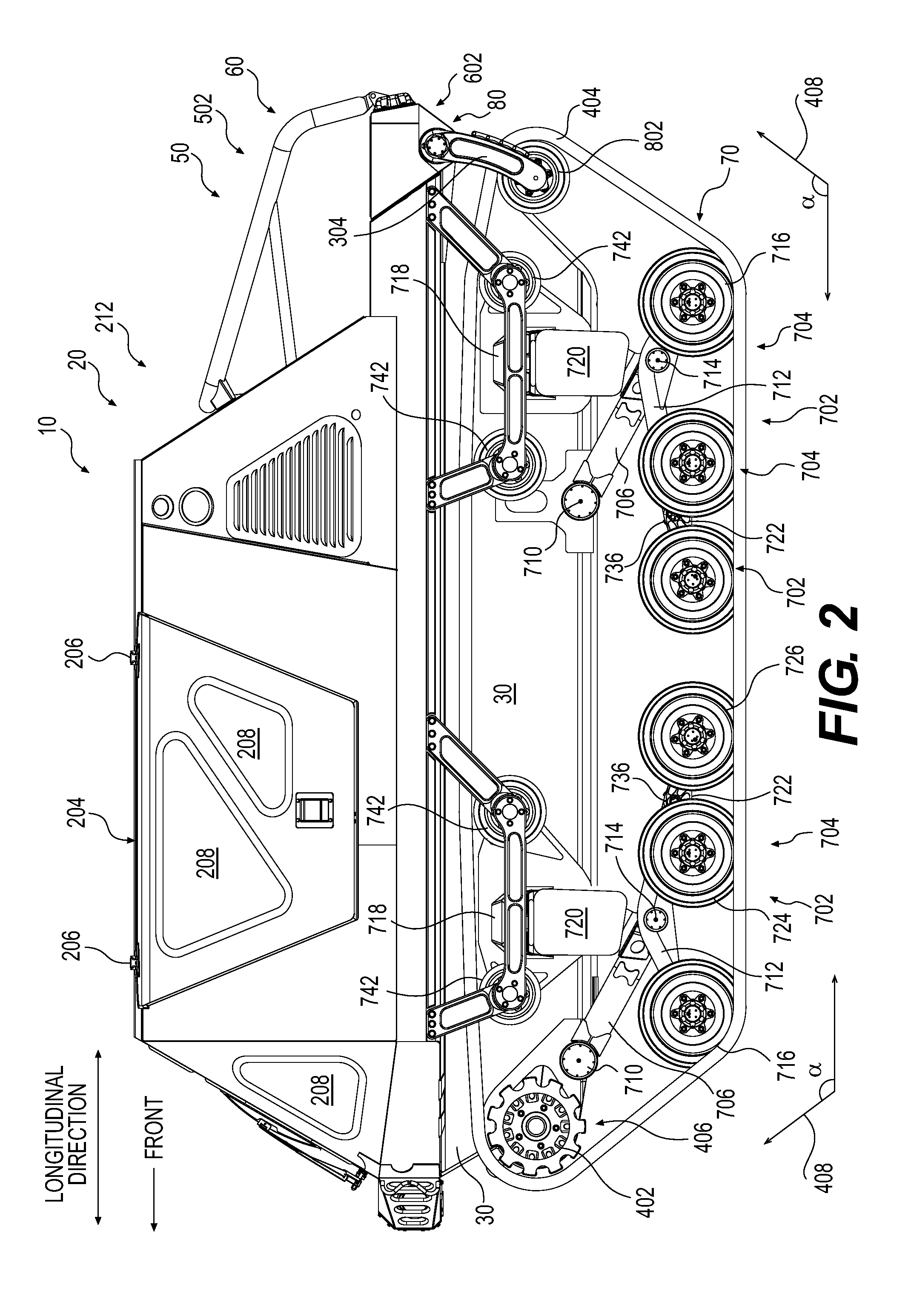

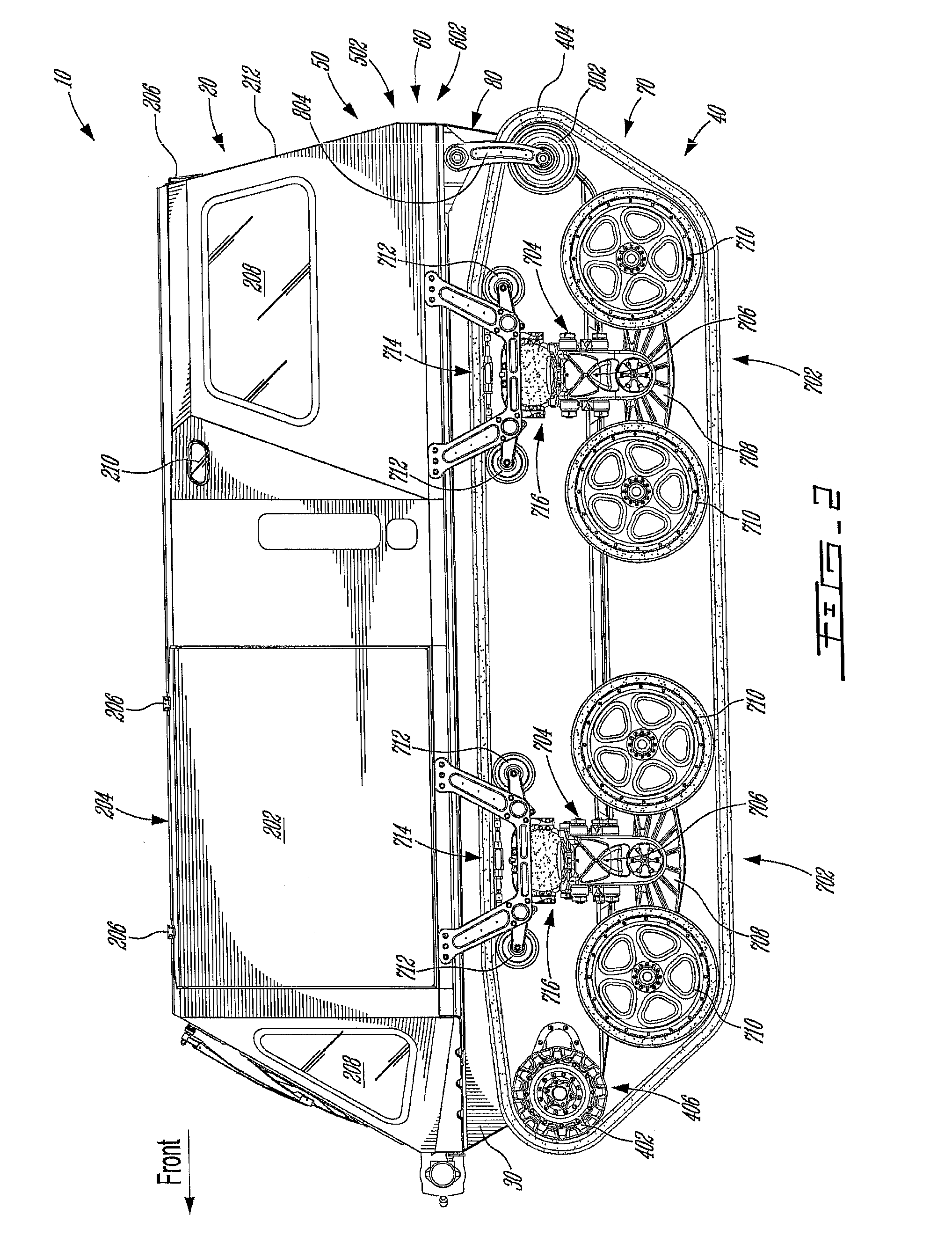

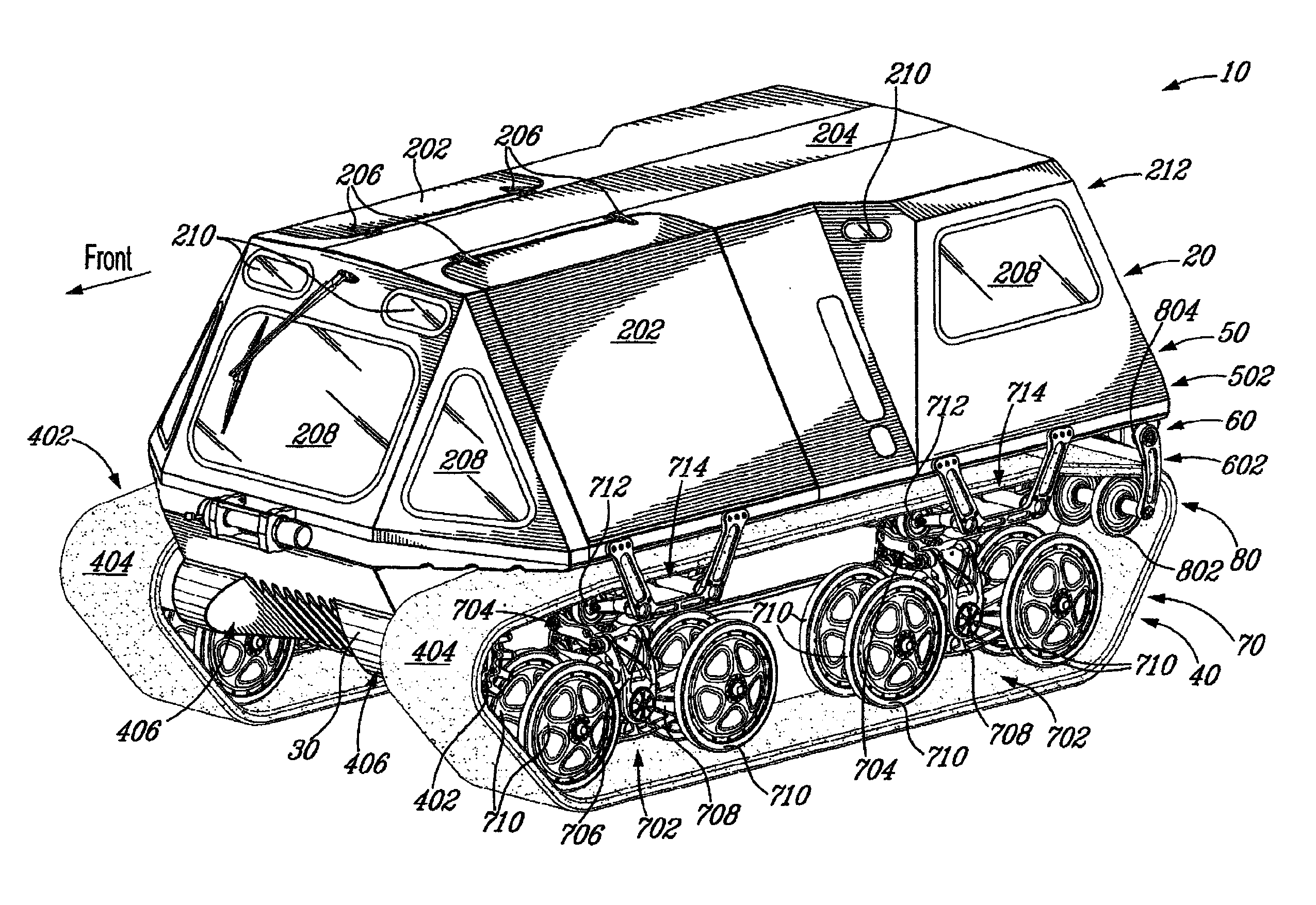

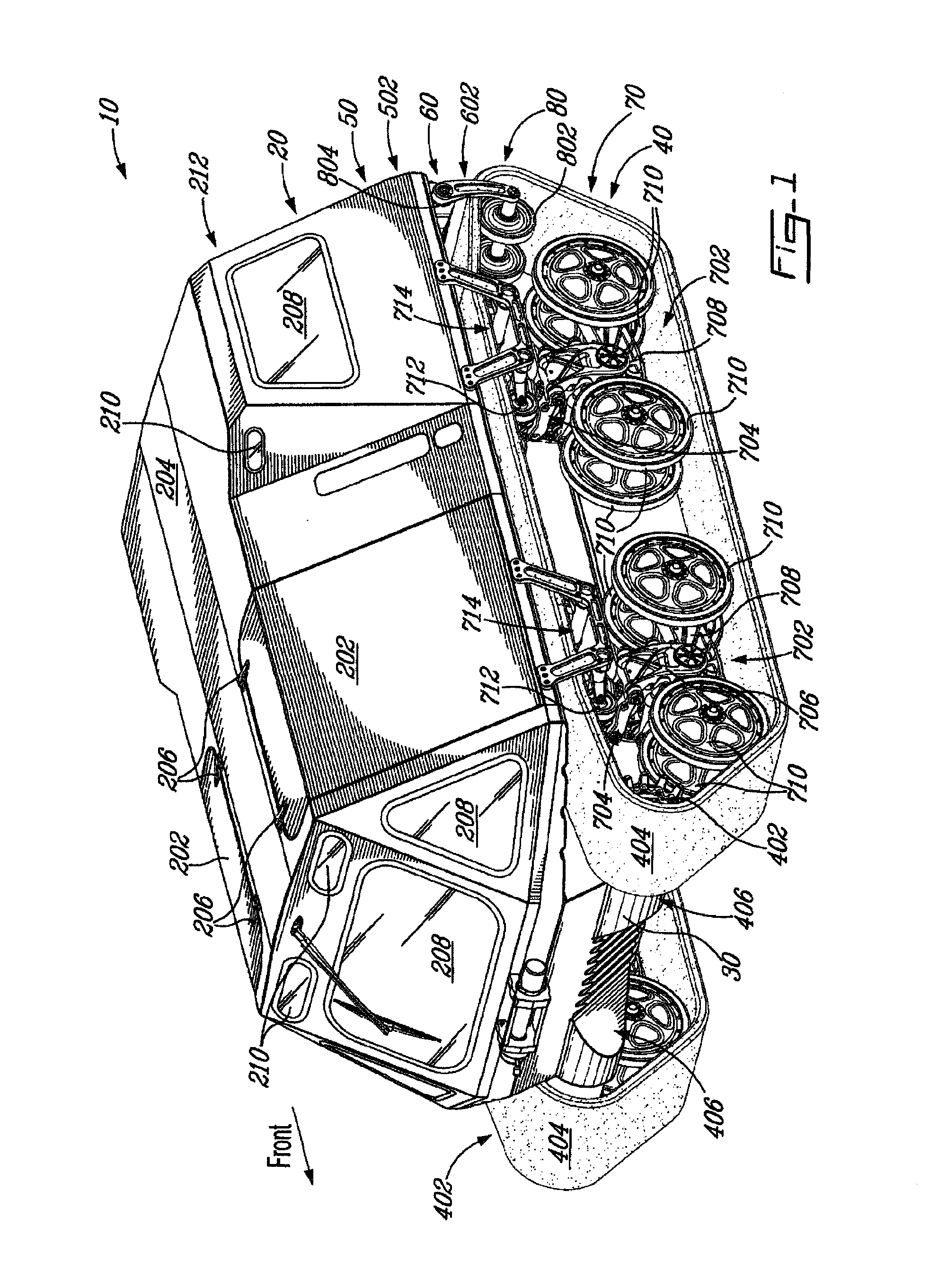

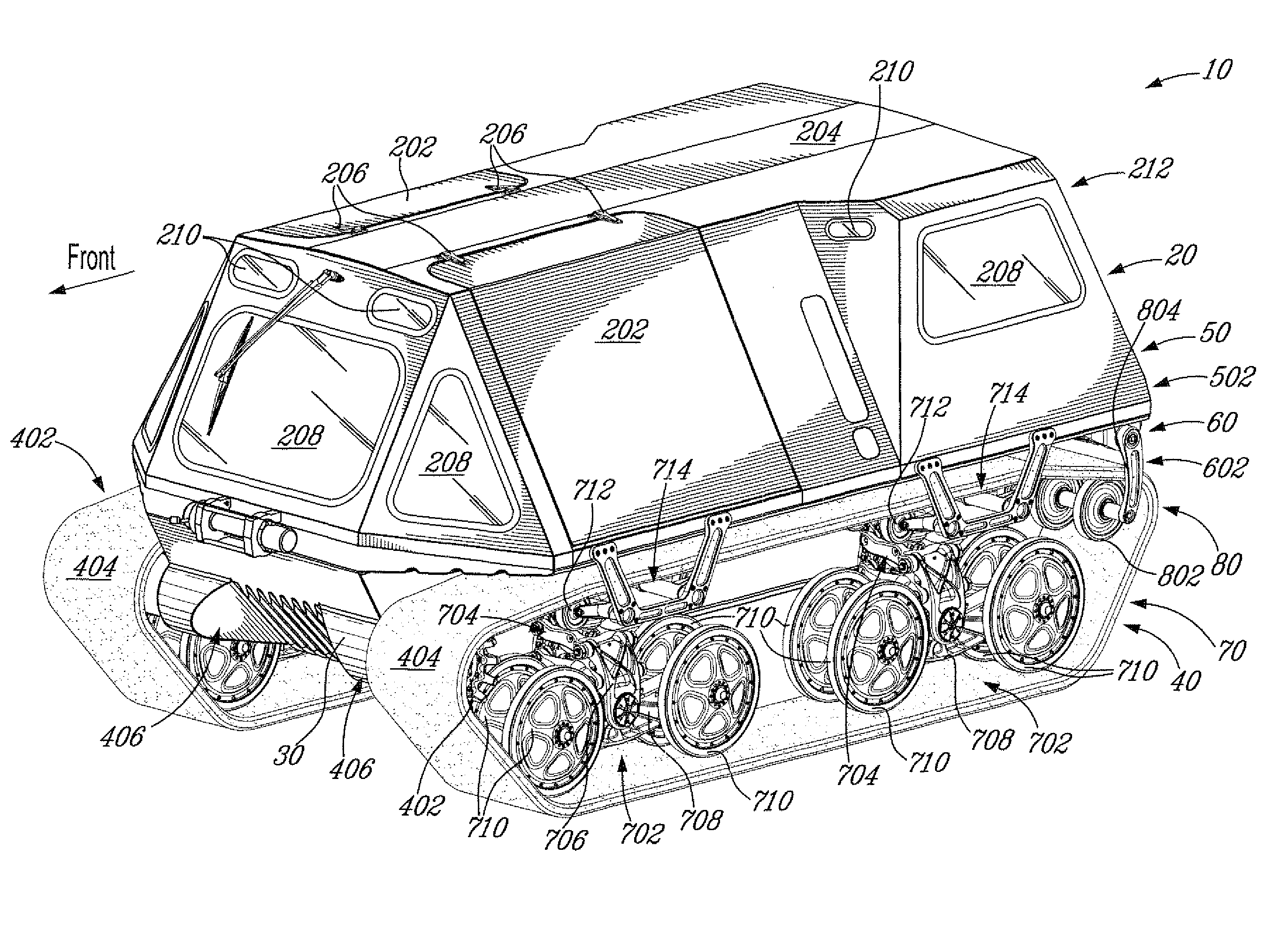

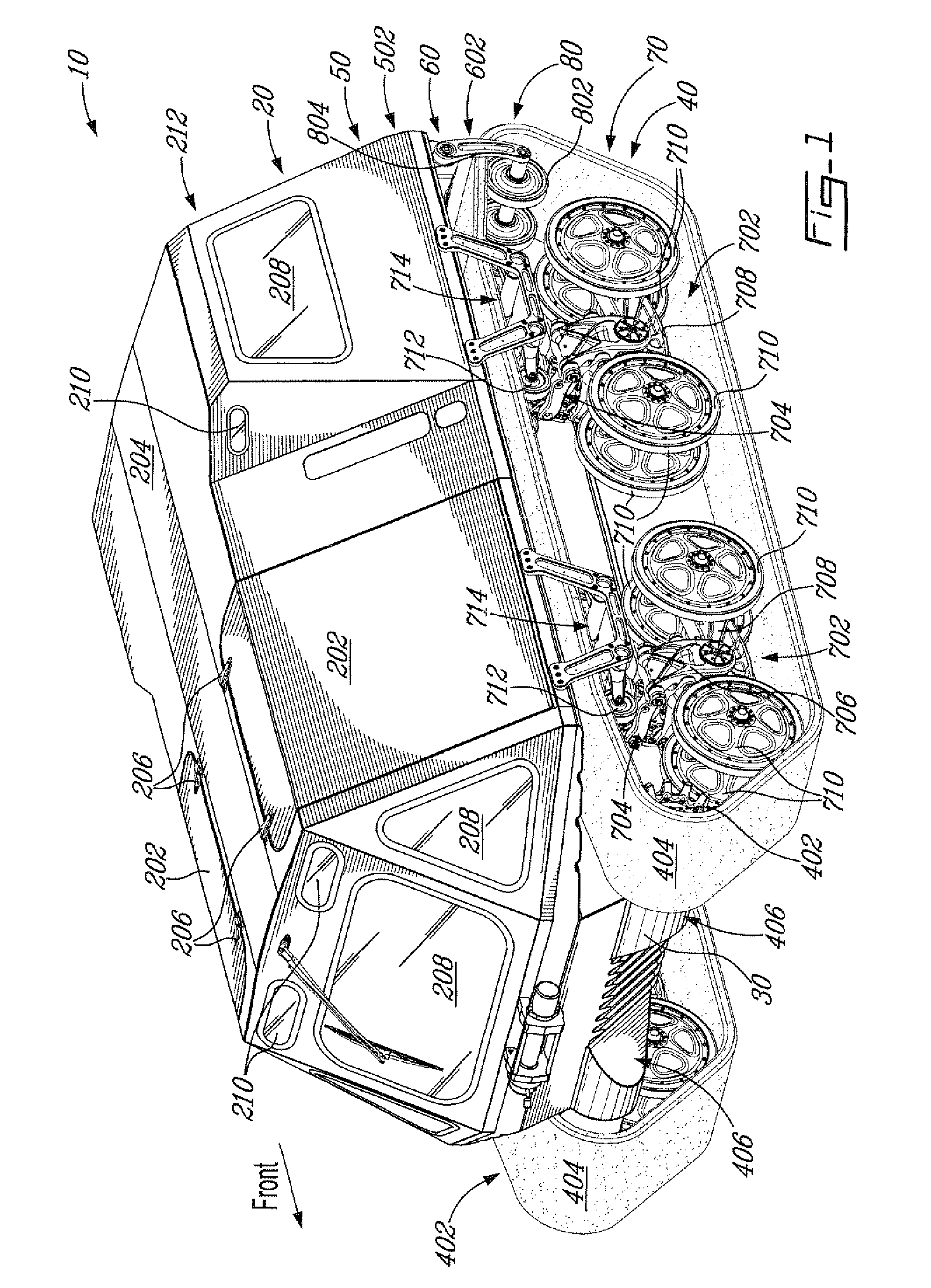

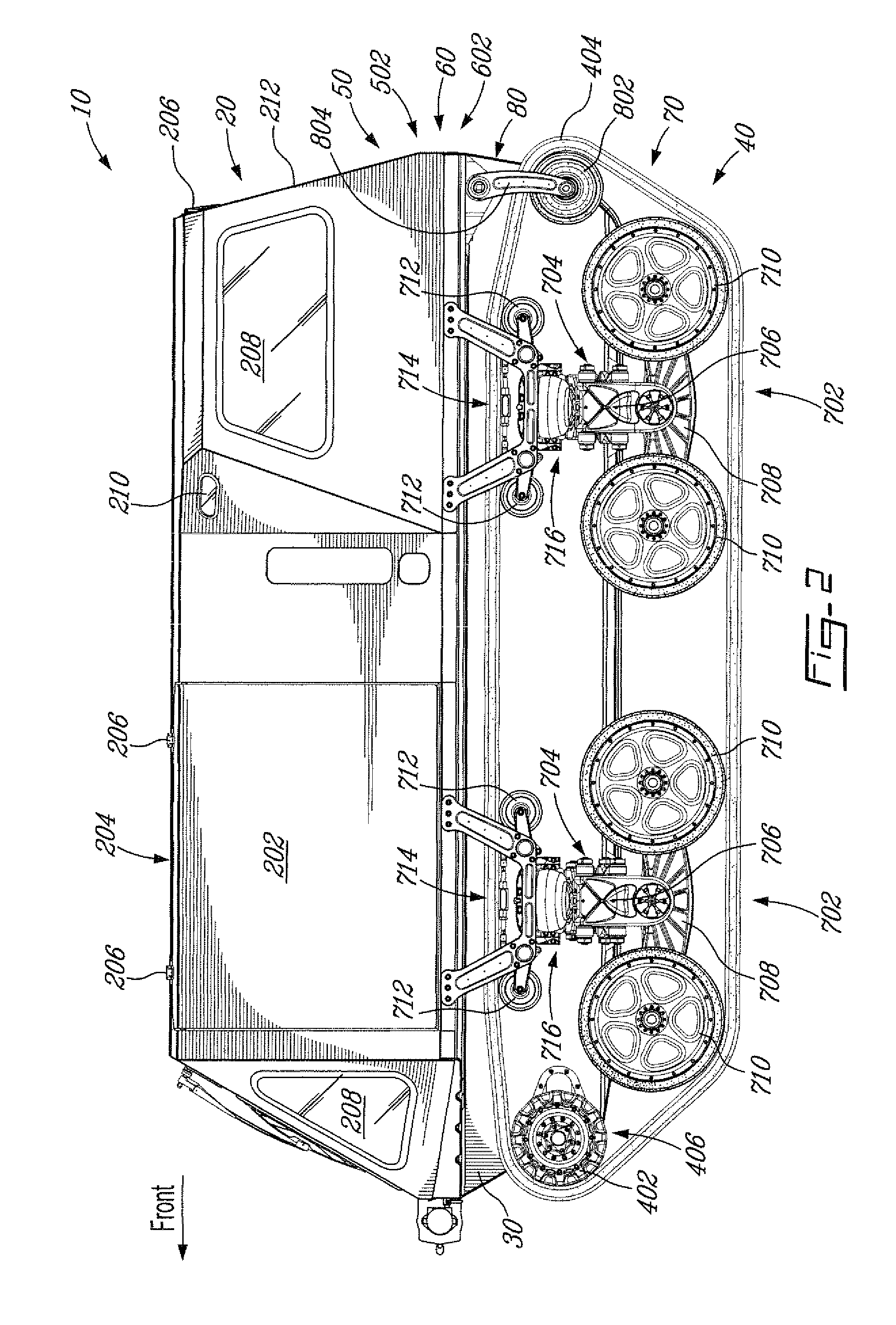

Endless belt tensioner system and method of use thereof

ActiveUS20100230184A1High suspension travelLow maintenanceEndless track vehiclesAutomotive engineeringBelt drive

An endless belt tensioner system adapted to apply a tensioning force on a ground-contacting endless belt of a vehicle is provided, the tensioning force being substantially proportional to an endless belt drive force applied to the endless belt to move the vehicle. A vehicle and a method about the same are also provided.

Owner:LEQUIPE FABCONCEPT

Positioning and stabilising structure and system incorporating same

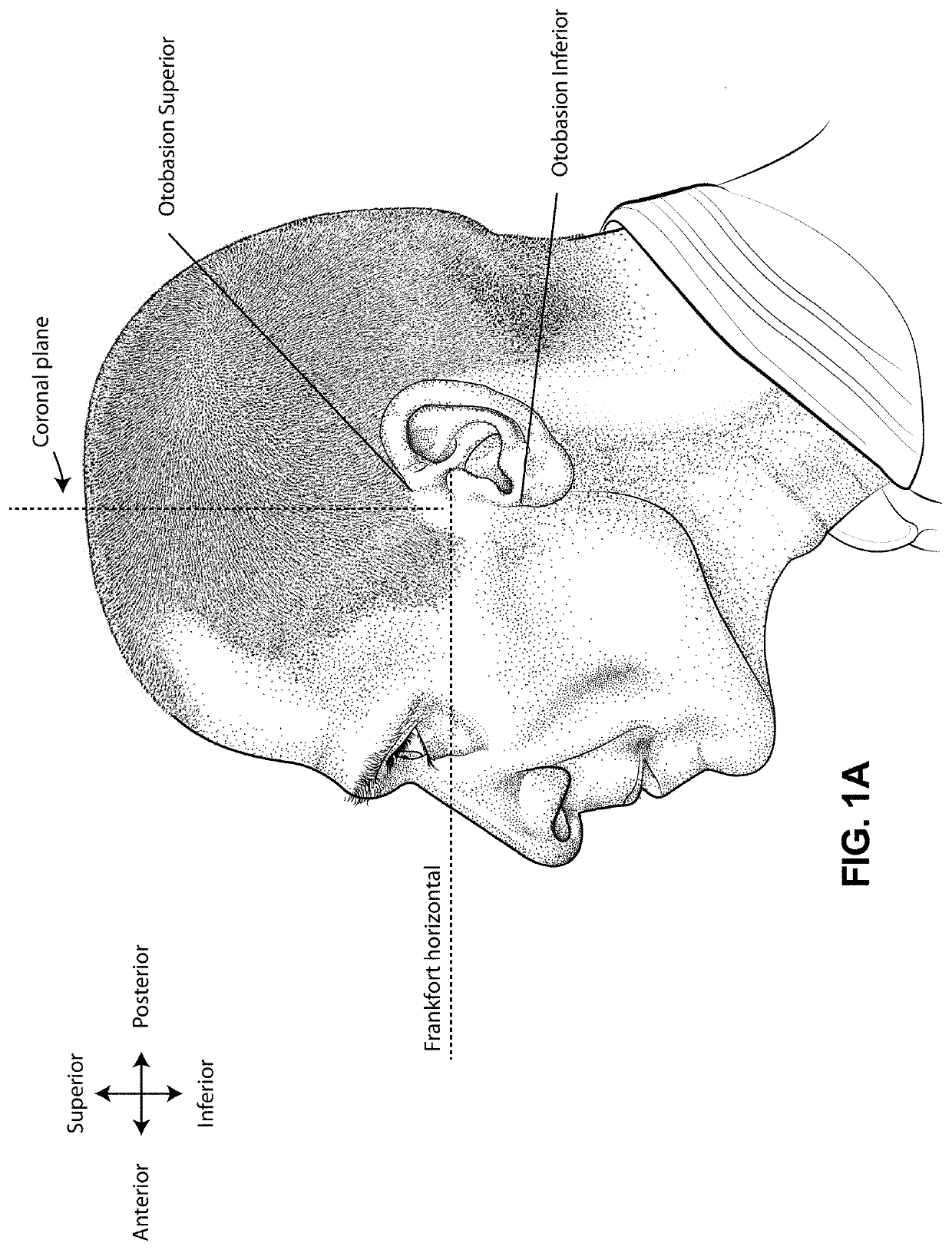

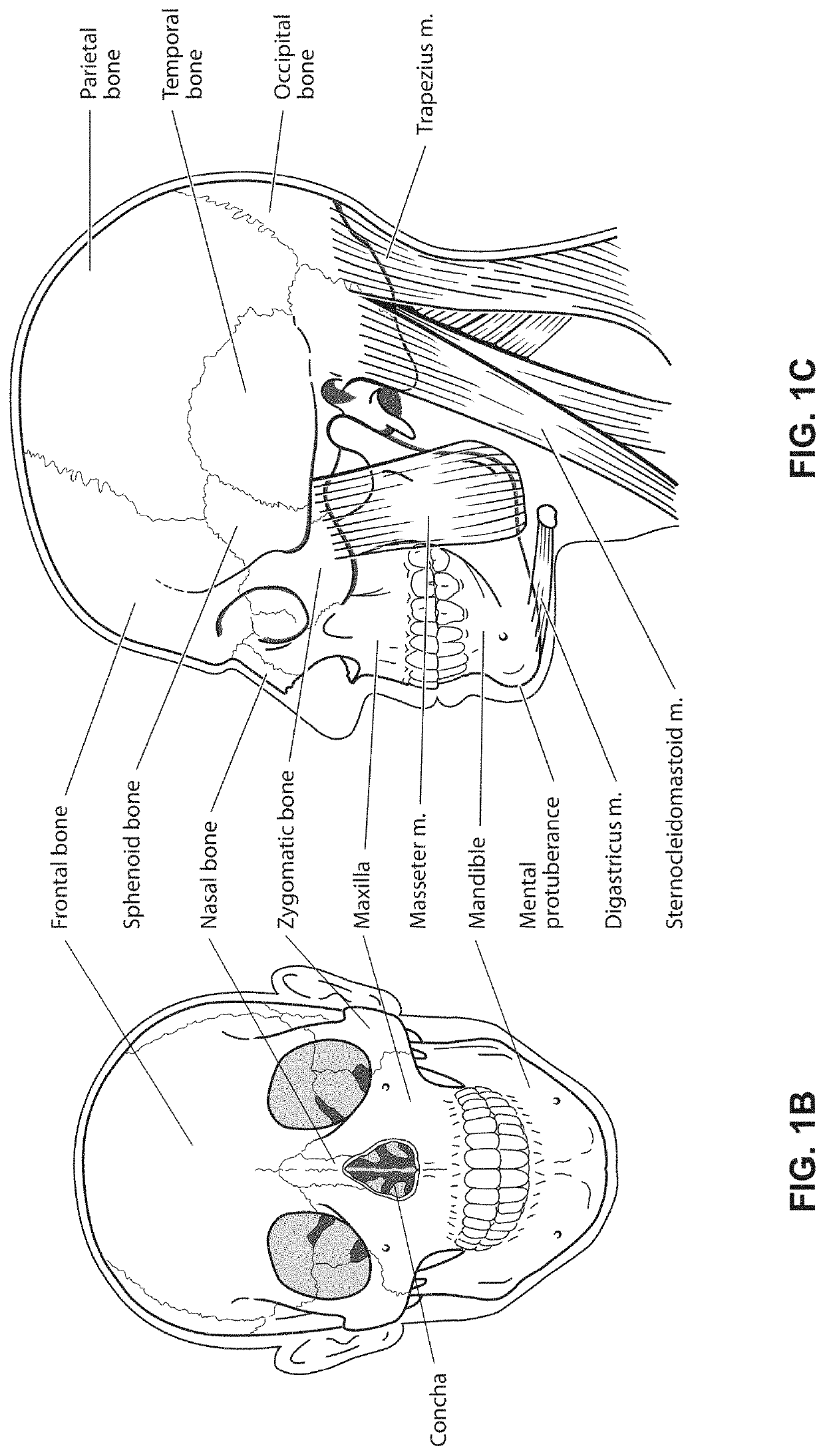

ActiveUS20210302748A1Relieve pressureImprove the display effectOptical elementsPhysical medicine and rehabilitationNeck muscle

A head-mounted display system includes a head-mounted display unit and a positioning and stabilising structure structured and arranged to hold the head-mounted display unit in an operational position over a user's face in use. The positioning and stabilising structure includes a rear support structure adapted to contact posterior regions of a user's head and at least one connector structured and arranged to interconnect the rear support structure to the head-mounted display unit. The rear support structure is in the form of a hoop comprising an occipital portion configured and arranged engage the user's head along a portion of the occipital bone adjacent a junction where the neck muscles attach to the occipital bone in use.

Owner:RESMED LTD

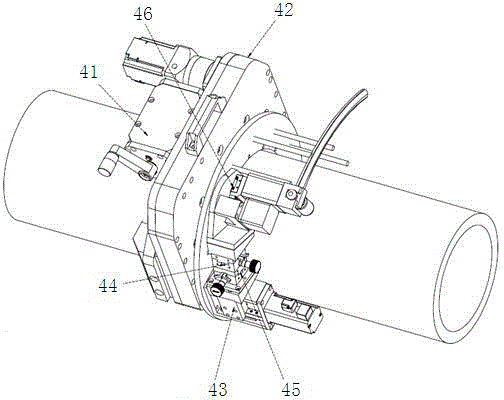

All-position pipeline welding workstation

ActiveCN104985302AReduce the need for technical expertiseSolve the problem of not being able to rotateWelding/cutting auxillary devicesElectrode holder supportersEngineeringArgon gas

The invention relates to an all-position pipeline welding workstation. The all-position pipeline welding workstation is characterized by comprising a pipeline cutting and beveling device and an open type welding device. The open type welding device comprises a welding chuck, an argon arc welding machine, a wire feeder, a water tank, an argon gas bomb and a control electric box. The pipeline cutting and beveling device comprises a conveying line front end, a conveying line rear end and a pipeline cutting and beveling machine arranged between the conveying line front end and the conveying line rear end. Through coordinate usage of the pipeline cutting and beveling device and the welding chuck device on a movable trolley, the purposes of conveying of pipelines and convenient welding of prefabricated pipelines are achieved; the characteristics of flexible and convenient disassembly, safety, reliability and the like are achieved; operation is convenient; the welding quality and efficiency are improved; labor intensity of operators is relieved; production cost and the occurrence rate of safety accidents are reduced.

Owner:扬州鑫凯诚机器人系统有限公司

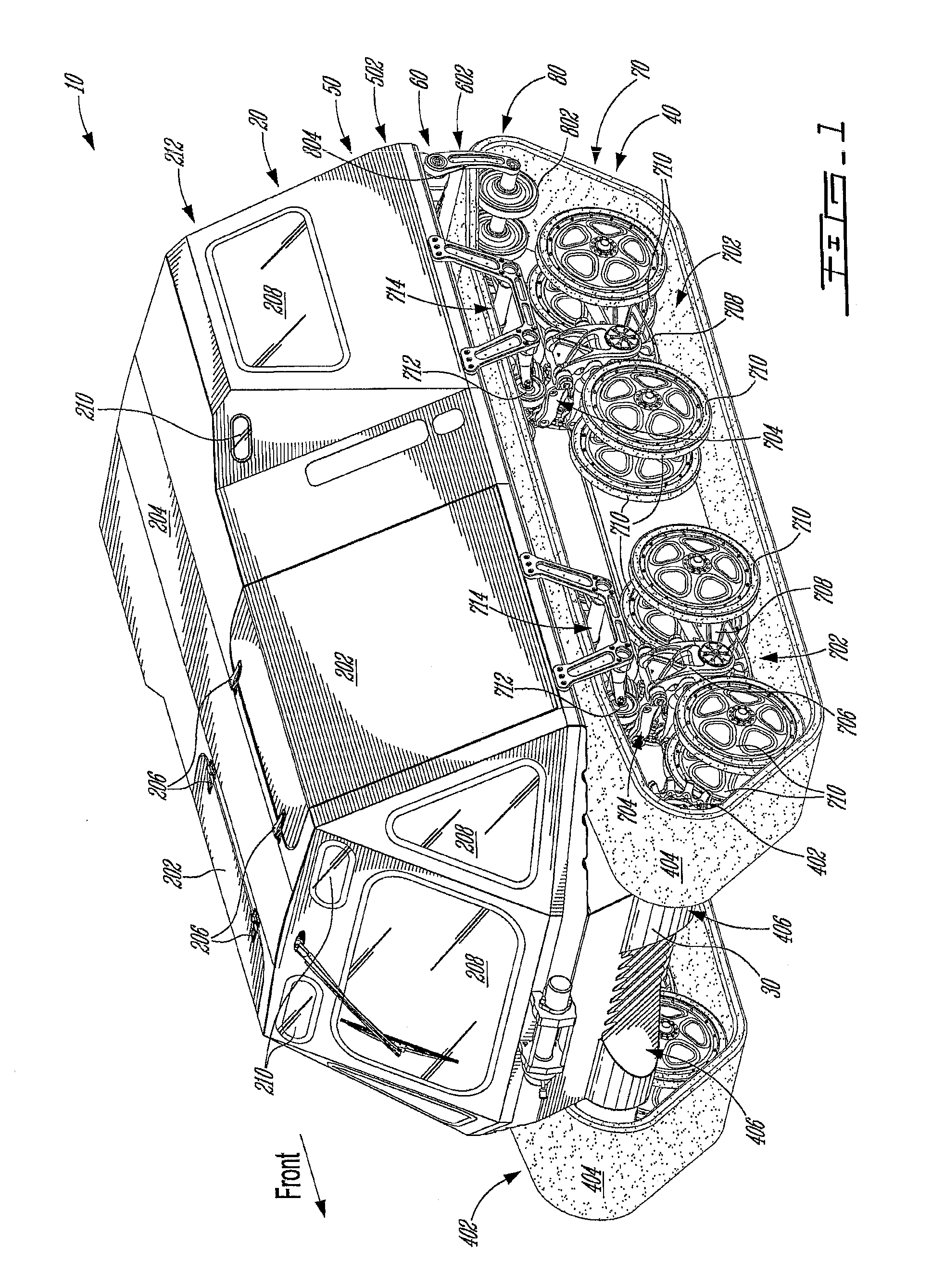

Vehicle suspension system

ActiveUS8708069B2Operation positioning is accurateReduce maintenanceGearingResilient suspensionsVehicle suspension systemAutomotive engineering

A vehicle equipped with a double tandem members suspension system to suspend the vehicle, the double tandem members being operatively interconnected together and adapted to receive idling wheels adapted to support and guide an endless belt thereon to provide significant suspension travel and prevents an endless belt disengagement from the idling wheels.

Owner:LEQUIPE FABCONCEPT

Leveling spacer device

A leveling spacer device for laying sheet shaped products for the covering of surfaces, including a base, which may be positioned at the rear of a laying surface of at least two sheet shaped products being adjacent and placed side-by-side relative to a side-by-side direction, a separator element rising from, and perpendicular to, the base and configured to slide between the facing side walls of the two sheet shaped products placed side by side, a threaded stem rising from the separator element with a screw axis orthogonal to the base, a presser screwable onto the threaded stem and an anti-sliding protection ring interposable between the presser and the base. The protection ring includes a first surface facing towards and configured to contact the presser and a second opposing surface facing towards the base. The second surface has a sliding friction coefficient greater than a sliding friction coefficient of the first surface.

Owner:RAIMONDI

Swinging type plug-in structure of bus duct

PendingCN109713627AEasy to installEasy to moveTotally enclosed bus-bar installationsElectrical conductorEngineering

The invention discloses a swinging type plug-in structure of a bus duct. The swinging type plug-in structure of the bus duct comprises a plug-in box body, and a multi-phase plug arranged in the plug-in box body and used for being electrically connected with a conductor in a bus duct. Movable hooks mounted through torsional springs are arranged on two sides of the upper part of the front end of theplug-in box body. Fixed hooks are arranged on the two sides of the upper portion of the rear end of the plug-in box body. The plug-in box body is connected to the two sides of the lower portion of the bus duct through the movable hooks and the fixed hooks in a hung mode and can move in a reciprocating mode along the bus duct. The plug can correspond to a conductor in the bus duct in position through movement of the plug-in box body, so that the plug can be inserted into the conductor to achieve plug-in fit. After the structure is adopted, the bus duct is simple in installation and very convenient in operation. The corresponding positions of the plug and the conductor are accurate. Therefore, the conductive connection leaning property is very high, and the operation positioning is accurateand reliable due to driving of an operation mechanism. In addition, the hanging structure of the plug-in box body can be conveniently moved, so that the accurate positioning is further facilitated. The use reliability is improved.

Owner:WETOWN ELECTRIC GRP CO LTD

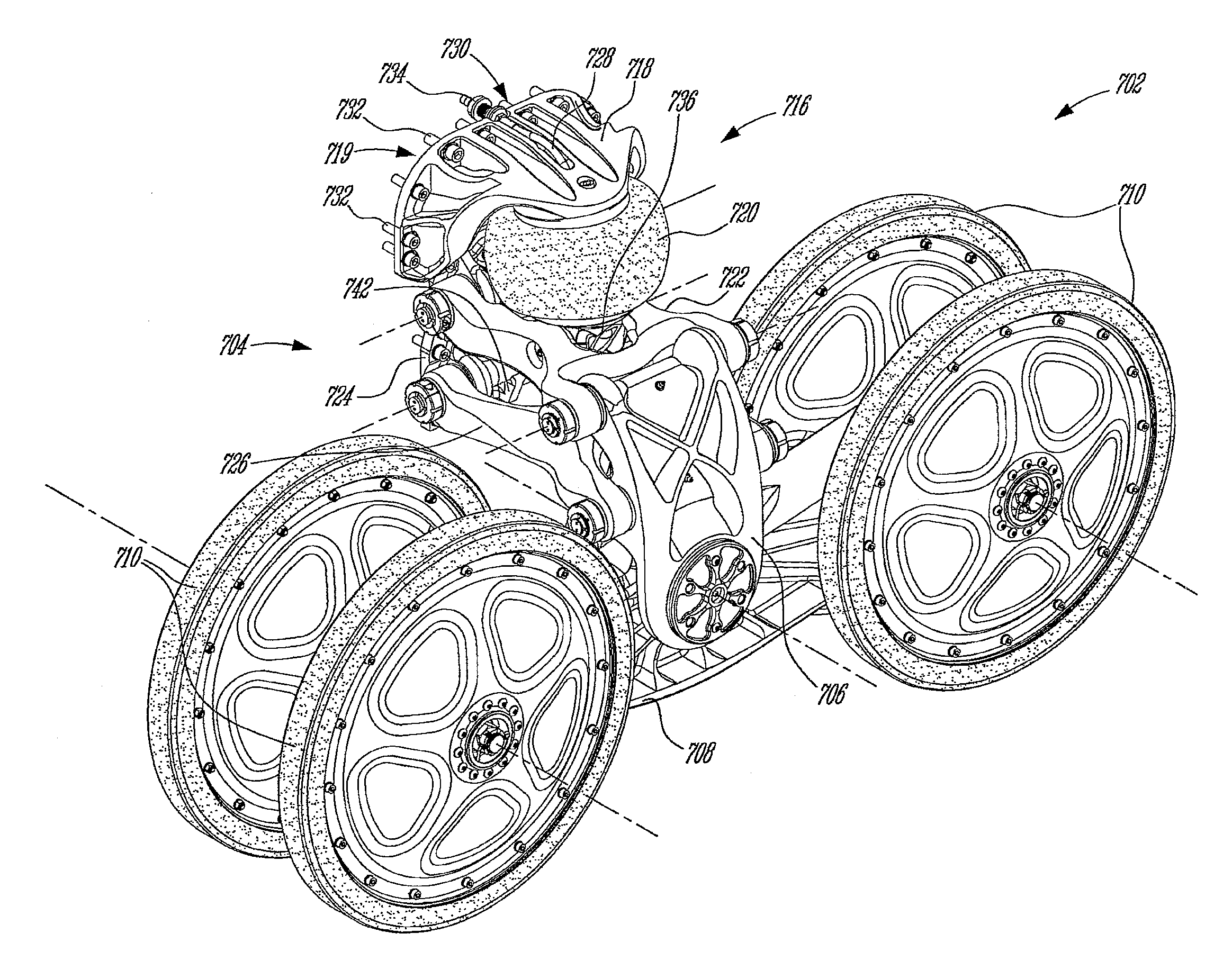

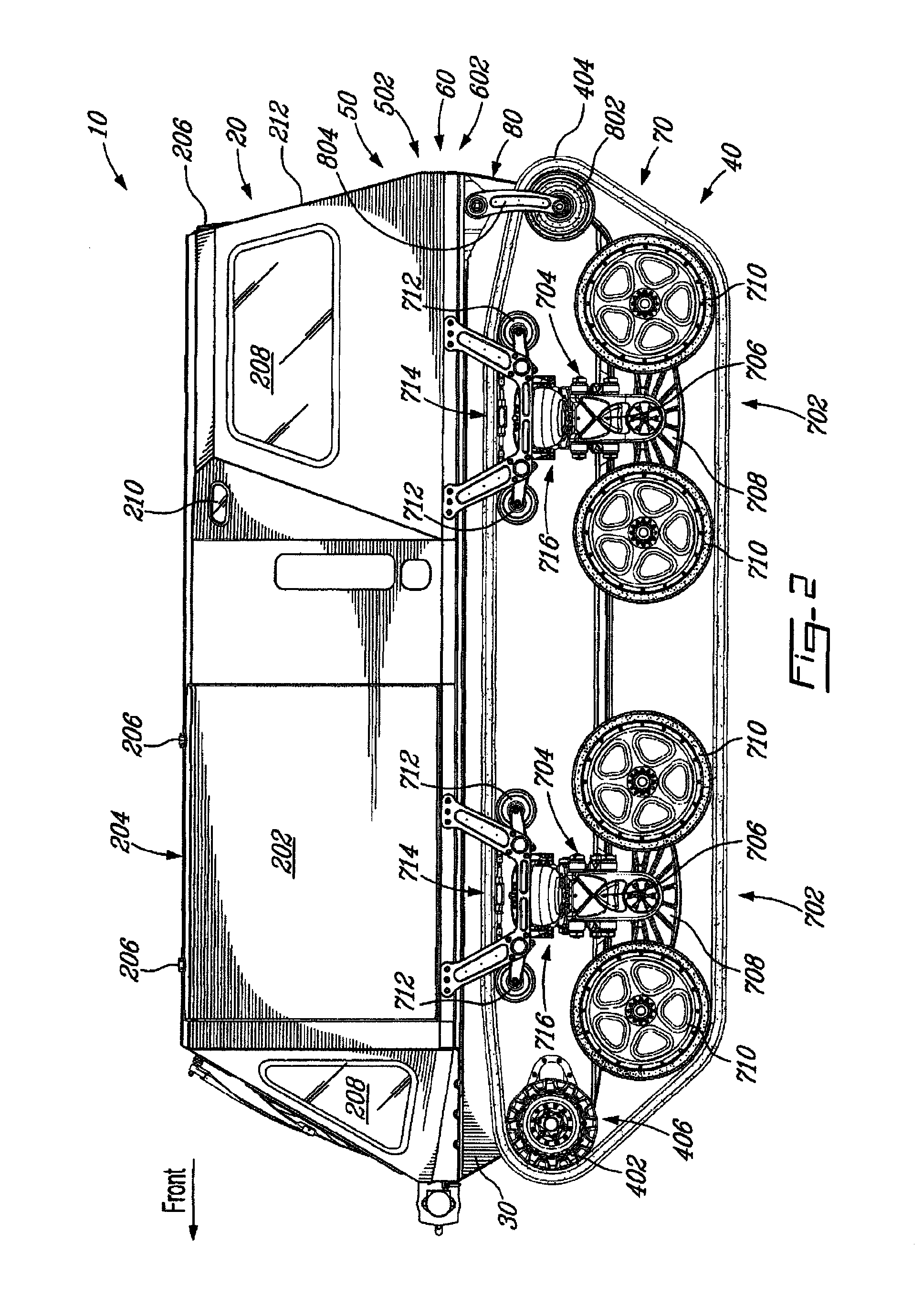

Double wishbones and double pivots vehicle suspension system

ActiveUS20120267866A1Operation positioning is accurateHigh suspension travelGearingResilient suspensionsVehicle suspension systemAutomotive engineering

A vehicle equipped with a double wishbones and double tandem members suspension system to suspend the vehicle, the double tandem members being operatively interconnected together and adapted to receive idling wheels adapted to support and guide an endless belt thereon to provide significant suspension travel and prevents an endless belt disengagement from the idling wheels. A suspension and a kit thereof are also provided.

Owner:LEQUIPE FABCONCEPT

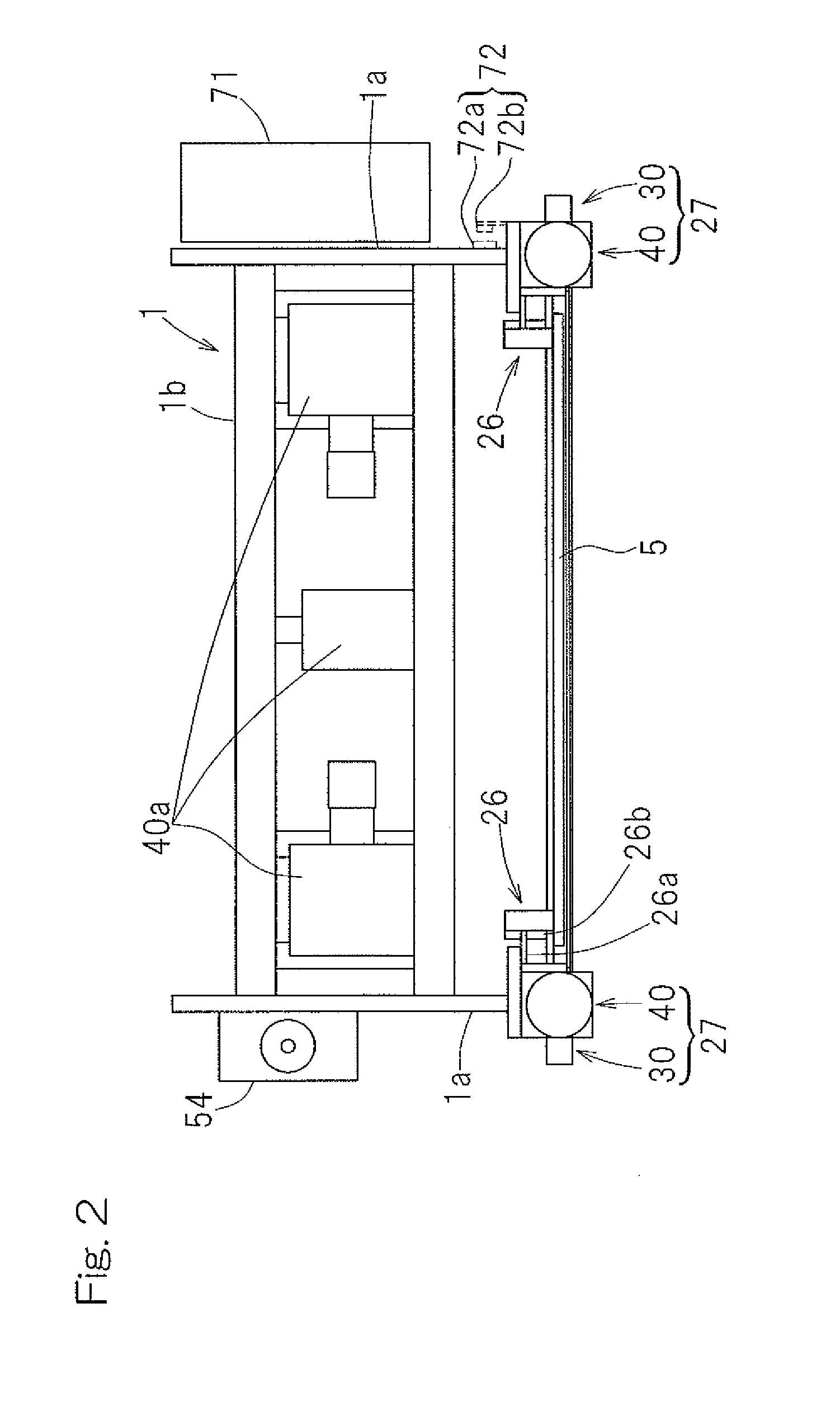

Press machine

ActiveUS9138794B2High speed and stabilized movementSolve large capacityPress ramMotor driveTop dead center

A press machine includes a lifting mechanism that selectively lowers and lifts a die on a movable side. The lifting mechanism includes a motor driven lifting unit using a servomotor as a drive source thereof, and a hydraulically driven lifting unit using a hydraulic actuator as a drive source thereof. The lifting mechanism is controlled so as to enable the motor driven lifting unit to move the die on the movable side from a standby position to a drive system changeover position immediately before a press start position at which the die on the movable side starts contacting a workpiece to be processed and so as to enable the hydraulically driven lifting unit to move the die on the movable side from the drive system changeover position to a top dead center position.

Owner:MURATA MASCH LTD

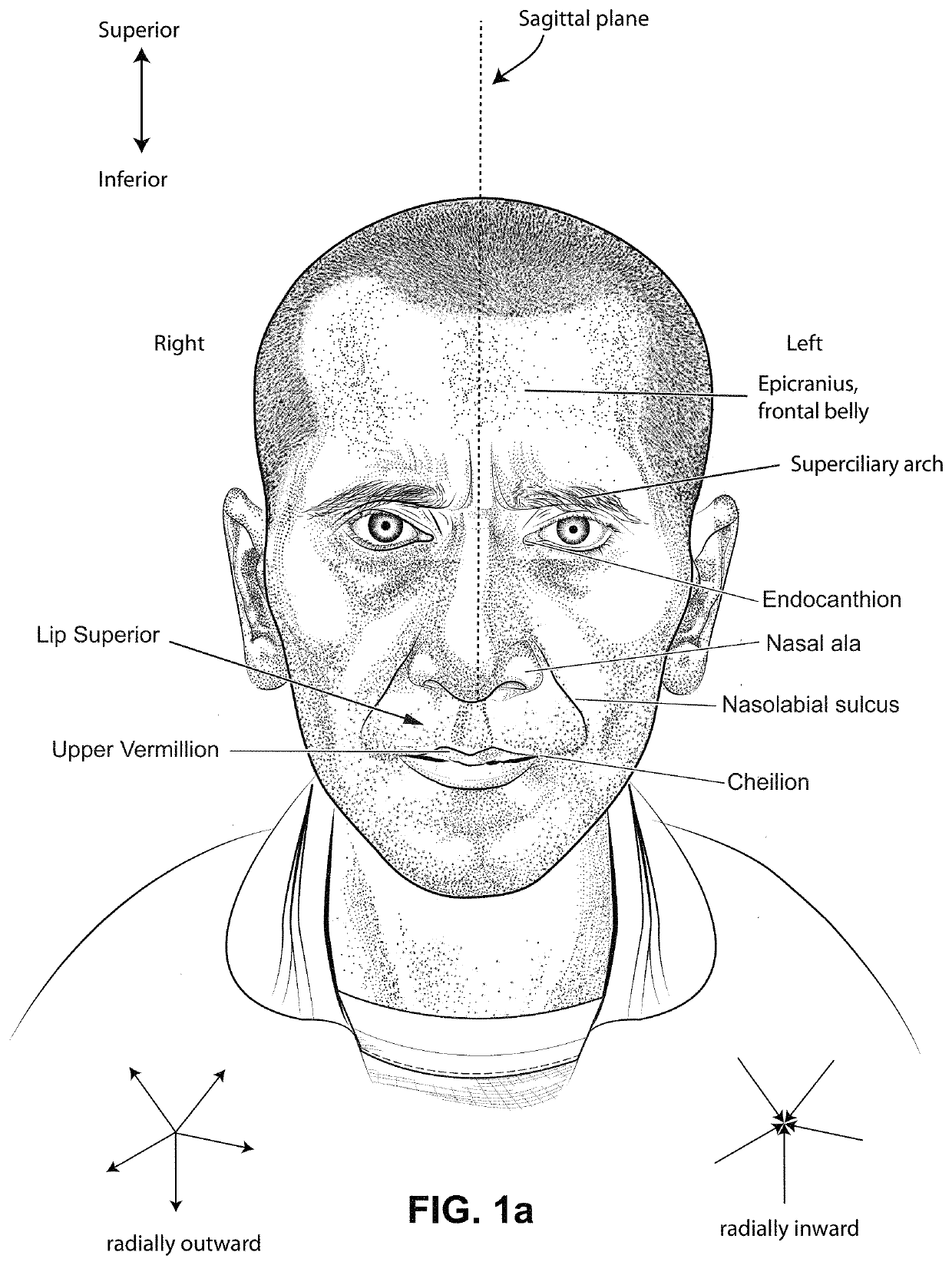

Positioning, stabilising, and interfacing structures and system incorporating same

ActiveUS20220026724A1Relieve pressureImproving user comfortInput/output for user-computer interactionDetails for portable computersComputer scienceMechanical engineering

A head-mounted display system includes a positioning and stabilising structure structured and arranged to hold a display unit in an operational position over a user's face in use and an interfacing structure for the display unit constructed and arranged to be in opposing relation with the user's face. The interfacing structure comprises a substantially continuous face engaging surface adapted to contact the user's face around a periphery of the user's eyes. The interfacing structure comprises silicone. The interfacing structure is configured and arranged such that force applied to the user's face is distributed around the periphery thereof. The interfacing structure comprises a first compliance at a first region and a second compliance at a second region, wherein the first region and the second region are configured around the periphery of the interfacing structure to allow selective distribution of the force onto the user's face.

Owner:RESMED LTD

Endless belt tensioner system and method of use thereof

ActiveUS20130119754A1Operation positioning is accurateWide travel suspensionPlungersGearingGround contactAutomotive engineering

An endless belt tensioner system adapted to dynamically apply a tensioning force on a ground-contacting endless belt of a vehicle is provided, the tensioning force being managed to prevent the endless belt to disengage from an operating configuration when the suspension is actuated. A vehicle and a method of use thereof are also provided.

Owner:LEQUIPE FABCONCEPT

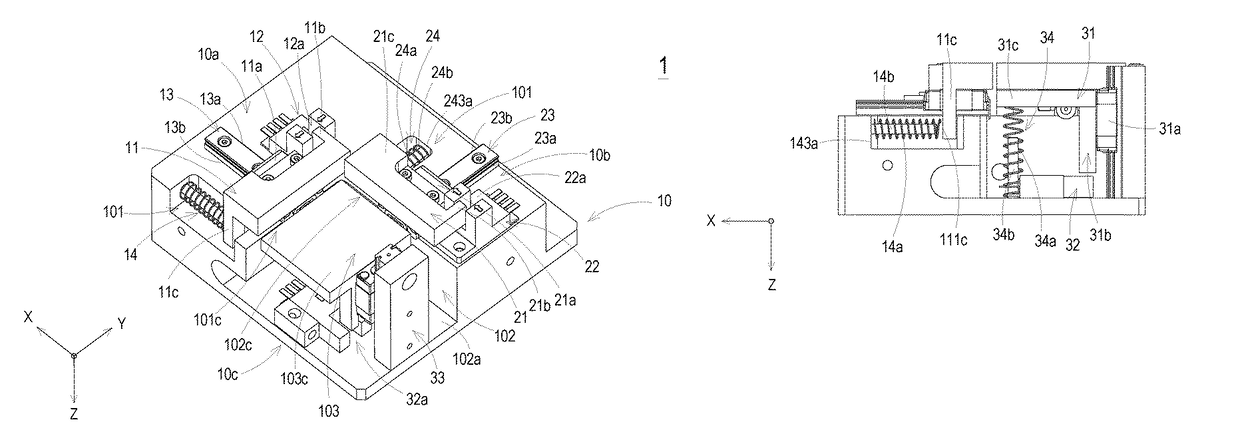

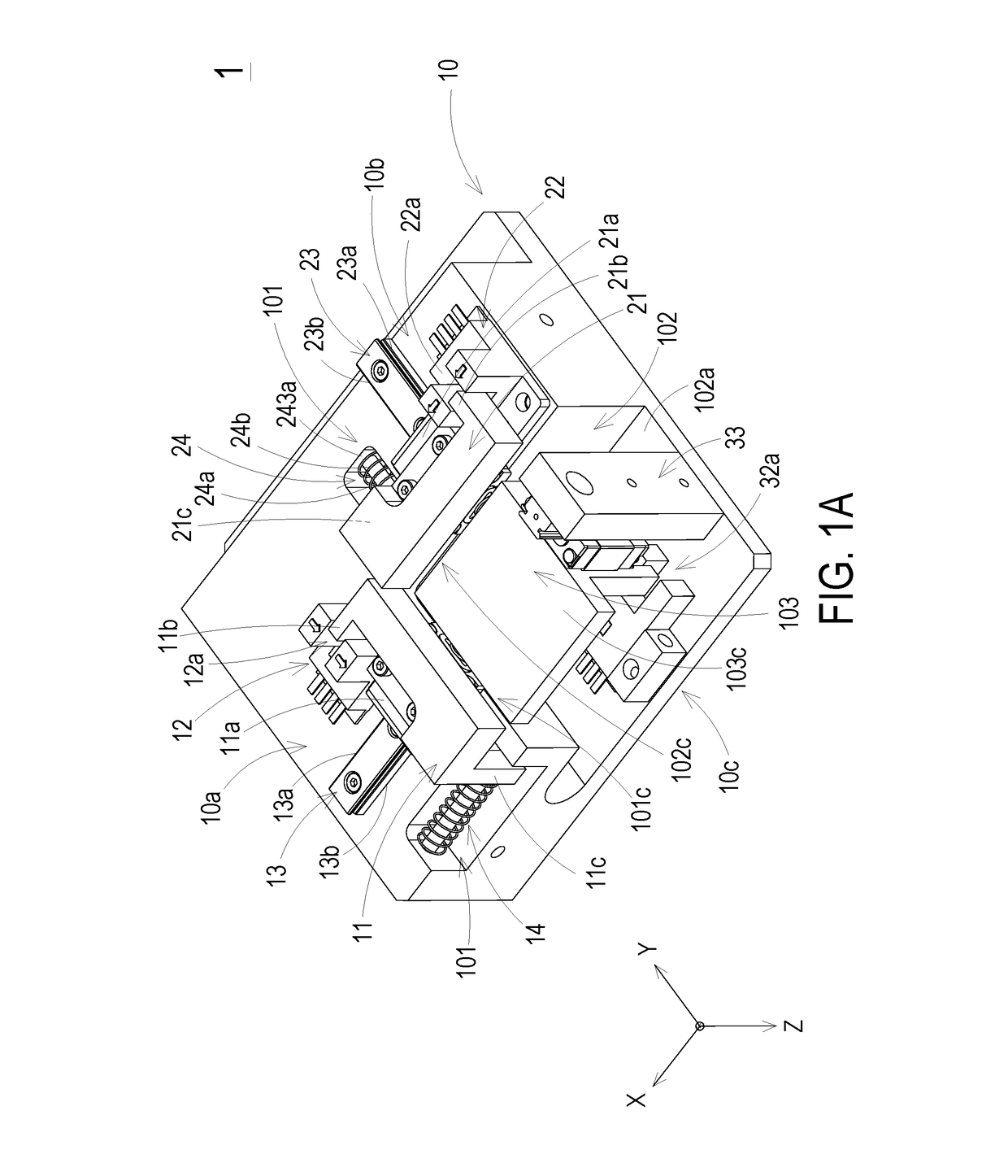

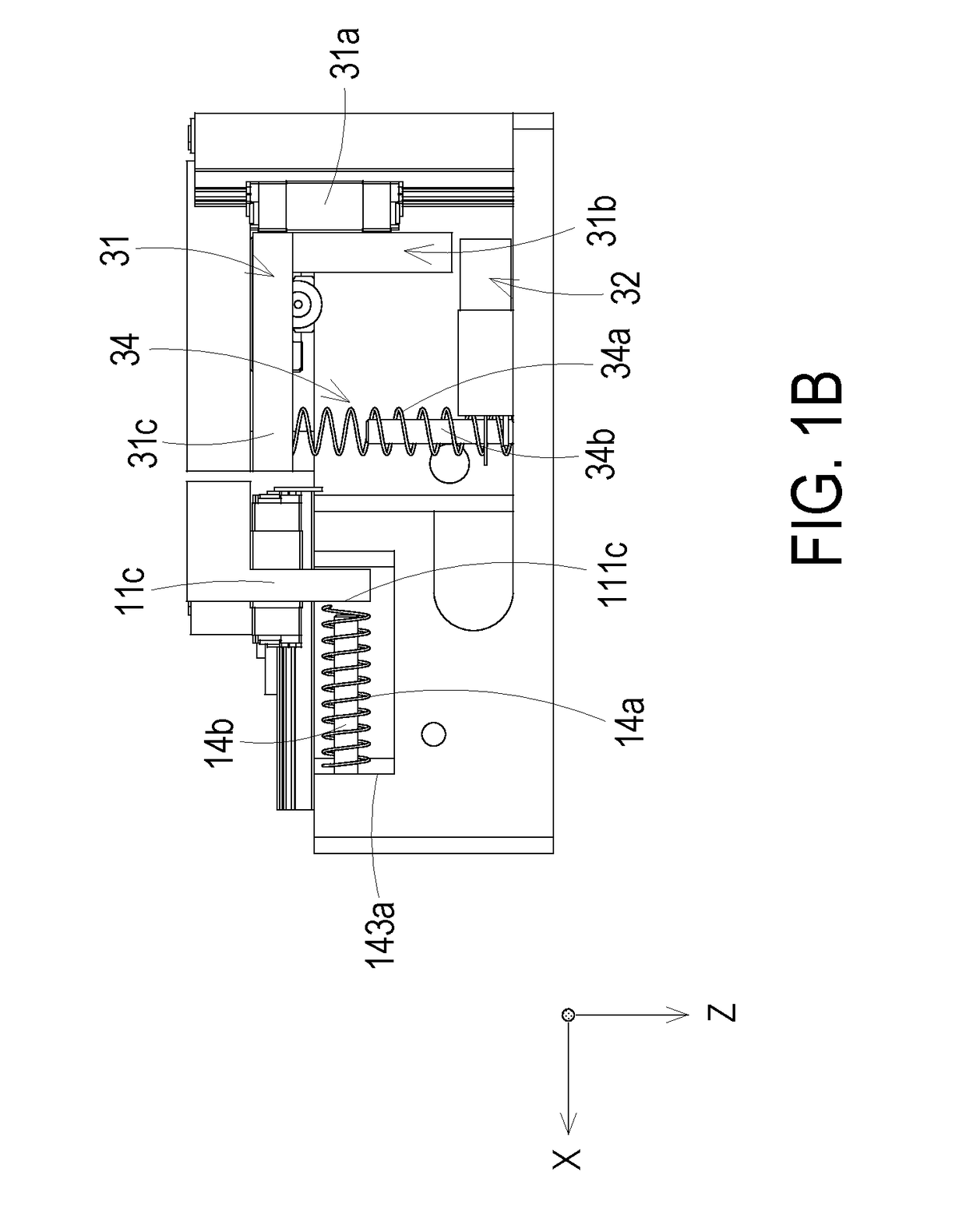

Tool calibration apparatus of robot manipulator

ActiveUS10065319B2Low costHigh precision calibrationProgramme controlProgramme-controlled manipulatorMeasurement deviceEngineering

A tool calibration apparatus for a robot manipulator having a tool is disclosed. The tool calibration apparatus comprises a base, an X-axis measurement device, a Y-axis measurement device and a Z-axis measurement device. Each of the X-axis measurement device, the Y-axis measurement device and the Z-axis measurement device comprises a measuring plate and a sensor. The measuring plates of the X-axis measurement device, the Y-axis measurement device and the Z-axis measurement device move in a direction along the X-axis, Y-axis, and Z-axis, respectively. The sensors of the X-axis measurement device, the Y-axis measurement device and the Z-axis measurement device measure a displacement of the corresponding measuring plate. According to the displacements, information of a tool center point of the tool is acquired so as to calibrate the tool center point.

Owner:DELTA ELECTRONICS INC

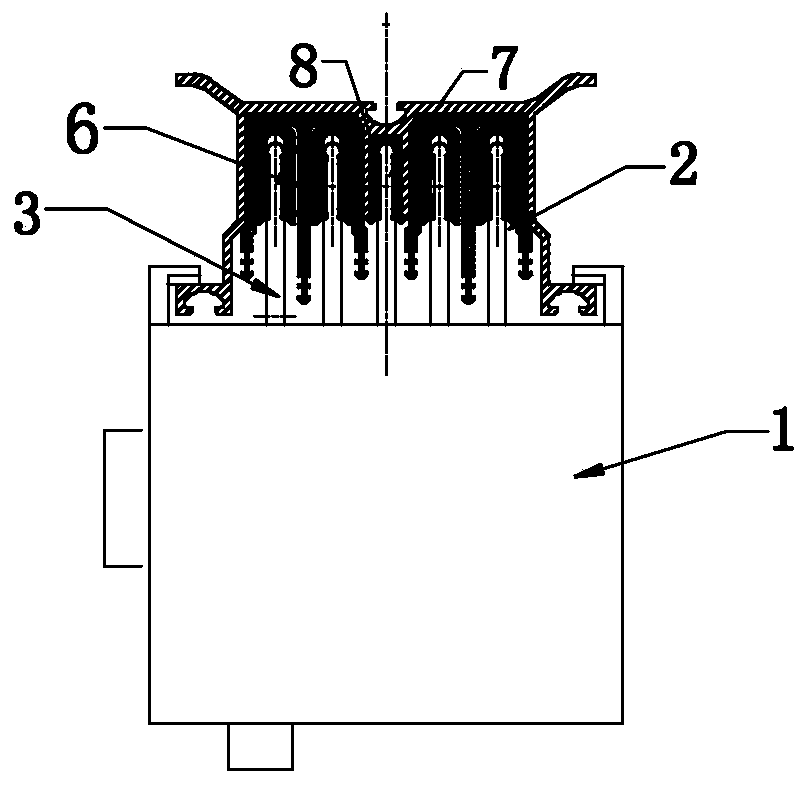

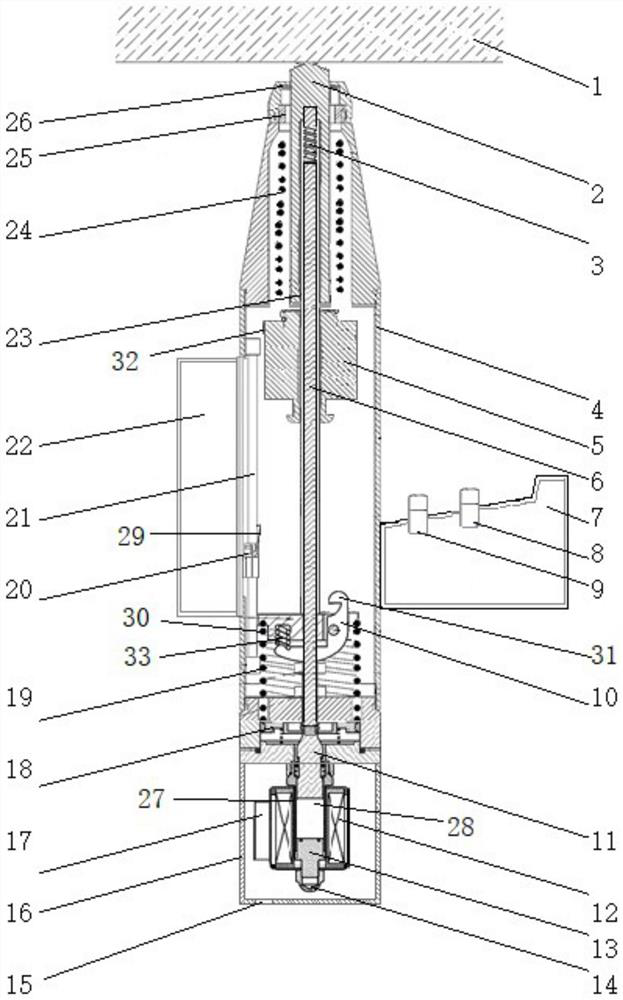

Electromagnetic power concrete quality detection resiliometer device

ActiveCN113670754AChange the shortcomings of labor-intensive operationOperation positioning is accurateInvestigating material hardnessStructural engineeringPower apparatus

The invention provides an electromagnetic power concrete quality detection resiliometer device. The electromagnetic power concrete quality detection resiliometer device comprises a shell, an electromagnetic power device and a resilience indicating value mechanism which are mounted in the shell, and a handle mounted outside the shell, the resilience indicating value mechanism comprises a resilience mechanism and an indicating value mechanism, and the electromagnetic power device comprises a coil, a fixed iron core, a movable iron core and an adjusting nut. When the coil of the fixed iron core is electrified, an electromagnetic effect is generated to attract the movable iron core, the pull rod is inserted into the central guide rod and connected with an elastic striking rod, and the pull rod drives the elastic striking rod and an elastic striking hammer to a test launching position when the movable iron core is attracted, so that quick return is realized. According to the electromagnetic power concrete quality detection resiliometer device, the elastic striking hammer is rapidly reset in an electromagnetic power mode, the function of continuously launching the elastic striking rod can be achieved, manual work is not completely relied on, the labor intensity of workers is reduced, and the apparatus is accurate in operation positioning and good in safety.

Owner:CHINA NAT CHEM ENG THIRD CONSTR +1

Endless belt tensioner system and method of use thereof

ActiveUS8371402B2Operation positioning is accurateWide travel suspensionEndless track vehiclesGround contactEngineering

An endless belt tensioner system adapted to apply a tensioning force on a ground-contacting endless belt of a vehicle is provided, the tensioning force being substantially proportional to an endless belt drive force applied to the endless belt to move the vehicle. A vehicle and a method about the same are also provided.

Owner:LEQUIPE FABCONCEPT

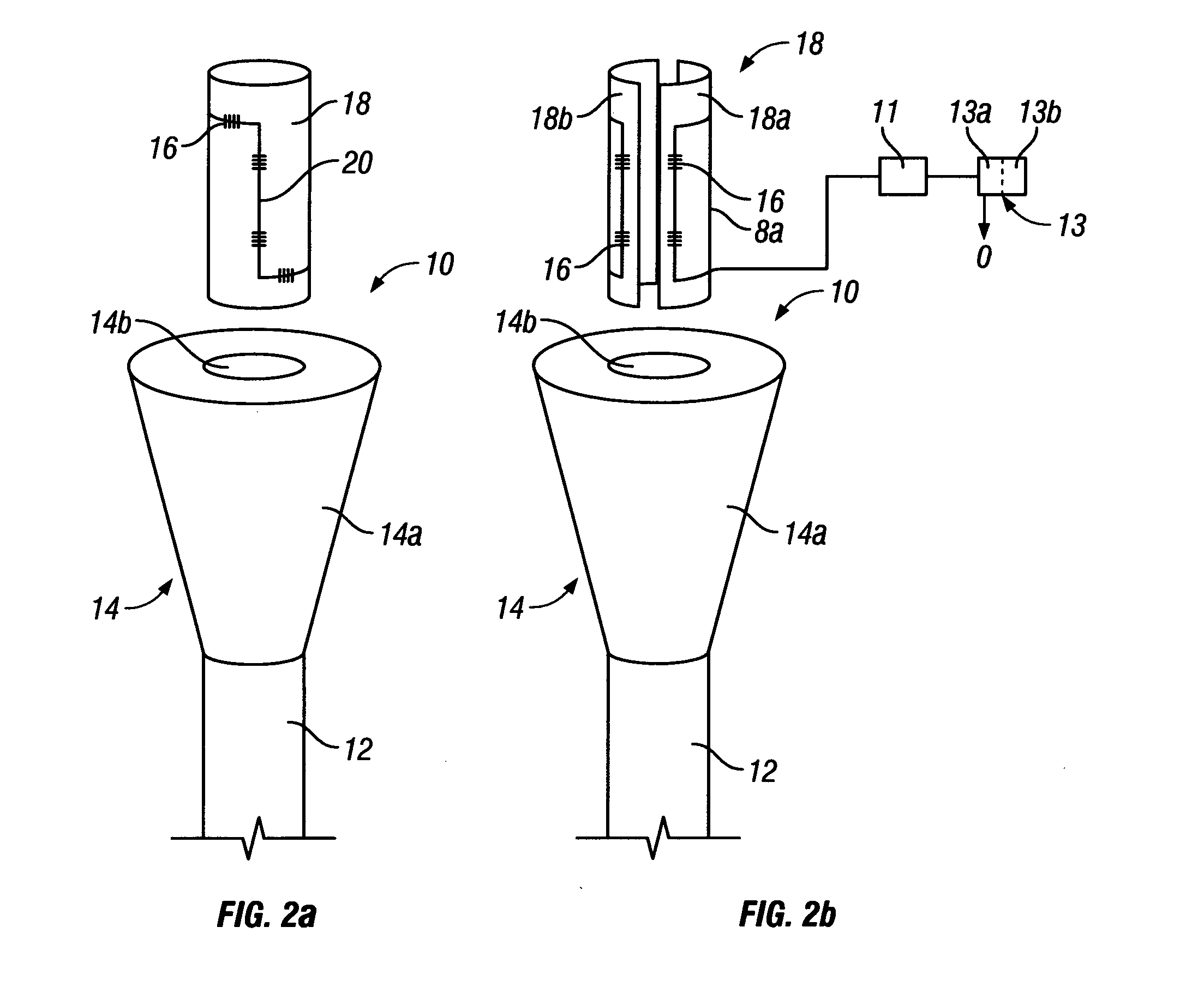

Monitoring sensor for metered amounts of powder

ActiveUS10801986B2Improve interchangeabilityPrevent movementWeighing apparatus using elastically-deformable membersSecuring devicesEngineeringMetered powder

A monitoring sensor for metered amounts of powder includes a sensor sleeve to channel the metered amount of powder through it and a sensor base body, in which the sensor sleeve is held interchangeably. A holding plate is attached to the interchangeable sensor sleeve. The sensor base body has a contact surface for the holding plate. The monitoring sensor includes a holding magnet for pressing the holding plate against the contact surface.

Owner:HARRO HOFLIGER VERPACKUNGSMASCHEN

Positioning and stabilising structure and system incorporating same

ActiveUS11262589B2Relieve pressureImprove the display effectOptical elementsMechanical engineeringPhysics

A head-mounted display system includes a head-mounted display unit and a positioning and stabilising structure structured and arranged to hold the head-mounted display unit in an operational position over a user's face in use. The positioning and stabilising structure includes a rear support structure adapted to contact posterior regions of a user's head and opposing temporal connectors structured and arranged to interconnect the rear support structure to the head-mounted display unit, the opposing temporal connectors adapted to be disposed on opposing sides of the user's head and extend along the temporal regions of the user's head. At least the rear support structure comprises a textile material configured to conform to the posterior regions of the user's head.

Owner:RESMED LTD

Aluminum foil film stripping machine

InactiveCN107471810AEasy to useOperation positioning is accurateLamination ancillary operationsLaminationEngineeringPlastic film

The invention discloses an aluminum foil film stripping machine. The stripping machine comprises an operation chamber, an oven, a composite mechanism, a delivery roller, a stripping table, a stripper, a stripping roller and an infrared sensor, wherein the oven is arranged at the top of the operation chamber; a drying chamber is formed in the upper part of the operation chamber; the composite mechanism is arranged on one side of the lower part in the operation chamber; the delivery roller is arranged on the other side of the lower part in the operation chamber; the stripping table is arranged outside the operation chamber; the stripper and the stripping roller are arranged on the stripping table; the infrared sensor is arranged on the stripper; and the delivery roller is connected with the stripping roller. According to the aluminum foil film stripping machine, a plastic film directly enters into the stripping machine and is stripped in the stage after being dried, so that the plastic film can be flatly rolled on the stripping roller and then can be used conveniently, the operation is accurately positioned, and the production efficiency is improved. The aluminum foil film stripping machine has small occupied space, good stripping effect and long service life, can save costs and is convenient to operate.

Owner:张家港爱铝铝箔科技有限公司

Positioning, stabilising, and interfacing structures and system incorporating same

ActiveUS11169384B2Relieve pressureImprove the display effectInput/output for user-computer interactionDetails for portable computersEngineeringComputer science

A head-mounted display system includes a positioning and stabilising structure structured and arranged to hold a display unit in an operational position over a user's face in use and an interfacing structure for the display unit constructed and arranged to be in opposing relation with the user's face. The interfacing structure comprises a substantially continuous face engaging surface adapted to contact the user's face around a periphery of the user's eyes. The interfacing structure comprises silicone. The interfacing structure is configured and arranged such that force applied to the user's face is distributed around the periphery thereof. The interfacing structure comprises a first compliance at a first region and a second compliance at a second region, wherein the first region and the second region are configured around the periphery of the interfacing structure to allow selective distribution of the force onto the user's face.

Owner:RESMED LTD

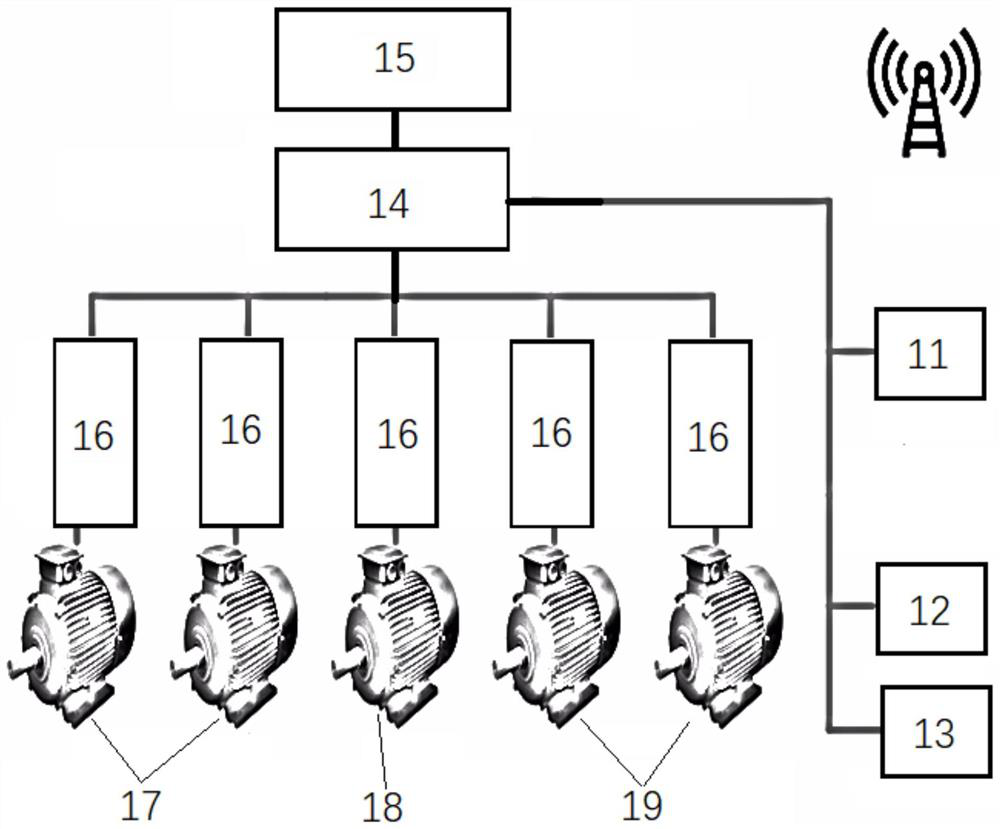

Travelling crane intelligent driving control system and method

PendingCN112645219AControl spendingImprove stabilityLoad-engaging elementsControl engineeringElectrical control

The invention discloses a travelling crane intelligent control system and method. The system comprises a hoisting mechanism, a trolley mechanism and a cart mechanism with a position positioning function, and a control mechanism. The control mechanism is independently arranged outside a travelling crane, and the control mechanism communicates with the hoisting mechanism, the trolley mechanism and the cart mechanism. The control mechanism judges the current height of the hoisting mechanism through positioning information and enables the hoisting mechanism to run to a preset height. After the hoisting mechanism runs to the preset height, the control mechanism controls the trolley mechanism and the cart mechanism to run to preset positions. The control mechanism controls the heights and positions of the lifting mechanism, the trolley mechanism and the cart mechanism at the same time to complete transportation operation. According to the travelling crane intelligent driving control system and method, wireless network communication is introduced into the travelling crane system, the travelling crane intelligent control function is achieved through electrical control, and the positioning precision of all mechanisms of the travelling crane is guaranteed through the high-precision positioning system.

Owner:SHANGHAI ZPMC ELECTRIC +1

Device for providing connection elements

ActiveUS8763853B2Avoid disadvantagesLow production costStapling toolsCoin-freed apparatus detailsEngineeringStorage cell

A device for providing connection elements, such as rivets and the like has a storage unit with at least one outlet, two stacked, replaceable cartridges each having at least one output flange for dispensing connection elements, and a cartridge guide and a detachable cartridge lock assigned to each cartridge which for its installation is slideable via the cartridge guide to an operating position and fixable by the cartridge lock assigned to the cartridge guide and engaged with the cartridge for locking.

Owner:BROETJE AUTOMATION

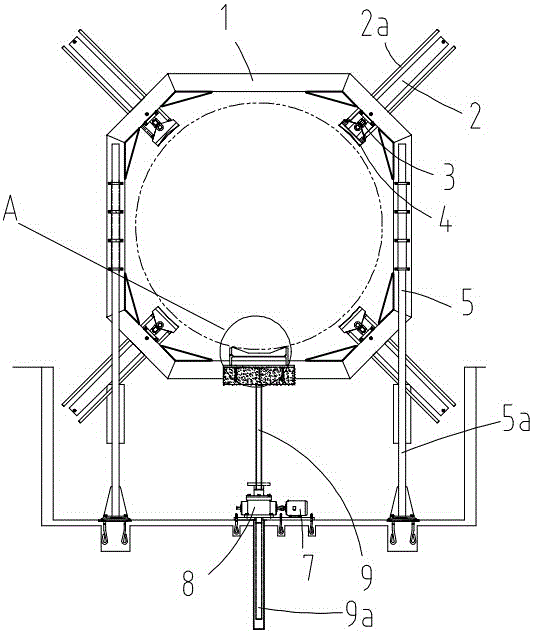

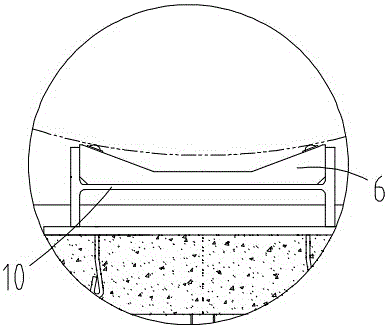

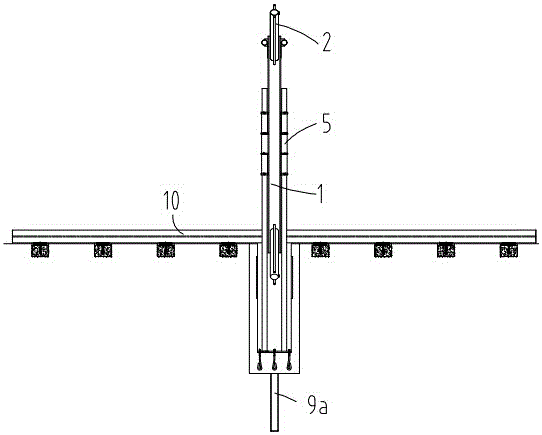

Pressure vessel cylinder body pairing machine and its use method

ActiveCN104353963BSmall sizeAvoid scratchesWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPiston rod

The invention discloses a barrel assembling machine for a pressure container and an application method of the barrel assembling machine. The barrel assembling machine comprises an assembling machine frame, wherein I-beams are arranged on the left side and the right side of the assembling machine frame; a plurality of barrel assembling devices which are symmetrically arranged on the assembling machine frame; each barrel assembling device comprises an oilcylinder, a lug base and a pressure plate; the oil cylinders are hinged to the pressure plate through the lug bases; a piston rod of each oil cylinder is capable of pushing the corresponding pressure plate to the center of the assembling machine frame; each pressure plate is a V-shaped plate with a concave middle; the V-shaped plates face the center of the assembling machine frame; the assembling machine frame is also provided with a lifting device; the lifting device comprises a motor, an elevator, a screw rod and a frame guide post; the frame guide post is fixedly arranged; the motor is connected with the elevator; one end of the screw rod is connected with the elevator and the other end of the screw rod is propped against the assembling machine frame; the elevator can control the screw rod to vertically displace under the drive of the motor; the assembling machine frame can be vertically arranged on a limiting rod in a sliding manner. The barrel assembling machine has the advantages of being convenient to assemble, high in efficiency and low in work difficulty, and is capable of ensuring the assembling accuracy.

Owner:南京宝泰特种材料股份有限公司

Monitoring sensor for metered amounts of powder

ActiveUS20190219533A1Easily removePrecise operationWeighing apparatus using elastically-deformable membersSecuring devicesMagnetEngineering

A monitoring sensor for metered amounts of powder includes a sensor socket to channel the metered amount of powder through it and a sensor base body, in which the sensor socket is held interchangeably. A holding plate is attached to the interchangeable sensor socket. The sensor base body has a contact surface for the holding plate. The monitoring sensor includes a holding magnet for pressing the holding plate against the contact surface.

Owner:HARRO HOFLIGER VERPACKUNGSMASCHEN

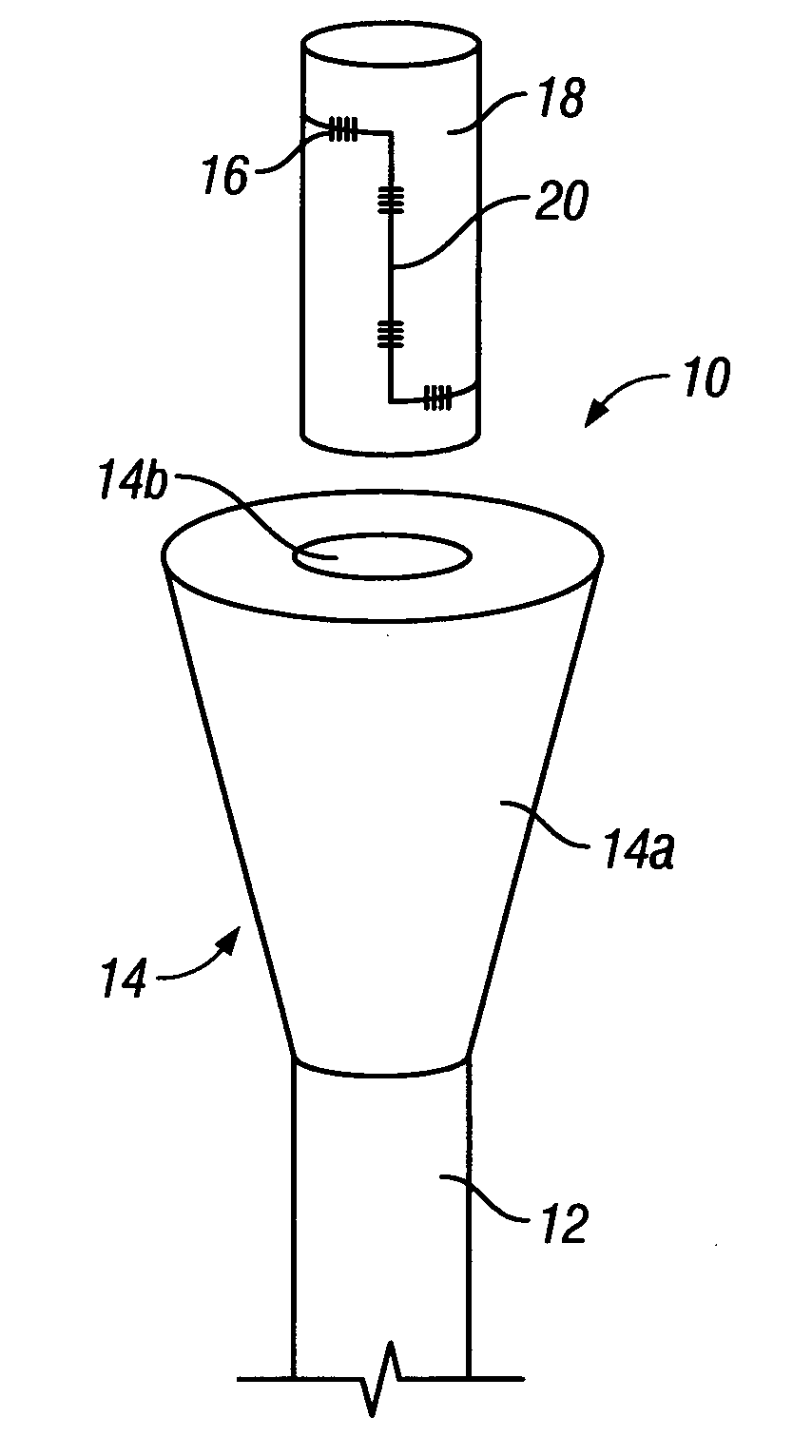

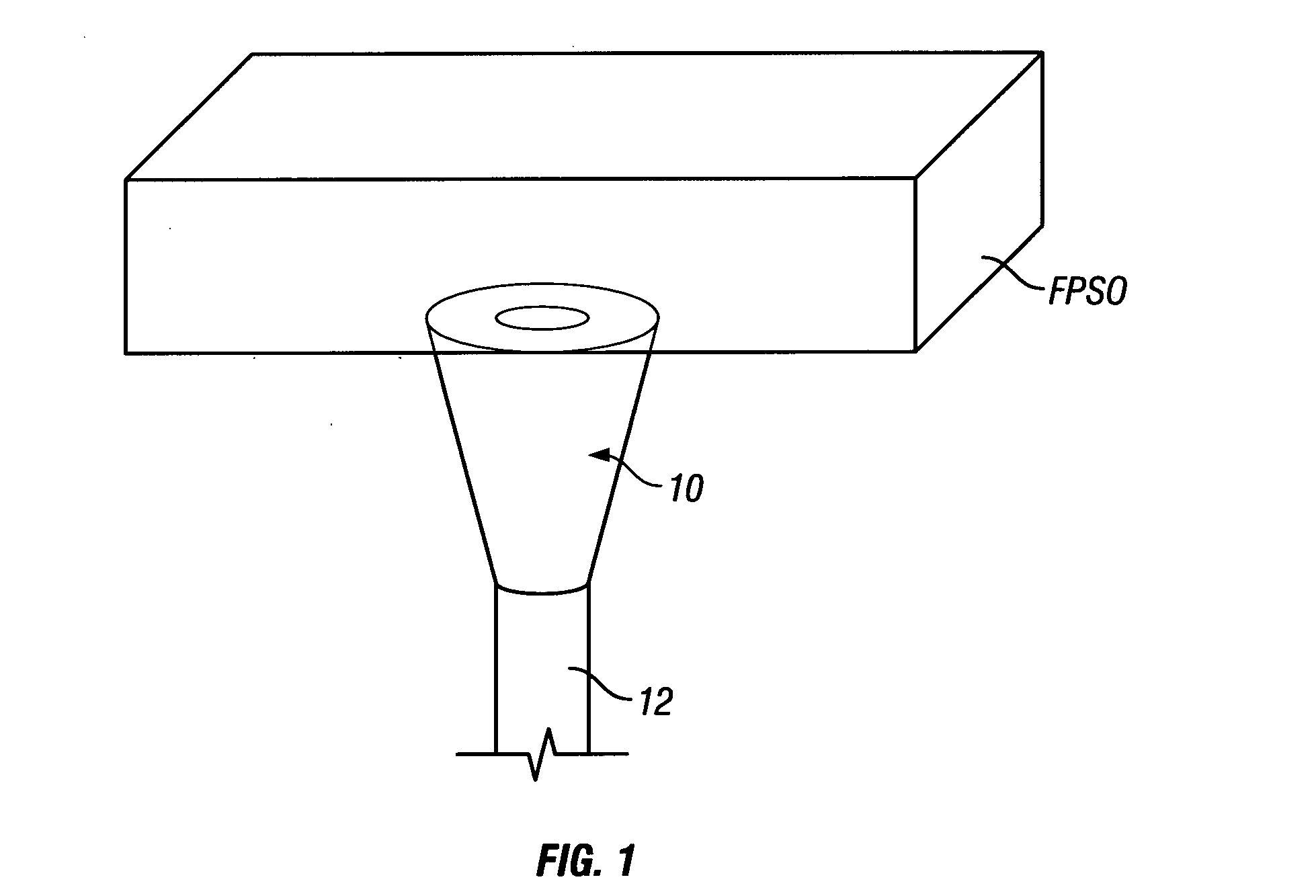

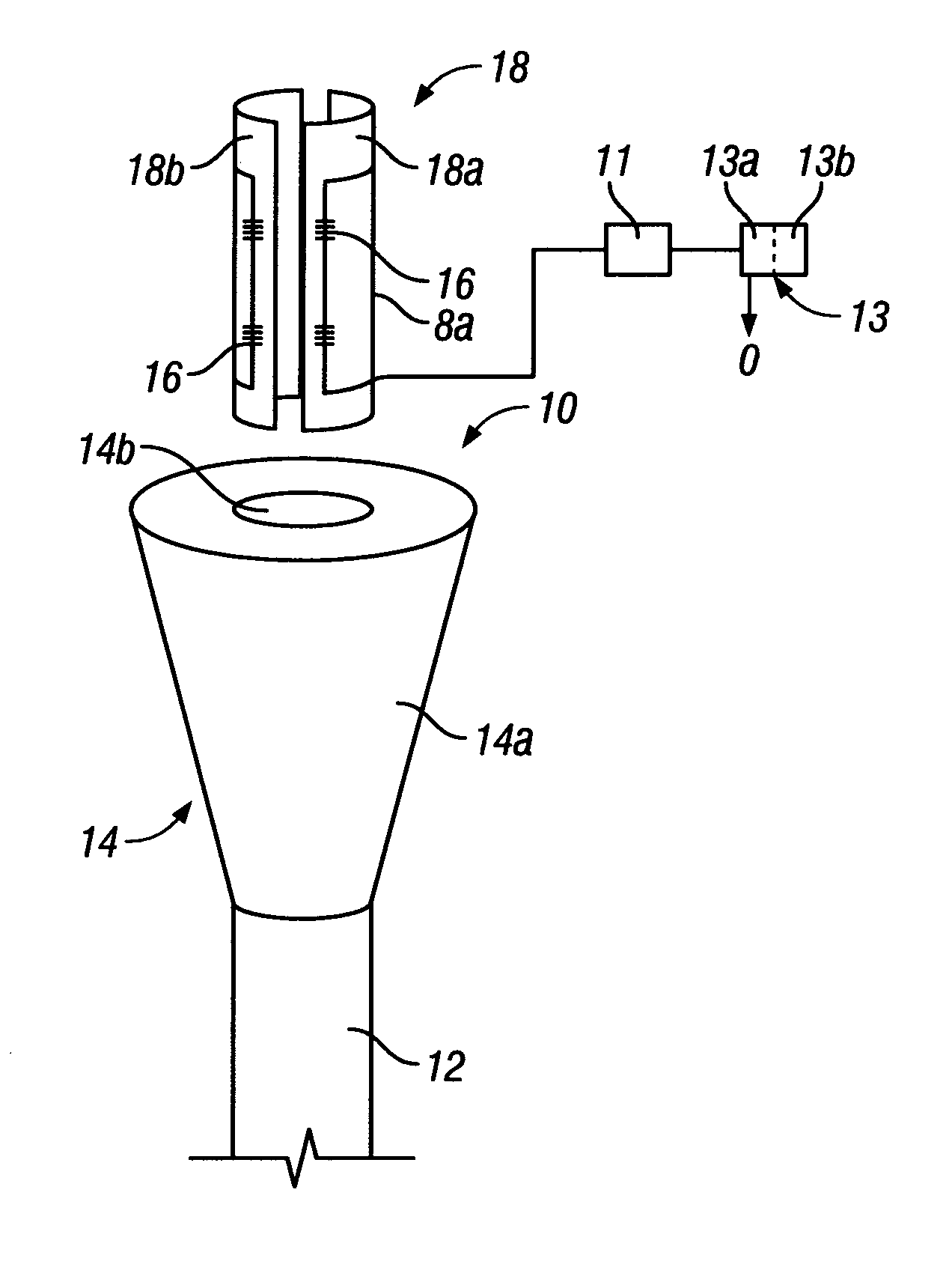

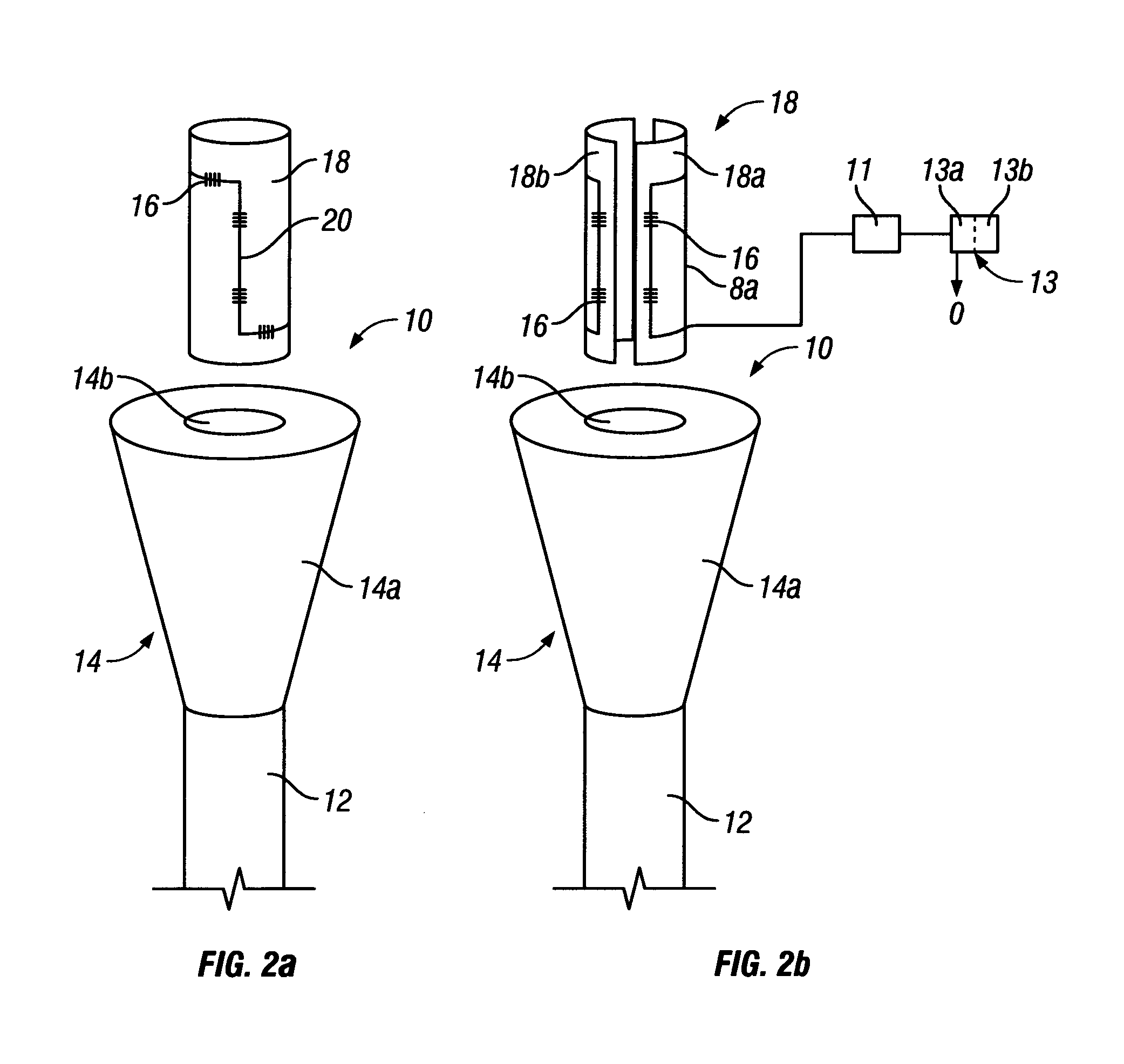

Flexible pipe terminal end-attachment device

ActiveUS9404609B2Reduce difficultyOperation positioning is accurateDrilling rodsConstructionsEngineeringStrain sensor

A terminal end-attachment device (10) for a flexible pipe (12) comprising an attachment body (14) adapted to receive a terminal end of a flexible pipe (12) and to couple the said flexible pipe to a hydrocarbon production installation structure. The device (10) further comprising a strain sensor (16) coupled to a sensor carrier (18), at least part of the sensor carrier (18) and the strain sensor (16) being at least partially incorporated within the attachment body (14). A method of manufacturing a terminal end-attachment device (10) for a flexible pipe (12) is also provided.

Owner:ONESUBSEA L L C

Positioning and stabilising structure and system incorporating same

ActiveUS11243405B2Relieve pressureImprove the display effectOptical elementsPhysical medicine and rehabilitationNeck muscle

A head-mounted display system includes a head-mounted display unit and a positioning and stabilising structure structured and arranged to hold the head-mounted display unit in an operational position over a user's face in use. The positioning and stabilising structure includes a rear support structure adapted to contact posterior regions of a user's head and at least one connector structured and arranged to interconnect the rear support structure to the head-mounted display unit. The rear support structure is in the form of a hoop comprising an occipital portion configured and arranged engage the user's head along a portion of the occipital bone adjacent a junction where the neck muscles attach to the occipital bone in use.

Owner:RESMED LTD

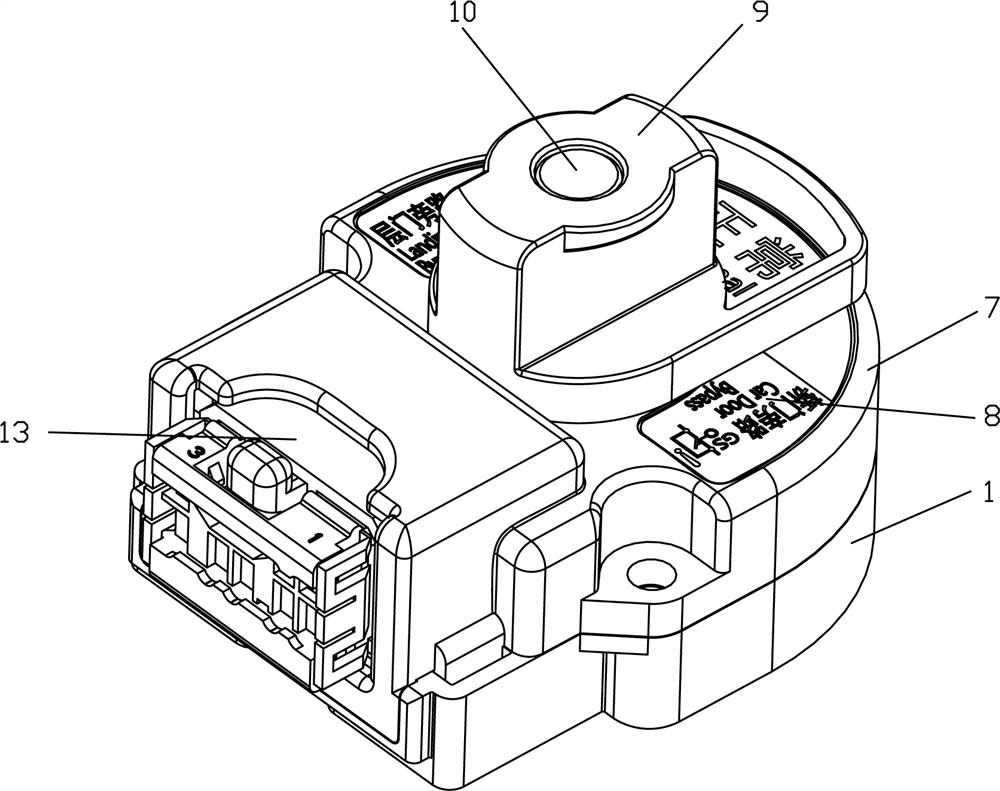

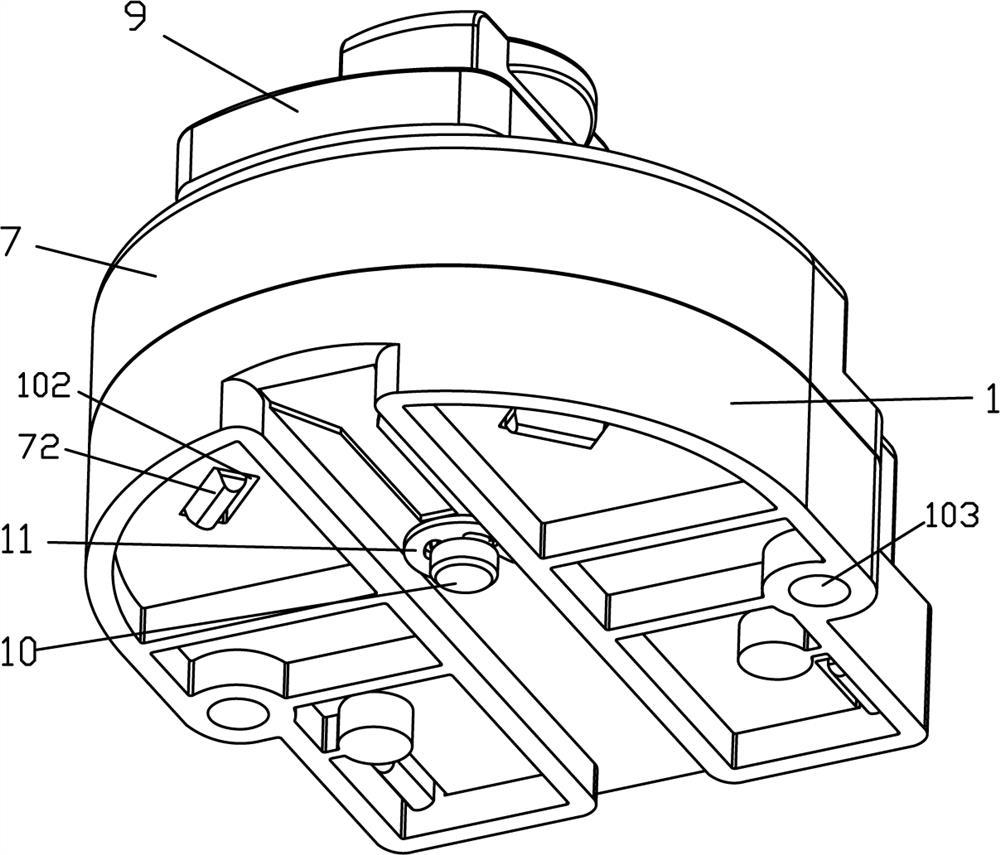

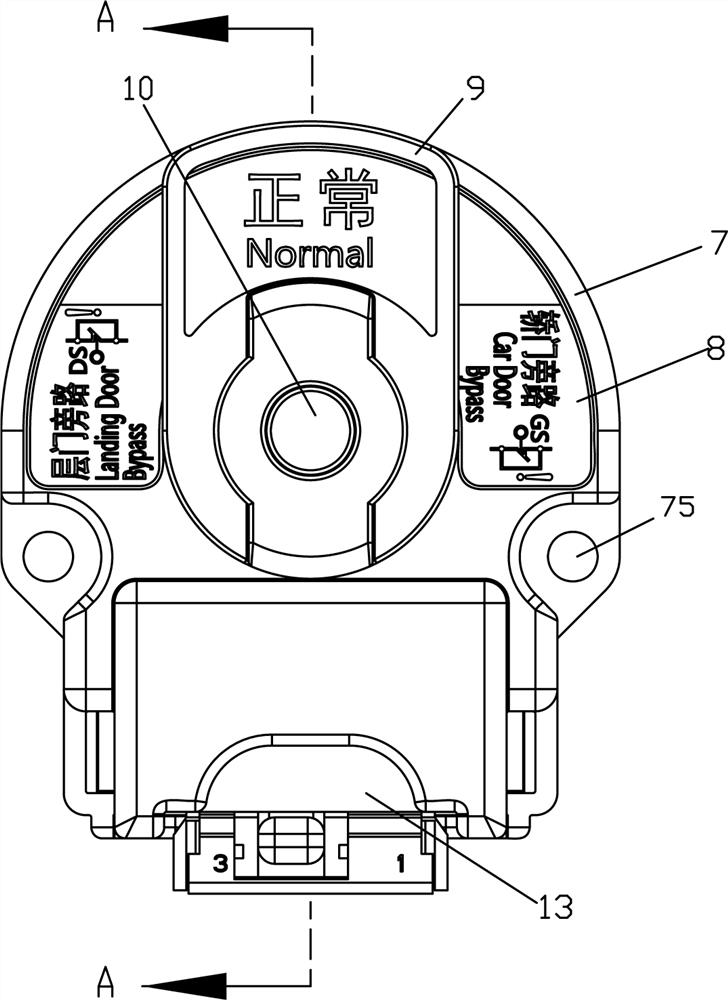

Elevator bypass contact protection device

PendingCN114758917AOperation positioning is accurateEasy to operate and locateContact operating partsElevatorsEngineeringStructural engineering

An elevator bypass contact protection device comprises a base; the circuit board is arranged in the base; the welding pin terminal seat is arranged above the front part of the circuit board and is provided with three fixed blocks which are arranged in a shape like a Chinese character'pin ', and the rear end surfaces of the three fixed blocks are encircled to form a central accommodating groove; the six welding pin terminals are respectively arranged on the welding pin terminal seats; the three pairs of conductive assemblies are respectively arranged in the three fixing blocks on the welding pin terminal seat bottom plate; the adjusting wheel is arranged in the central accommodating groove; the rotating shaft is arranged in the adjusting wheel; the upper cover covers the welding pin terminal seat, and a positioning column is convexly arranged on one side of the top surface of the upper cover; the knob is arranged on the top surface of the upper cover, and three positioning holes matched with the positioning columns are formed in the rear part of the bottom surface of the knob at 90-degree intervals; and the electric connector is arranged at the rear part of the upper end surface of the circuit board. The knob lifting design is combined with the positioning structure, so that the knob is more accurate and convenient to operate and position, meanwhile, the structure is simple, the assembly process is simplified and improved, the working time is shortened, and the cost is reduced.

Owner:SHANGHAI HOPPY ELECTRONICS ELECTRIC APPLIANCE +2

Positioning and stabilising structure and system incorporating same

A head-mounted display system includes a head-mounted display unit and a positioning and stabilising structure structured and arranged to hold the head-mounted display unit in an operational position over a user's face in use. The positioning and stabilising structure includes a rear support structure adapted to contact posterior regions of a user's head and a forehead support connector, which includes a forehead support strap, which extends generally along and in the direction of the sagittal plane and connects the rear support structure to a superior edge region of the head-mounted display unit. The forehead support connector further includes a forehead support rigidiser that provides rigidification to a portion of the forehead support connector.

Owner:RESMED LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com