Pressure vessel cylinder body pairing machine and its use method

A pressure vessel and matching technology, which is applied in the field of pressure vessel barrel matching machines, can solve the problems of affecting the appearance quality of pressure vessel welding, difficult operation, poor safety, etc., to increase the range of matching barrels, simplify operations, The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

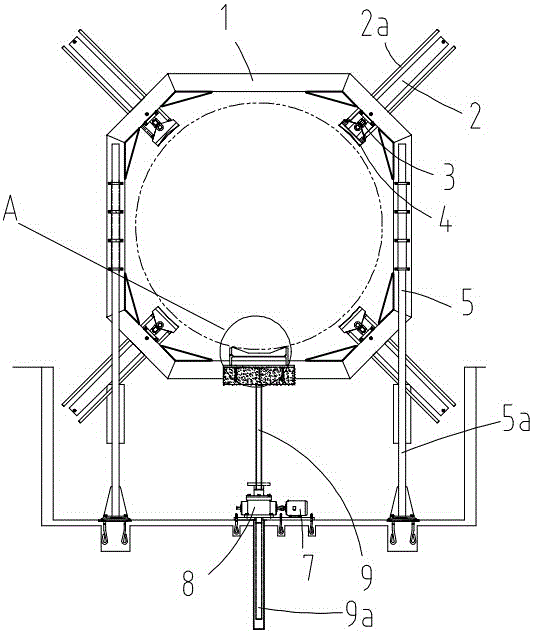

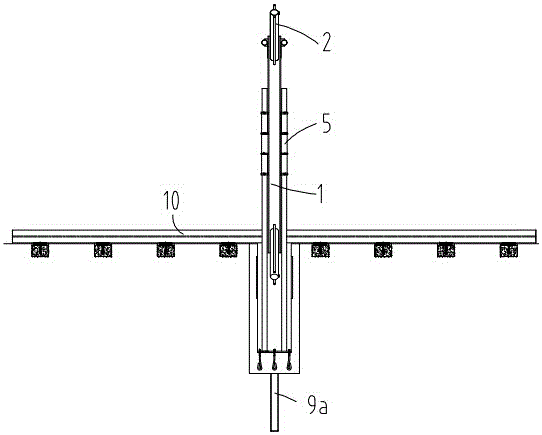

[0028] Figure 1 to Figure 5 Shown is the structural representation of the present invention.

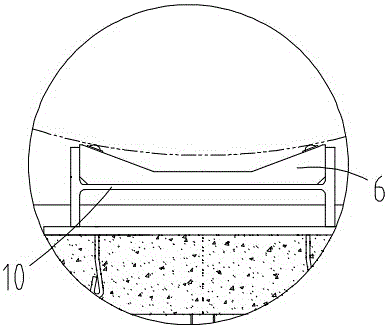

[0029] The reference signs therein are: assembly machine frame 1, oil cylinder 2, oil cylinder guide column 2a, ear seat 3, connecting pin 3a, pressure plate 4, frame guide column 5, limit rod 5a, roller bracket 6, motor 7, Elevator 8, screw mandrel 9, embedded sleeve 9a, I-beam 10.

[0030] Such as Figure 1 to Figure 5 As shown, the pressure vessel cylinder assembling machine of the present invention includes a assembling machine frame 1, and the left and right sides of the assembling machine frame 1 are provided with I-beams 10, and the two pressure vessel cylinders that need to be docked are placed on the two sides respectively. On the I-beam 10 on the side, the docking interface is located in the frame 1 of the pairing machine. It is characte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com