Coal mine narrow gauge railway monolithic road-bed

A technology of integral ballast bed and ballast bed, applied in the field of new ballast bed, can solve the problems affecting driving safety, etc., and achieve the effect of roadway sanitation and track maintenance reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

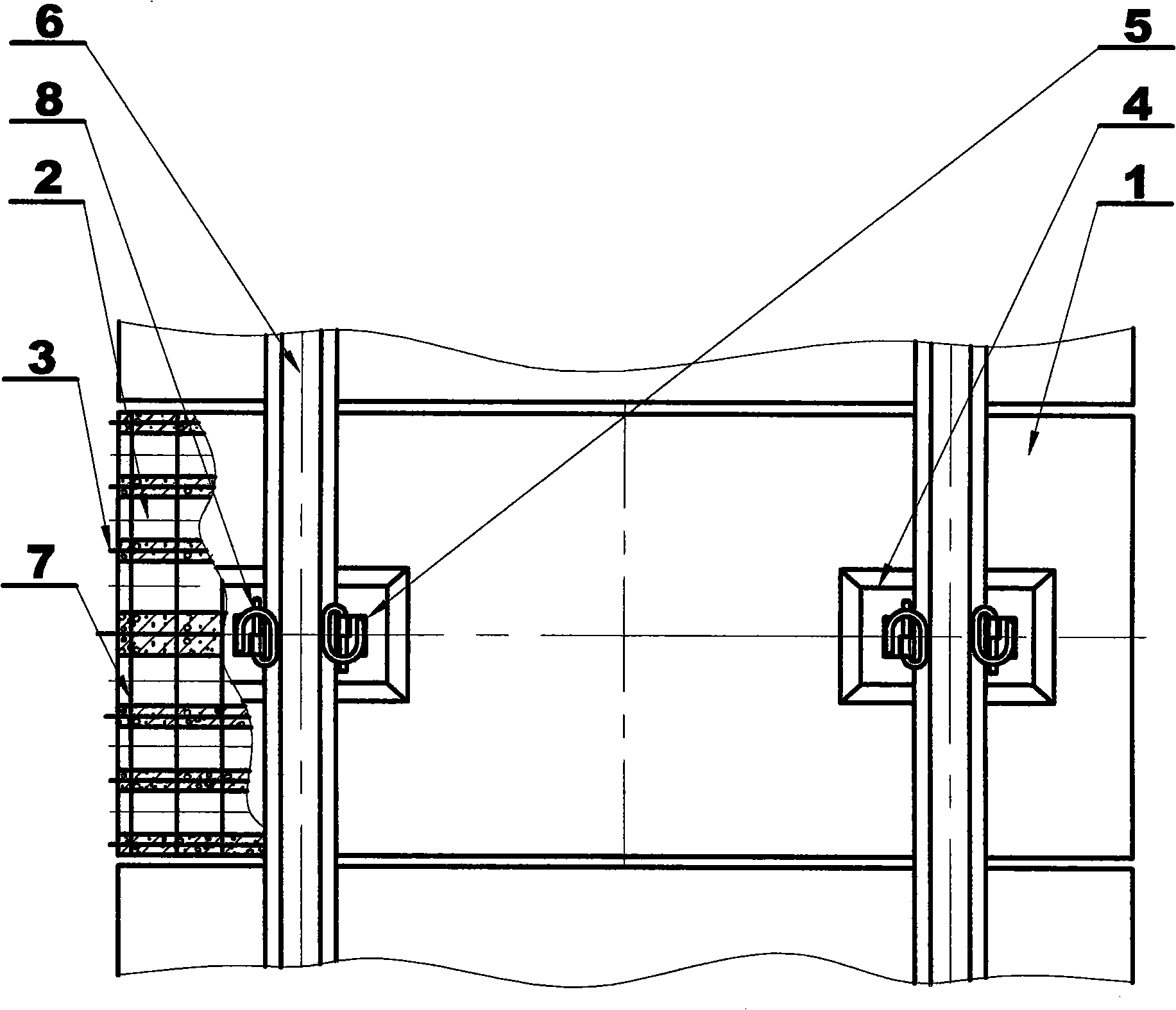

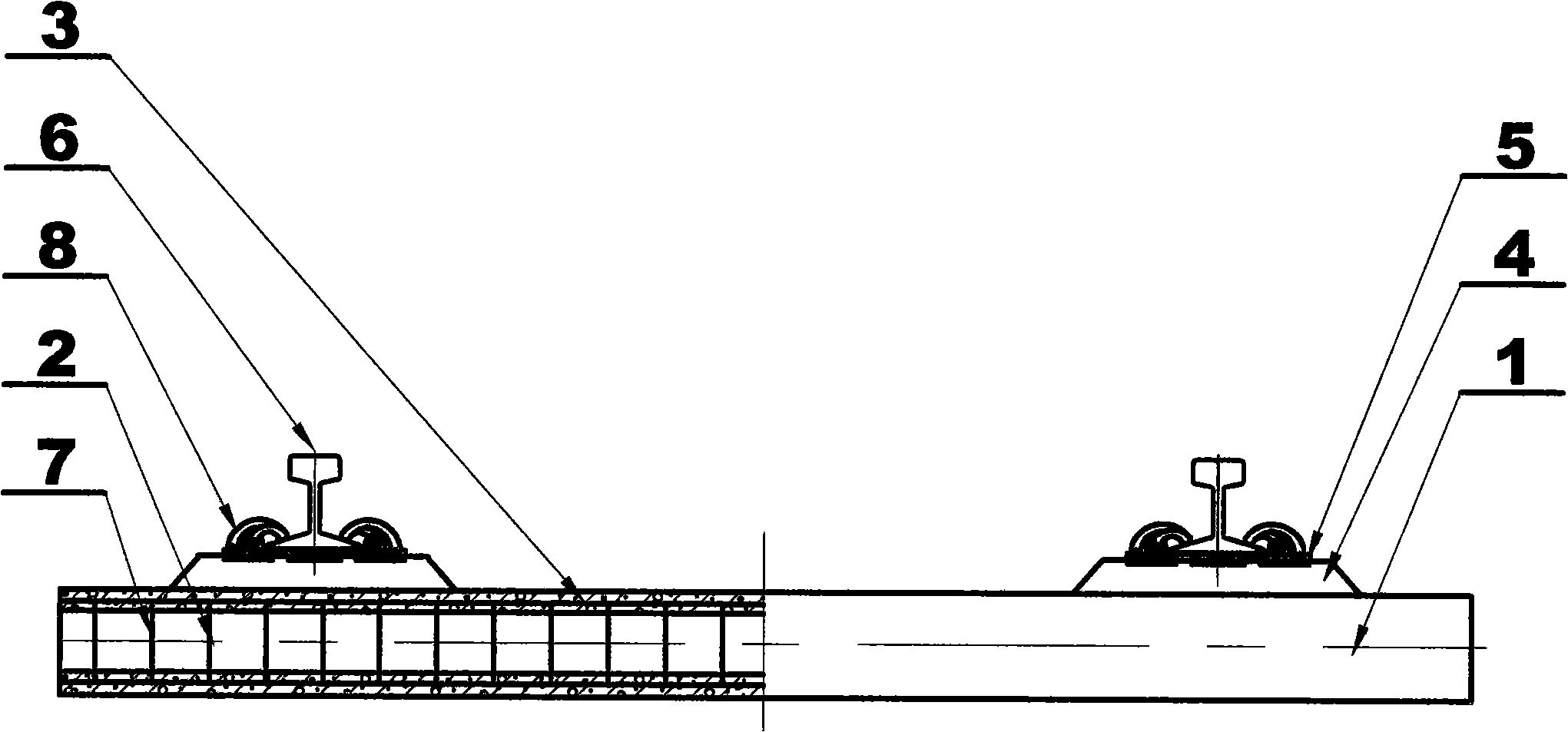

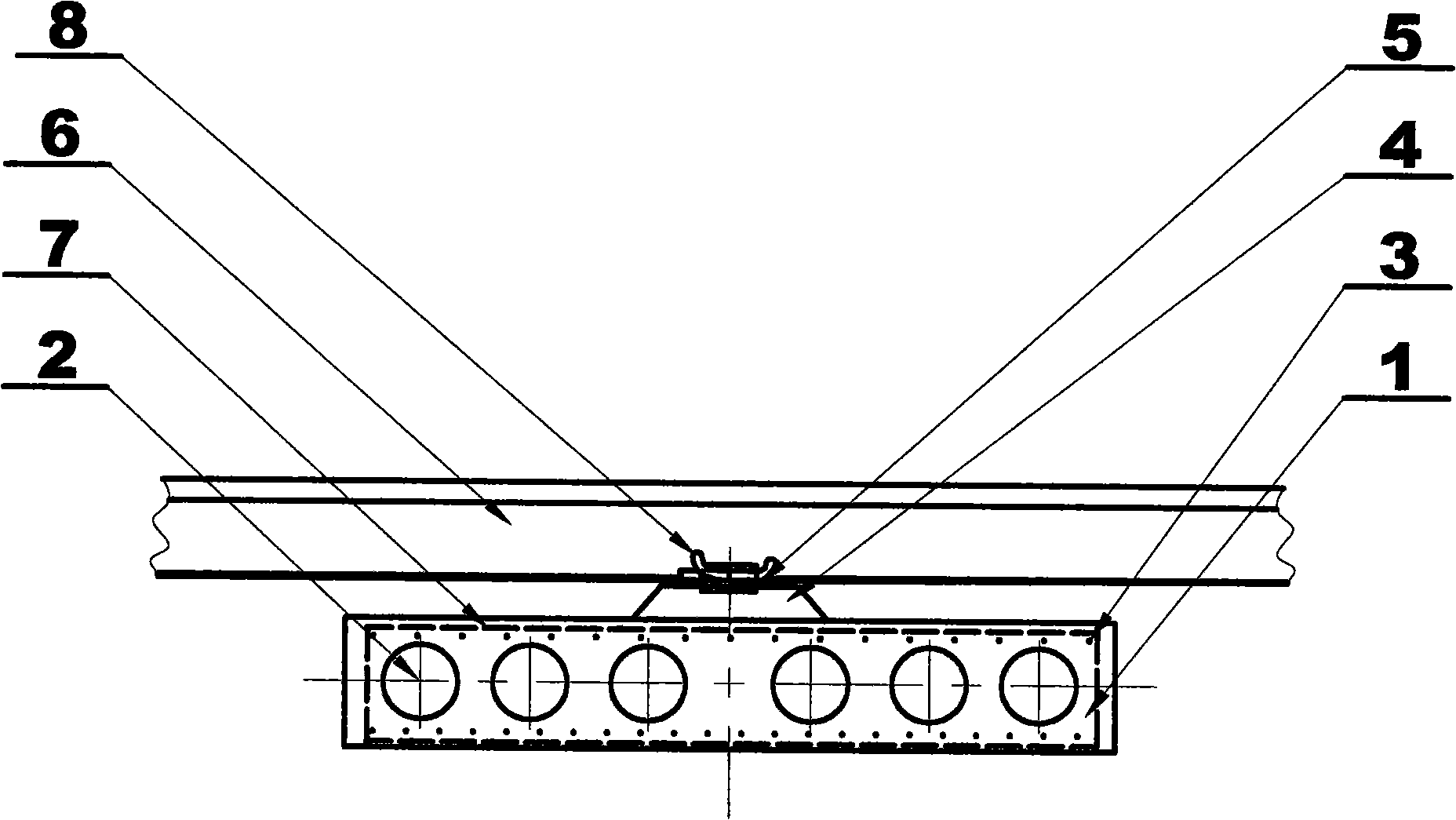

[0021] In the figure, the overall track bed 1 is prefabricated by concrete, and a central cavity 2 is set in the track bed 1 to reduce the weight of the track bed and be used for running water. The longitudinal strength of the ballast bed is improved by using prestressed steel bars 3 in the longitudinal direction; the transverse strength of the ballast bed is improved by using threaded steel bar tie hoops 7 in the horizontal direction. The upper surface of the ballast bed 1 is prefabricated with two rail-holding bases 4 for pre-embedding the rail-holding base 5 according to the railway gauge requirements. Railroad rail 6 is fixed on the rail-holding device base 5 of ballast bed with rail-holding device spring 8. When laying the track, there is no gap between the track bed and the track bed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com