Turbine pump sealing mechanism and turbine pump

A technology of sealing mechanism and turbo pump, which is applied in the direction of pumps, pump components, mechanical equipment, etc., can solve the problems of large loss and low sealing reliability, and achieve the effects of reducing the acting pressure, ensuring the sealing performance and reducing the wear of the seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

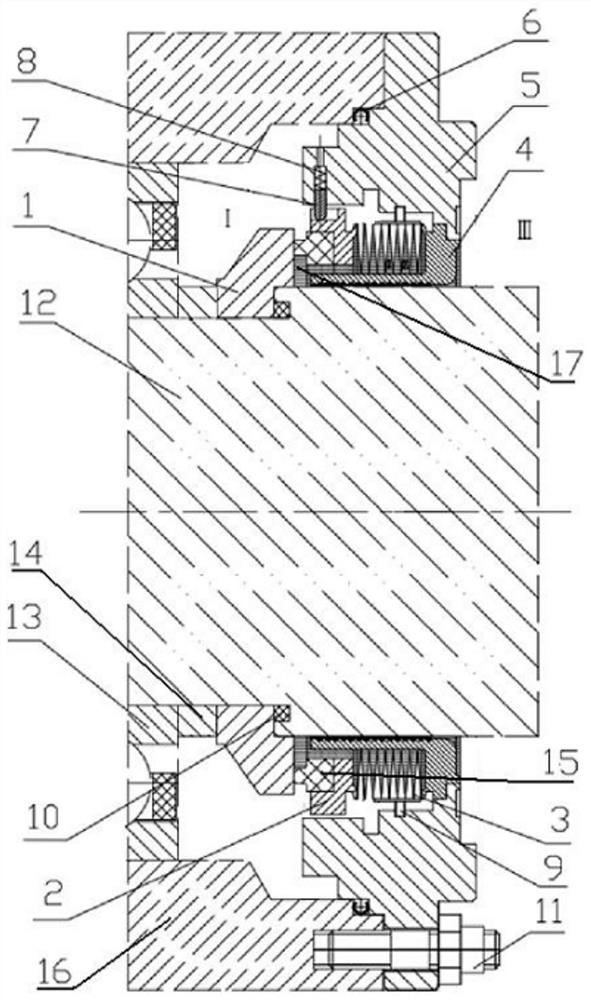

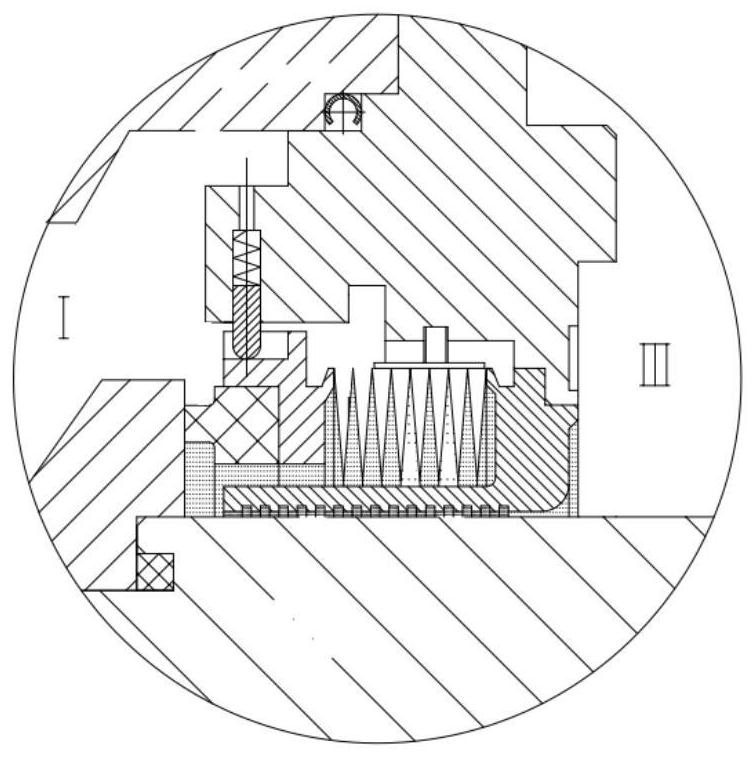

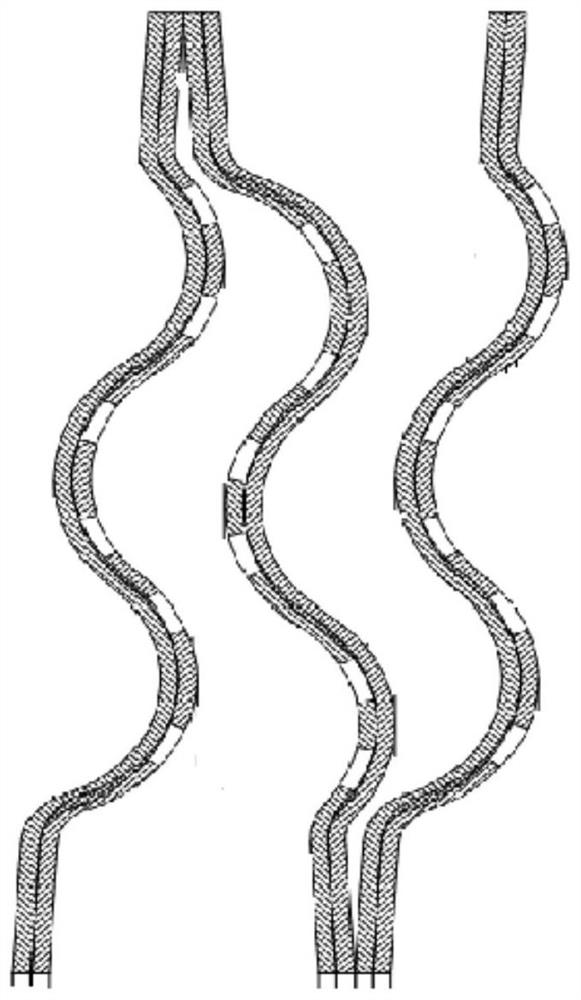

[0054] The invention provides a turbo pump sealing mechanism, see figure 1 and figure 2 . figure 1 It is a side sectional view of the turbo pump sealing mechanism of this embodiment. figure 2 for figure 1 A partially enlarged schematic diagram. image 3 It is a schematic cross-sectional view of the double-layer bellows in the sealing mechanism of the turbo pump in this embodiment. Figure 4 A schematic diagram of the end face of the double-layer bellows of the turbo pump sealing mechanism of the embodiment. Such as figure 1 and figure 2 As shown, the sealing mechanism of the turbo pump in this embodiment includes: a moving ring 1 , a stationary ring 2 , a double-layer bellows 3 , an isolation ring 4 , a sealing casing 5 and a rotating shaft 12 .

[0055] in,

[0056] The sealing housing 5 is adapted to be connected to a turbo pump housing 16 of a turbo pump.

[0057] The isolation ring 4 is sheathed on the rotating shaft 12 and forms a seal on a contact surface wit...

Embodiment 2

[0072] The present invention also provides a turbo pump, wherein the turbo pump sealing mechanism as described in Embodiment 1 is arranged between the turbo pump assembly and the pump assembly.

[0073] in,

[0074] The rotating shaft 12 is connected to the turbine assembly.

[0075] The moving ring 1, the static ring 2 and the double-layer bellows 3 are arranged on the side close to the pump assembly.

[0076] The sealed housing 5 passes through a connecting piece, such as figure 1 The screw 11 in the middle is connected and fastened with the turbo pump casing 16.

[0077] The connection relationship of various components inside the turbo pump sealing mechanism is as described in the first embodiment above, and will not be repeated here.

[0078] The turbo pump sealing mechanism provided in this embodiment, by using the above turbo pump sealing mechanism, has high sealing reliability and low loss in a high-pressure environment, and is suitable for use in a high-speed, high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com