Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Lower specific pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

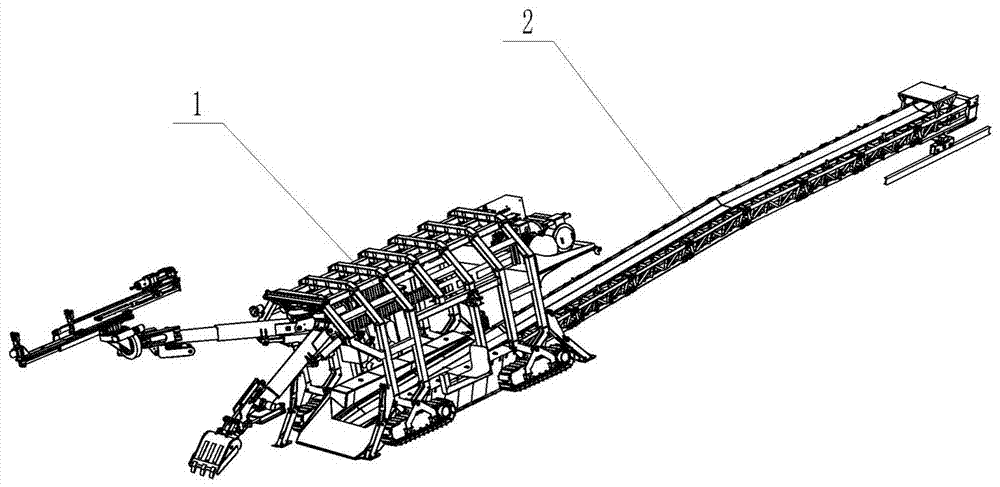

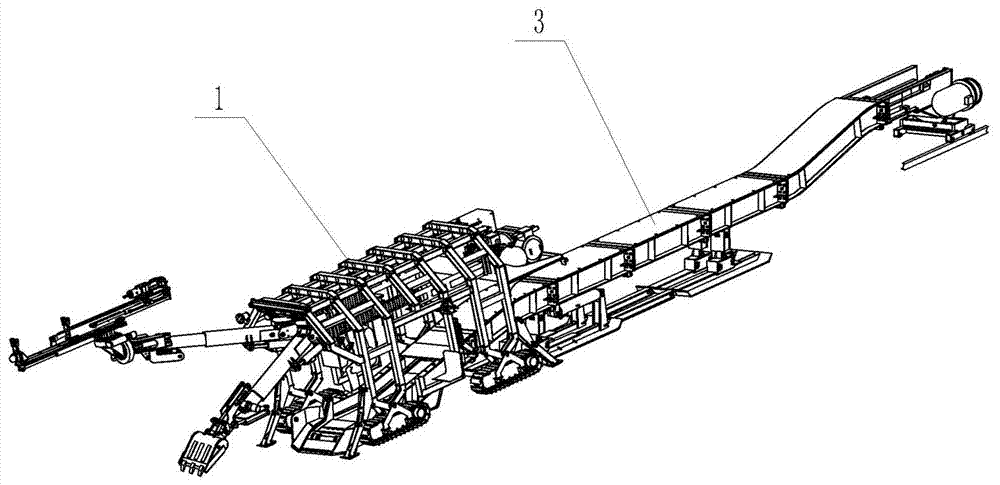

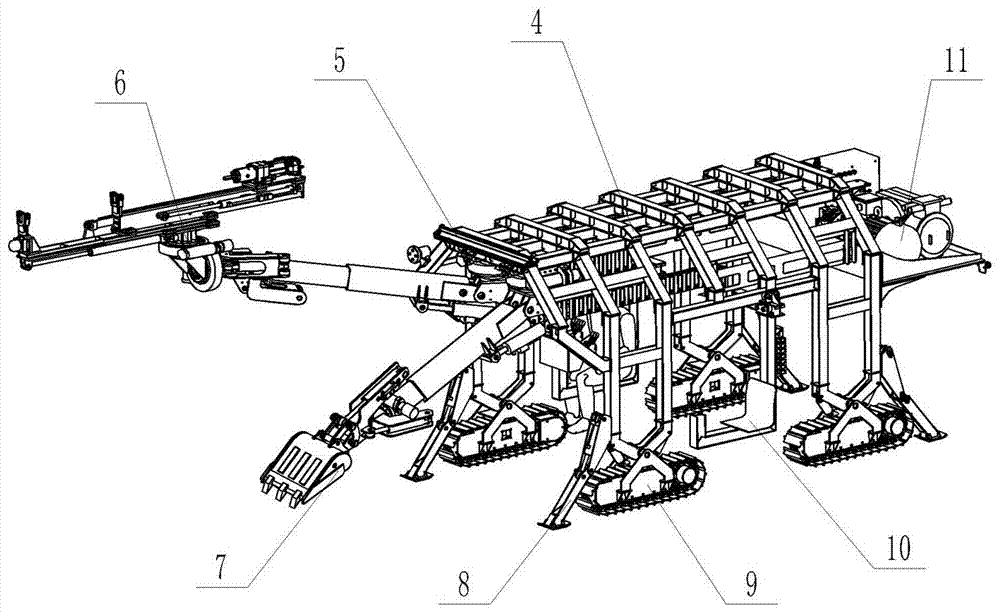

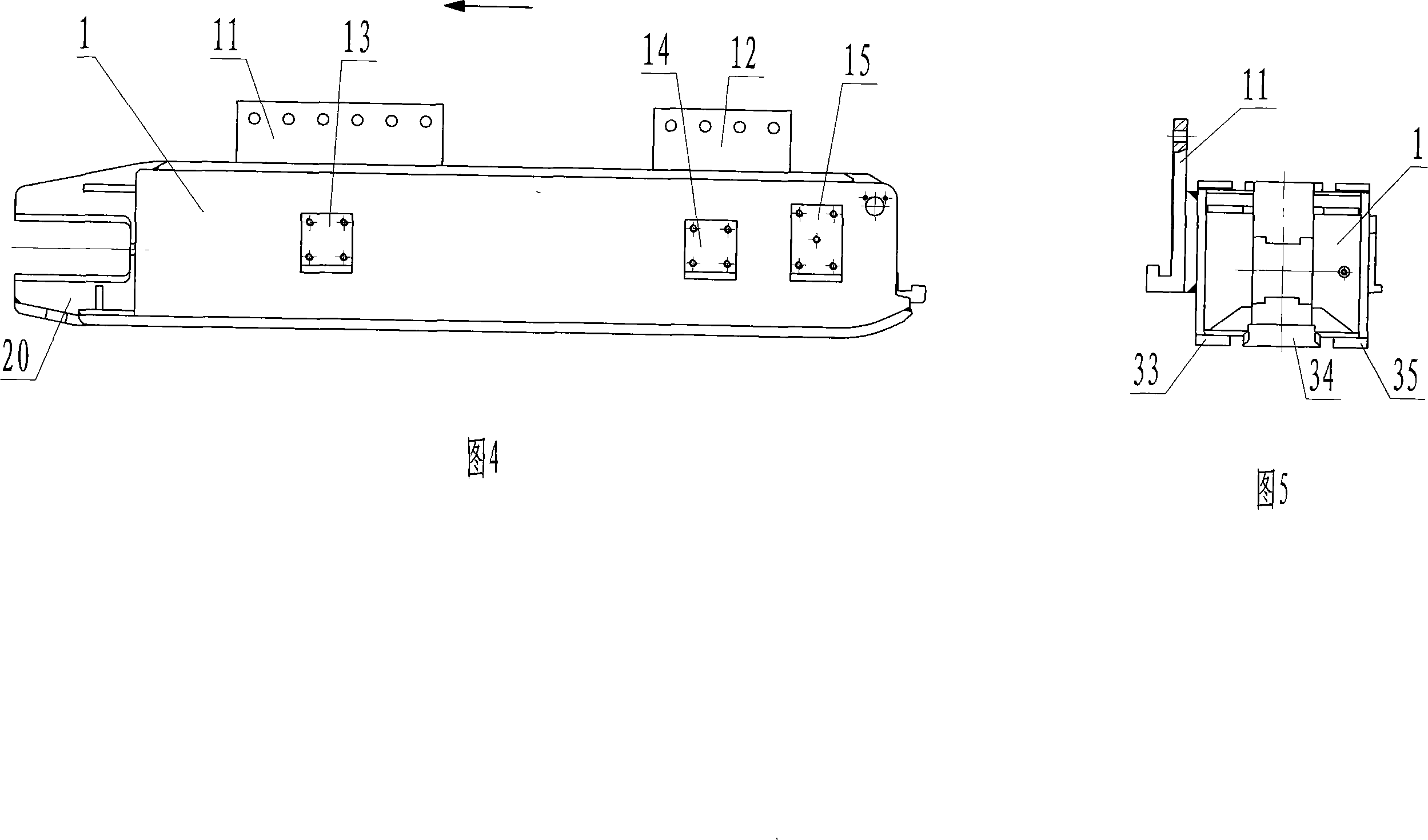

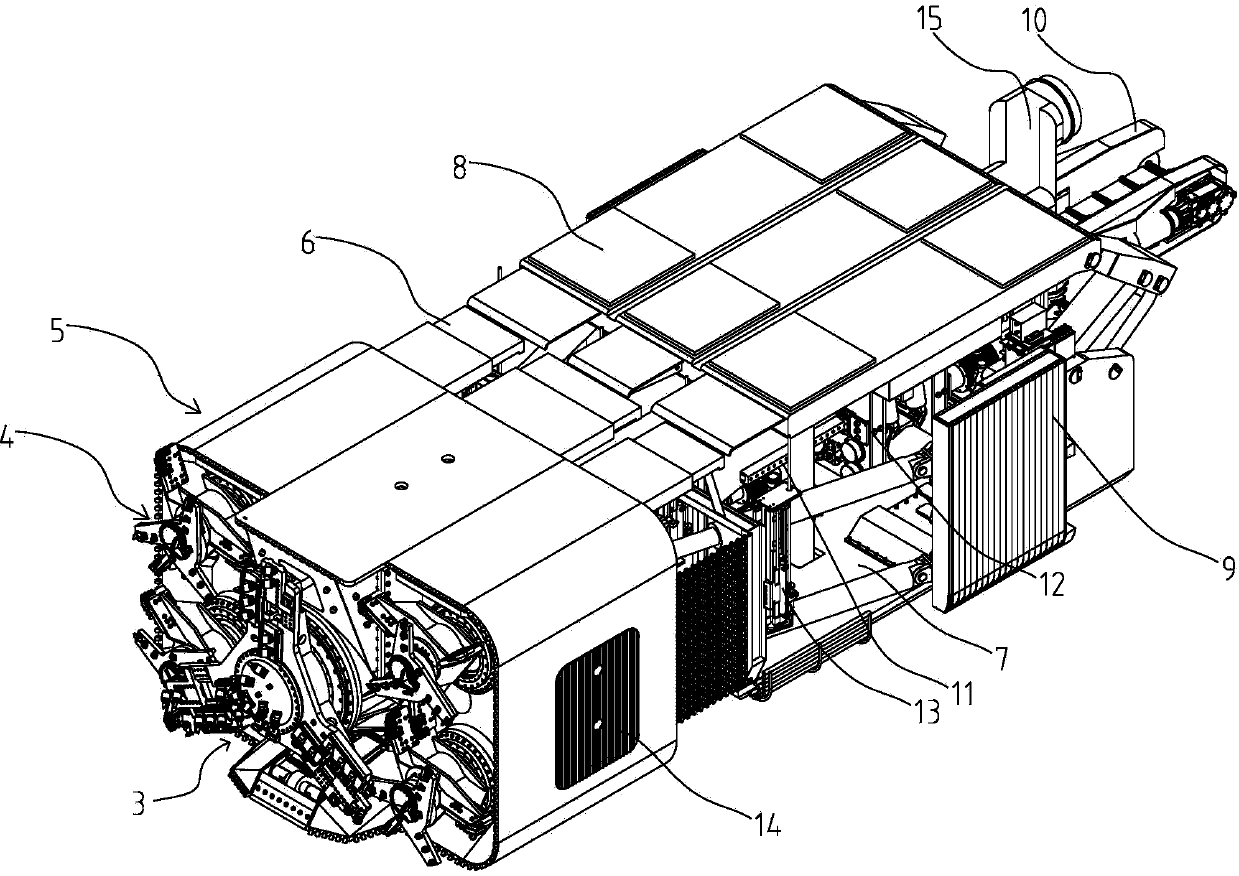

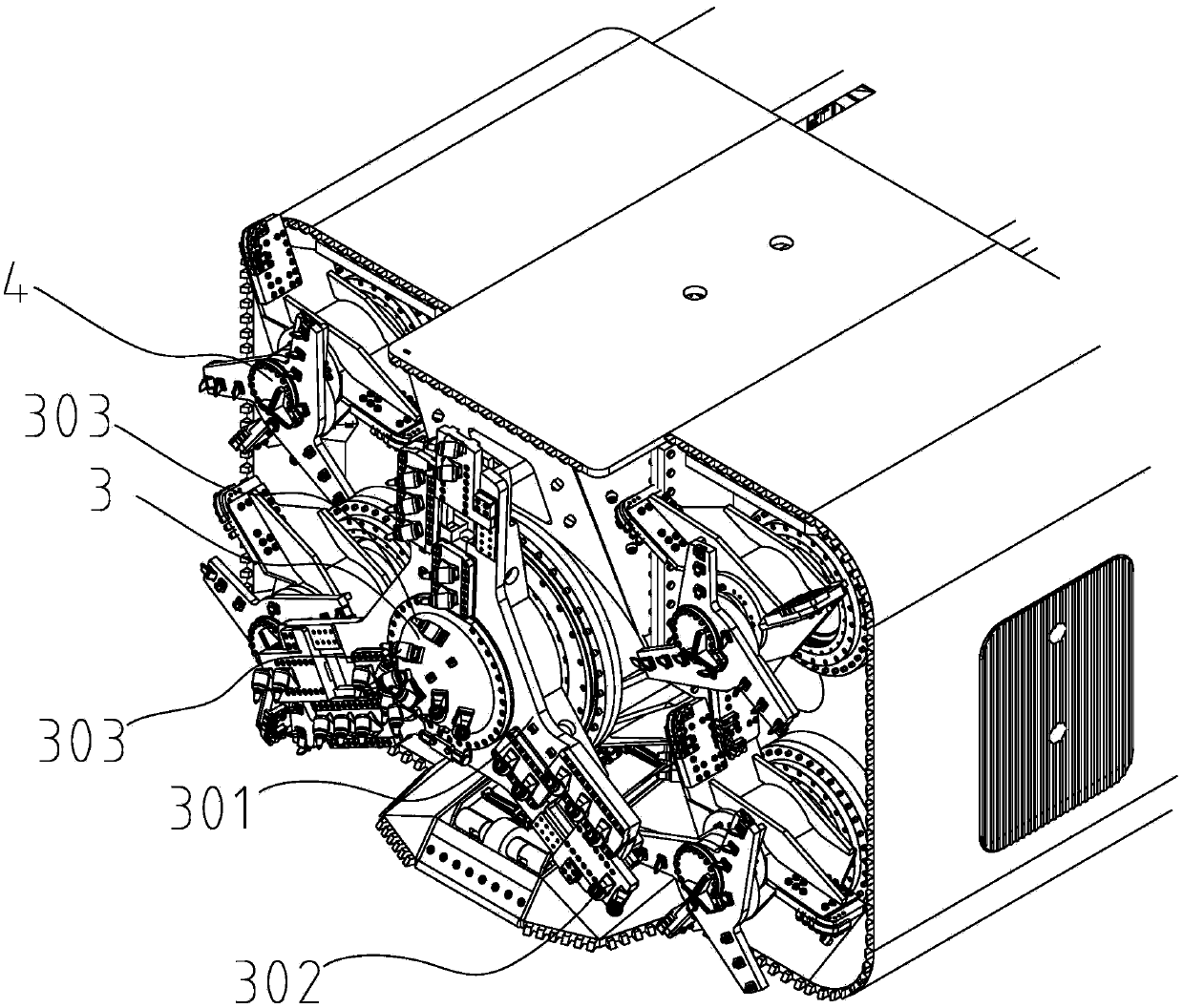

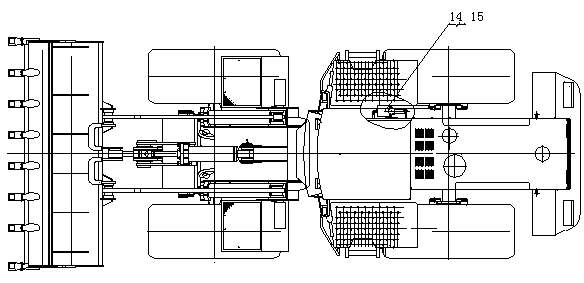

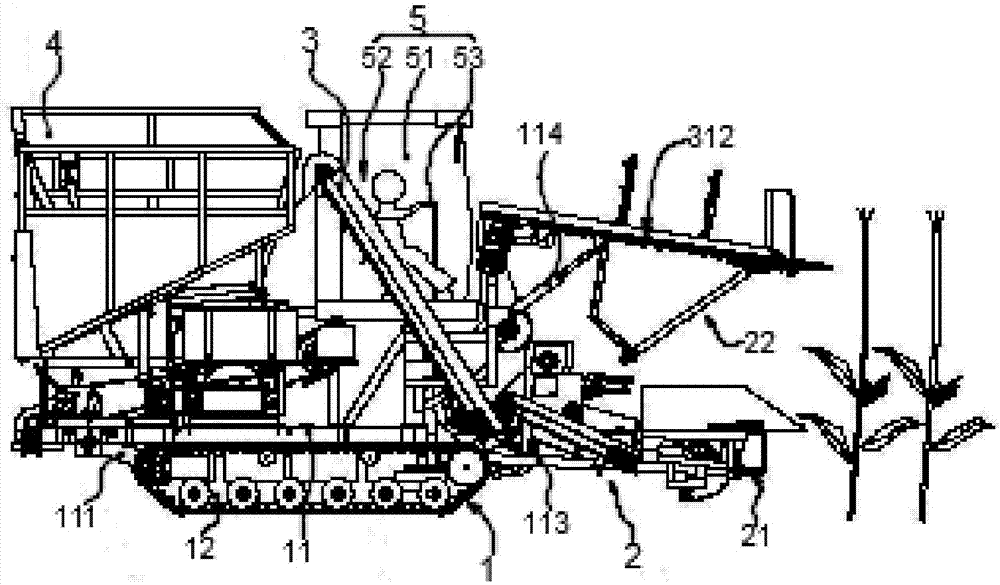

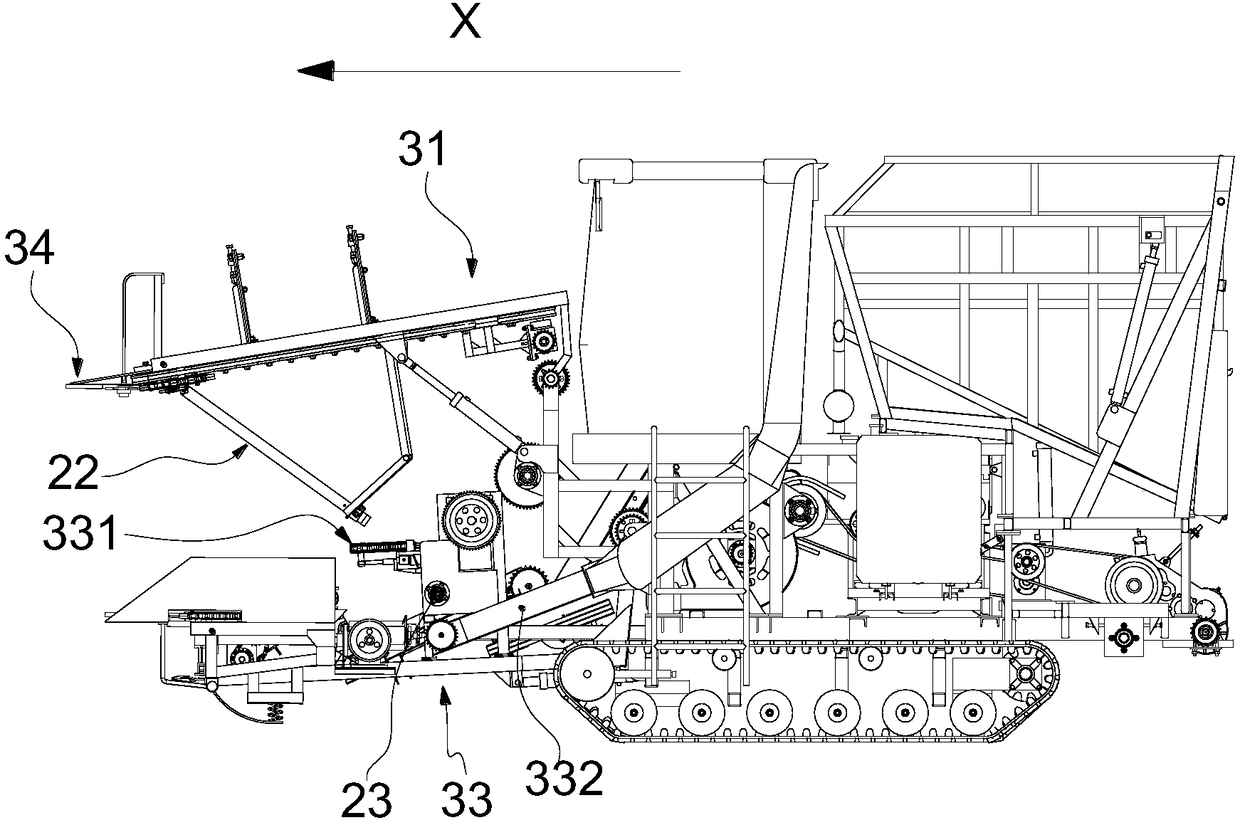

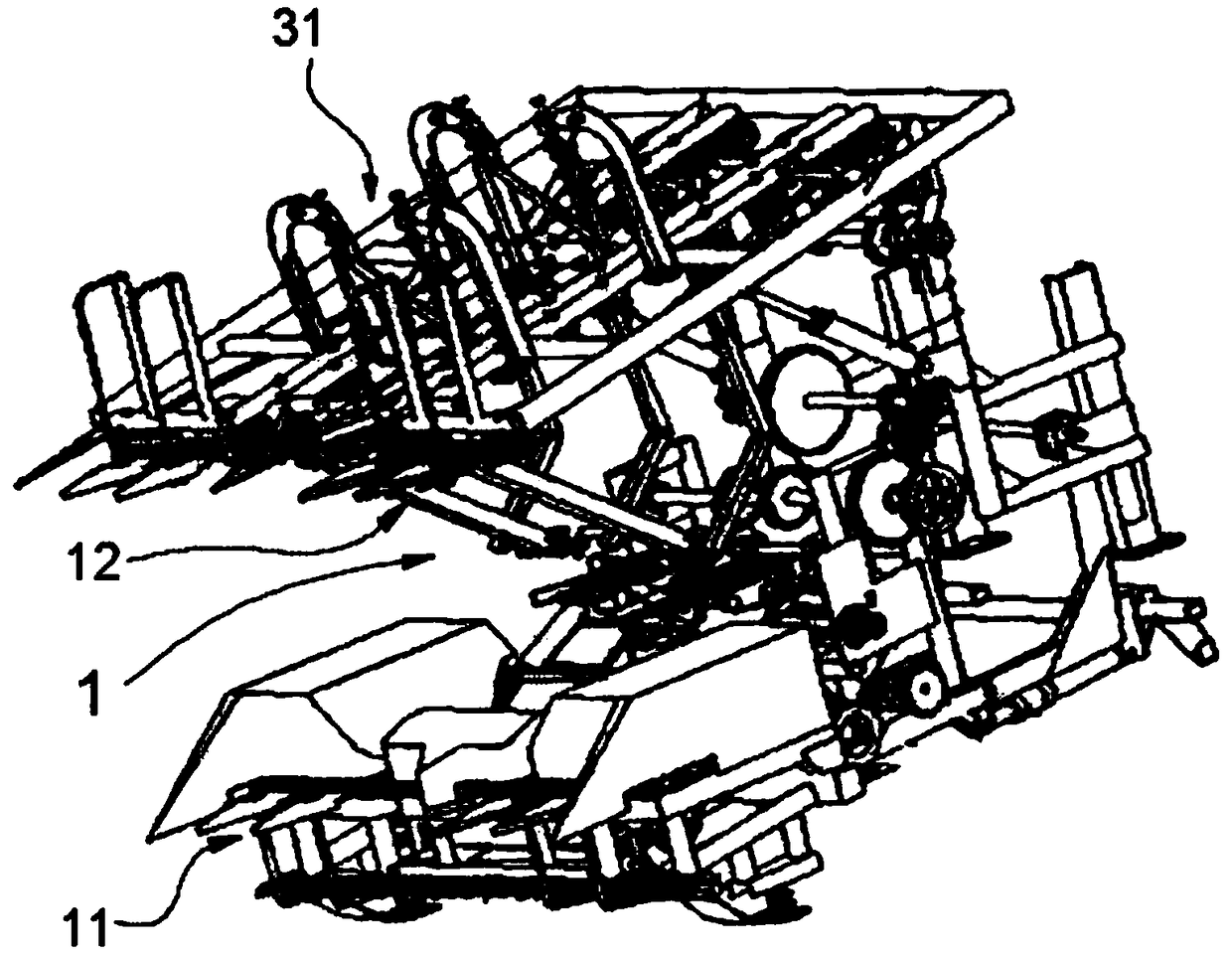

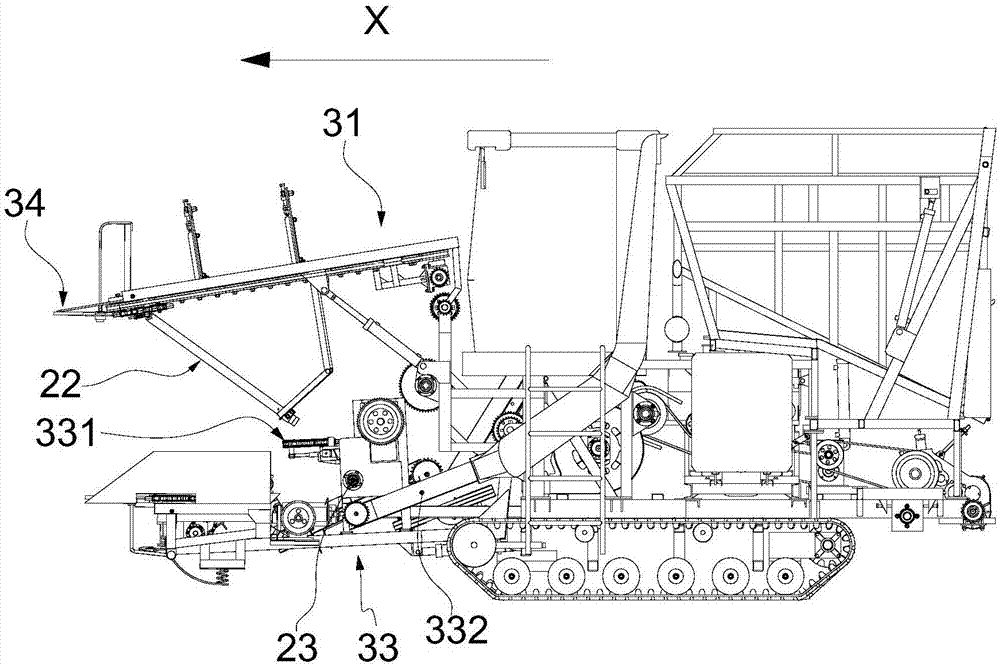

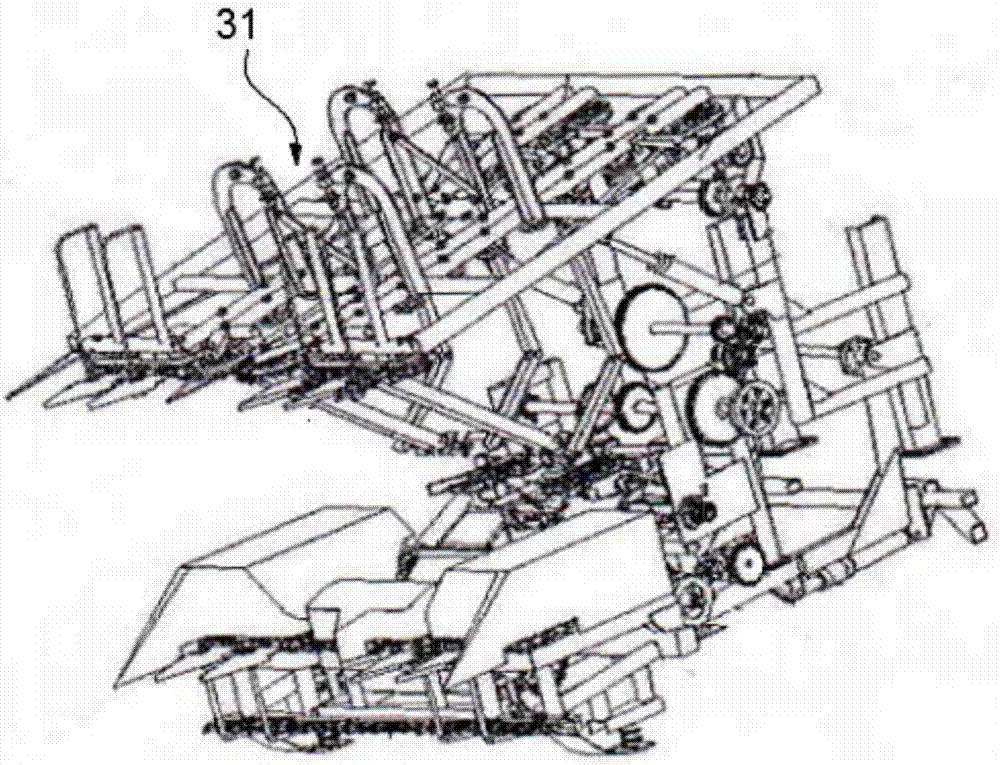

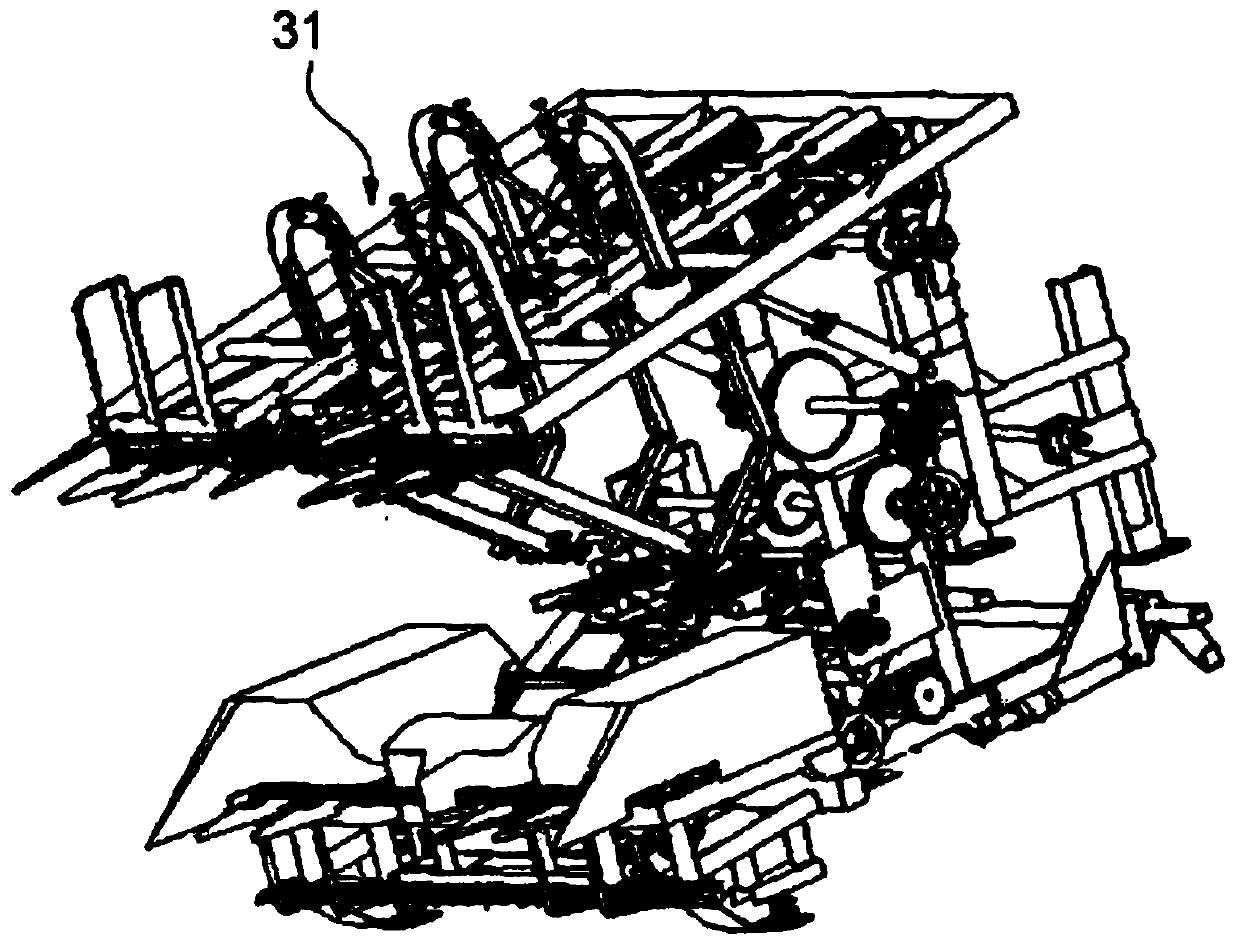

Drilling and loading and transporting complete equipment for stone drift blasting driving

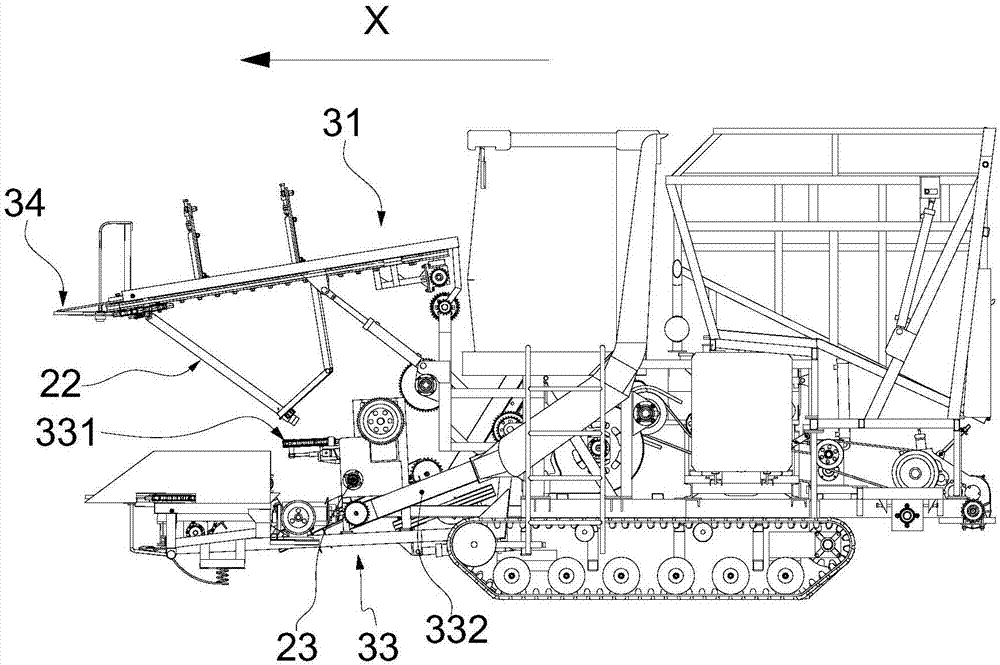

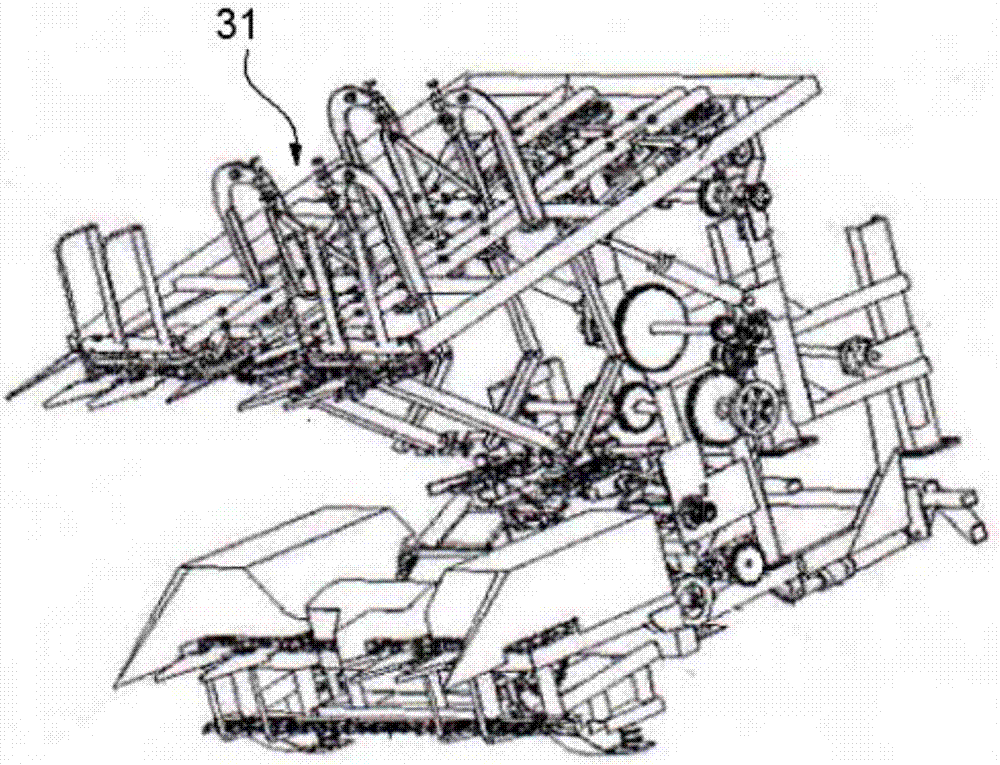

PendingCN107060802AImprove walking adaptabilityImprove stabilityDerricks/mastsMine roof supportsEngineeringDriving mode

Drilling and loading and transporting complete equipment for stone drift blasting driving is disclosed. The problems that existing blasting driving modes and material transporting equipment are low in degree of mechanization and automation, high in labor intensity and poor in safety, and the working efficiency is influenced are solved. The drilling and loading and transporting complete equipment comprises a crawler-type frame drill loader and a material transloading and conveying device, and is characterized in that the front portion of a frame type support of the crawler-type frame drill loader is provided with a drilling machine assembly and a bucket assembly correspondingly; track walking mechanisms are arranged at the lower portions of the two sides of the frame type support correspondingly; a cannon curtain is arranged at the front end of the frame type support; and the material transloading and conveying device is provided with a spading plate, an automatic-moving mechanism and a protective structure and arranged in a transporting space at the inner sides of the crawler-type frame drill loader. According to the drilling and loading and transporting complete equipment for stone drift blasting driving, the design is reasonable, the structure is compact, the occupied roadway space is small, and the drilling and loading and transporting complete equipment can be applied to hole drilling, broken stone loading and material continuous transporting of a blasting driving face; and a roadway roof can be supported temporarily, the damage to the equipment can be reduced, movement is stable, the adaptability is high, and the working efficiency and the safety of the blasting driving face are enhanced obviously.

Owner:SHENYANG TIAN AN TECH CO LTD

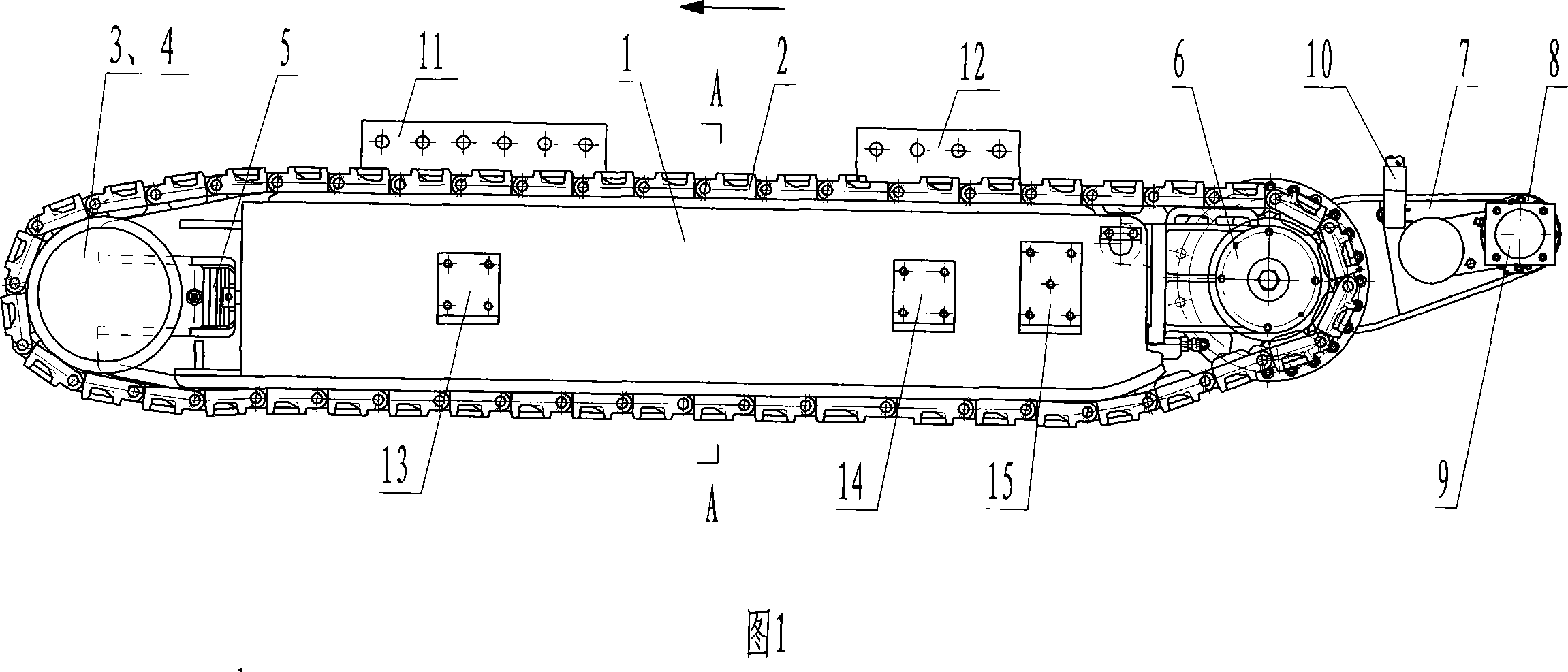

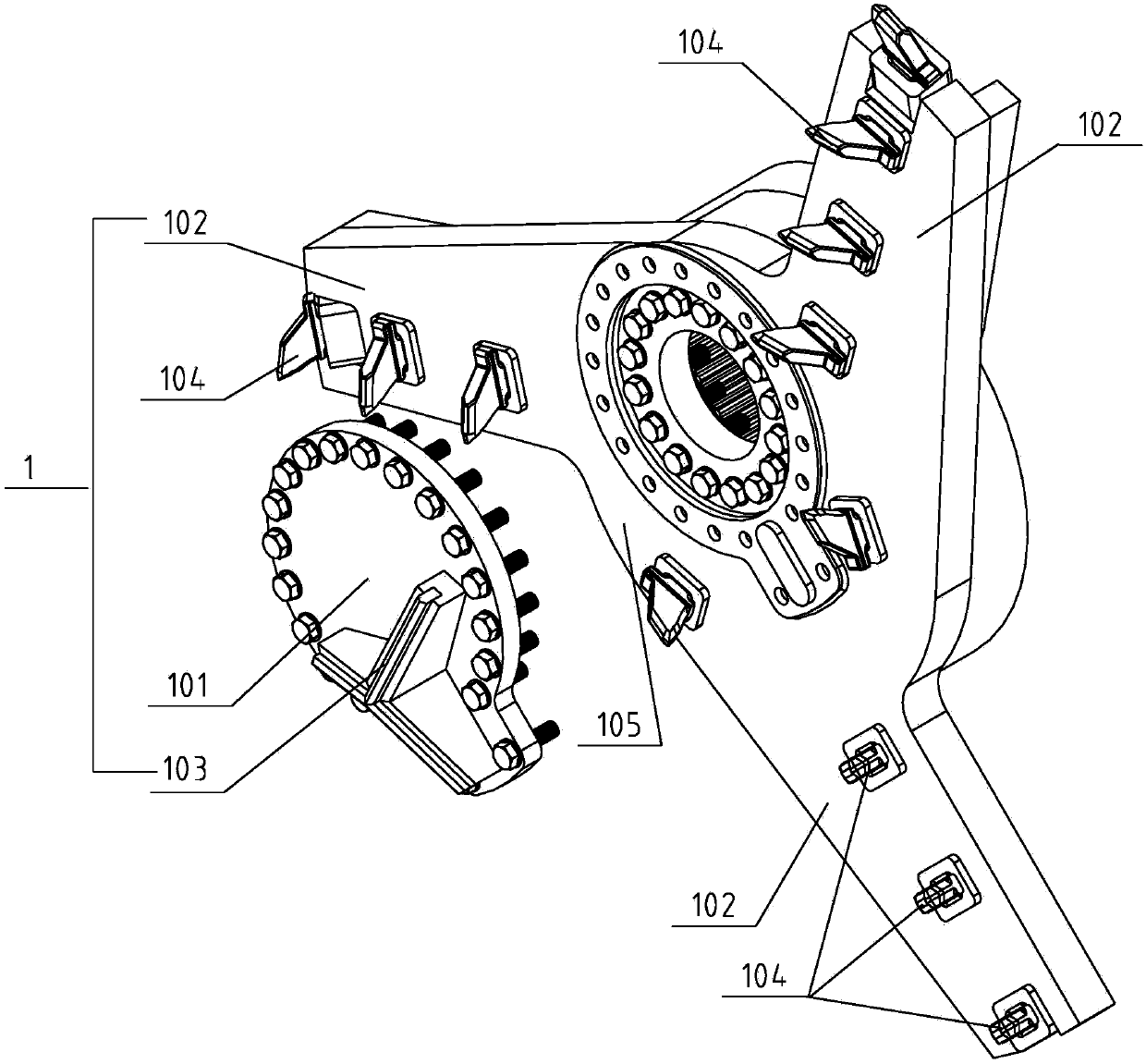

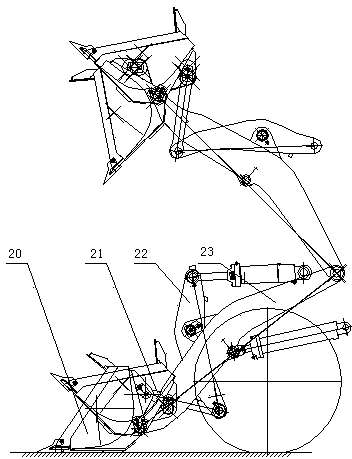

Pedrail running gear without thrust wheel

InactiveCN101224762AObvious walking structureIncrease walking spaceEndless track vehiclesMotor driveGear wheel

The invention discloses a crawler motion device without thrust wheels, and consists essentially of a track frame, a track chain, a guide wheel, a strainer mechanism, a driver mechanism, a speed reducer, a brake, a hydraulic pressure motor, a chain wheel, a connecting board and a sustaining block, and the track chain is directly arranged on the track frame, and is adjusted by the guide wheel and a strainer oil cylinder, the hydraulic pressure motor drives the speed reducer for retarding work, the retarding rotation of the speed reducer is driven by three groups of shaft gears and a secondary satellite gear and the braking of the speed reducer is controlled by the hydraulic pressure motor. The device has reasonable design, compact structure, even stress, convenient operation and using, and flexible motion and turning, reduces the height of the whole device and the number of accessories, improves the stability, reliability, mechanical performance, safety coefficient of a mechanical boring machine and a motion mechanism, is an ideal crawler motion device that fits working in severe environments, and is also applicable for other similar motion mechanisms.

Owner:TAIYUAN INST OF COAL SCI RES INST +1

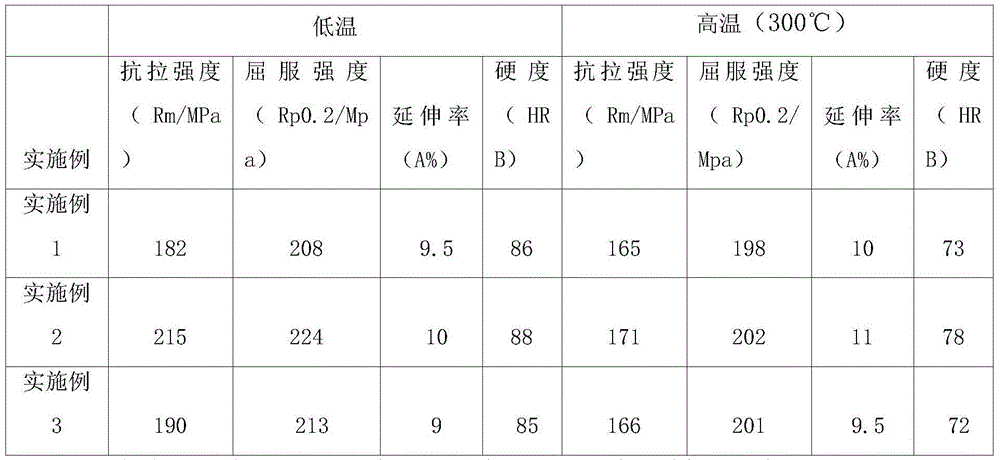

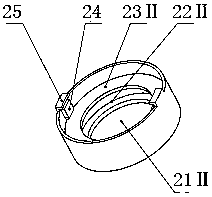

Swash plate of automobile air-condition compressor and production method of swash plate

ActiveCN104831133AImprove cutting performanceLow costPositive displacement pump componentsPositive-displacement liquid enginesPre treatment5005 aluminium alloy

The invention discloses a swash plate of an automobile air-condition compressor. The swash plate is prepared from an aluminium alloy comprising the following components in percentage by weight: 13-15% of Si, 4-5% of Cu, 0.2-0.3% of Mg, 0.8-1.5% of Ni, 0-0.1% of Mn, 0-0.5% of Fe, 0-0.1% of Zn, 0-0.2% of Ti, 0.1-0.3% of C, 0.1-0.3% of RE and the balance of Al. The invention further provides a production method of the swash plate of the automobile air-condition compressor. According to the production method provided by the invention, the high-temperature strength and the high-temperature hardness of the swash plate are improved, the cutting properties and the plasticity are improved, and low-cost production is realized by choosing and controlling elements in the aluminium alloy for the swash plate, and then replacing casting by forging, optimizing the pre-treatment and the post-treatment of the forging, and optimizing process parameters during the various treatment processes.

Owner:SHANDONG HUICHUAN AUTO PARTS

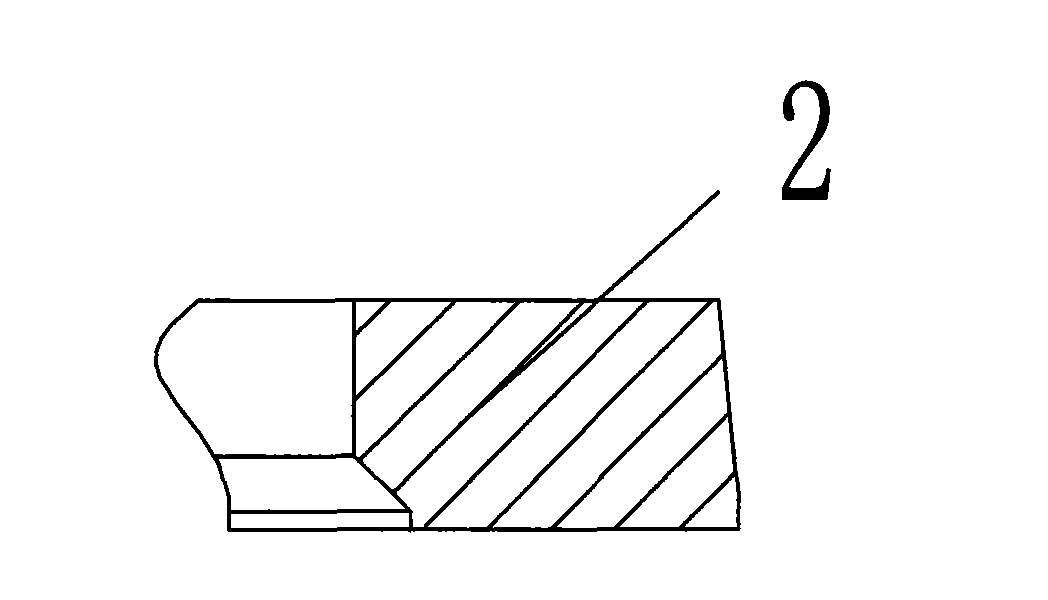

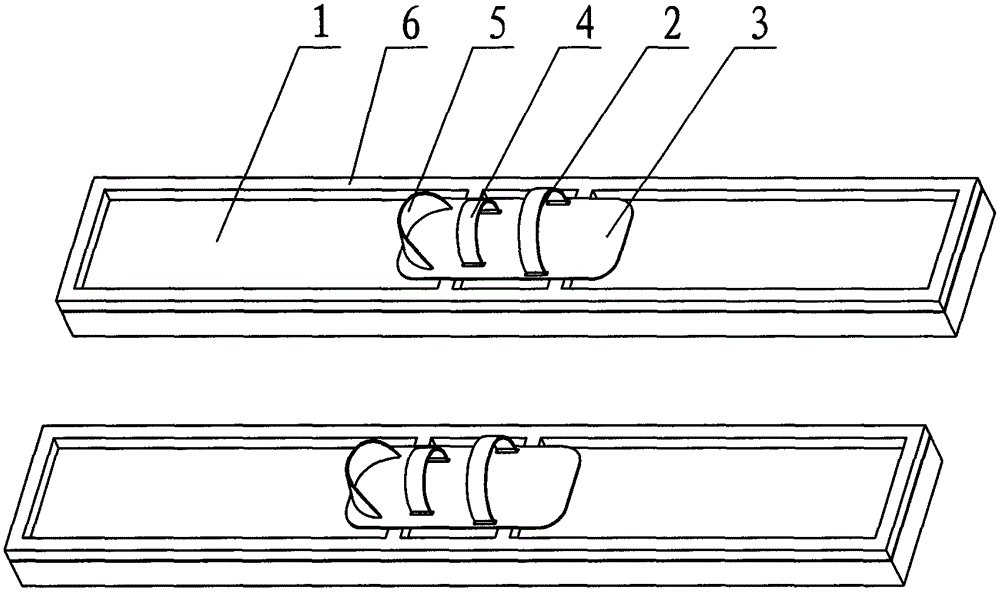

Piston ring set used for natural gas engine

InactiveCN101649792AStrong resistance to fusion wearImprove deformation abilityPiston ringsMachines/enginesPiston ringSteel belt

The invention discloses a piston ring set used for a natural gas engine, which comprises two gas rings and an oil ring, wherein the first gas ring is a double-ladder structure ring, the second gas ring is a detorsion structure ring, and the third oil ring is three pieces of flexible steel-belt combined oil rings; the embedded and molybdenum-spraying ring treatment is carried out on the surface ofthe first double-ladder structure ring, the molybdenum layer has strong scuffwear resistance capacity, and the double-ladder structure has strong deadlocking and carbon-deposition prevention capacities, thereby greatly prolonging the service life; the second gas ring adopts the detorsion structure and has extremely strong oil-scraping capacity as well as remarkably-reduced oil consumption and frictional work; the oil ring is formed by three pieces of flexible steel-belt combined oil rings, and three pieces of flexible steel-belt combined oil rings have the radial thickness of 3.7+ / -0.15, strong flexibility, light weight, strong deformation capacity complied with a cylinder sleeve, strong oil-return capacity, improved oil-scraping capacity and effectively-reduced oil consumption.

Owner:NANJING FAYN PISTON RING

Automobile air conditioner compressor planetary plate and production method thereof

ActiveCN104789826AHigh strengthEasy to useMetal-working apparatusAfter treatmentUltimate tensile strength

The invention provides an automobile air conditioner compressor planetary plate. The planetary plate is prepared from an aluminum alloy which comprises the following components in percentage by weight: 8%-9% of Si, 1%-1.5% of Cu, 0.4%-0.7% of Mg, 0.1%-0.3% of C, 0.8%-1.5% of Ni, 0-0.1% of Mn, 0-0.2% of Fe, 0-0.1% of Zn, 0.3%-0.4% of Ti, 0.1%-0.2% of RE and the balance of Al. The invention also provides a production method of the automobile air conditioner compressor planetary plate. The elements in the aluminum alloy for the planetary plate are selected and controlled, a forging technique is further used instead of the casting technique, the pretreatment before forging and after-treatment after forging are optimized, and the technological parameters in each treatment process are optimized, thereby enhancing the strength of the planetary plate and further improving the service performance and service life of the planetary plate.

Owner:SHANDONG HUICHUAN AUTO PARTS

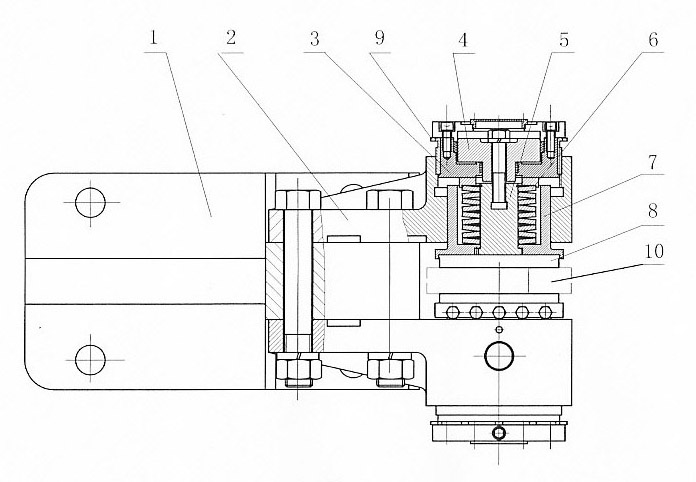

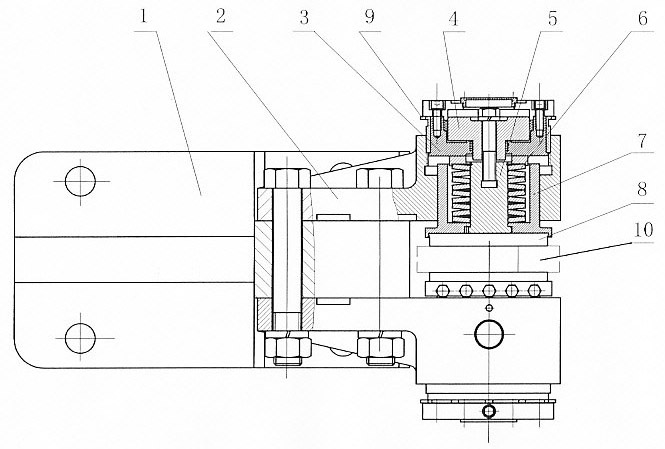

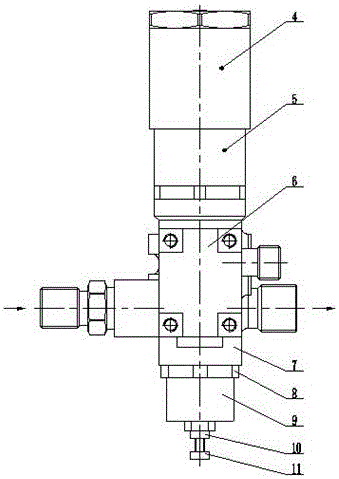

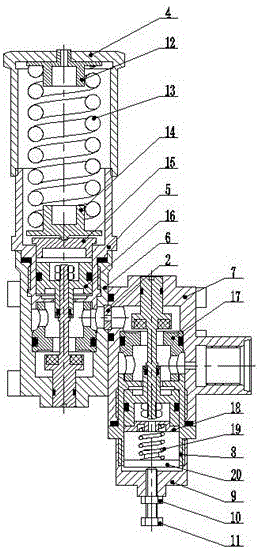

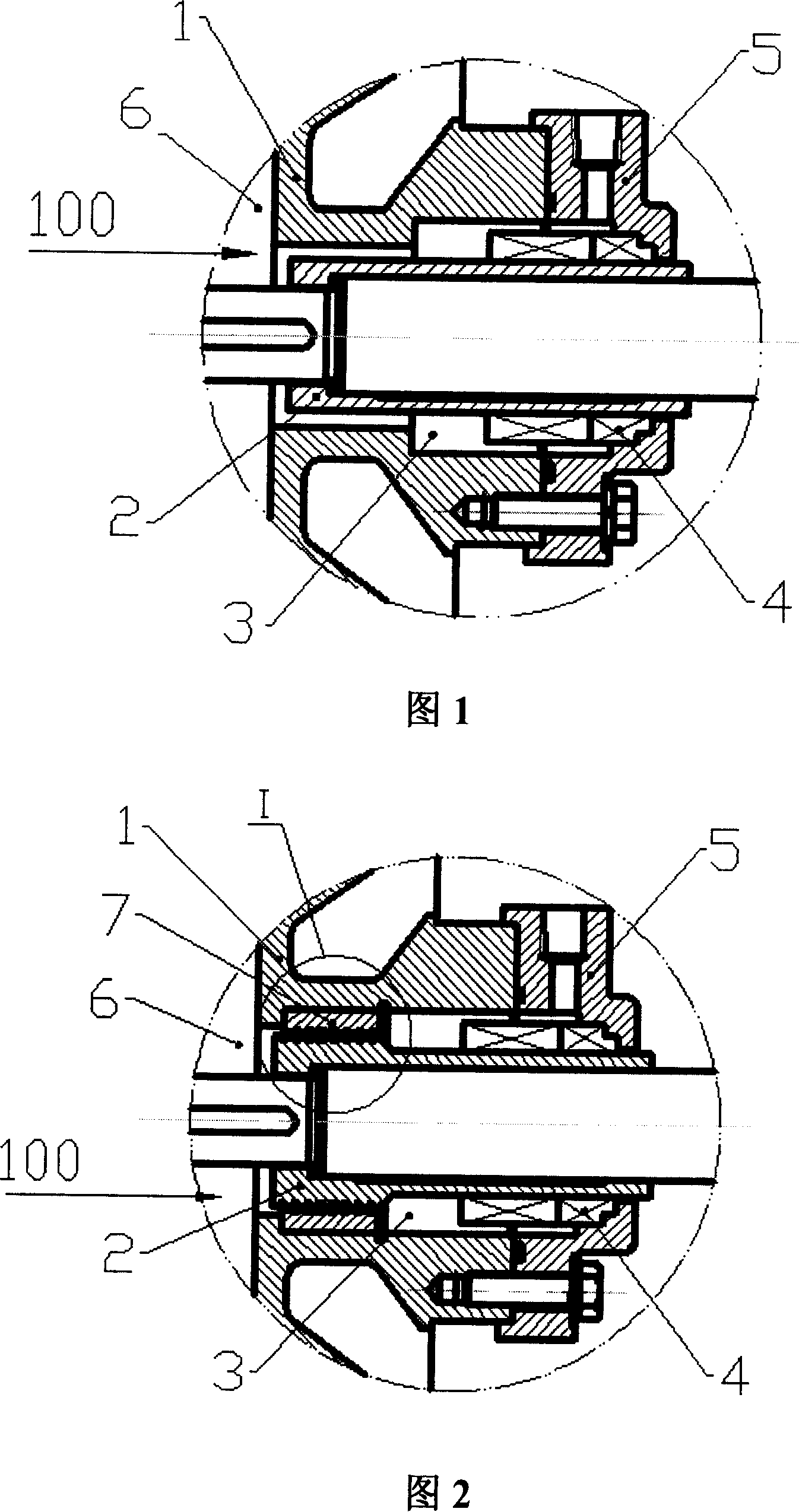

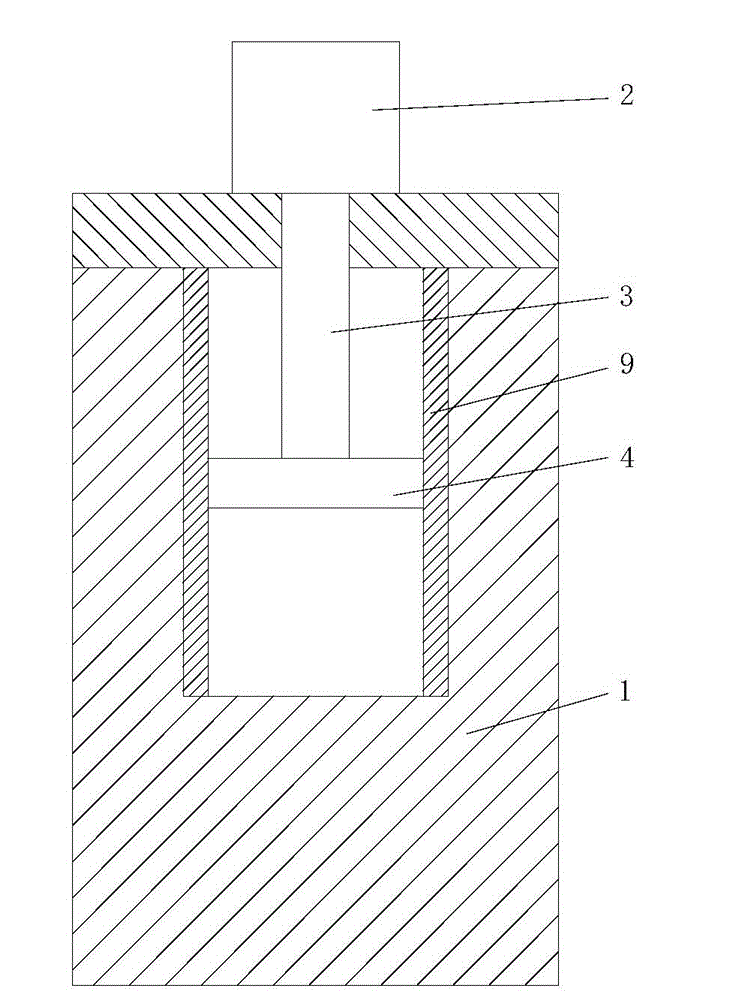

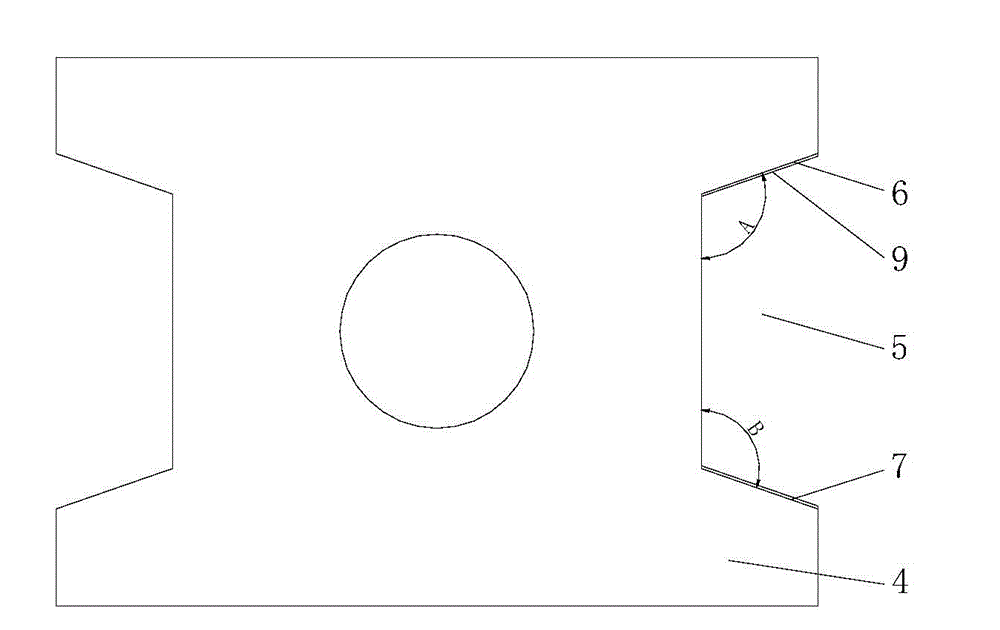

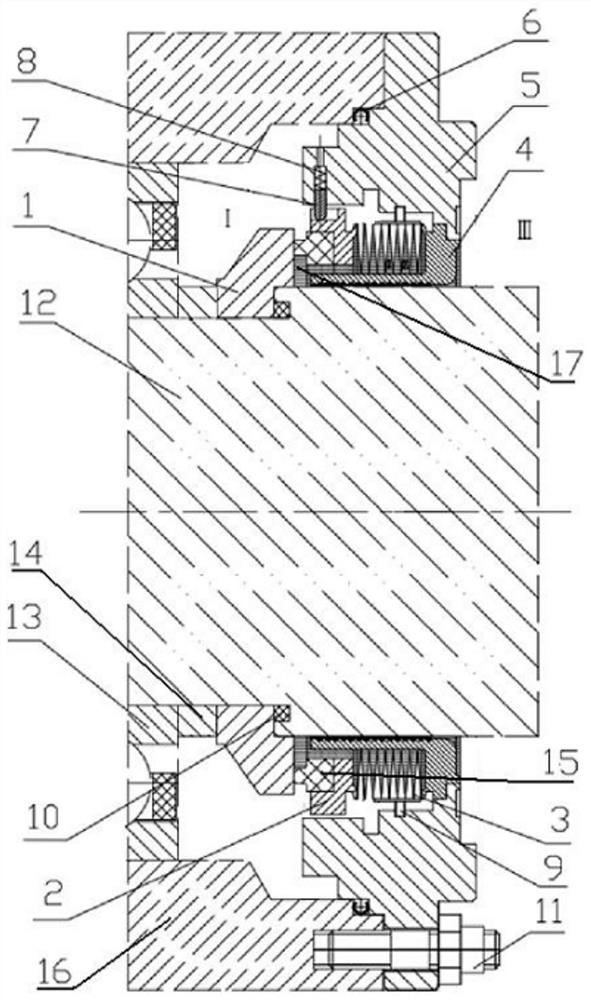

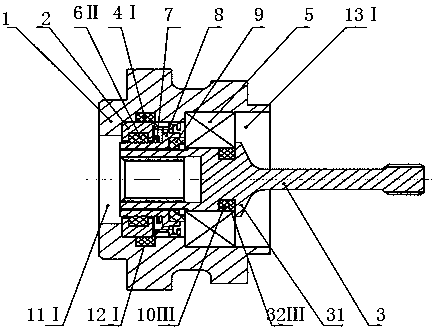

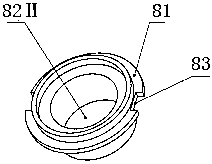

Brake method of lifting winch/lifting machine for mines and disc-shaped brake

InactiveCN102040175ASimple structureLower specific pressureBraking membersBrake actuating mechanismsSolenoid valveBrake shoe

The invention relates to a disc-shaped brake of a lifting winch / lifting machine for mines, consisting of a brake leg 1, a support 2, a cylinder 3, a piston 4, a guide rod 5, a butterfly-shaped spring 6, a brake shoe seat 7, a brake shoe 8 and an adjusting threaded sleeve 9, wherein the support 2 is positioned on the brake leg 1; the cylinder 3 and the brake shoe seat 7 are arranged in inner holes of the support 2; the piston 4 and the guide rod 5 are positioned on the support 2; the butterfly-shaped spring 6 is arranged in the brake shoe seat 7 and is contacted with the outer end surface of the cylinder 3; and the adjusting threaded sleeve 9 is positioned between the support 2 and the cylinder 3. Since the design is adopted, compared with the prior art, by utilizing the disc-shaped brake, the structure of the disc-shaped brake can be simplified, the cost is reduced, and the potential safety hazard of emergent brake failure after the electromagnet is clamped can be eliminated, so that the maintenance and the replacement of the brake shoe on site are more convenient, the maintenance cost of the brake shoe is saved, the contact area of the brake shoe is increased, and the specific pressure of the brake shoe is reduced, therefore, the utilization ratio of the brake shoe is improved, and the loss of the brake shoe is reduced.

Owner:耒阳市湘发环保机械制造有限公司

Automobile air conditioner compressor hollow piston and production method thereof

ActiveCN104805339AHigh tensile strengthHigh yield strengthPositive displacement pump componentsPositive-displacement liquid enginesPorosityWeld seam

The invention discloses an automobile air conditioner compressor hollow piston, which comprises aluminum alloy prepared from the following ingredients in percentage by weight: 11 to 13 percent of Si, 3.5 to 4.5 percent of Cu, 0.2 to 0.5 percent of Mg, 0.8 to 1.5 percent of Ni, 0.1 to 0.3 percent of Cr, 0.1 to 0.3 percent of C, 0 to 0.1 percent of Mn, 0 to 0.5 percent of Zn, 0 to 0.15 percent of Ti, 0.1 to 0.3 percent of RE and the balance Al. The invention also provides a production method of the automobile air conditioner compressor hollow piston. Through the selection and the control on elements in the aluminum alloy for the hollow piston, the intensity and the hardness of the piston are improved; through further improvement on the laser welding process, the welding seam fine porosity rate is reduced, the welding tension is enhanced, and the welding quality is improved, so the use performance of the hollow piston is improved, and the service life of the hollow piston is prolonged.

Owner:SHANDONG HUICHUAN AUTO PARTS

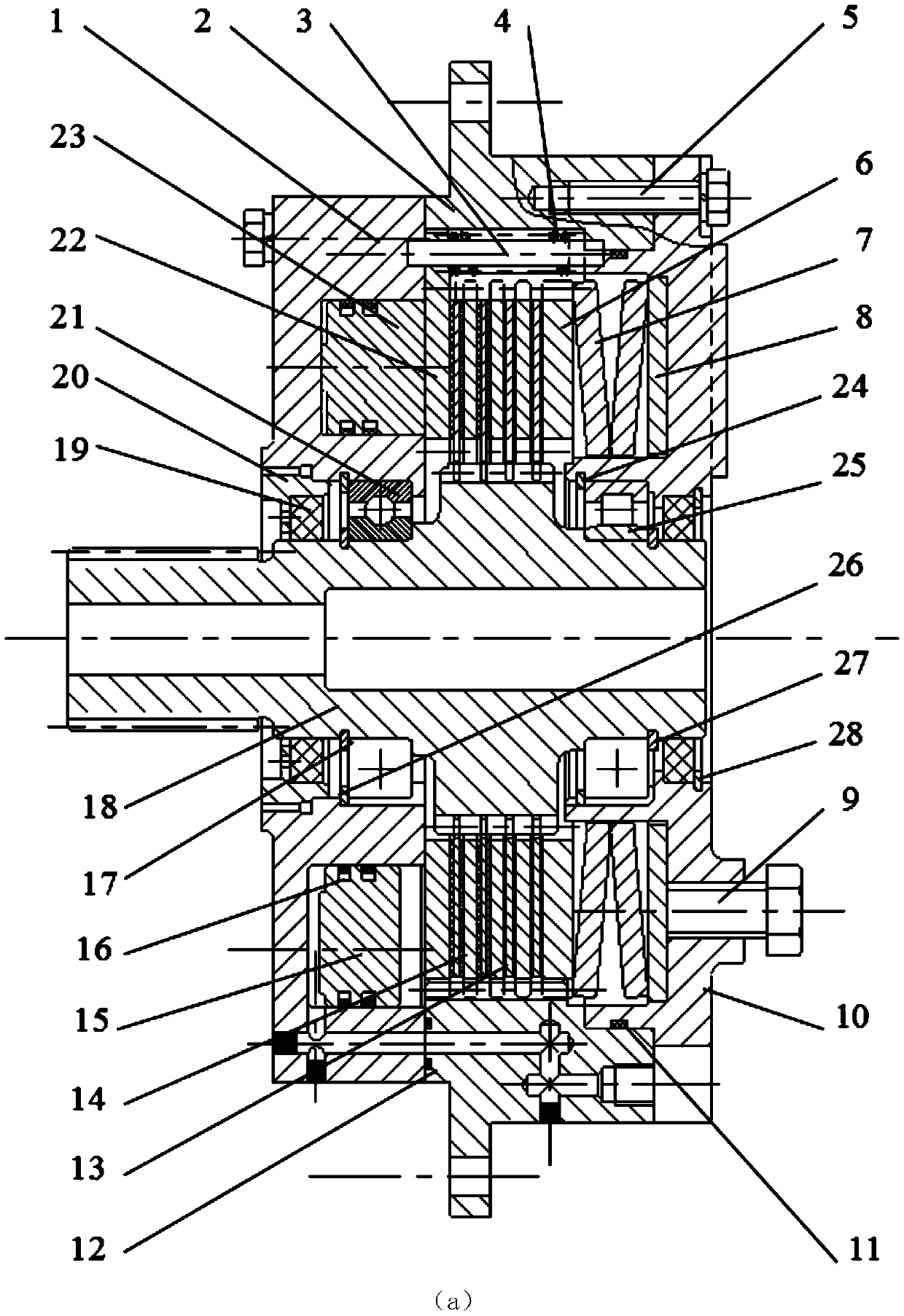

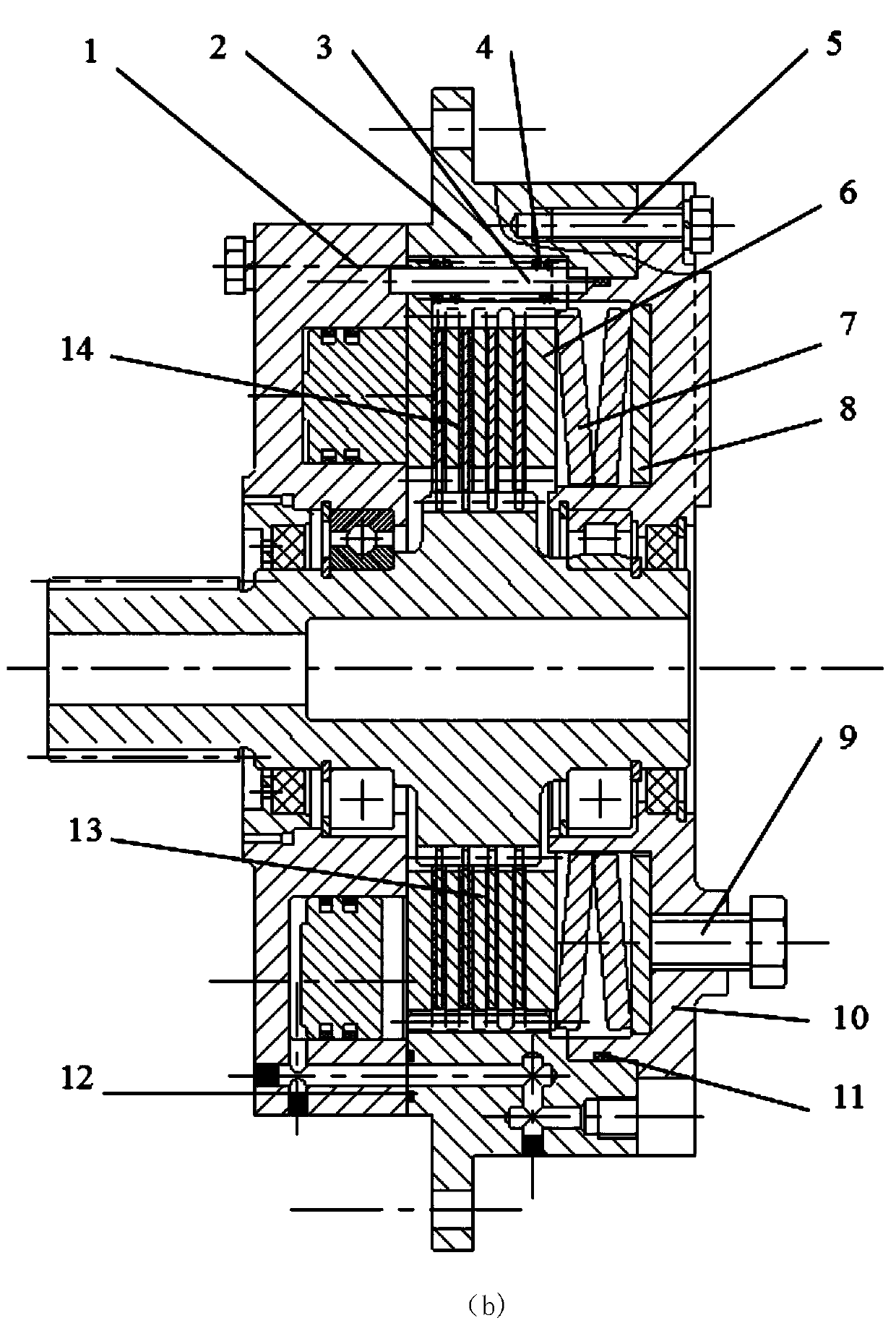

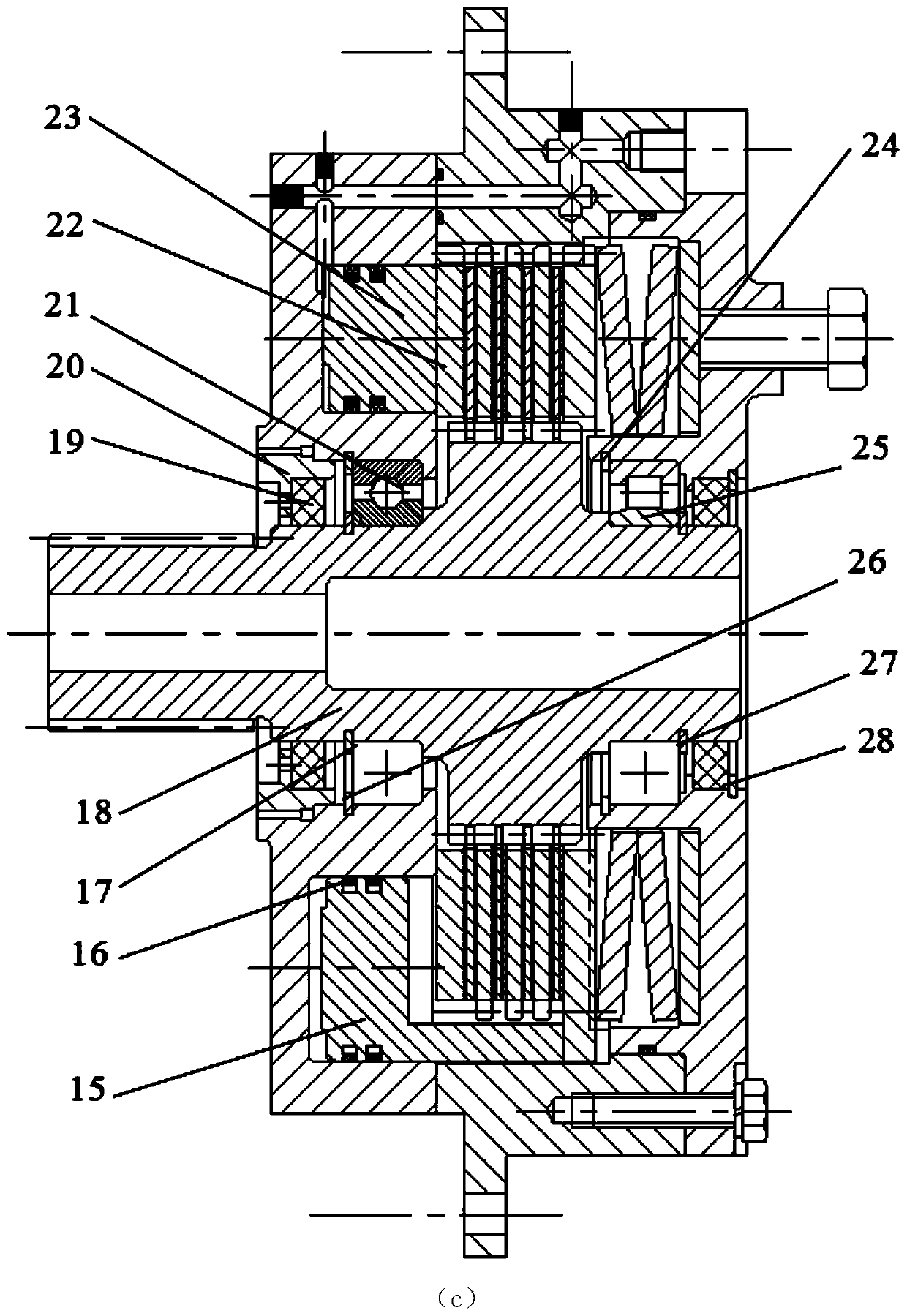

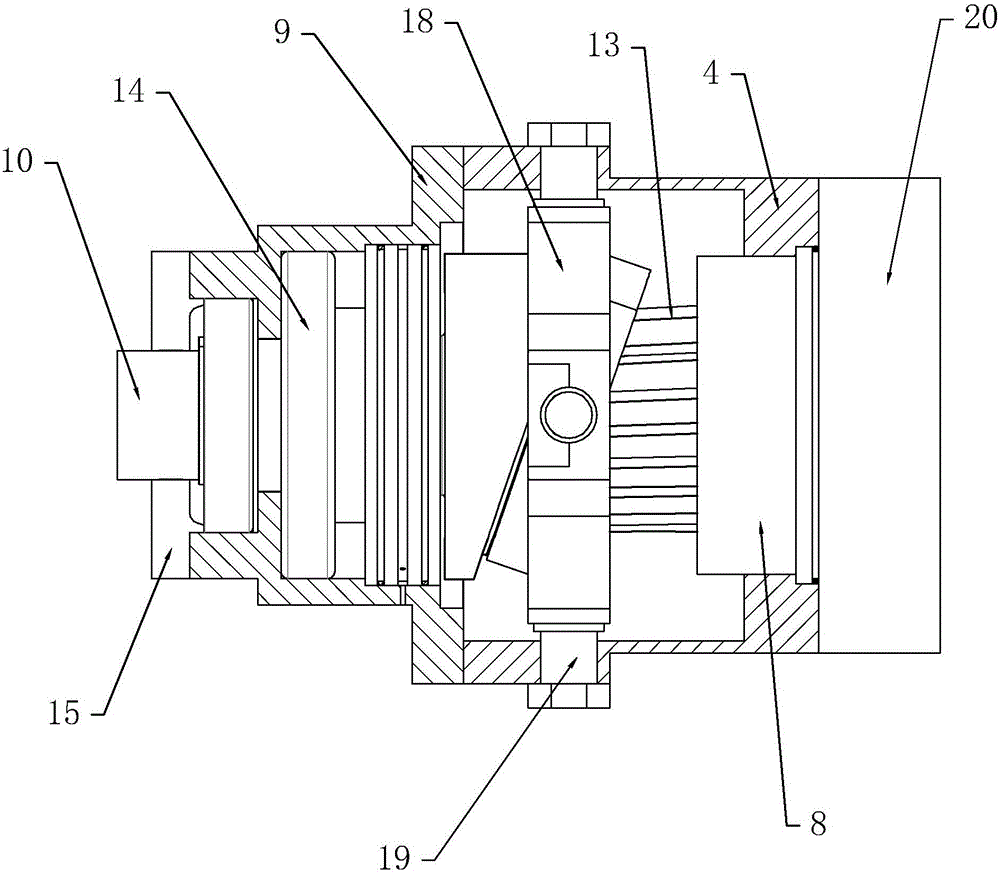

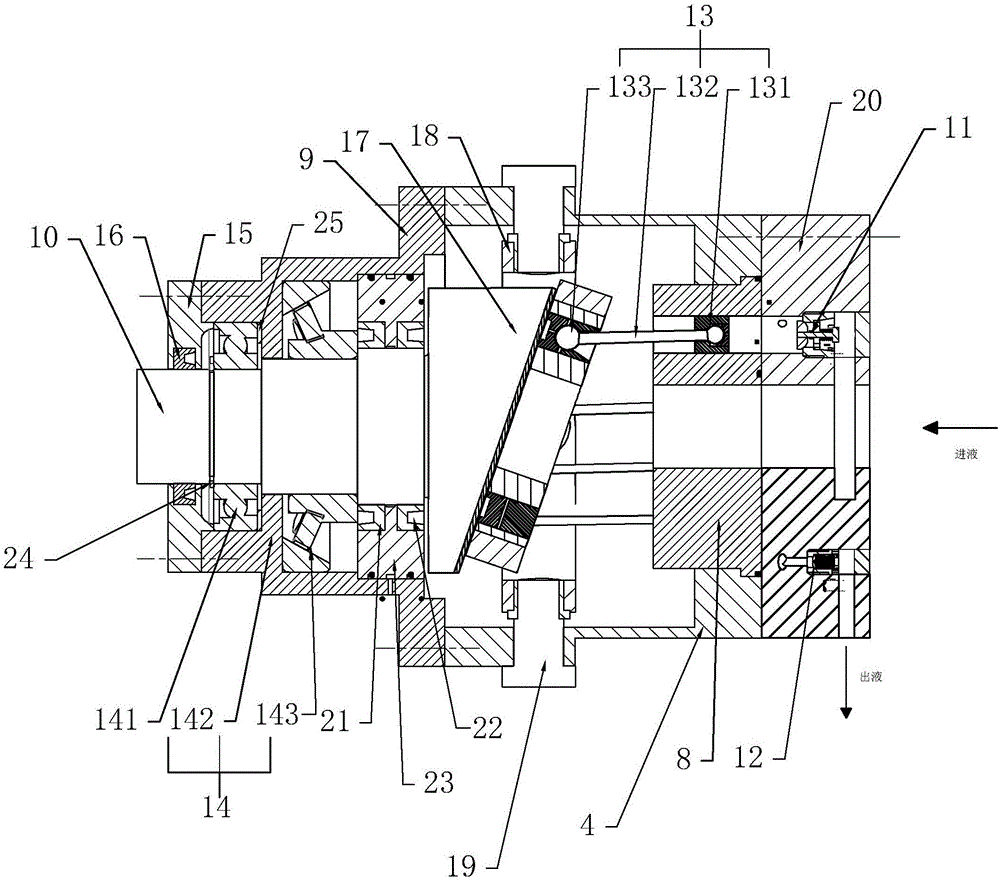

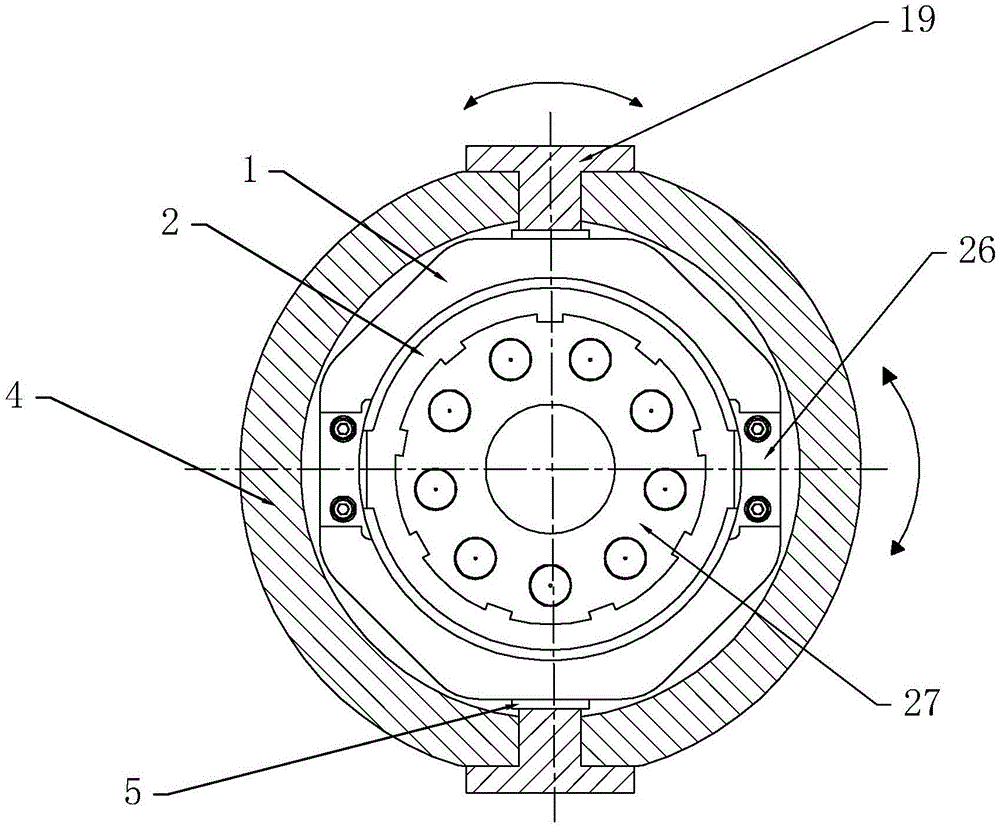

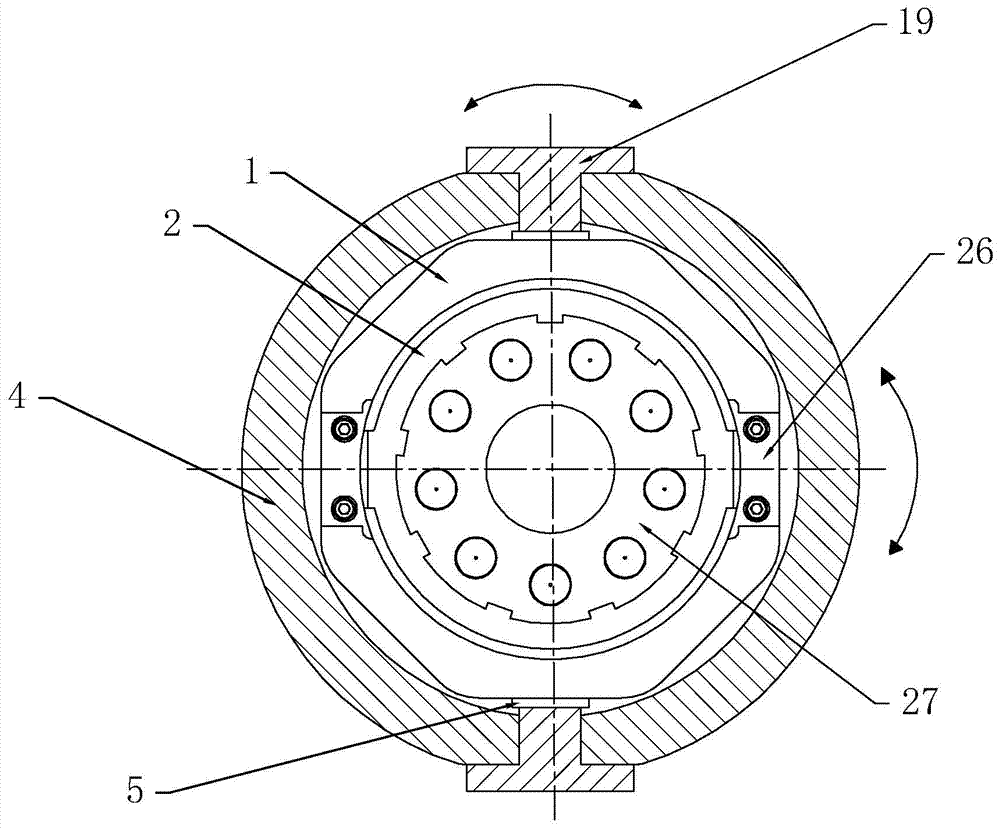

Driving brake and parking brake integrated wet type brake with adjustable separation gap

ActiveCN110701217AIntegrated service brake functionFunctional integrationAxially engaging brakesFluid braking transmissionBrake torqueControl theory

The invention provides a driving brake and parking brake integrated wet type brake with an adjustable separation gap, and belongs to the technical field of vehicle brake. The problems that the requirement of vehicle speed increasing for the property of a brake is higher and higher, the size is large, the function is single, multiple brake friction sheets are not prone to separating, and a dry typebrake is high in temperature rise are solved. The brake comprises a rear shell, a middle shell, an end cover, a guide column, a return spring, a baffle, a disc spring, a gasket, an adjusting bolt, aninner tooth friction plate, an outer tooth friction plate, a parking brake piston, an input gear shaft, a pressing plate and a driving brake piston. Functions of driving brake, parking brake, friction pair forced separating, friction pair separation gap adjusting, parking emergency relief and the like can be achieved. The driving brake piston and the parking brake piston are arranged on one part,the size of the brake is reduced, the brake life of the brake is prolonged, the braking torque stability is kept, and reliability is improved.

Owner:内蒙古第一机械集团股份有限公司

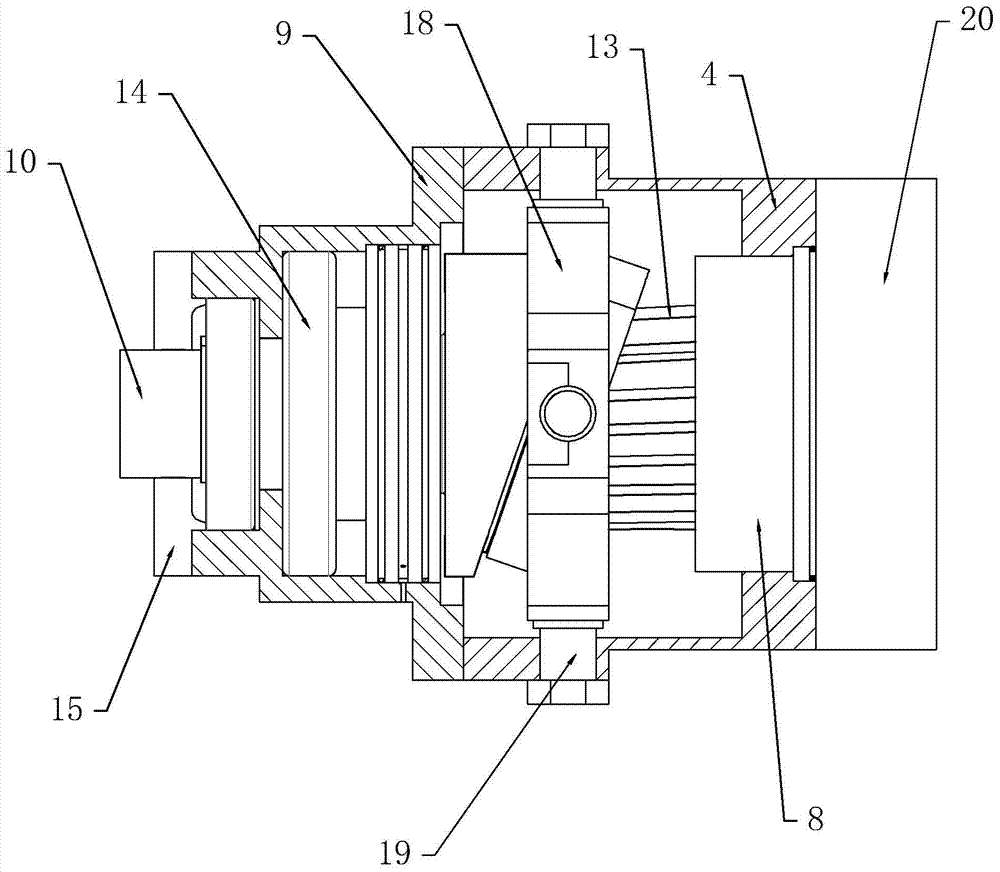

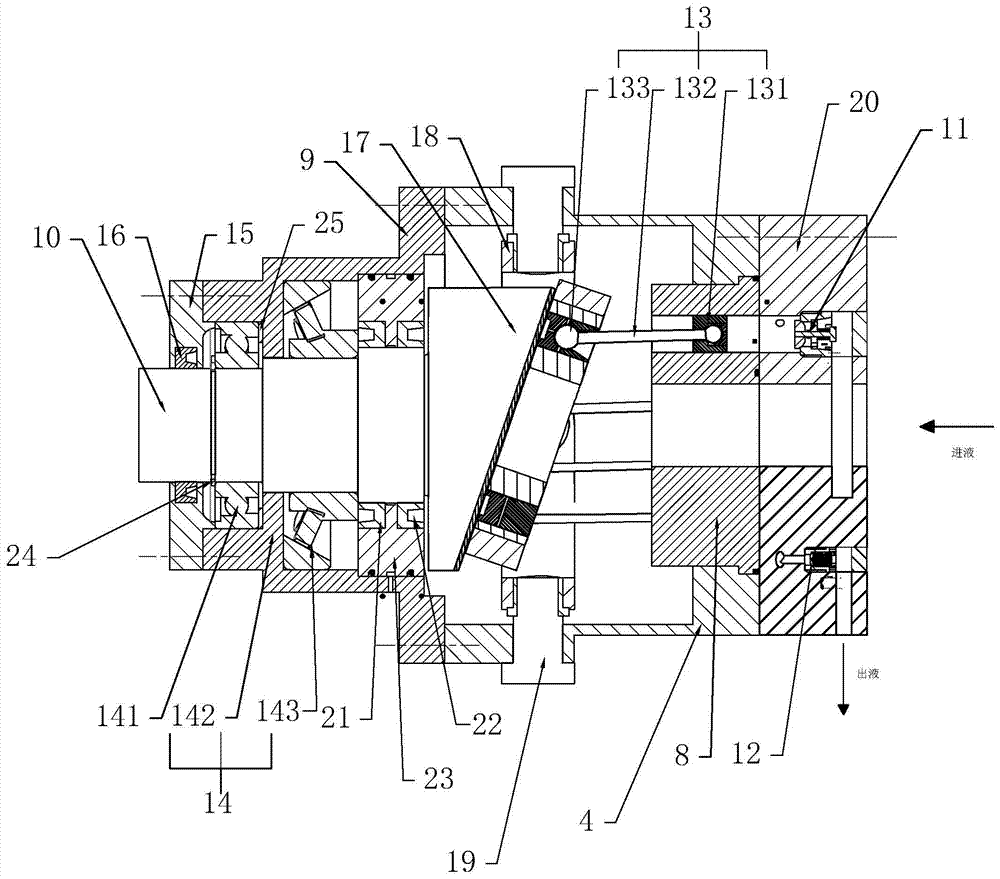

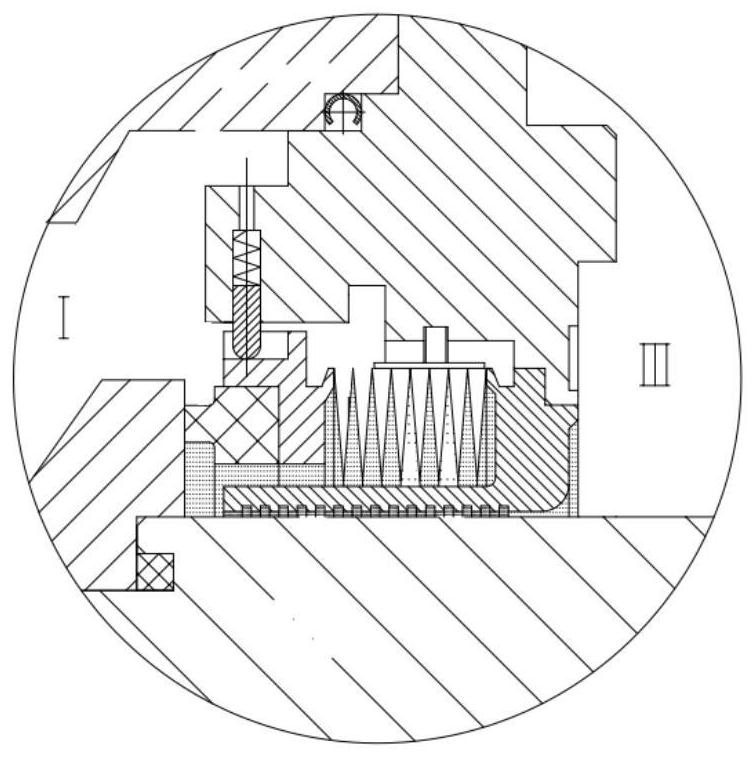

Novel axial plunger pump

ActiveCN105090008AImprove loosenessImprove the phenomenon of pulling off or even crackingPositive displacement pump componentsLiquid fuel engine componentsMechanical engineeringAxial piston pump

The invention discloses a novel axial plunger pump. According to the technical scheme, the novel axial plunger pump is characterized by comprising an end cover, a front shell, a pump shaft arranged inside the front shell, a rear shell, a swash plate and a cylinder, wherein the swash plate and the cylinder are installed inside the rear shell; the end cover, the front shell, the rear shell and the cylinder are sequentially and fixedly connected, and the swash plate is connected to the end, back on to the shell, of the pump shaft; a cross-shaped swinging plate and a plunger assembly are further arranged inside a plunger pump; a plunger hole, a valve hole, a pressing-out valve set and a pressing-in valve set are arranged inside the cylinder, the pressing-out valve set and the pressing-in valve set are located in the valve hole, one end of the plunger assembly is embedded in the plunger hole, and the other end of the plunger assembly is connected with the cross-shaped swinging plate; the cross-shaped swinging plate abuts against the swash plate in a contact manner; and due to the fact that in the prior art a retainer plate and a piston shoe are embedded into a whole through a piston shoe plate, and the piston shoe and the a plunger bulb are embedded into a whole through the piston shoe plate, lateral force of the cylinder and a plunger base is decreased, meanwhile, the tilt angle of the swash plate is increased, the return distance of the plunger base is enlarged, displacement of the plunger pump is improved, the efficiency of the plunger pump is improved, and the design of the cylinder is further simplified.

Owner:HANGZHOU LVJU TECH +1

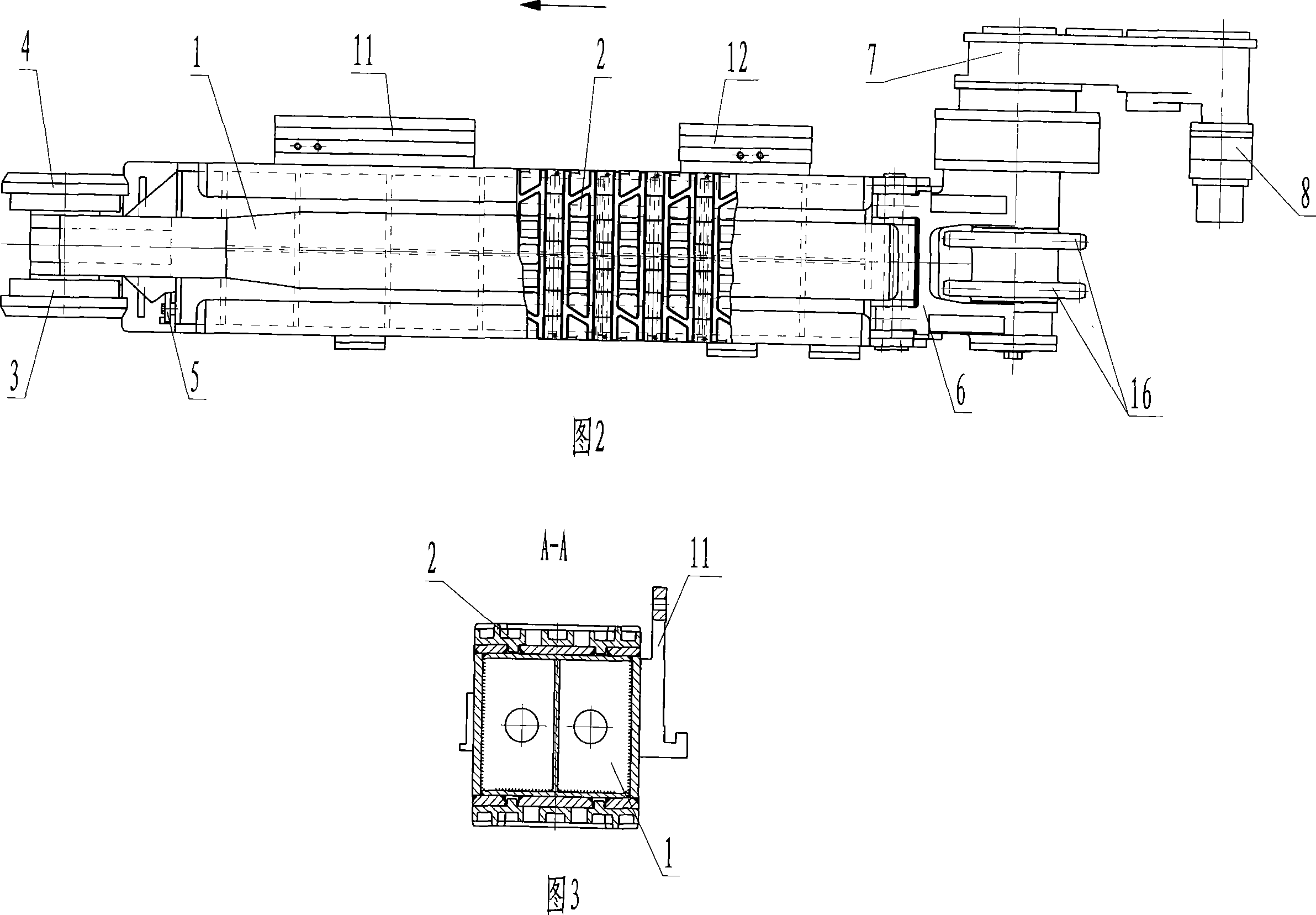

Rapid rectangular full-face tunnel boring machine for mining

InactiveCN103742135ARealize parallel operationImprove tunneling efficiencyCutting machinesElectrical controlEngineering

The invention relates to a rapid rectangular full-face tunnel boring machine for mining. The rapid rectangular full-face tunnel boring machine comprises a rectangular tunnel boring machine head, a support propelling mechanism, a horizontal supporting mechanism, a main guide beam, a scraper conveyer, a saddle turning mechanism, an anchor rod advance supporting unit, an electrical control system, a hydraulic pressure system, a measurement guiding system, a ventilating system, a cooling system, a dedusting system and the like; the rapid rectangular full-face tunnel boring machine for mining is in a structure that a large cutter head is matched with four small combined cutter heads, so as to achieve the purpose of achieving rectangular full-face excavated section; the rapid rectangular full-face tunnel boring machine is in a split structure wholly and can achieve parallel operations of tunneling and anchor rod supporting, therefore, the anchor rod is not a restraining factor influencing the tunneling operation; the rectangular tunnel boring machine head and a support platform are separated into two sections, and a main beam and a saddle are adopted for turning, so that the possibility of small turning radius can be achieved; the support platform vibrates slightly before tunneling operation, therefore, the stability of the whole rapid rectangular full-face tunnel boring machine system is improved favorably; and the specific pressure of a roof and a floor is low and the anchor rod advance temporary support is adopted, so that a situation that the roof and the floor are difficult to tunnel can be solved.

Owner:CHINA COAL TECH & ENG GRP SHANGHAI +1

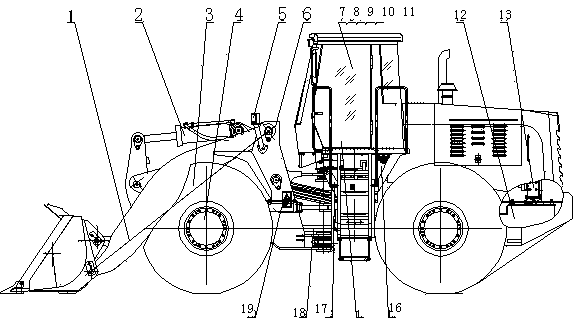

Wheeled loader

InactiveCN103967060AIncrease contact areaLower specific pressureMechanical machines/dredgersClimate change adaptationGround contactEngineering

The invention discloses a wheeled loader. The wheeled loader, in terms of design, is mainly characterized in that vacuum tubeless vacuum tires having large ground-contact area and adaptive to desert conditions are selected, an engine with good wind-sand prevention and strong power is adopted, a hydraulic oil tank with good radiating performance is adopted, the whole loader is harmonized, a travelling platform meeting ergonomic demands is adopted, an operating device in optimized design is employed, and a desert radiator assembly with large radiating area and high radiating efficiency is employed. The wheeled loader in the optimized design has the advantages that the loader is better in floating performance, dynamic property, trafficability, economy and stability; the product can normally operate in soft places, especially the edge of the desert.

Owner:SINOMACH HI LUOYANG

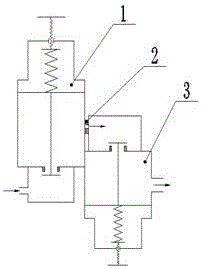

Two-stage gas pressure reducing valve

InactiveCN106090363AAvoid disturbanceHigh control precisionEqualizing valvesSafety valvesPressure stabilizationEngineering

A two-stage gas pressure reducing valve is composed of two pressure reducing valves. A primary pressure reducing valve on the left side is positively installed, a secondary pressure reducing valve on the right side is inversely installed, an inlet of the secondary pressure reducing valve is connected with an outlet of the primary pressure reducing valve, and a throttle orifice is arranged between the secondary pressure reducing valve and the primary pressure reducing valve. After high-pressure gas undergoes pressure reduction and pressure stabilization through the primary pressure reducing valve, medium-pressure gas having a certain value is obtained; the medium-pressure gas enters the secondary pressure reducing valve through the throttle orifice, and the secondary pressure reducing valve continues to perform pressure reduction and pressure stabilization on the medium-pressure gas, so that the medium-pressure gas enters the secondary pressure reducing valve through the throttle orifice, so as to meet the requirements of a gas pipe system. Compared with the prior art, the two-stage gas pressure reducing valve has the remarkably advantages that 1) outlet pressure control accuracy is high, the pressure is stable, dynamic characteristics are good, pressure regulating amplitude is high, and the pressure reduction effect is obvious; 2) during the pressure regulation, a sensitive element and a throttle valve core react simultaneously, and the reaction aftereffect is reduced, so that the pressure regulating response is quicker and more accurate.

Owner:CHANGDE XIANGYU EQUIP MFG

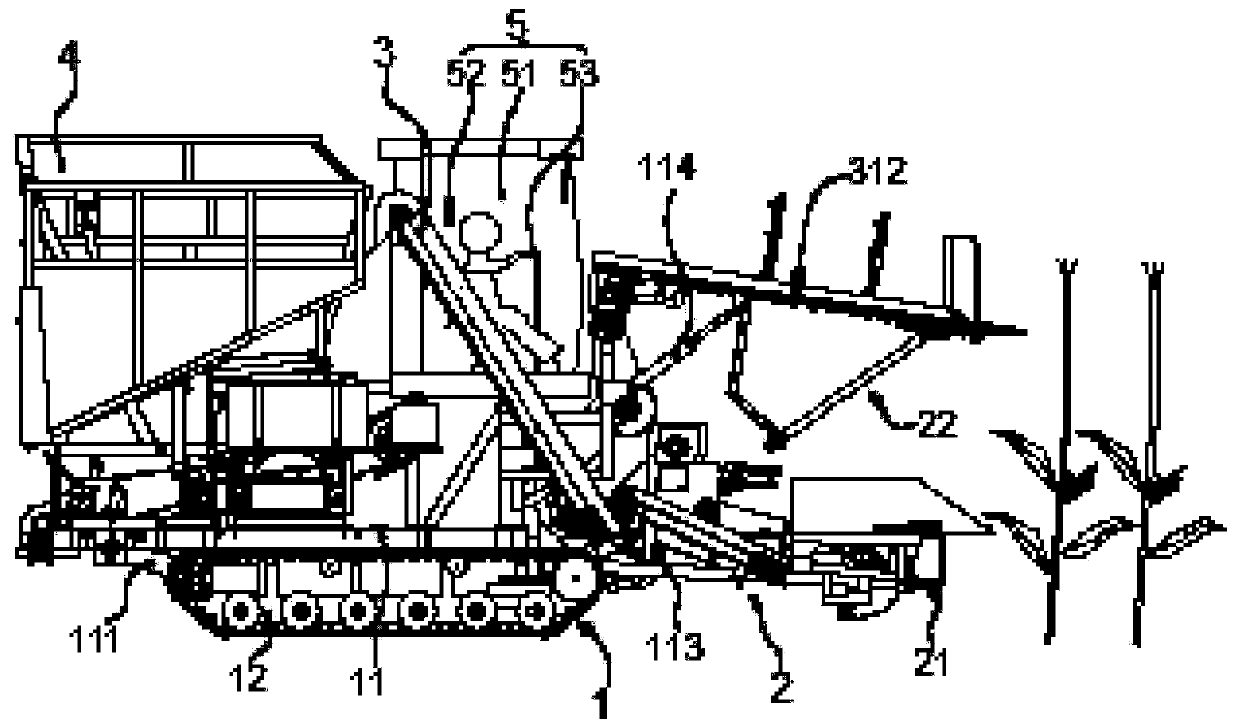

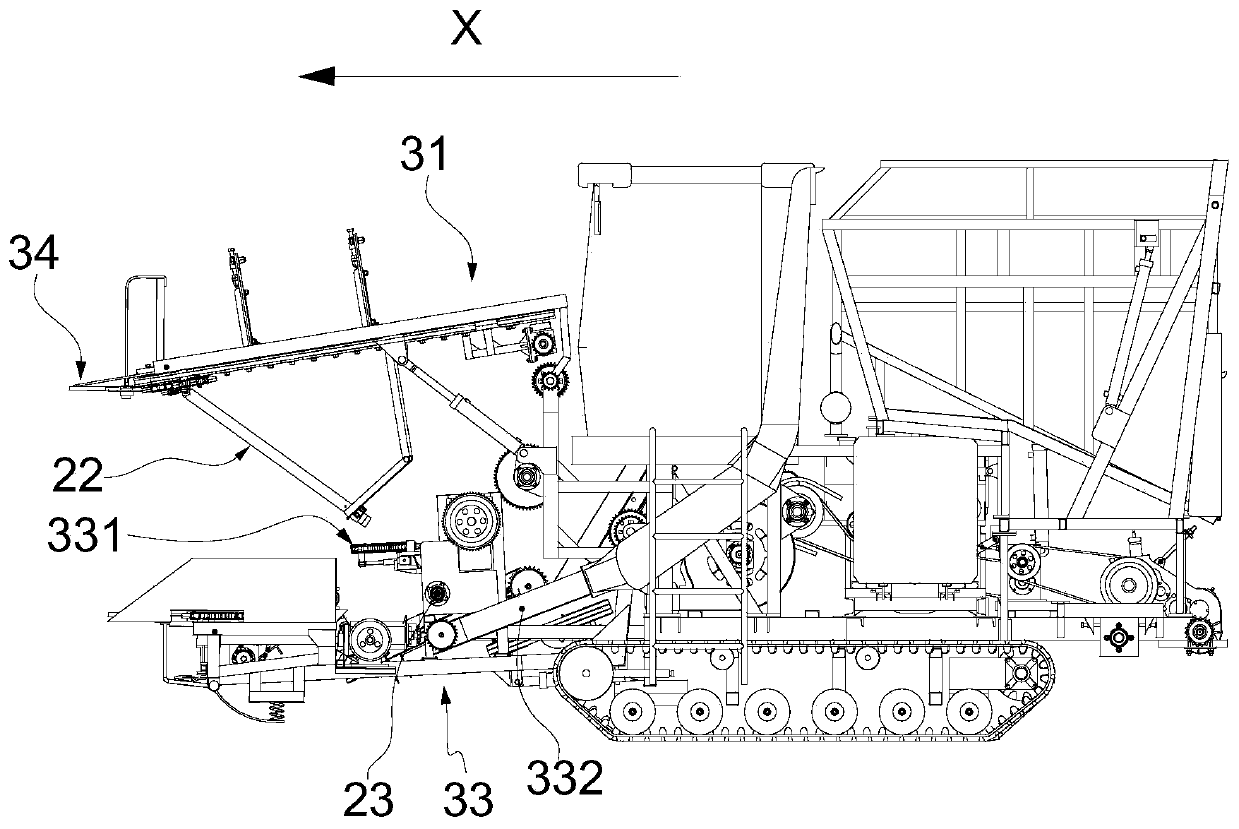

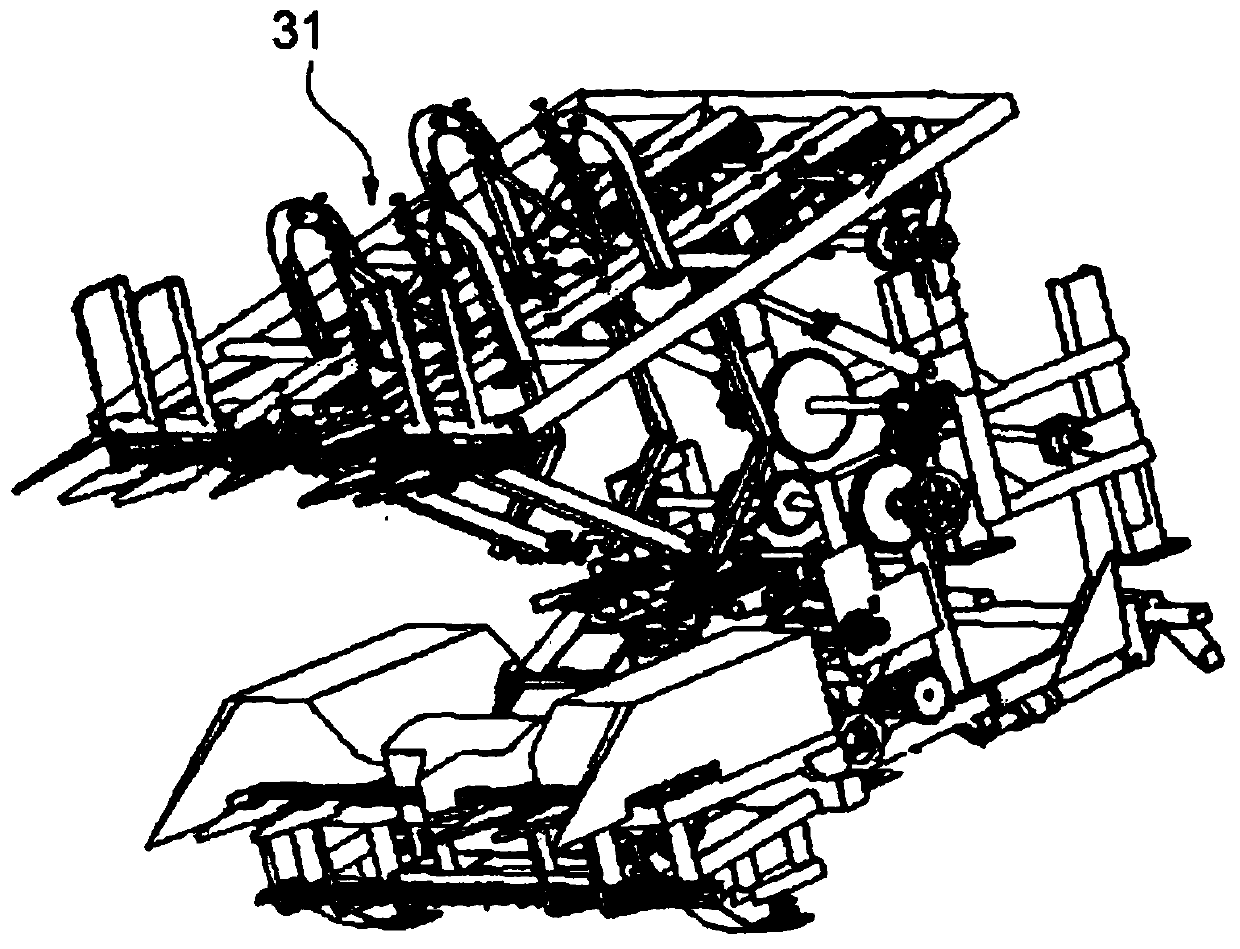

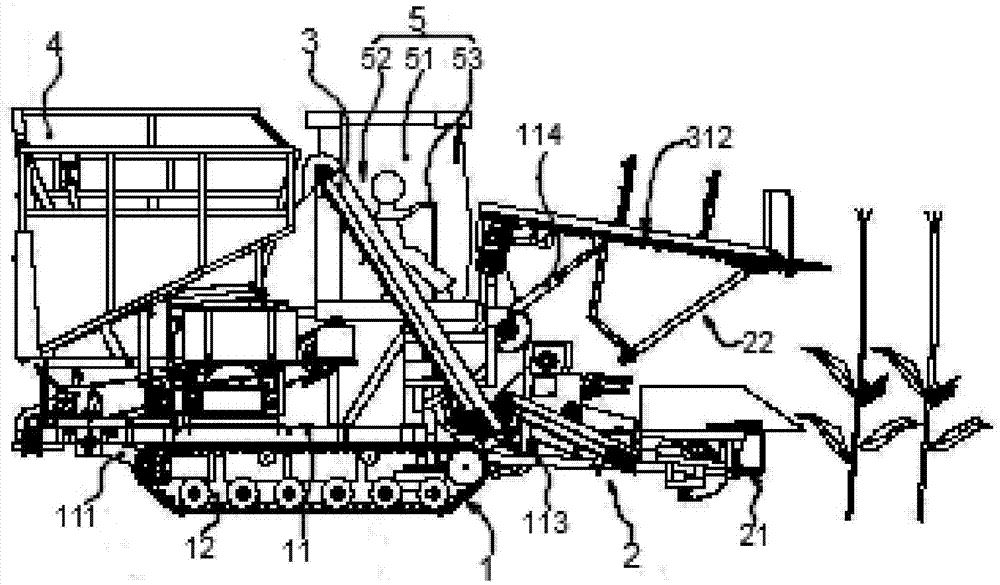

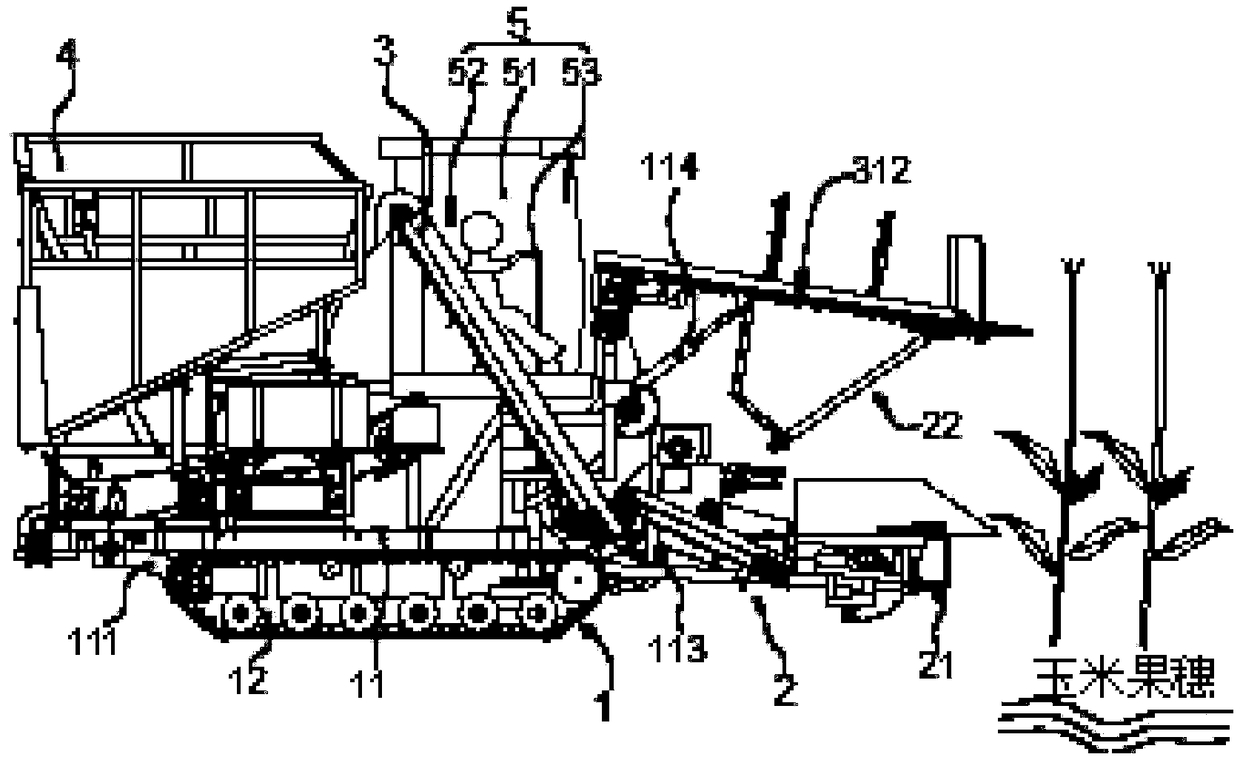

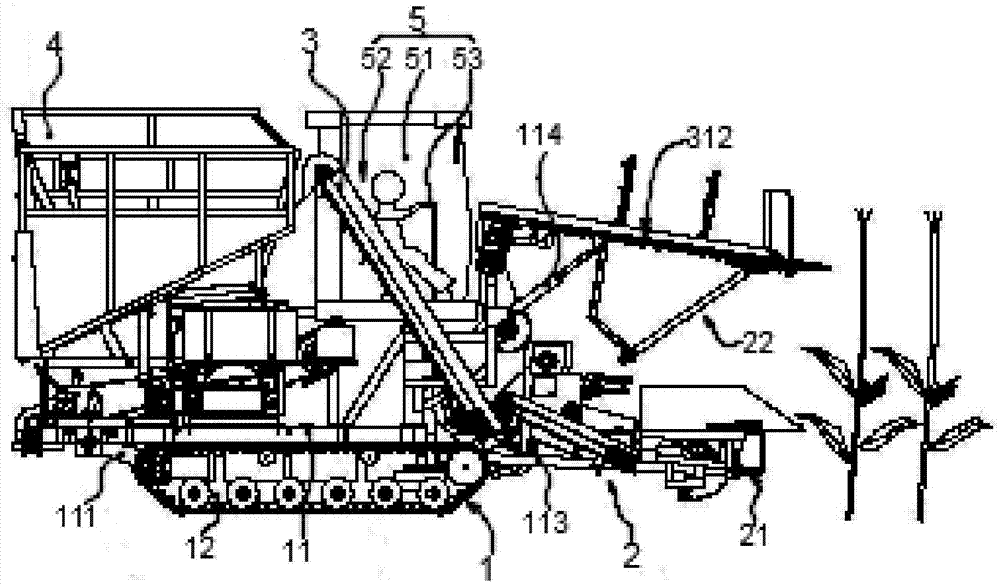

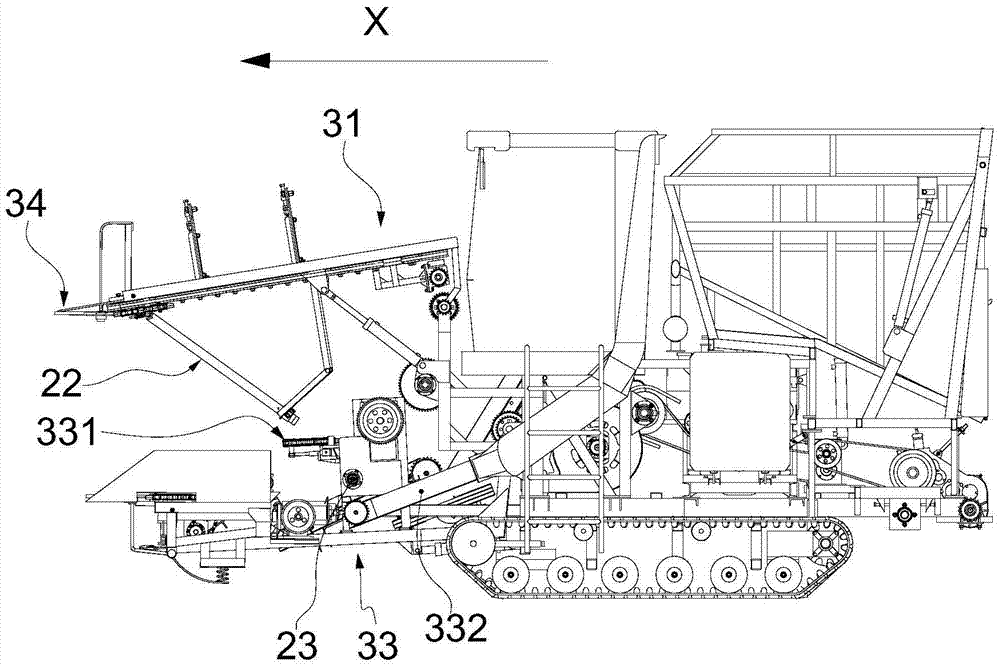

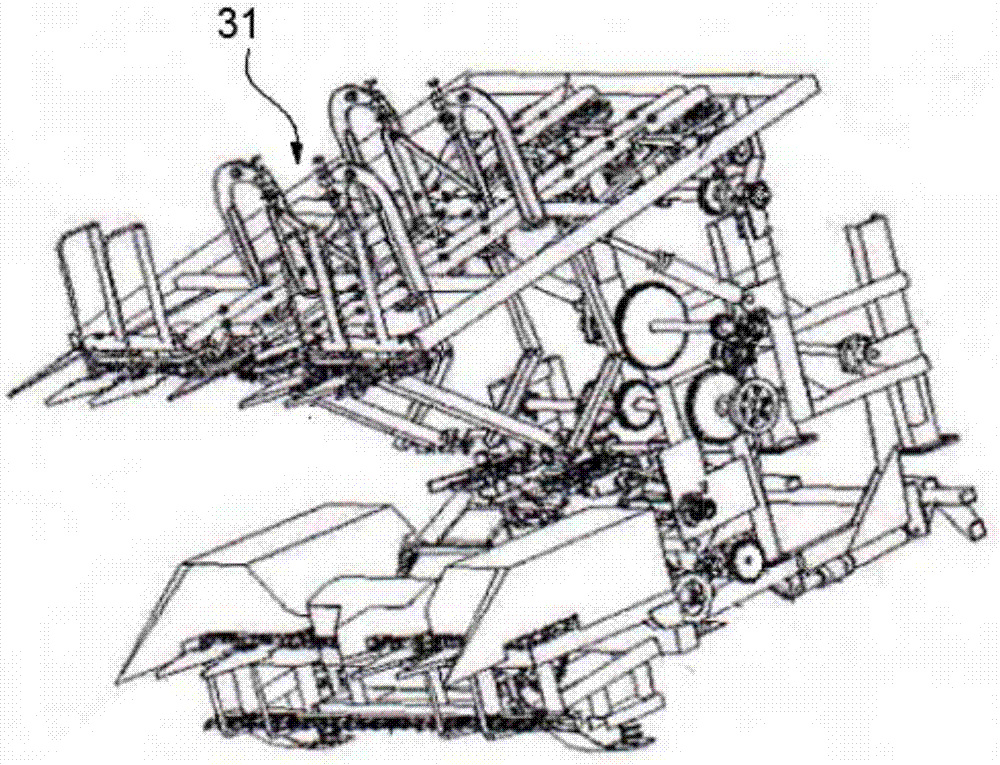

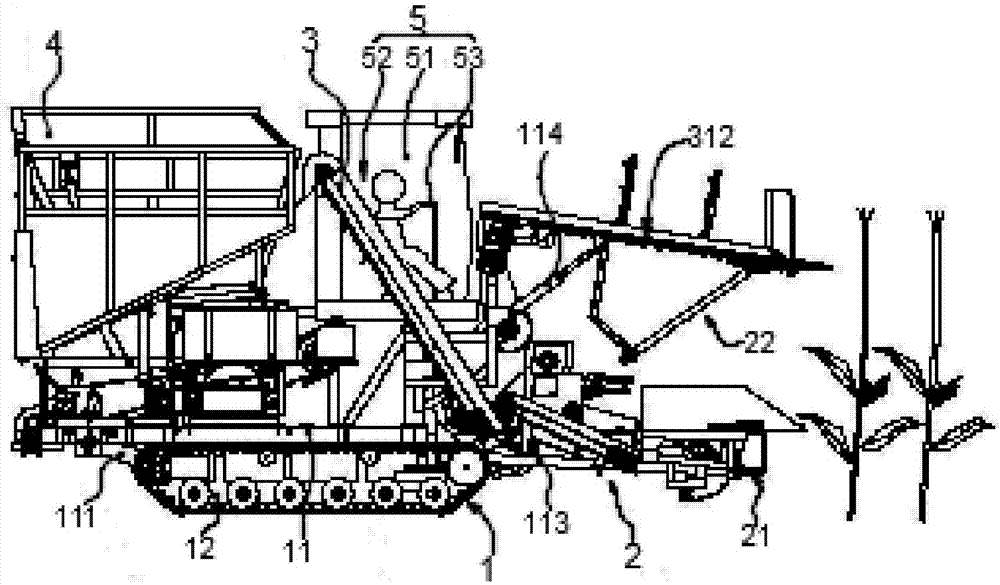

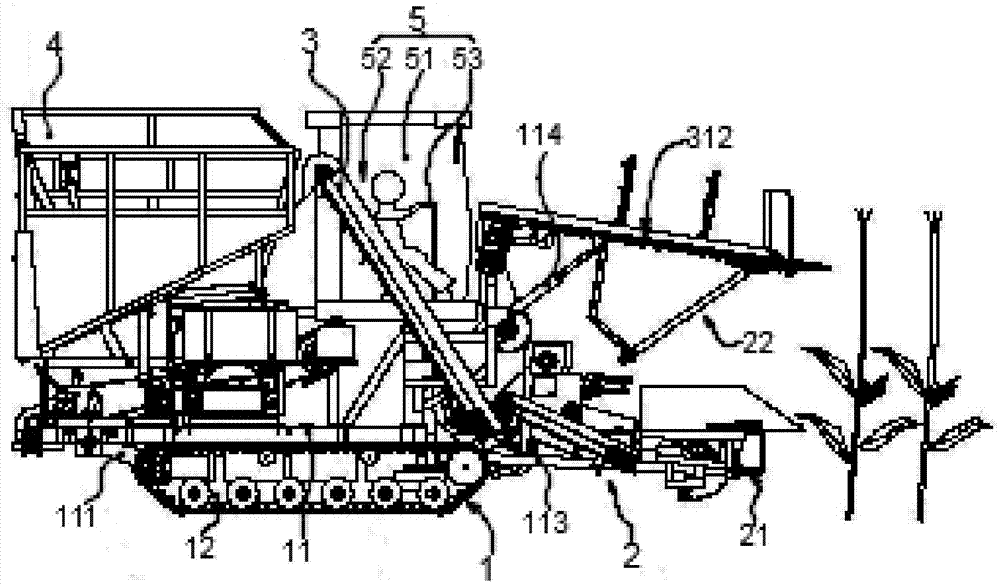

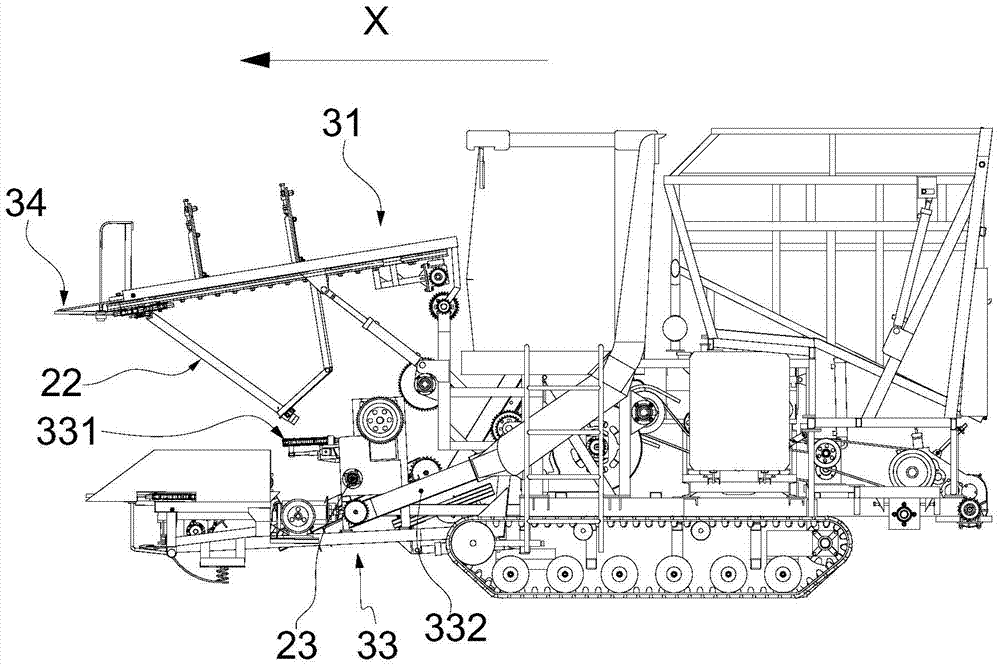

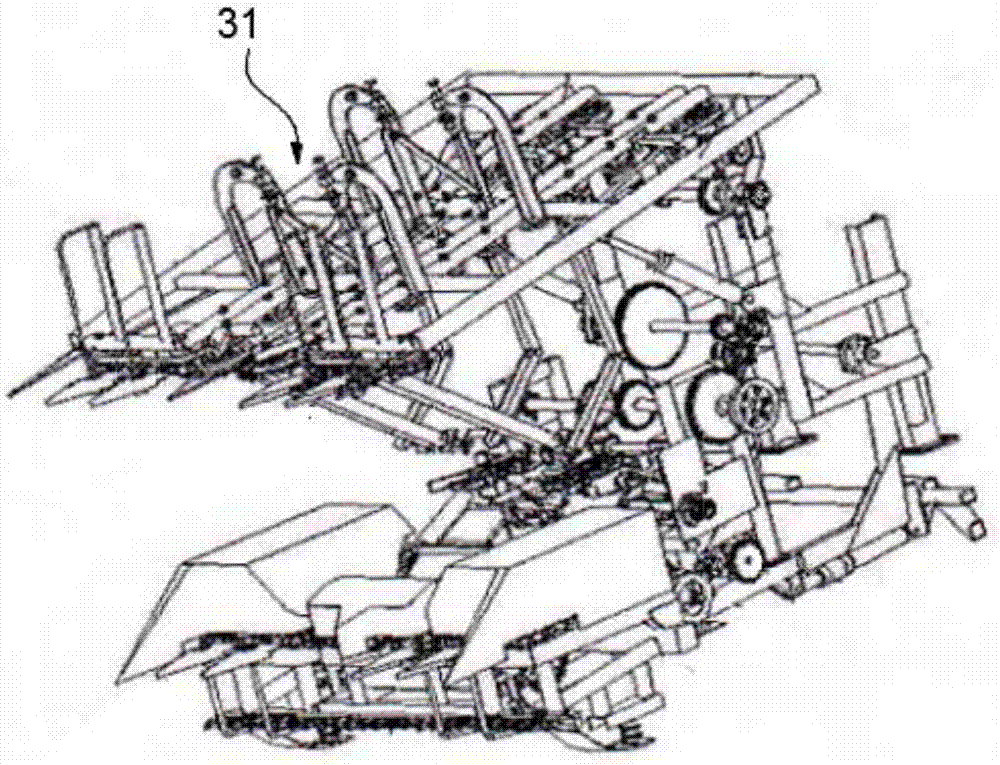

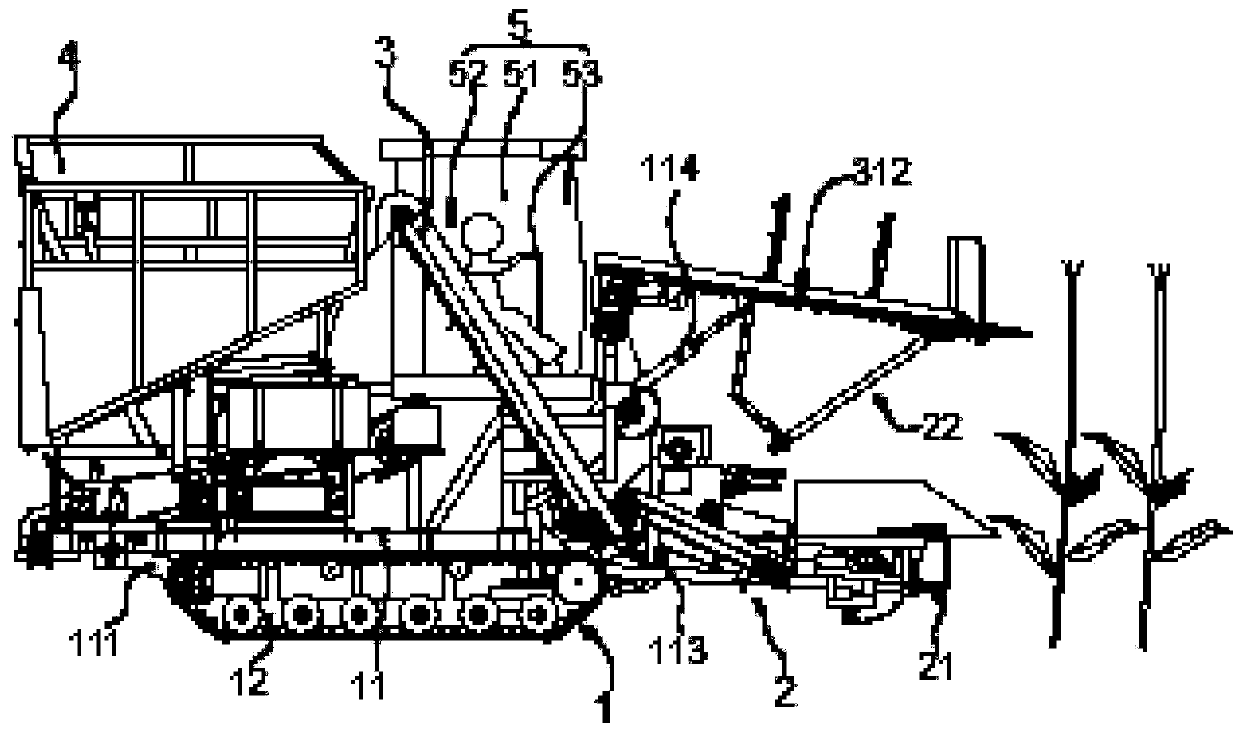

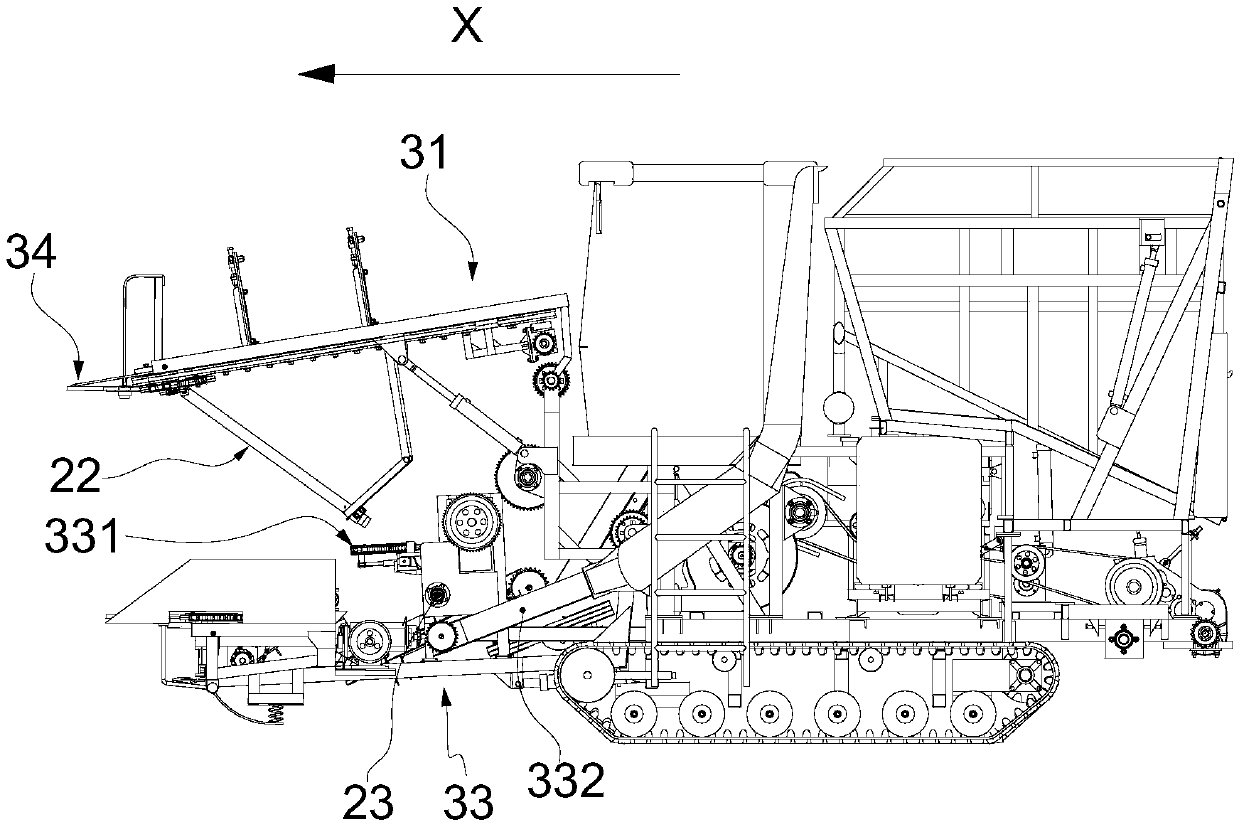

Fresh corn harvester

A fresh corn harvester comprises a chassis assembly, a harvesting assembly, a conveying assembly, an aggregate assembly, a steering assembly and a driving assembly, wherein the harvesting assembly, the steering assembly and the aggregate assembly are sequentially arranged on the chassis assembly, the conveying assembly is arranged on the chassis assembly in a crossing way, the driving assembly provides driving force for the mechanical movements of the whole harvester, the harvesting assembly is used for harvesting clusters and stems of the corn, and the conveying assembly is used for respectively and independently conveying the whole corn plants, the harvested corn clusters and the harvested corn stems to the aggregate assembly. Compared with the prior art, the harvester is specially suitable for Chinese fresh corn planting environment, not only are the functions of harvesting both the stems and the clusters are achieved, but also the harvester can be used for harvesting in opposite rows without manual assistance, and can be used for full-automatic harvesting and collecting, so that the cost is reduced; in addition, the fresh corn harvester reduces the cluster damage rate, increases the recovery total amount of stems and improves the income.

Owner:XIANGTAN ZHILIAN TECH MATASTASIS PROMOTE CO LTD

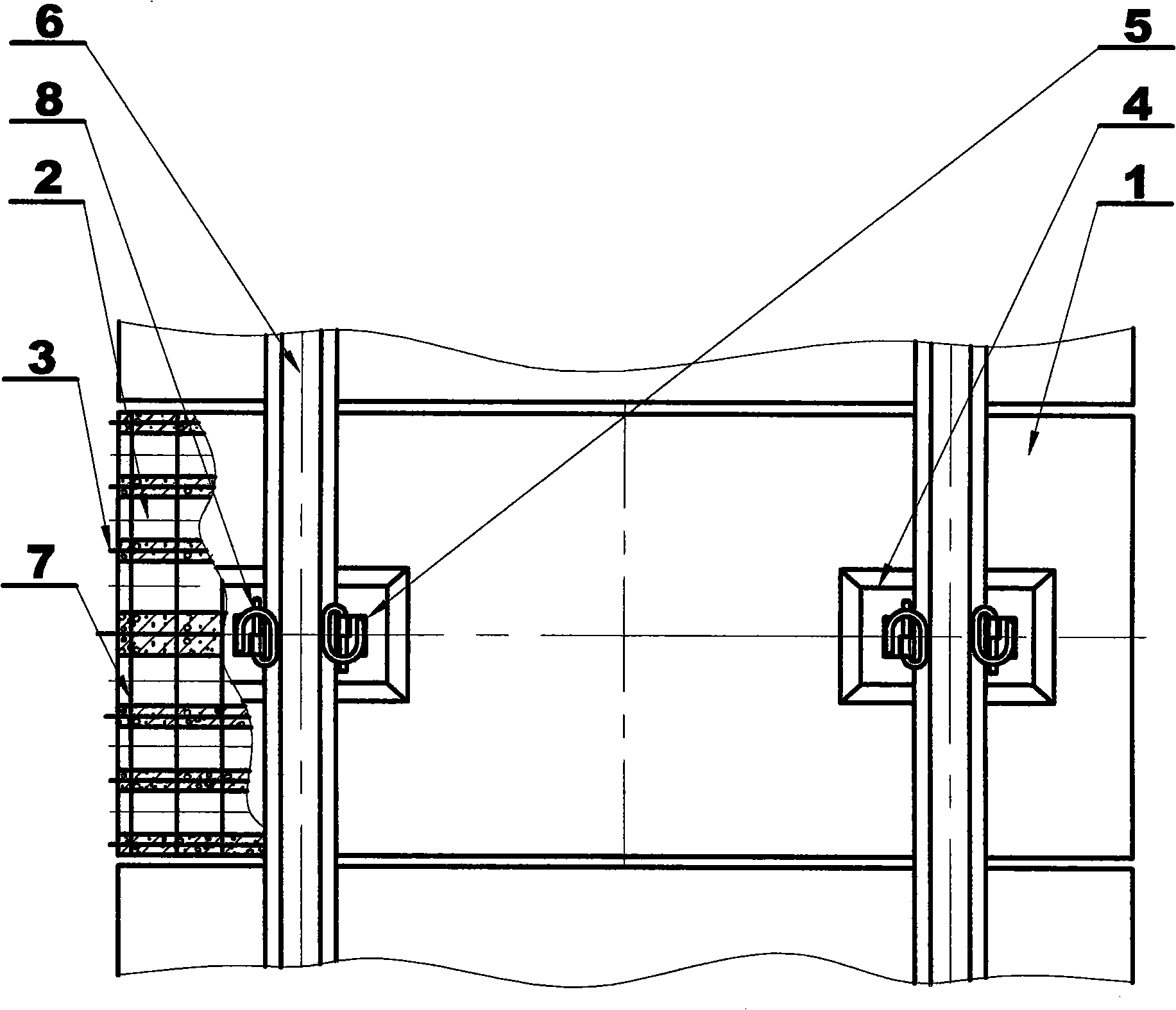

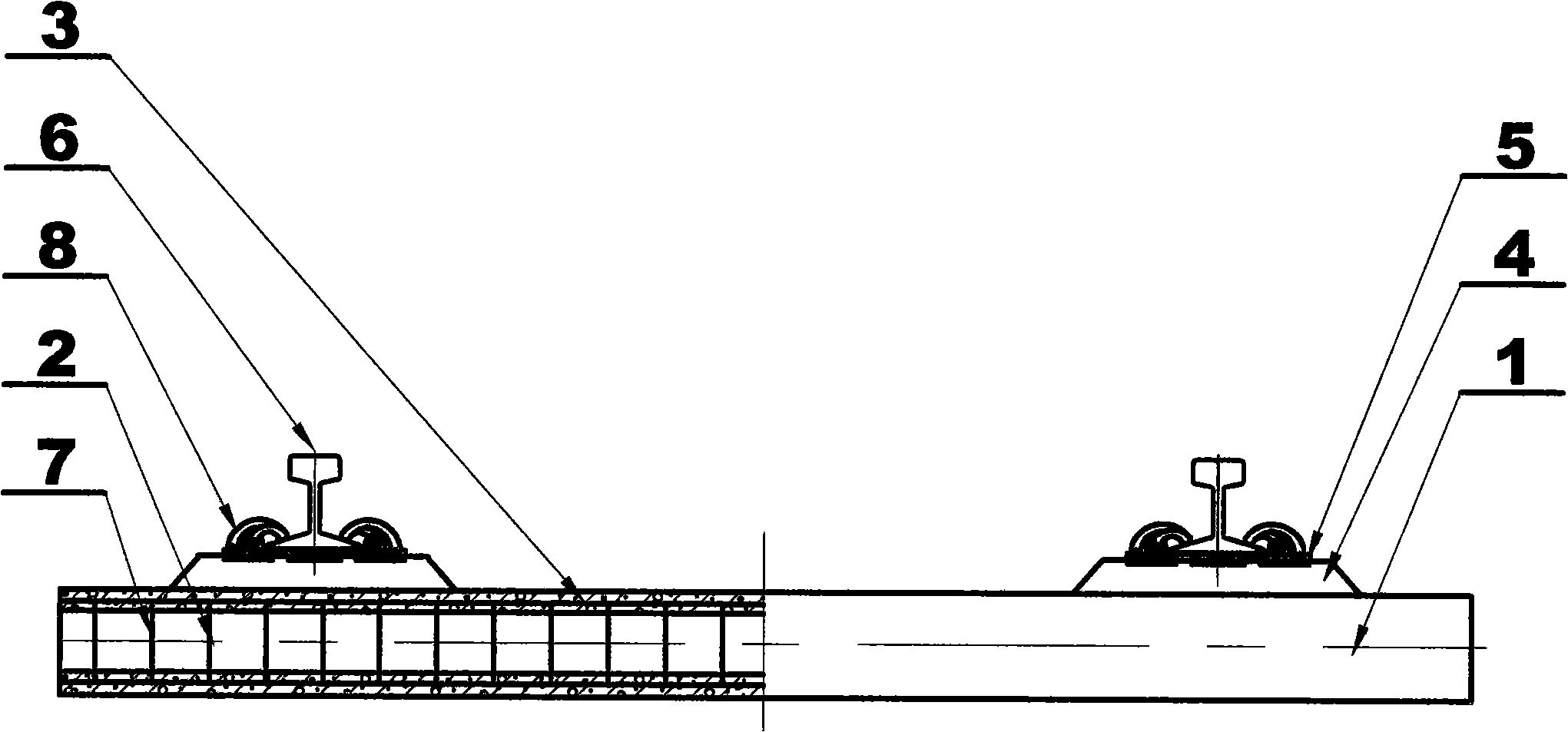

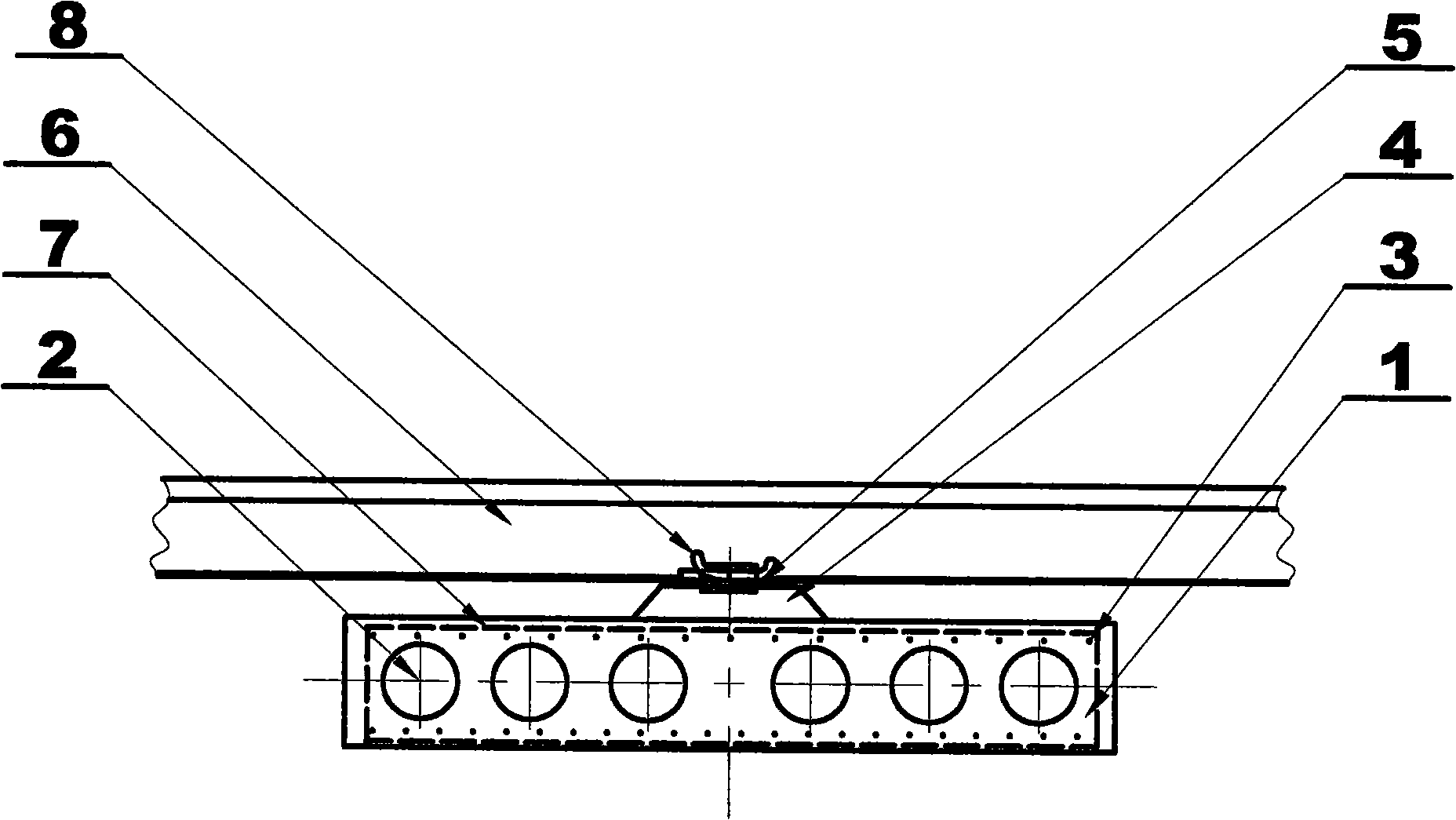

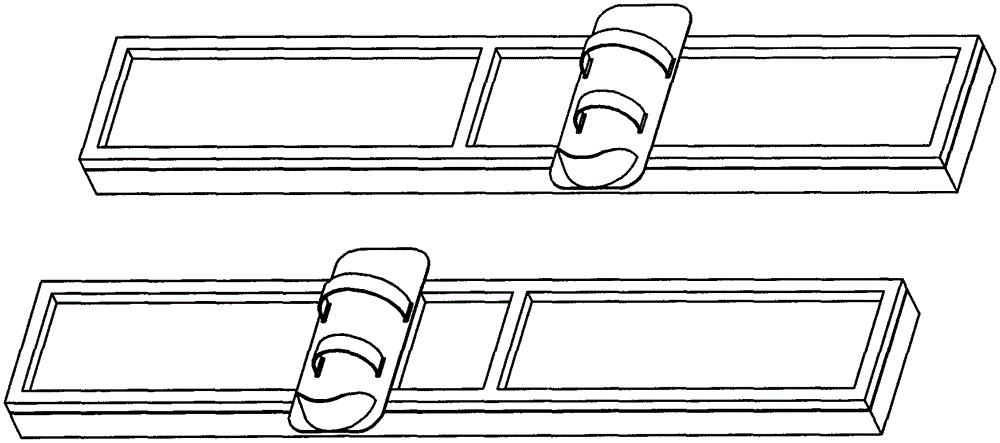

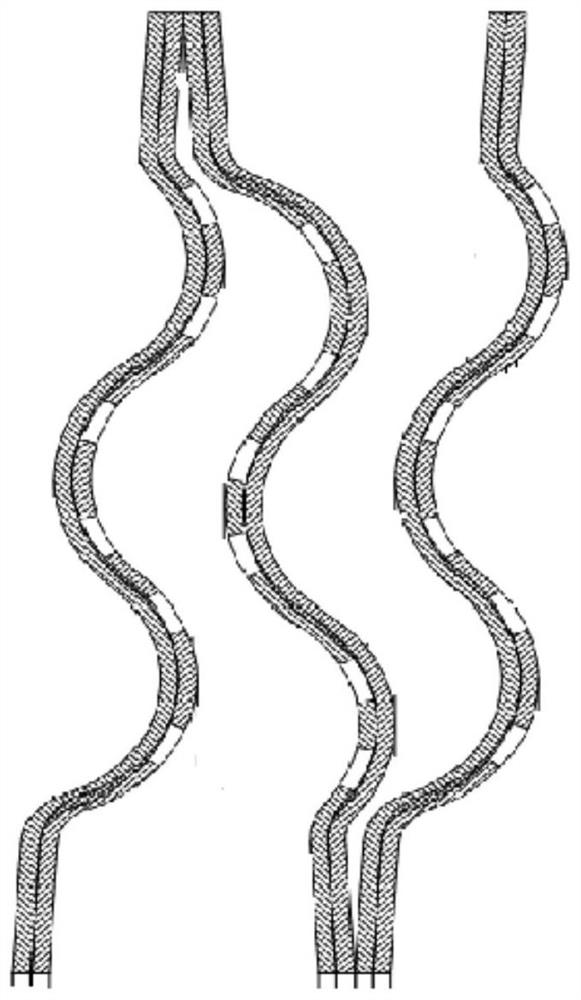

Coal mine narrow gauge railway monolithic road-bed

InactiveCN101280542ALower specific pressureReduce maintenanceBallastwayMovable tracksPre stressPre stressing

The invention relates to an integral ballast bed which can prevent loose and soft roadway floor from being pressed, the integrated ballast bed is realized by increasing width and reducing the load intensity of ballast bed on the roadway floor. The integral ballast bed is premade by concrete, the built-in pre-stressed steel bars and the threaded steel bar hoops are used to improve the strength of the ballast bed. The ballast bed is vertically provided with a central hollow cavity so as to reduce the weight of the ballast bed and is also used as a water flowing channel. The upper plate surface of the ballast bed is premade with two rail fixer pedestals according to the requirement of the gauge, the rail fixer pedestals are pre-buried with rail fixer bases. The railway rail is arranged fixedly on the rail fixer bases of the integral ballast bed by rail fixer springs, thereby finishing the paving of railway.

Owner:沙同庆

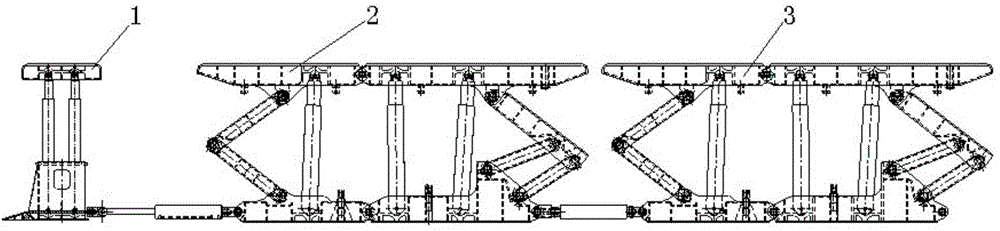

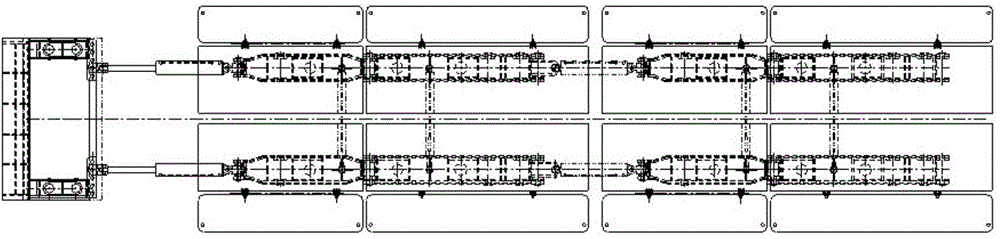

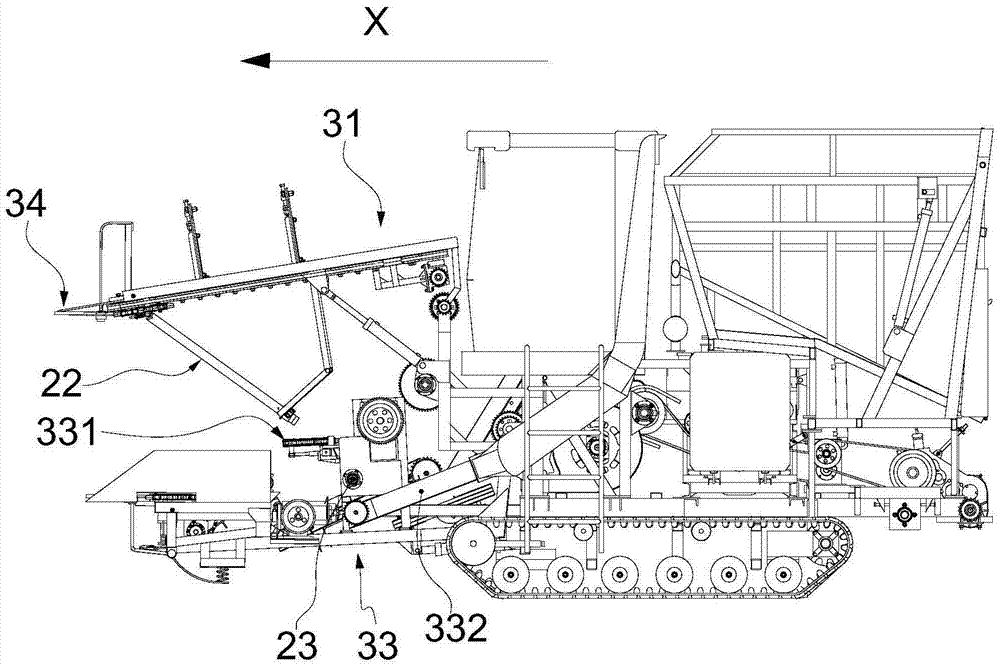

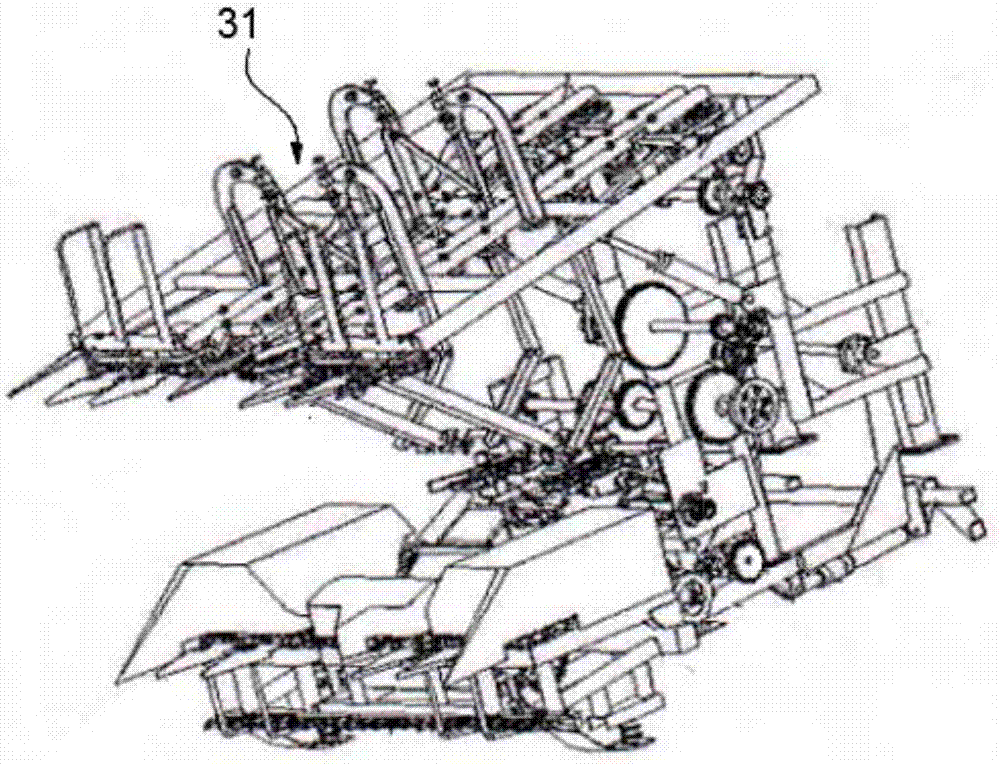

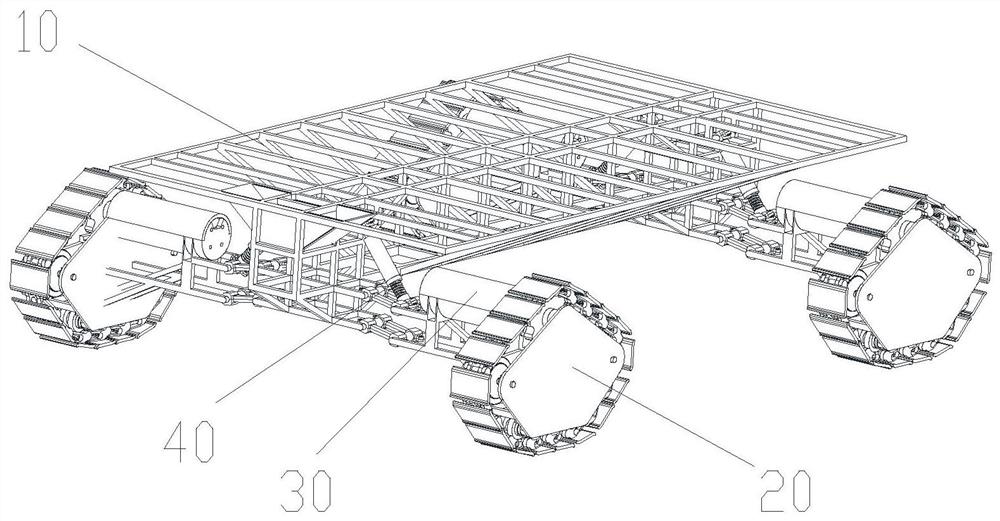

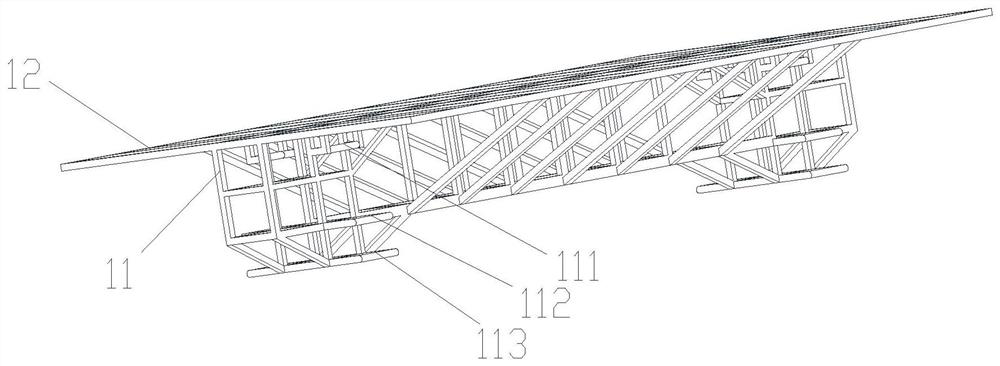

Harvester

InactiveCN106888682AIncrease ground areaLower specific pressureMowersAgricultural lifting devicesRecovery totalEngineering

The invention provides a harvester. The harvester comprises a chassis assembly, a harvesting assembly, a conveying assembly, a collecting assembly, a driving assembly and a drive assembly. The harvesting assembly, the driving assembly and the collecting assembly are sequentially arranged on the chassis assembly, the conveying assembly stretches across the chassis assembly, the drive assembly provides power drive for mechanical motion of the whole machine, the harvesting assembly is used for harvesting corn ears and stems, and the conveying assembly is used for independently conveying whole corn plants, the harvested corn ears and the harvested corn stems to the collecting assembly. Compared with the prior art, the harvester is specially suitable for fresh corn planting environments in China, has the stem and ear harvesting function, can achieve non-row harvesting without manual assistance, and can achieve the full-automatic harvesting and collecting functions, and the cost is reduced; in addition, by means of the harvester, the ear damage rate is reduced, the recovery total quantity of the stems is increased, and income is increased.

Owner:XIANGTAN ZHILIAN TECH MATASTASIS PROMOTE CO LTD

Novel air return way advance support

The invention discloses a novel air return way advance support. The novel air return way advance support comprises an integrated base and an integrated top beam. A cross head hinge joint point is arranged in the middle of the integrated top beam. Stand columns are arranged between the front portion of the integrated top beam and the integrated base and between the rear portion of the integrated top beam and the integrated base respectively. A covering beam is arranged between the hinge joint point of the integrated top beam and the rear portion of the integrated base. The front portion and the rear portion of the integrated top beam are arranged into a front and back symmetrical structure with the cross head hinge joint point as the center. Wall protection plates are arranged at the front end, the rear end and the two sides of the integrated top beam respectively. Multiple novel air return way advance supports are sequentially arranged in an air return way in a front and back mode. The integrated bases of every two adjacent supports are connected through a push-pull oil cylinder. The novel air return way advance support can adapt to the working condition that a bottom plate of a roadway is not smooth, the top protection area can be enlarged, and the personnel safety is protected.

Owner:CHINA COAL BEIJING COAL MINING MACHINERY

Stem cob harvesting type fresh corn harvester

The invention provides a stem cob harvesting type fresh corn harvester. The stem cob harvesting type fresh corn harvester includes a chassis assembly, a harvesting assembly, a conveying assembly, a collecting assembly, a driving assembly and a drive assembly; the harvesting assembly, the driving assembly and the collecting assembly are successively arranged on the chassis assembly; the conveying assembly crosses the chassis assembly; the drive assembly provide power for mechanical motion of the whole harvester; the harvesting assembly is used for harvesting corncobs and stems; and the conveying assembly is used for independently conveying the whole corns, the harvested corncobs and the harvested corn stems to the collecting assembly. Compared with the prior art, the harvester is especially suitable for Chinese fresh corn planting environments, can harvest the corncobs and the corn stems, can achieve non-row harvesting, can avoid human assistance, can automatically harvest and collect corncobs and corn stems, and can reduce the cost; and in addition, the stem cob harvesting type fresh corn harvester can reduce the damage rate of the corncobs, can increase the recovery yield of the stems, and can increase the income.

Owner:XIANGTAN ZHILIAN TECH MATASTASIS PROMOTE CO LTD

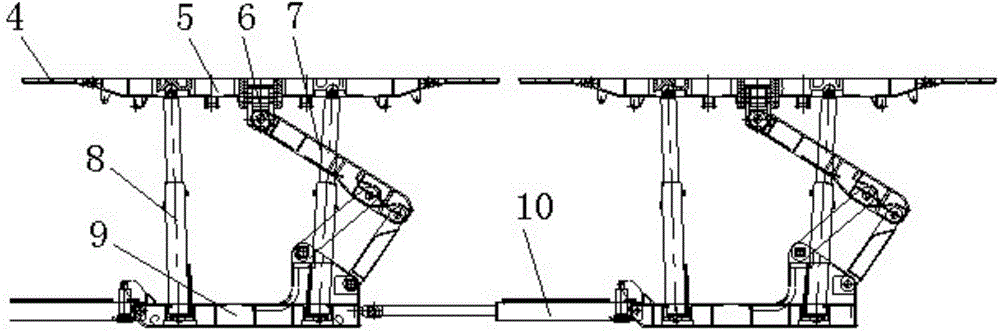

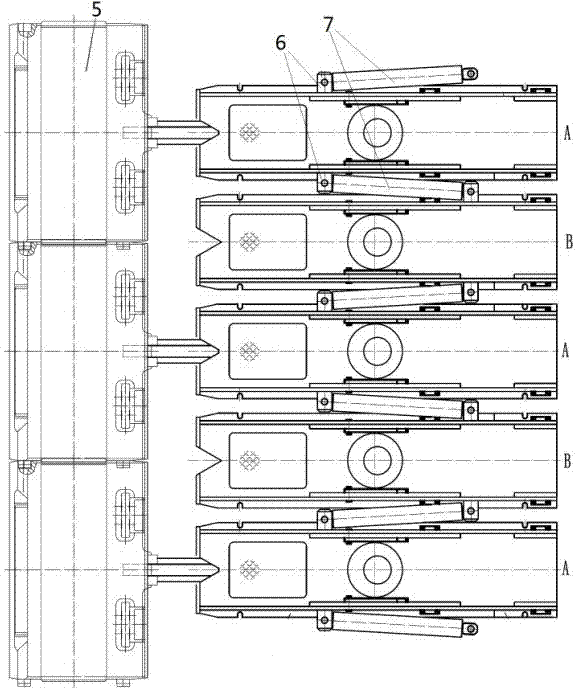

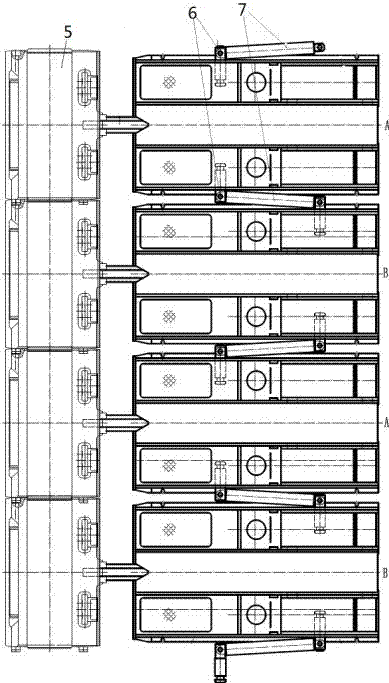

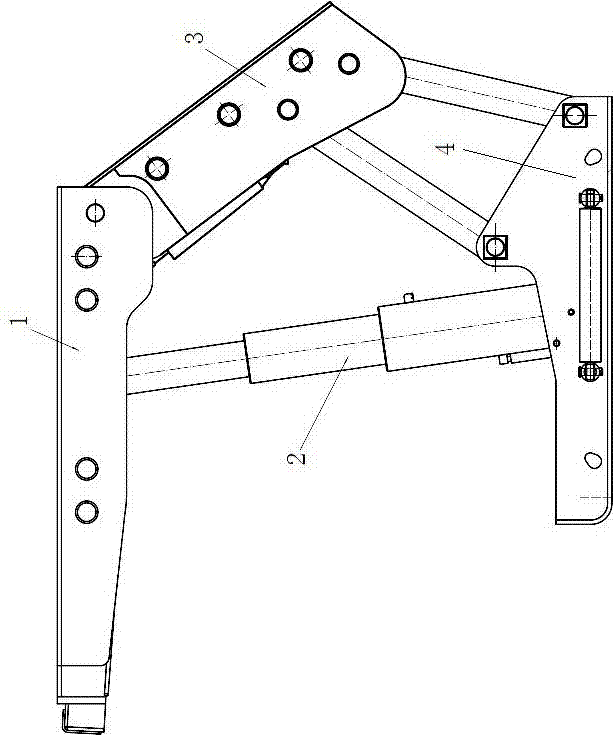

Single stand column dual-moving hydraulic support and moving mechanism and moving method

The invention provides a single stand column dual-moving hydraulic support, a moving mechanism and a moving method. The support comprises a top beam, a base, a stand column and a support stabilizing mechanism. The stand column is one in number. The lower end of the stand column is connected with the base, and the other end of the stand column is connected with the top beam or the support stabilizing mechanism. The two sides of the stand column are provided with moving lug shafts. A distributing mode of the moving lug shafts is divided into a front form A and a rear form B, and a moving jack A and a moving jack B are connected and pushed and moved. Compared with the prior art, the support has the advantages that the single stand column is arranged, a crotch opening of the base is avoided, a push rod is avoided, the overall size is small, and the weight is light.

Owner:SHANDONG XINMEI MASCH EQUIP CO LTD

Harvester

InactiveCN108307786AIncrease ground areaLower specific pressureMowersAgricultural lifting devicesEngineeringChassis

Owner:XIANGTAN ZHILIAN TECH MATASTASIS PROMOTE CO LTD

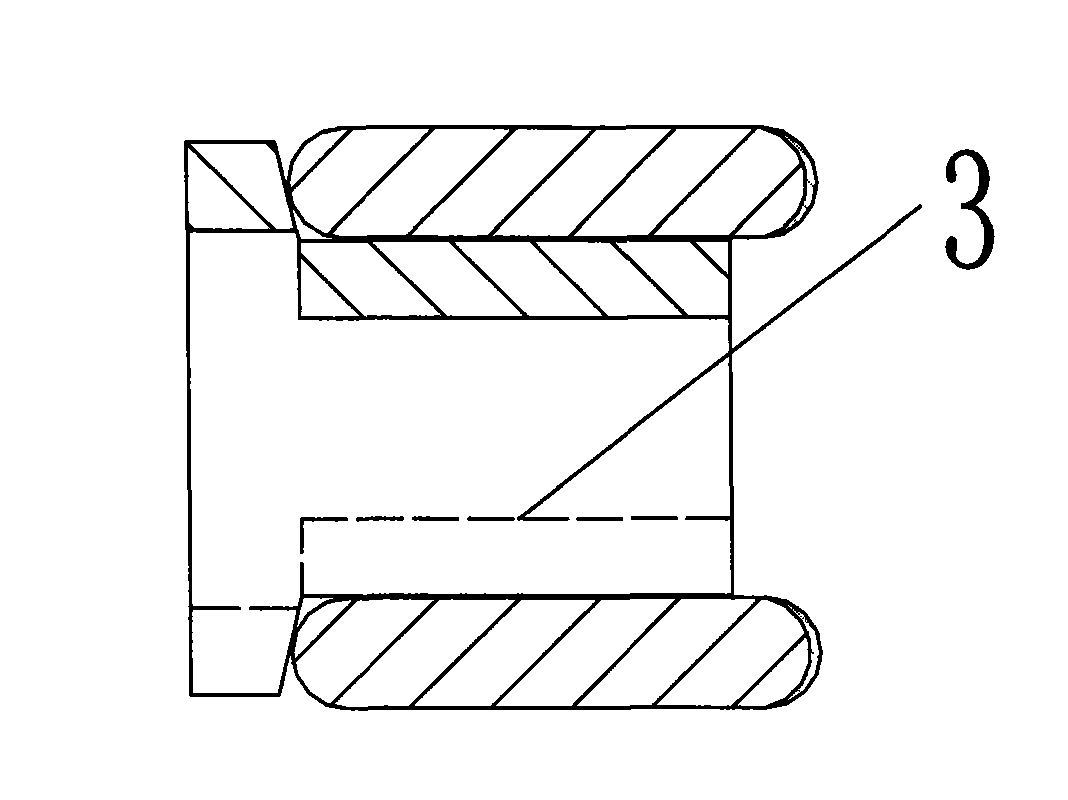

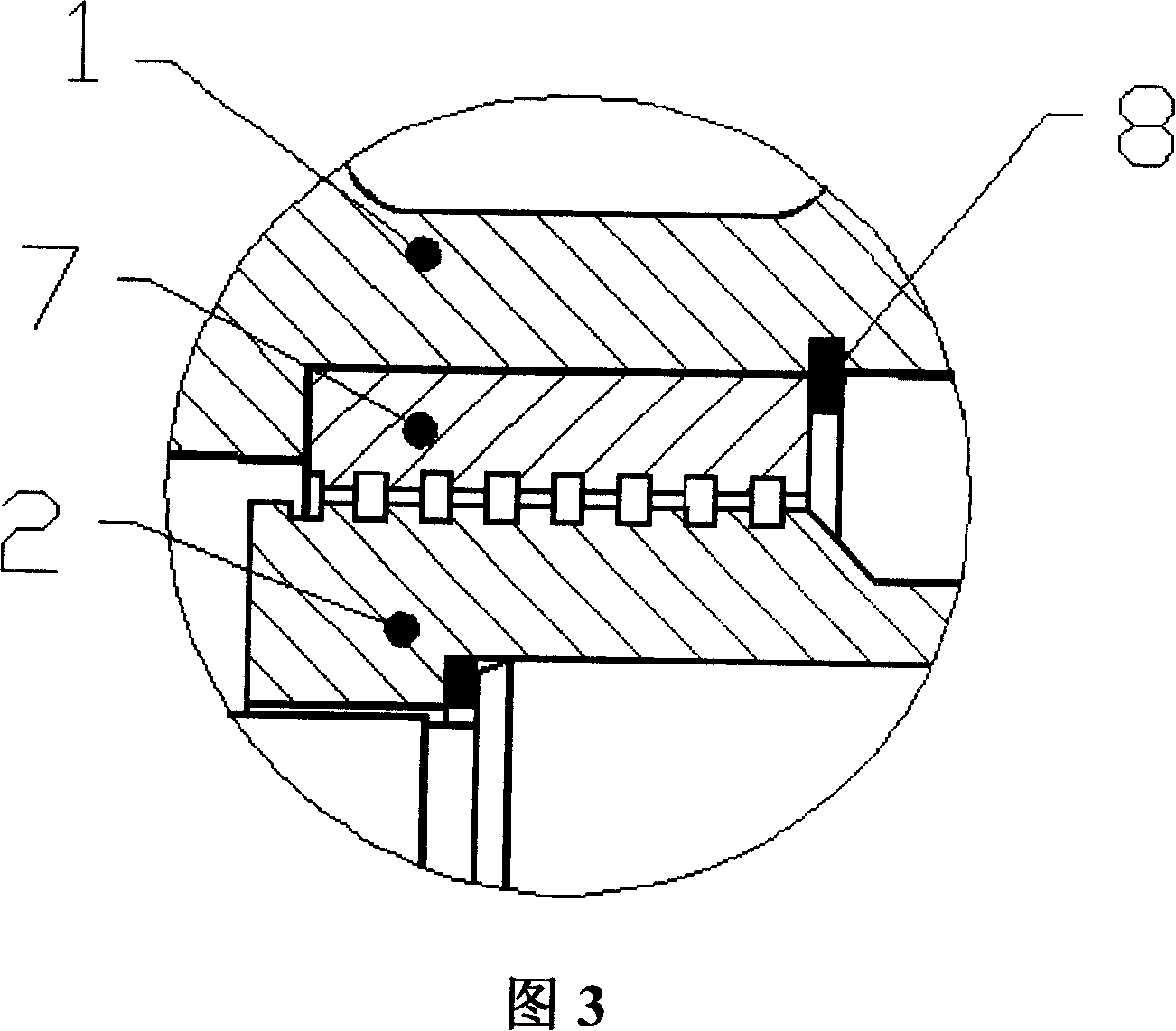

Sealing structure of single-stage single-suction centrifugal pump for chemical procedure

InactiveCN101122298ALower specific pressureExtend your lifePump componentsPumpsSingle stagePump chamber

The invention relates to a seal structure of a single-stage and single-suction chemical process centrifugal pump, and comprises a pump cover (1), a shaft sleeve (2), a seal chamber (3), a mechanical seal (4), a mechanical seal cover (5), and a pump chamber (6), as well as a spiral seal (7). One end of the spiral seal (7) is connected to the pump cover (1) and the seal chamber (3), while the other end of the spiral seal (7) is connected to the pump chamber (6). The beneficial effect of the invention is that the medium pressure entering the seal chamber is greatly reduced due to the pumping function of the spiral seal; thus, a general mechanical seal can be used to reduce the cost; on the other hand, the specific pressure of an end surface of the mechanical seal can be reduced, and abrasion of a friction pair is reduced, so as to prolong the usable life of the mechanical seal.

Owner:上海开利制泵有限公司

Fresh corn harvester

The invention provides a fresh corn harvester comprising a chassis assembly, a harvesting assembly, a transmission assembly, an aggregating assembly, a driving assembly and a drive assembly. the harvesting assembly, the driving assembly and the aggregating assembly are successively arranged on the chassis assembly; the transmission assembly is arranged on the chassis assembly in a cross mode; the drive assembly provides driving power for the mechanical movement of the whole machine; the aggregating assembly is used for harvesting core cluster and stalks; the transmission assembly is used for independently transmitting whole core plants, core cluster after harvesting and corn stalks after harvesting to the aggregating assembly. Compared with the prior art, the harvester provided in the invention is specially suitable for the cultivation environment of the fresh corn in China; the harvester has the functions of harvesting cluster and stalks and harvesting without in rows; the harvester need not human assistance and automatic harvesting and aggregating can be realized so as to reduce cost; in addition, by means of the fresh corn harvester of the invention, the cluster damage rate is reduced; the total recovery amount is increased and therefore the income is increased.

Owner:XIANGTAN ZHILIAN TECH MATASTASIS PROMOTE CO LTD

All-hydraulic die forging hammer

InactiveCN104550600AIncrease widthExtended service lifeForging press detailsForging press drivesMechanical engineering

The invention relates to an all-hydraulic die forging hammer which comprises a U-shaped lathe bed, wherein the U-shaped lathe bed is provided with an all-hydraulic power head; the all-hydraulic power head comprises a working cylinder; a hammer lever is mounted in the working cylinder; the lower end of the hammer lever is connected with a sliding block; guide grooves are respectively formed in the first side surface and the second side surface, which are contacted with the lathe bed, of the sliding block; each guide groove is internally provided with a groove bottom surface, as well as a first guide surface and a second guide surface arranged on the groove bottom surface, wherein both the first guide surface and the second guide surface are inclined planes; guide rails are arranged on the opposite inner side wall surfaces of the U-shaped lathe bed respectively, and are inserted into the guide grooves to be in sliding fit with the guide grooves. The all-hydraulic die forging hammer has the advantage of high guide precision, and the die forging precision is not affected by a temperature rise.

Owner:CHANGZHOU JINGLING CASTING & FORGING

Footboard capable of being used for worker to walk on solar cell panels

The invention discloses a footboard capable of being used for a worker to walk on solar cell panels. The footboard comprises a sole and an upper which allow the worker to wear, and the upper is fixed on the sole. The footboard is characterized in that the sole with the flat bottom surface is made of elongated polyethylene foam cotton, the length of the sole ranges from 70 centimeters to 120 centimeters, the width of the sole ranges from 15 centimeters to 30 centimeters, the thickness of the sole ranges from 4 centimeters to 8 centimeters, the upper is fixed in the middle of the sole, and the wearing direction of the upper is parallel or perpendicular to the long side direction of the sole. The footboard capable of being used for the worker to walk on the solar cell panels has the advantages that the footboard is simple in structure, convenient to manufacture and use and low in price; the sole is made of the large-sized lightweight elongated polyethylene foam cotton, and accordingly contact area between the sole and every solar cell panel is enlarged, specific pressure on the solar cell panels is reduced greatly, the solar cell panels are less prone to being crushed, and the problem that the worker cannot conduct maintenance on the solar cell panels is solved effectively.

Owner:陆峰

Harvester

InactiveCN106888681AIncrease ground areaLower specific pressureMowersAgricultural lifting devicesEngineeringRecovery total

The invention provides a harvester. The harvester comprises a chassis assembly, a harvesting assembly, a conveying assembly, a collecting assembly, a driving assembly and a drive assembly. The harvesting assembly, the driving assembly and the collecting assembly are sequentially arranged on the chassis assembly, the conveying assembly stretches across the chassis assembly, the drive assembly provides power drive for mechanical motion of the whole machine, the harvesting assembly is used for harvesting corn ears and stems, and the conveying assembly is used for independently conveying whole corn plants, the harvested corn ears and the harvested corn stems to the collecting assembly. Compared with the prior art, the harvester is specially suitable for fresh corn planting environments in China, has the stem and ear harvesting function, can achieve non-row harvesting without manual assistance, and can achieve the full-automatic harvesting and collecting functions, and the cost is reduced; in addition, by means of the harvester, the ear damage rate is reduced, the recovery total quantity of the stems is increased, and income is increased.

Owner:XIANGTAN ZHILIAN TECH MATASTASIS PROMOTE CO LTD

Axial piston pump

ActiveCN105090008BLarge swing angleReduce radial forcePositive displacement pump componentsLiquid fuel engine componentsRadial piston pumpEngineering

The invention discloses a novel axial plunger pump, the main points of which are technical solutions including an end cover, a front casing, a pump shaft arranged in the front casing, a rear casing, a swash plate installed in the rear casing, and a cylinder body , the end cover, the front casing, the rear casing and the cylinder body are fixedly connected in sequence, the end of the pump shaft facing away from the casing is connected to the swash plate, and the plunger pump is also equipped with a cross wobble plate and a plunger assembly , the cylinder body is provided with a plunger hole, a valve hole, a pressure-out valve group and a pressure-in valve group, the pressure-out valve group and the pressure-in valve group are located in the valve hole, and one end of the plunger assembly is embedded in the plunger hole , the other end of the plunger assembly is connected to the cross wobble plate, the cross wobble plate is in conflict with the swash plate, and the shoe plate integrates the return plate and the shoe in the prior art, and the shoe and the plunger ball head are inlaid into one, reducing the The lateral force of the cylinder body and the plunger seat is reduced, and at the same time, it is beneficial to increase the swing angle of the swash plate, which is beneficial to increase the return distance of the plunger seat, increase the displacement of the plunger pump, and improve the performance of the plunger pump. efficiency, further simplifying the cylinder design.

Owner:HANGZHOU LVJU TECH +1

Turbine pump sealing mechanism and turbine pump

ActiveCN112012954ASmall overall deformationReduce deformationPump componentsPumpsEngineeringTurbopump

The invention discloses a turbine pump sealing mechanism and a turbine pump applying the same. The turbine pump sealing mechanism comprises a moving ring, a static ring, a double-layer corrugated pipe, an isolating ring, a sealing shell and a rotating shaft; the sealing shell is suitable for being connected with a turbine pump shell of the turbine pump; the isolating ring is arranged on the rotating shaft in a sleeving mode and forms a seal with the contact surface of the rotating shaft; the end face of an outer ring of the isolating ring abuts against the inner wall of the sealing shell to form a seal, the moving ring is arranged on the end surface of one side of the rotating shaft in a sleeving mode and attached to the end surface of one side of the static ring to form a seal; the staticring is welded to the isolating ring in a sleeving mode, and the end face of one side of the static ring is attached to the moving ring to form a seal; the end face of the other side of the static ring is connected with the end face of one side of the isolating ring through the double-layer corrugated pipe; the two ends of the double-layer corrugated pipe are connected with the static ring and the isolating ring correspondingly; and small holes are uniformly formed in the side, in contact with leaked media, of the double-layer corrugated pipe. The turbine pump sealing mechanism is high in sealing reliability, small in loss in a high-pressure environment and suitable for being used in a high-speed and high-pressure medium environment easy to vaporize.

Owner:BEIJING XINGJI RONGYAO SPACE TECH CO LTD +2

Corn harvester

The invention provides a corn harvester. The corn harvester includes a chassis assembly, a harvesting assembly, a conveying assembly, a collecting assembly, a driving assembly and a drive assembly; the harvesting assembly, the driving assembly and the collecting assembly are successively arranged on the chassis assembly; the conveying assembly crosses the chassis assembly; the drive assembly provides power for mechanical motion of the whole harvester; the harvesting assembly is used for harvesting corncobs and stems; and the conveying assembly is used for independently conveying the whole corns, the harvested corncobs and the harvested corn stems to the collecting assembly. Compared with the prior art, the harvester is especially suitable for Chinese fresh corn planting environments, can harvest the corncobs and the corn stems, can achieve non-row harvesting, can avoid human assistance, can automatically harvest and collect corncobs and corn stems, and can reduce the cost; and in addition, the corn harvester can reduce the damage rate of the corncobs, can increase the recovery yield of the stems, and can increase the income.

Owner:XIANGTAN ZHILIAN TECH MATASTASIS PROMOTE CO LTD

Mechanical sealing device of high-speed high-pressure hydraulic pump

PendingCN110307340AImprove vibration resistanceImprove impact resistanceEngine sealsInterference fitDrive shaft

The invention discloses a mechanical sealing device of a high-speed high-pressure hydraulic pump. The mechanical sealing device comprises a shell body, a rear cover and a transmission shaft; the innerside of the shell body is provided with an annular groove I, and a rubber sealing ring I is arranged in the annular groove I; the rear end of the shell body is provided with a counter bored hole I, the outer ring of a bearing is in interference fit with the counter bored hole I, and the inner ring of the bearing is interference fit with the transmission shaft; the front end of the rear cover is provided with a through hole II, the inner side of the through hole II is provided with an annular groove II, a rubber sealing ring II is arranged in the annular groove II, the rear end of the rear cover is provided with a counter bored hole II, and an elastic element is installed in the counter bored hole II; the rear end of a supporting frame is provided with a flange, and the front end surface of the flange is closely attached to the elastic element; a sealing ring is movably connected with the supporting frame, the front end surface of the sealing ring is closely attached to the rear end surface of the flange, and the rear end surface of the sealing ring is closely attached to the front end surface of the inner ring of the bearing. The elastic element is used for providing compensationelastic force, it is ensured that the supporting frame, the sealing ring and the bearing are closely attached, and the mechanical sealing device has the characteristics of being simple in structure, good in sealing performance, resistant to high rotation speed and vibration impact, high in reliability, long in service life and the like.

Owner:XINXIANG HUAHANG AVIATION HYDRAULIC EQUIP

Stem and spike harvesting fresh maize harvester

The invention provides a stem and spike harvesting fresh maize harvester which comprises a chassis assembly, a harvesting assembly, a transfer assembly, an aggregate assembly, a driving assembly and adriving assembly, wherein the harvesting assembly, the driving assembly and the aggregate assembly are successively arranged on the chassis assembly; the transfer assembly bestrides the chassis assembly, the driving assembly provides power drive to mechanical movement of the whole harvester, the harvesting assembly is used for harvesting spikes and stems of maize, and the transfer assembly is used for transferring whole maize, harvested maize spikes and maize stems to the aggregate assembly independently. Compared with the prior art, the harvester is specially applicable to a Chinese fresh maize planting environment, not only has the stem and spike harvesting function, but also can carry out non-row-controlled harvesting without manual assistance, and has the function of harvesting and collecting maize full-automatically, so that the cost is lowered. In addition, the stem and spike harvesting fresh maize harvester reduces the damage rate of stems and spikes, improves the recovery total amount of stems and increases the income.

Owner:XIANGTAN ZHILIAN TECH MATASTASIS PROMOTE CO LTD

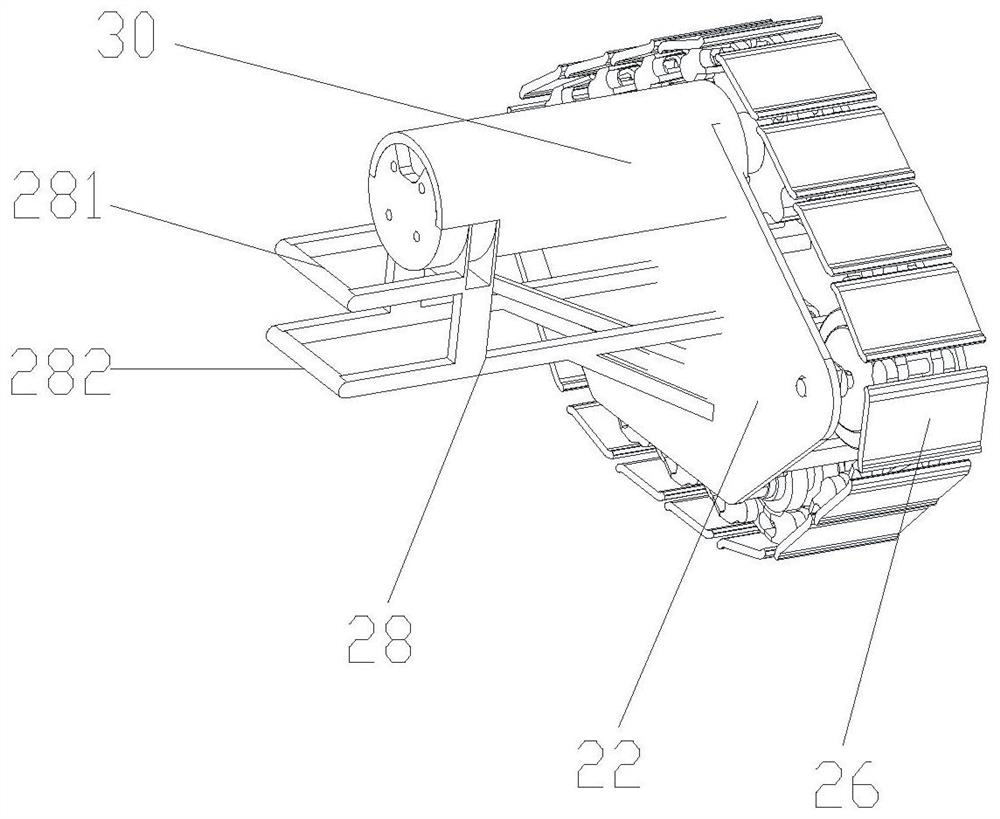

Underwater robot crawler walking chassis and underwater robot

ActiveCN112874735ASolve the problem of walkingAdjustable stiffnessPropulsive elementsUnderwater equipmentVehicle frameElectric machinery

The invention discloses an underwater robot crawler walking chassis and an underwater robot. The underwater robot crawler walking chassis comprises a frame used for installing the underwater robot; a crawler wheel assembly used for driving the frame; a waterproof motor used for providing power for the crawler wheel assembly; a waterproof motor arranged on the crawler wheel assembly and connected with the crawler wheel assembly; and a flexible suspension assembly used for flexibly connecting the frame and the crawler wheel assembly. The first end of the flexible suspension assembly is connected with the frame, and the second end of the flexible suspension assembly is connected with the crawler wheel assembly. According to the chassis, the frame and the crawler wheel assemblies are connected through the flexible suspension assembly, the characteristics of the flexible suspension structure of the wheel type chassis and the small grounding specific pressure of the crawler type chassis are combined, the rigidity of the flexible suspension assemblies is adjustable, and the chassis has good adaptability to soft seabed sand beaches and rugged and complex underwater road surfaces; and the frame is formed by welding a frame structure, so that functional modules can be added more easily.

Owner:EZHOU INST OF IND TECH HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com