Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Increase the maximum lift coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

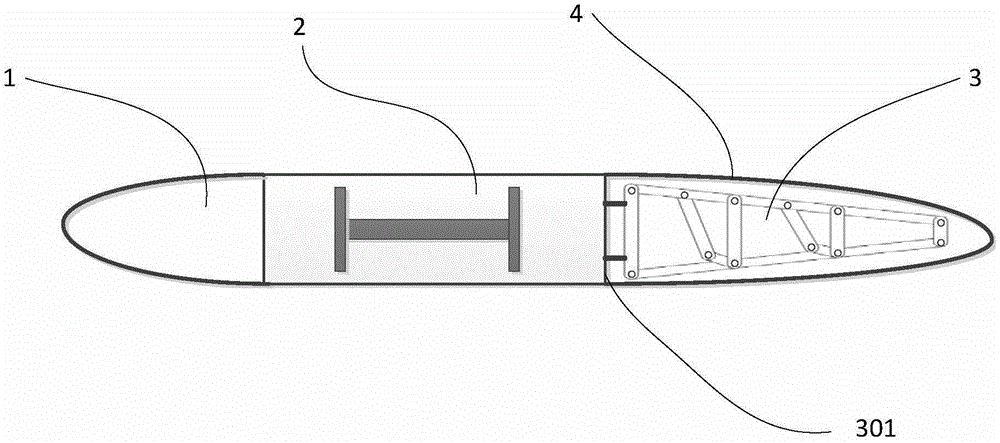

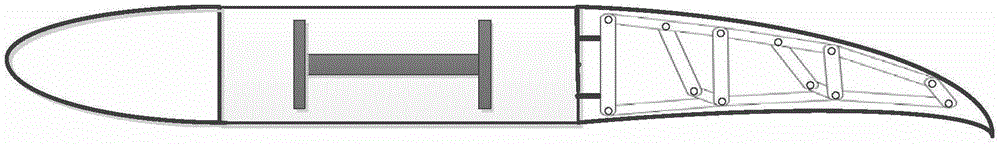

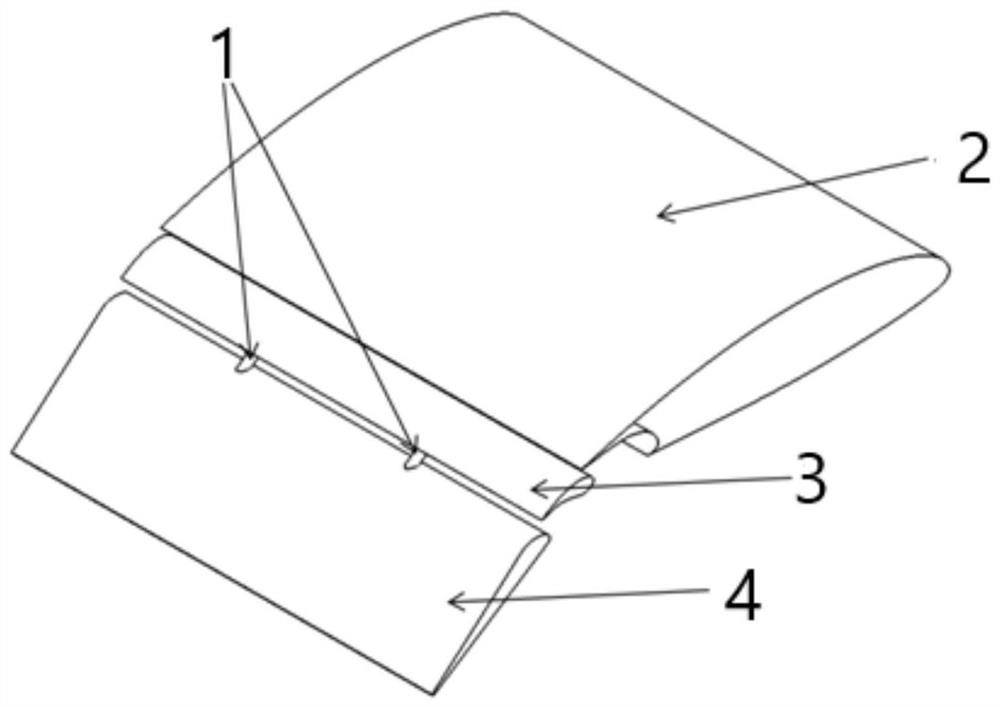

Shape memory spring driven hinder margin camber variable wing

InactiveCN101503113AImprove pressure distributionIncrease lift coefficientWing adjustmentsEngineeringMetal sheet

The invention provides a wing with changeable trailing edge camber driven by a shape memory spring, relating to a wing with a changeable trailing edge camber, and aiming at the problems of traditional airplanes that a mechanism is complex and heavy, airflow breakaway is quite early and aerodynamic efficiency is low. The front end face and the back end face of an upper metal plate are fixedly connected with the front end faces of a connecting plate and the trailing edge; the front end face and the back end face of the lower metal plate are fixedly connected with the front end face of the connecting plate and the trailing edge; the same side surface of the upper metal plate and the lower metal plate are fixed with an upper prop stay and a lower prop stay; the two ends of a first shape memory spring are fixedly connected with a fixed plate and the upper metal plate; the two ends of a second shape memory spring are fixedly connected with the front end faces of the upper prop stay and the trailing edge; the two ends of a third shape memory spring are fixedly connected with the fixed plate and the lower metal plate; and the two ends of a fourth shape memory spring are fixedly connected with the front end faces of the lower prop stay and the trailing edge. The invention has the advantages of light weight, simple structure and high aerodynamic efficiency.

Owner:HARBIN INST OF TECH

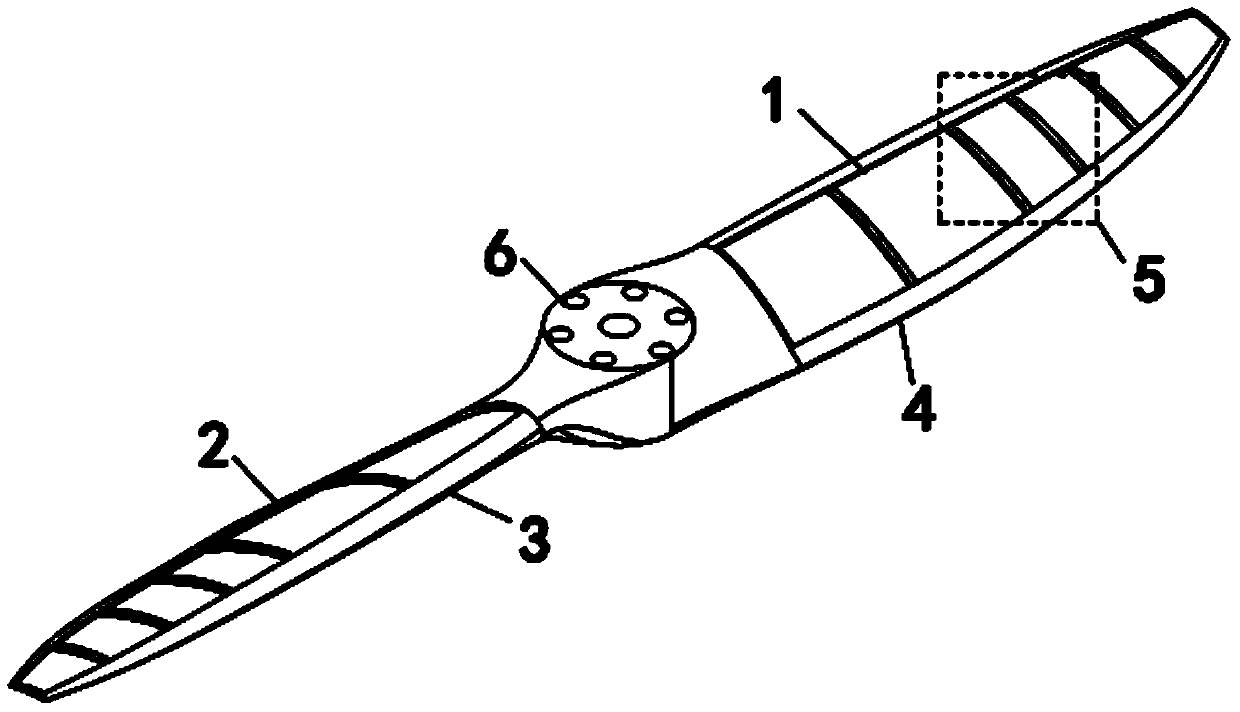

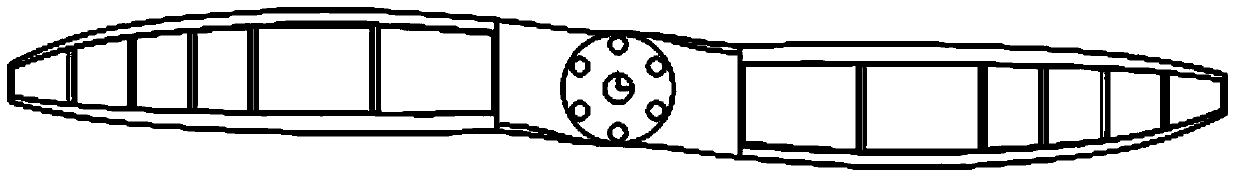

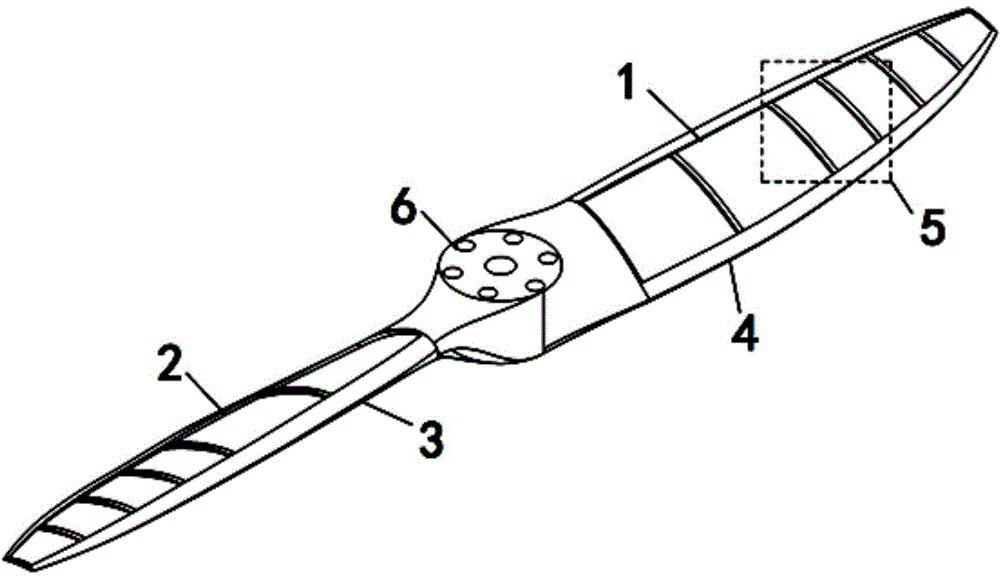

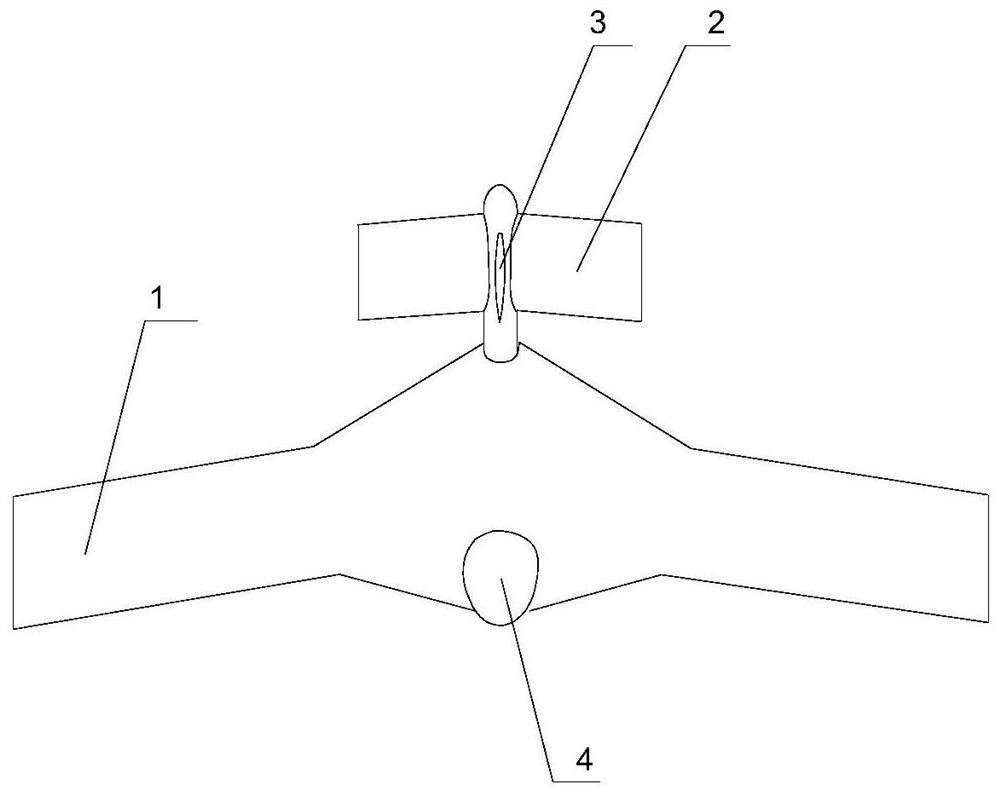

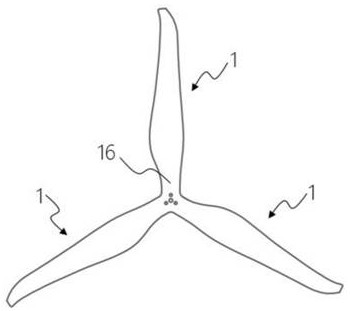

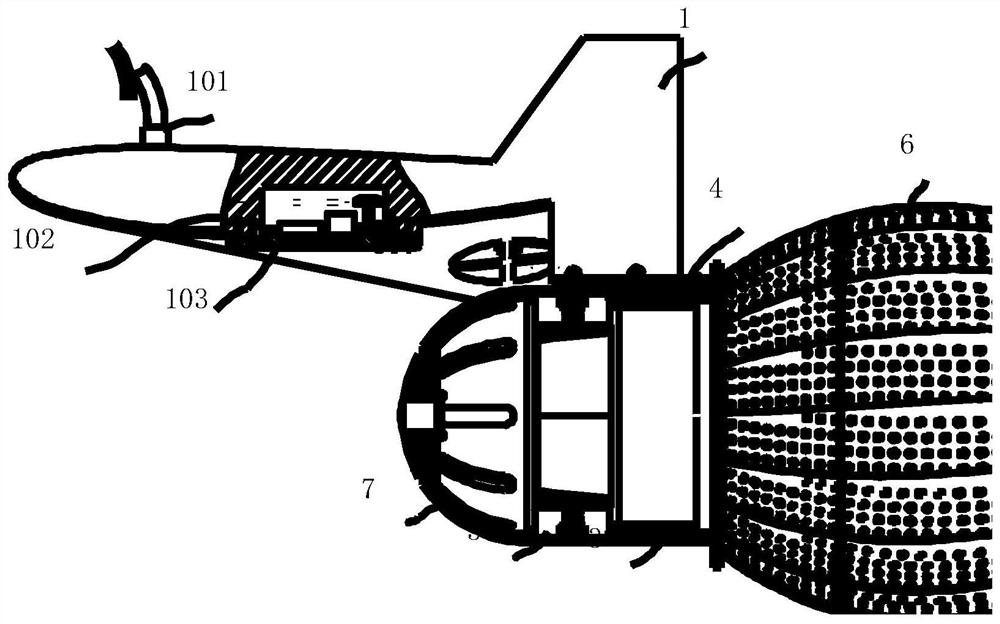

High-efficiency pneumatic layout structure of synergistic jet for high-altitude propeller and control method

ActiveCN104176241AIncrease stall angle of attackImproved stall characteristicsPropellersHigh-pressure areaAir pump

The invention provides a high-efficiency pneumatic layout structure of synergistic jet for a high-altitude propeller and a control method. The high-efficiency pneumatic layout structure is characterized in that a plurality of synergistic jet devices are distributed along propeller blades of the propeller in a spanwise sectional manner; each synergistic jet device comprises an air blowing opening formed in a negative-pressure area of the front edge of the upper surface of the propeller, an air suctioning opening formed in a high-pressure area of the rear edge of the upper surface of the propeller, an airflow pipeline arranged in the paddle and an air pump arranged in the airflow pipeline; the air blowing opening and the air suctioning opening are communicated by the airflow pipeline to form an air-blowing and air-suctioning loop; the air pump is used for driving air suctioning and air spraying to be implemented simultaneously, and by control of the air pump, the air suctioning amount and the air spraying amount are same. The high-efficiency pneumatic layout structure provided by the invention has the advantages that the defects of the traditional propeller layout and the common flow control technology can be made up, and the working efficiency of a propelling system of the high-altitude propeller can be improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

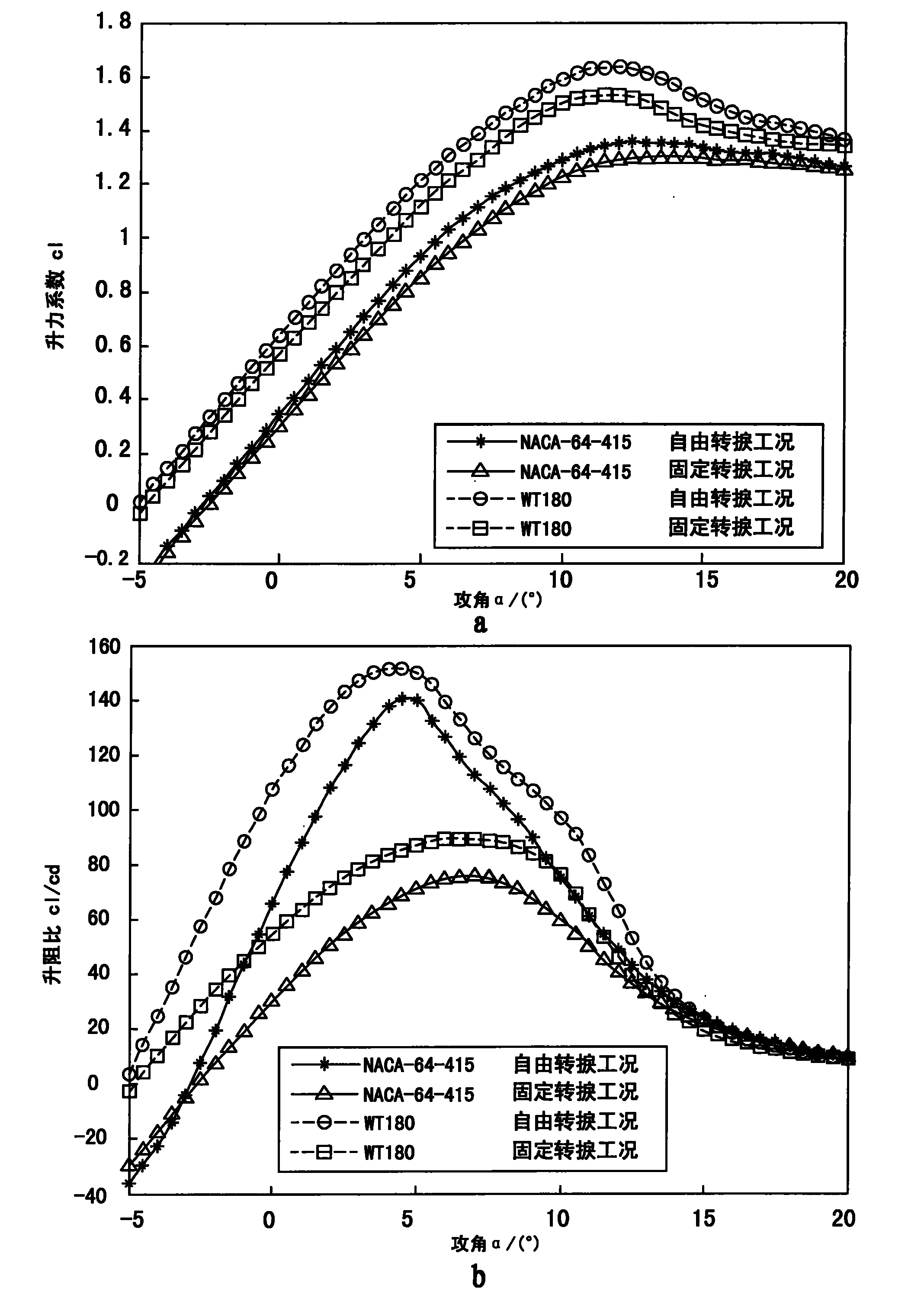

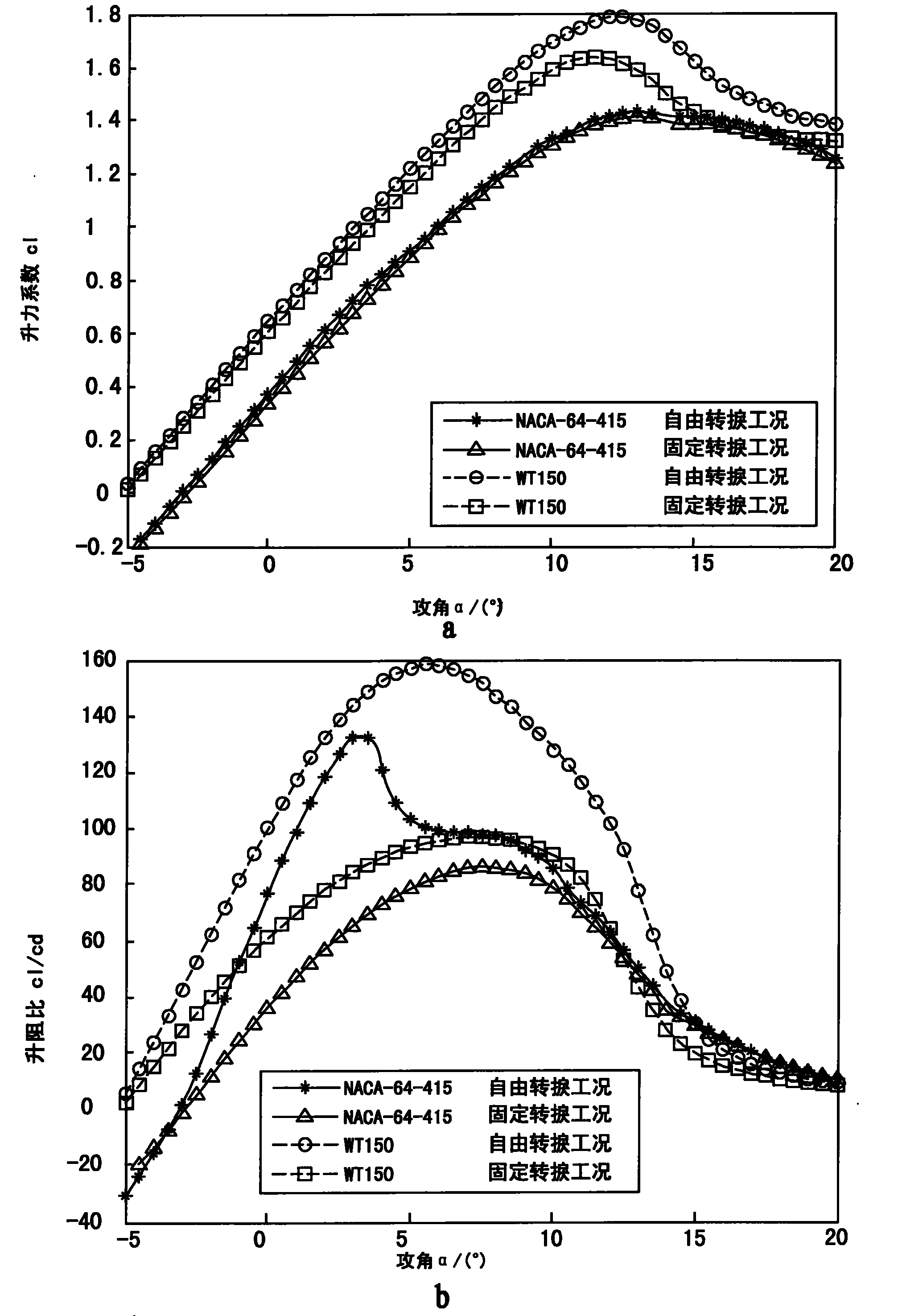

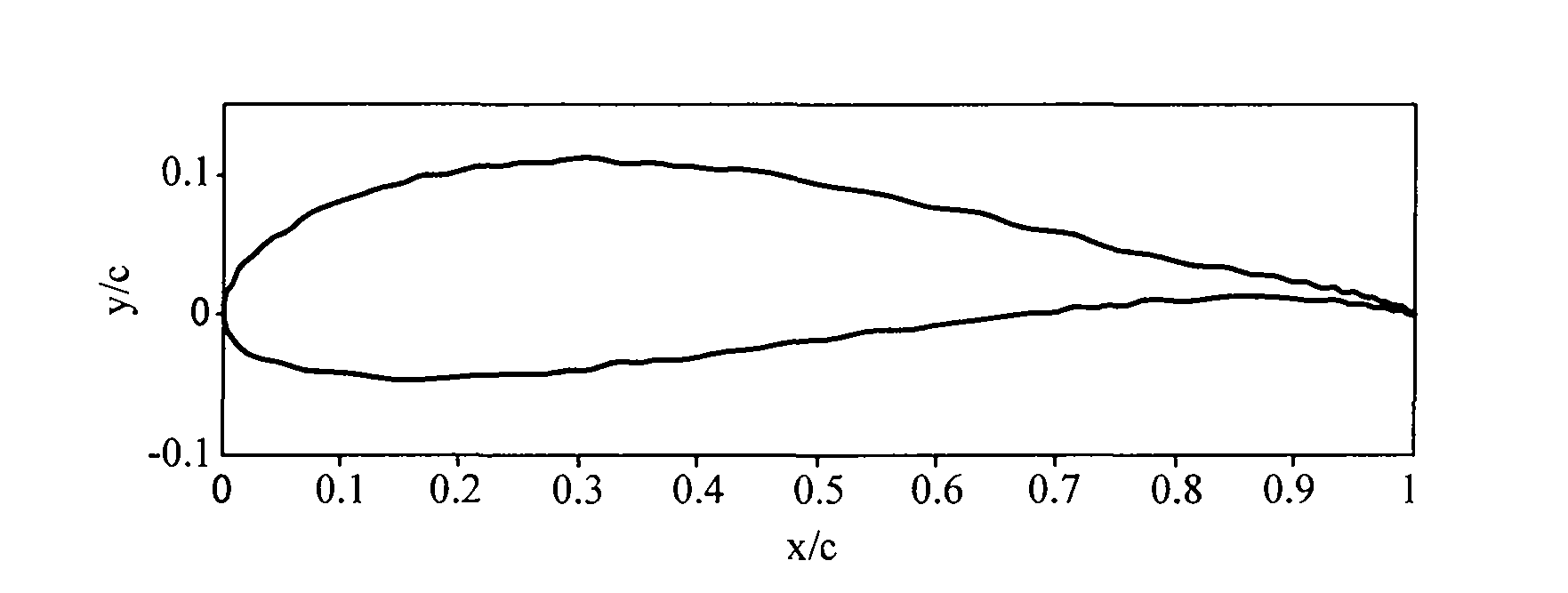

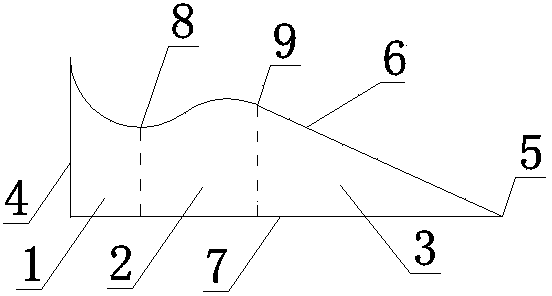

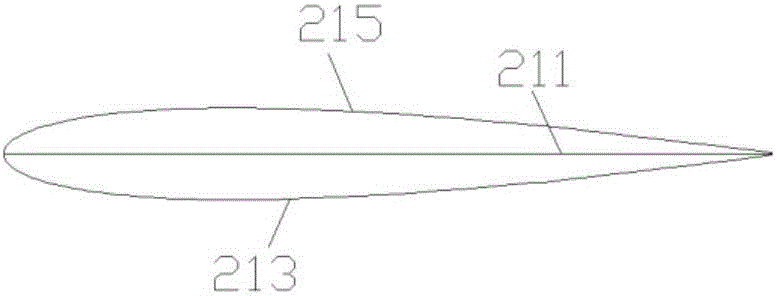

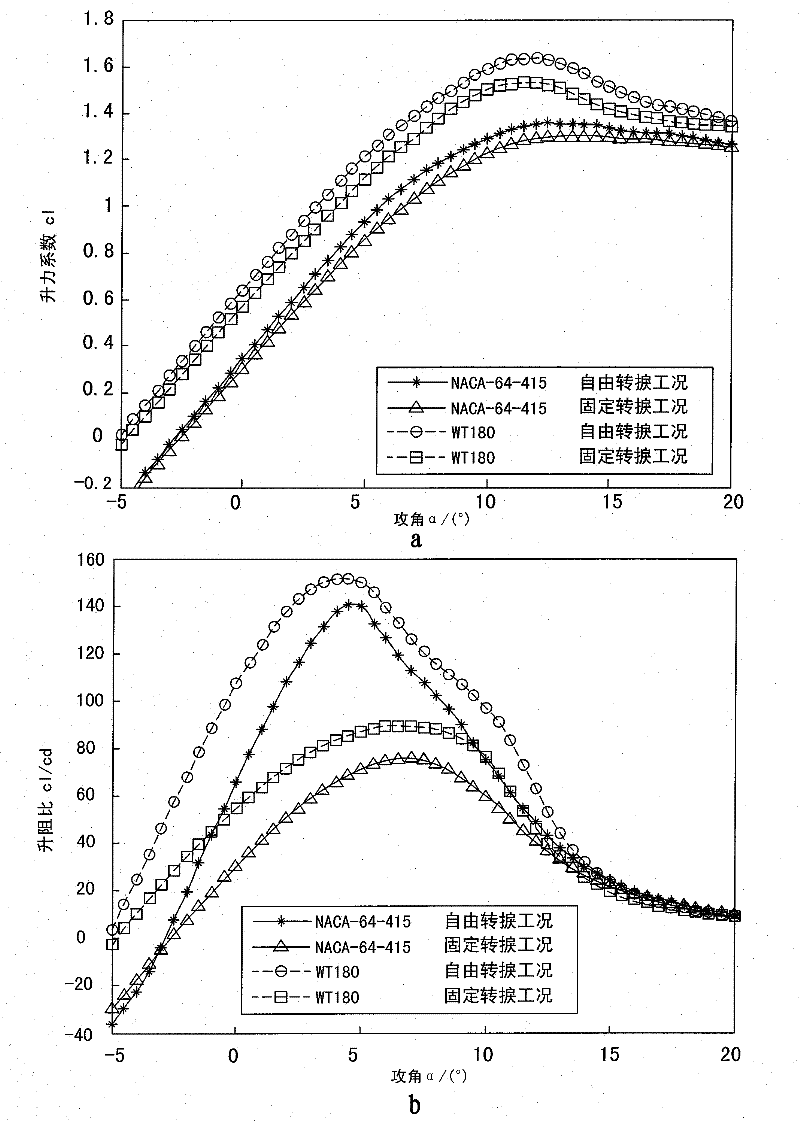

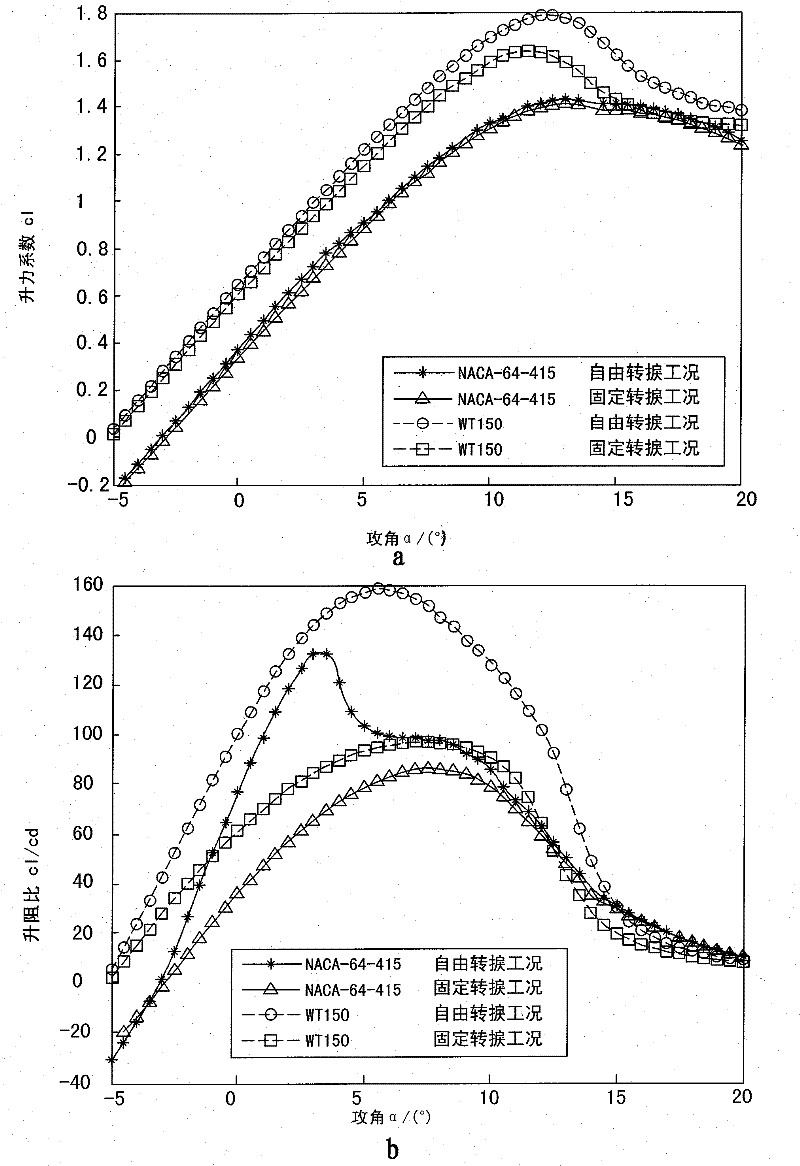

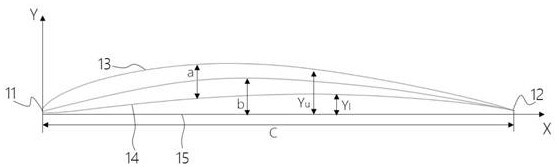

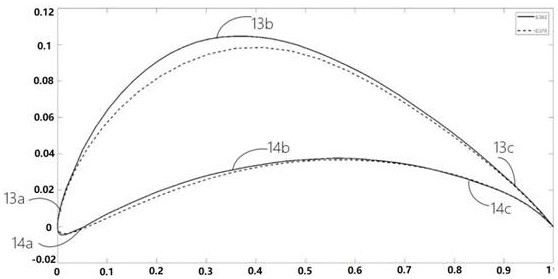

Method for designing special wind turbine airfoil profile and special wind turbine airfoil profile

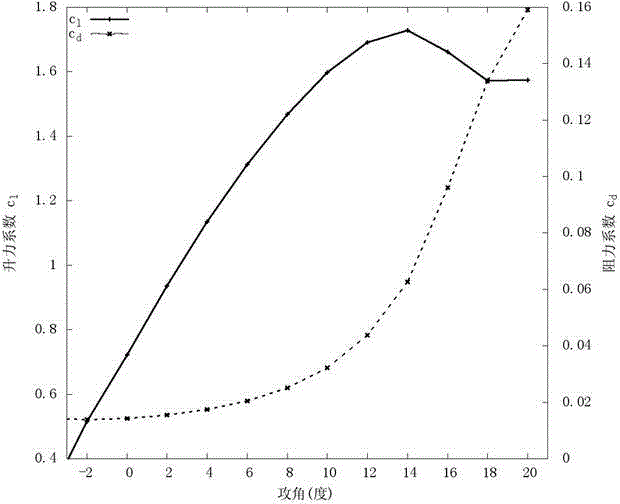

InactiveCN101923584AReduce roughness sensitivityLess impact from rough conditionsWind energy generationSpecial data processing applicationsSurface roughnessHigh lift

The invention discloses a method for designing a special wind turbine airfoil profile and a special wind turbine wing profile obtained by the designing method. In the invention, a corresponding airfoil profile can be obtained by expressing the geometrical shape of an airfoil profile with a simple high-order polynomial shape function and altering the coefficient of the shape function polynomial according to a special constraint condition. The special wind turbine airfoil profile is in a Reynolds number range with Re=1*106-3*106, has low-airfoil profile surface roughness sensitivity, higher lift coefficient and maximum lift drag ratio, as well as high lift drag ratio and favorable structural property in a larger attack angle range, and has favorable compatibility and acoustical property compared with other wind turbine airfoil profiles.

Owner:CHONGQING UNIV

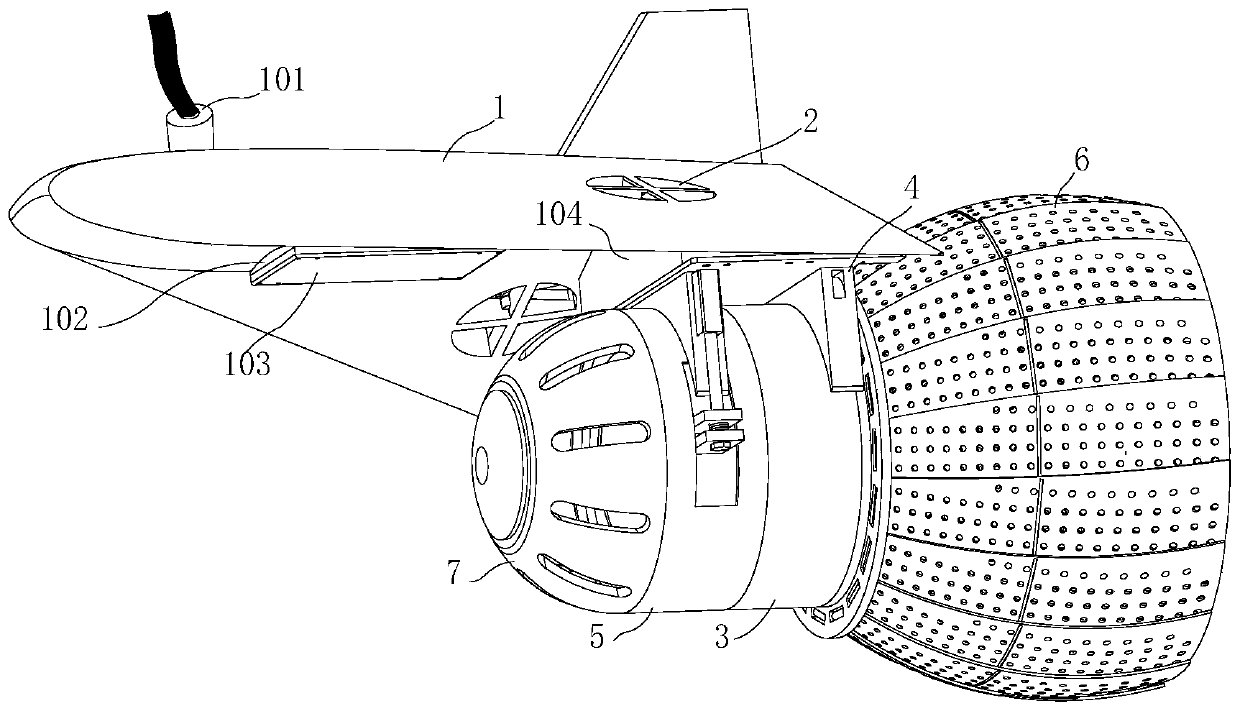

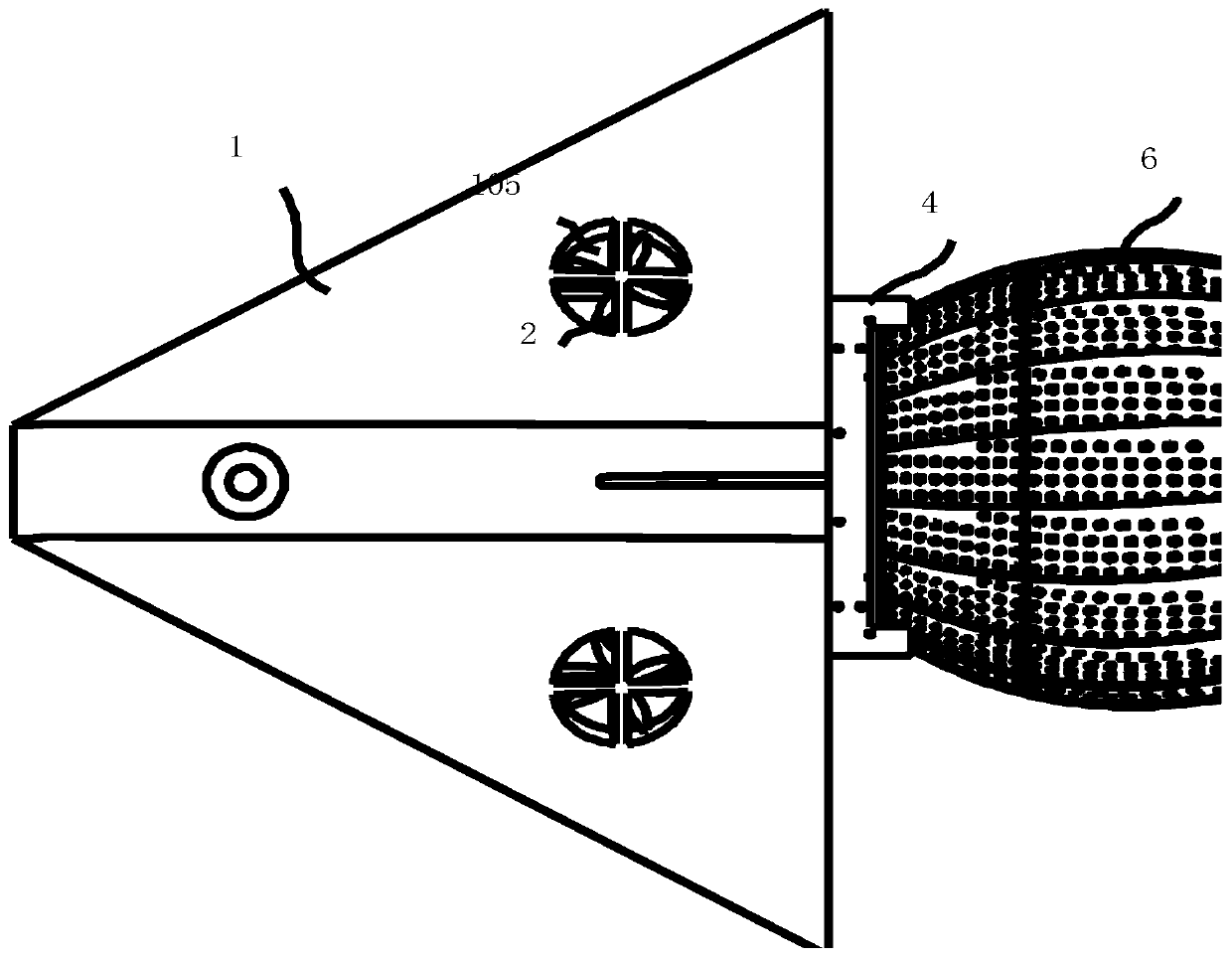

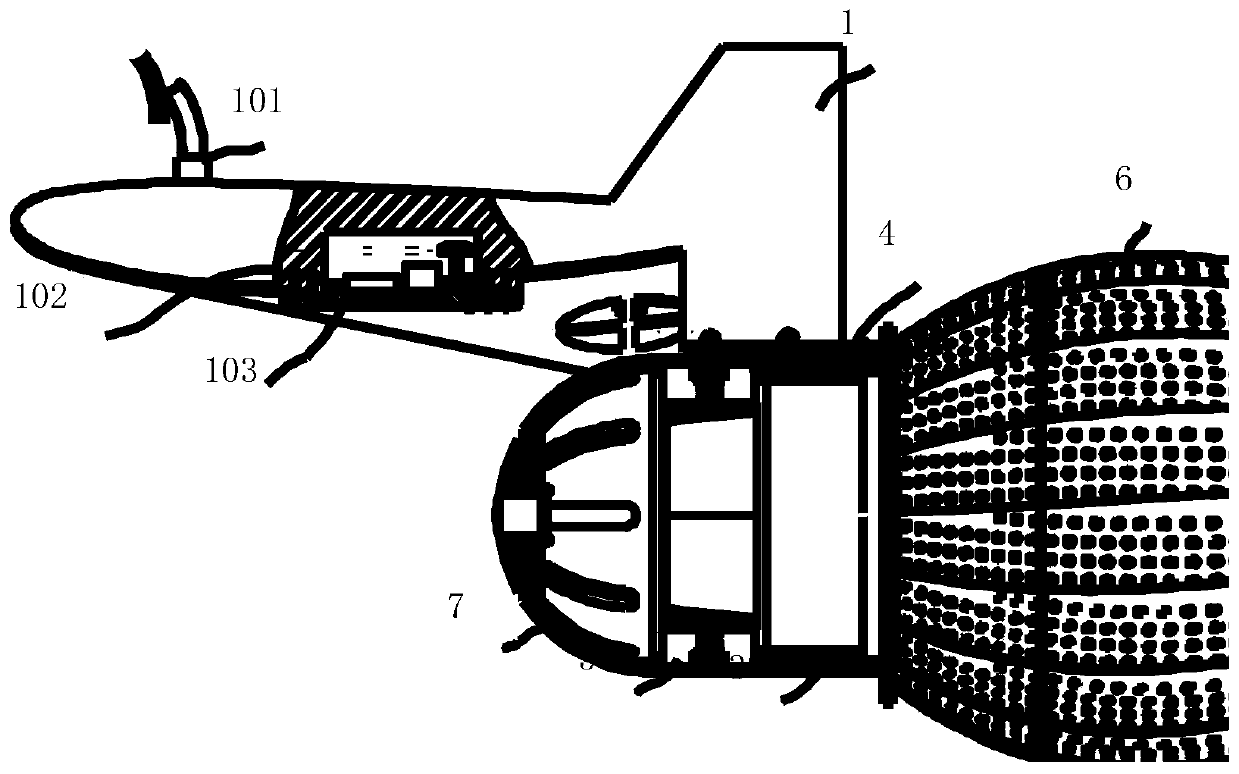

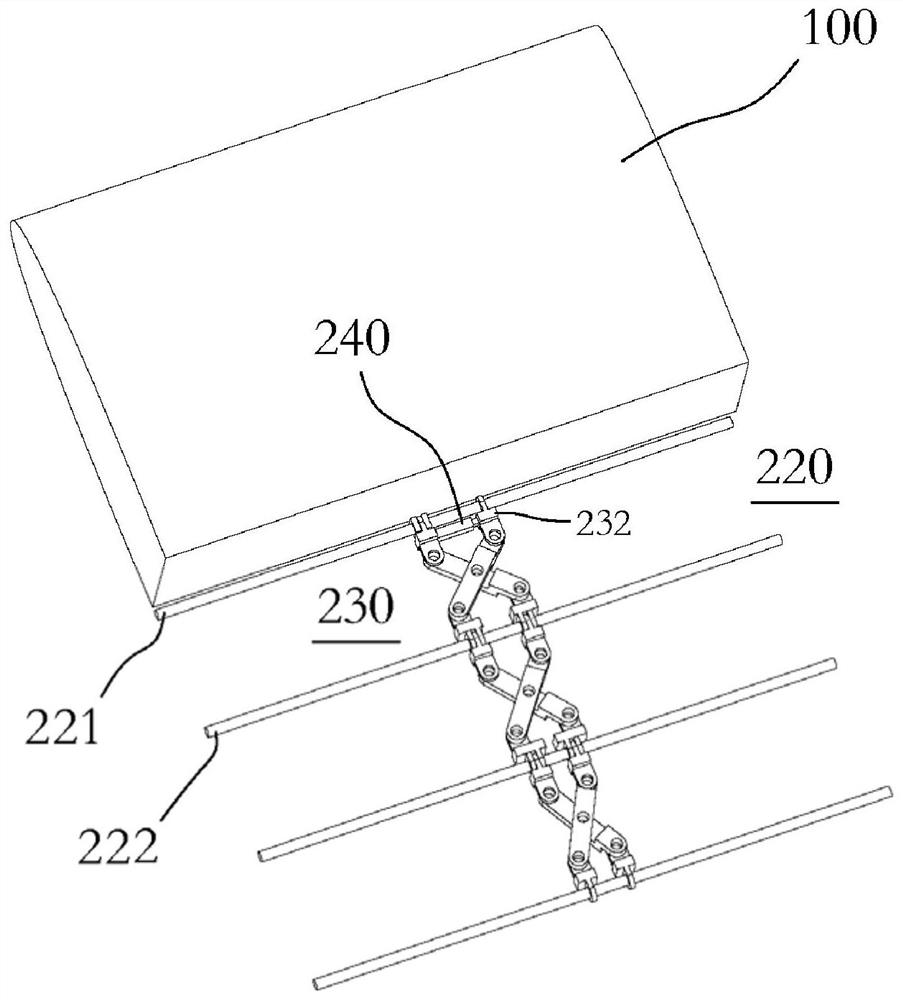

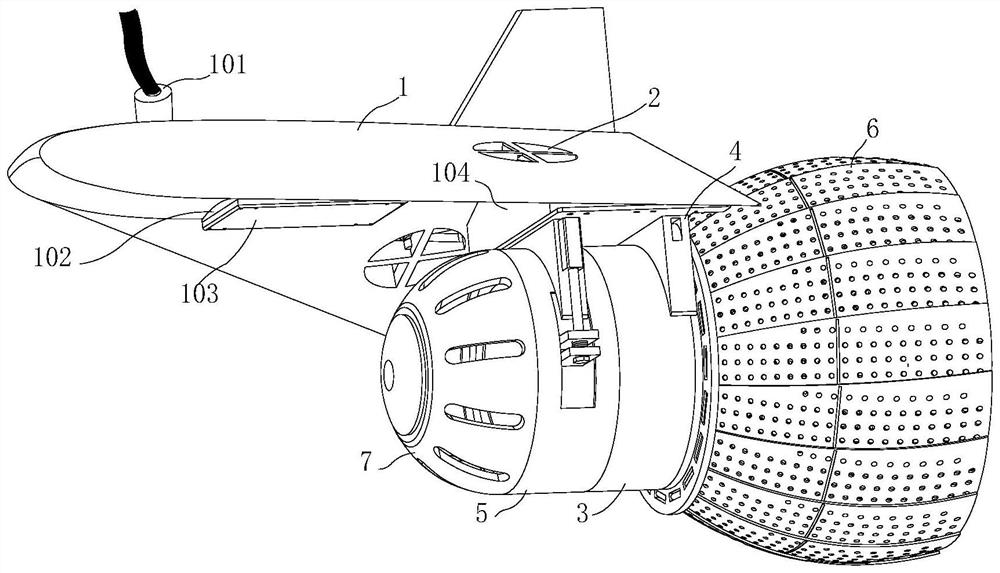

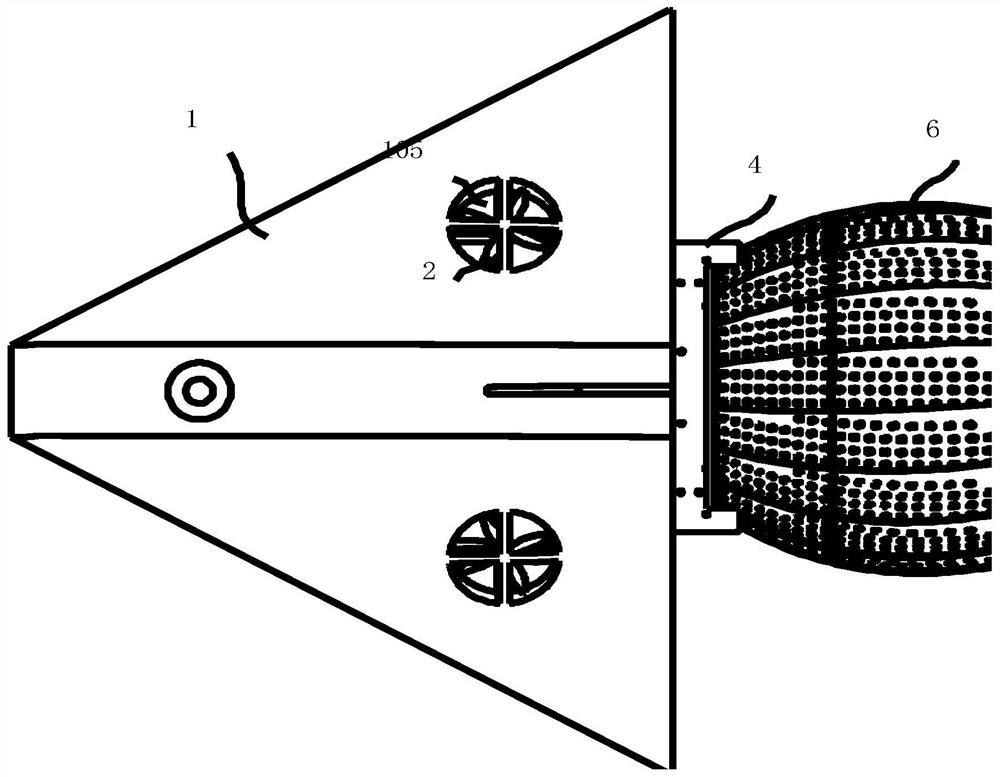

Dynamic base station for AUV recovery

ActiveCN110844027AReduced drag and weightReduced tow sailingVessel salvagingUnderwater vesselsMarine engineeringBase station

The invention discloses a dynamic base station for AUV recovery, belongs to the technical field of underwater robot recovery, and aims to solve the problems of instability in docking recovery, difficulty in operation, large drag resistance and certain potential safety hazards existing in the prior art. The dynamic base station comprises a recovery base station body, two attitude regulators symmetrically arranged on the recovery base station body, a connecting ring fixed on the recovery base station body, a guide cover, a locking device, a position detector, and a main controller, wherein one end of the guide cover is coaxially and fixedly connected with one end of the connecting ring, and the other end of the guide cover is a free end with opening adjustable; one end of the locking deviceis fixedly connected with the other end of the connecting ring, and an underwater robot which enters the dynamic base station is clamped or loosened through the locking device; the position detector is fixedly connected with the other end of the locking device; and the main controller is arranged in the recovery base station body, the rotating speed of the two attitude regulators is controlled through the main controller, and the main controller receives the detection signals of the position detector to control the locking device to clamp or release the underwater robot.

Owner:JILIN UNIV

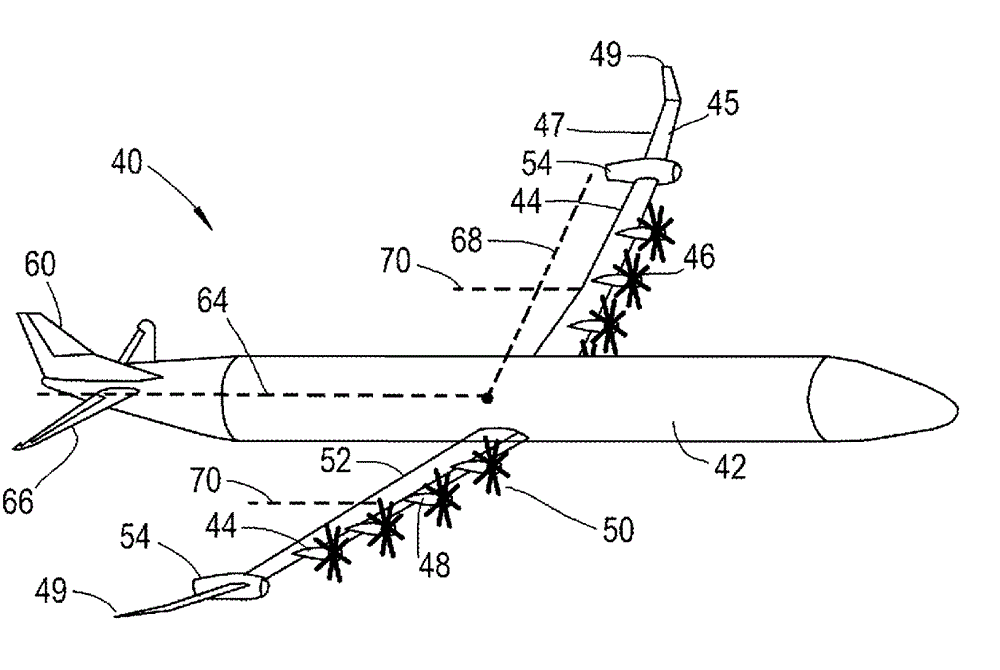

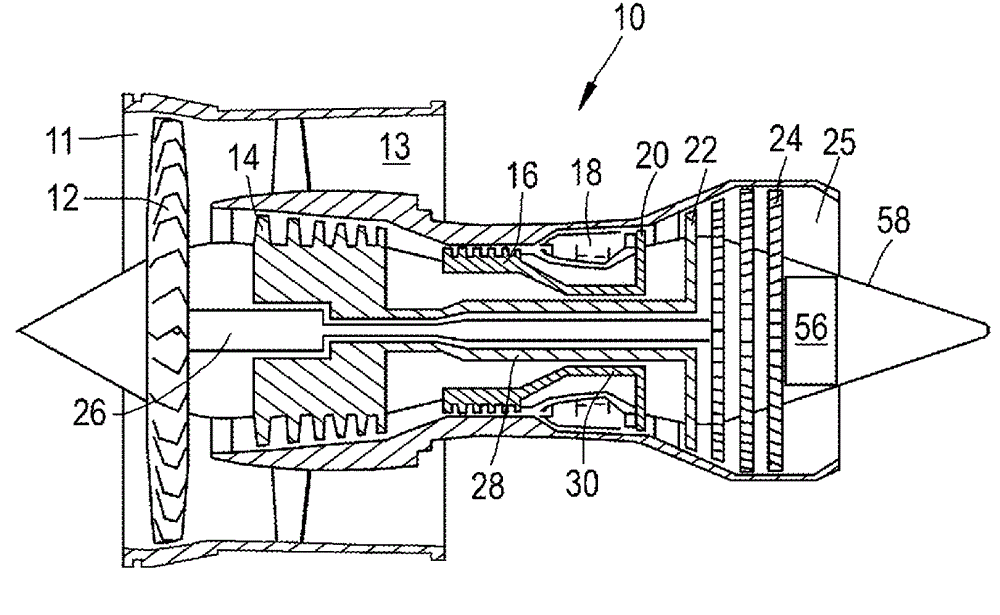

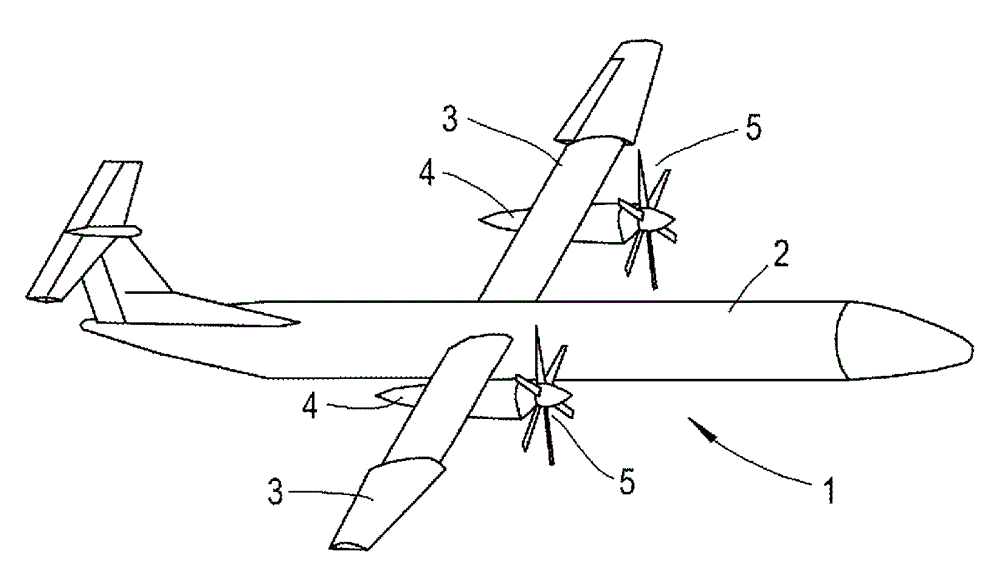

Aircraft

ActiveCN104670503AReduce loadImprove structural efficiencyPropellersGas turbine type power plantsLeading edgeCombustion

An aircraft (40). The aircraft (40) comprises a propulsion system comprising a pair of internal combustion engines (10) each driving an electrical power generator (56), each electrical power generator (56) being electrically coupled to a plurality of electrically driven propulsors (46). The propulsors (46) are located forward of a leading edge (45) of the wings (44) such that an airstream generated by the propulsors flows over the wings (44) in use. Each internal combustion engine (10) and electrical generator (56) is mounted on a respective wing (44) outboard of a centre of thrust (70) of the propulsors (46) on that wing (44).

Owner:ROLLS ROYCE PLC

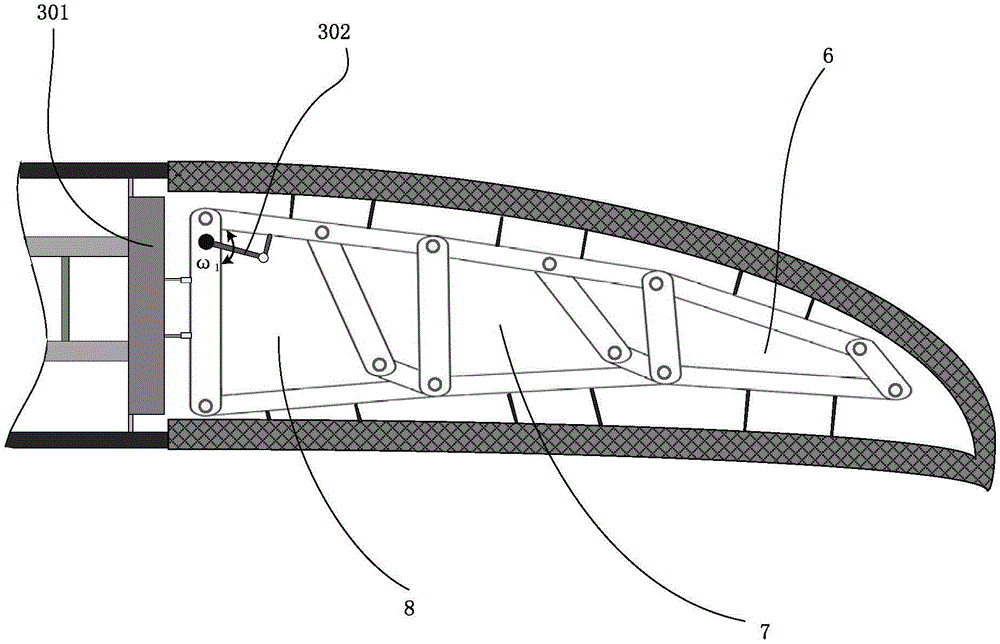

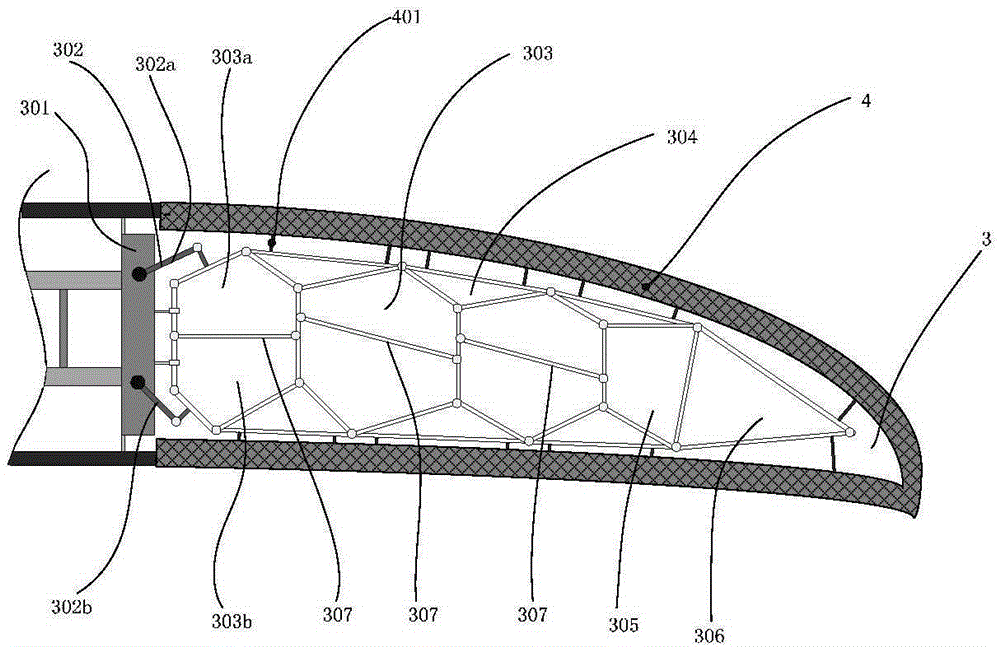

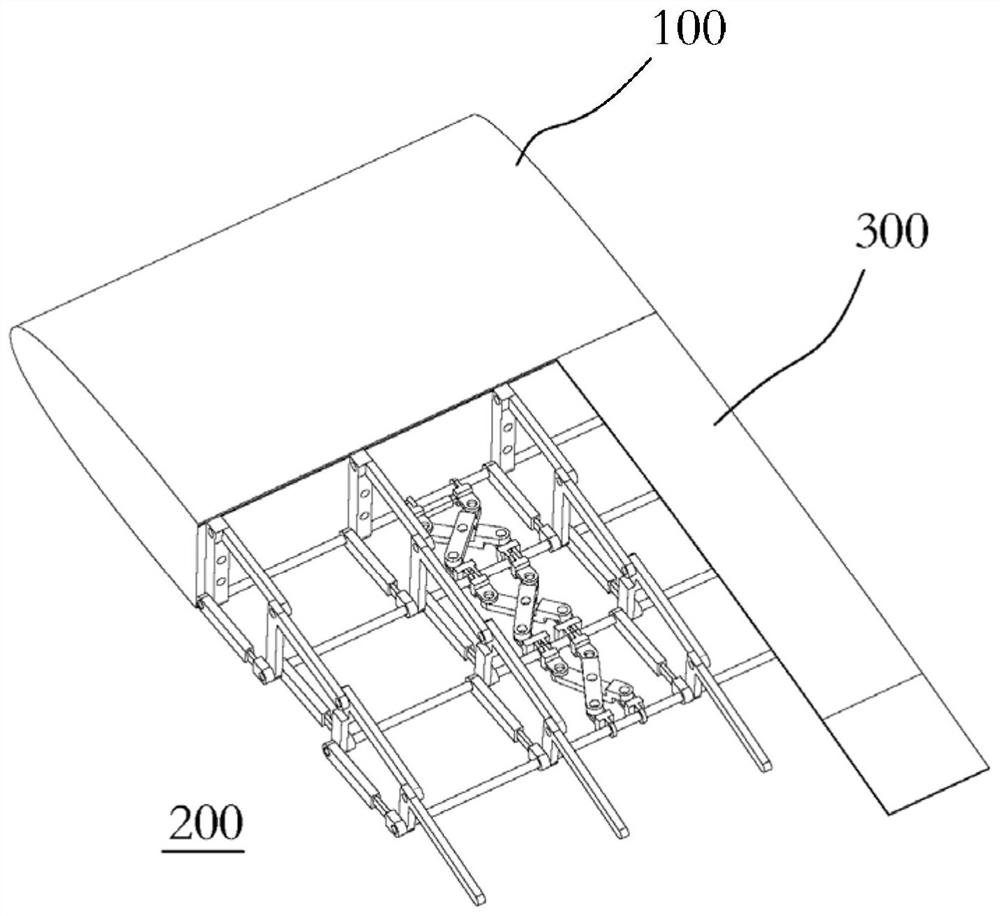

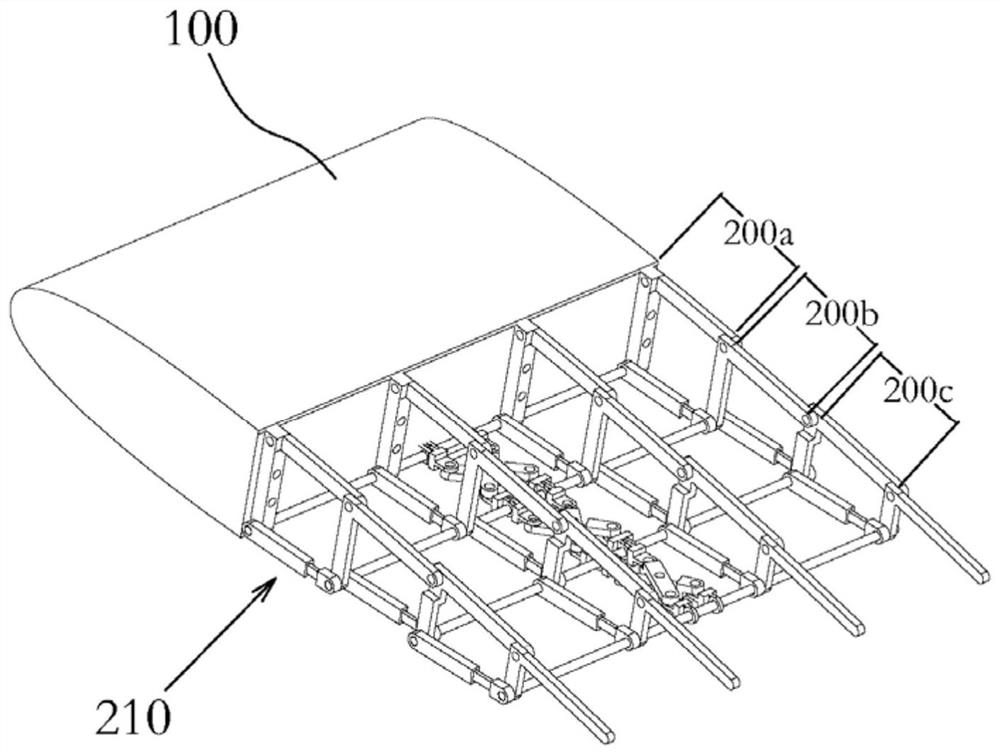

Complex-hinge transformable trailing edge mechanism based on planar linkage closed-loop units

ActiveCN106275388AImprove pressure distributionImprove aerodynamic characteristicsWing adjustmentsControl systemClosed loop

The invention provides a complex-hinge transformable trailing edge mechanism based on planar linkage closed-loop units. The complex-hinge transformable trailing edge mechanism comprises at least three closed-loop linkage units and a drive mechanism. Each closed-loop linkage unit is a planar linkage structure based on a 6R closed-loop unit and has one freedom degree. The closed-loop linkage units include a tail-end unit, at least one middle unit and a starting-end unit which are parallelly arranged, and the middle units are arranged between the starting-end unit and the tail-end unit. Compared with the prior art, the complex-hinge transformable trailing edge mechanism has the advantages that the basic units of the complex-hinge transformable trailing edge mechanism are independent 6R closed-loop units, the units influence on another, and the output of the previous unit is the input of the next unit; the whole mechanism contains few linkages and is lightweight; the freedom degree of the whole mechanism is 1, the mechanism can be driven by only one drive motor, the weight of the mechanism is reduced, system control difficulty is lowered, and the gradual bending effect of a transformable wing is good due to the fact that multiple basic unit modules are used.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

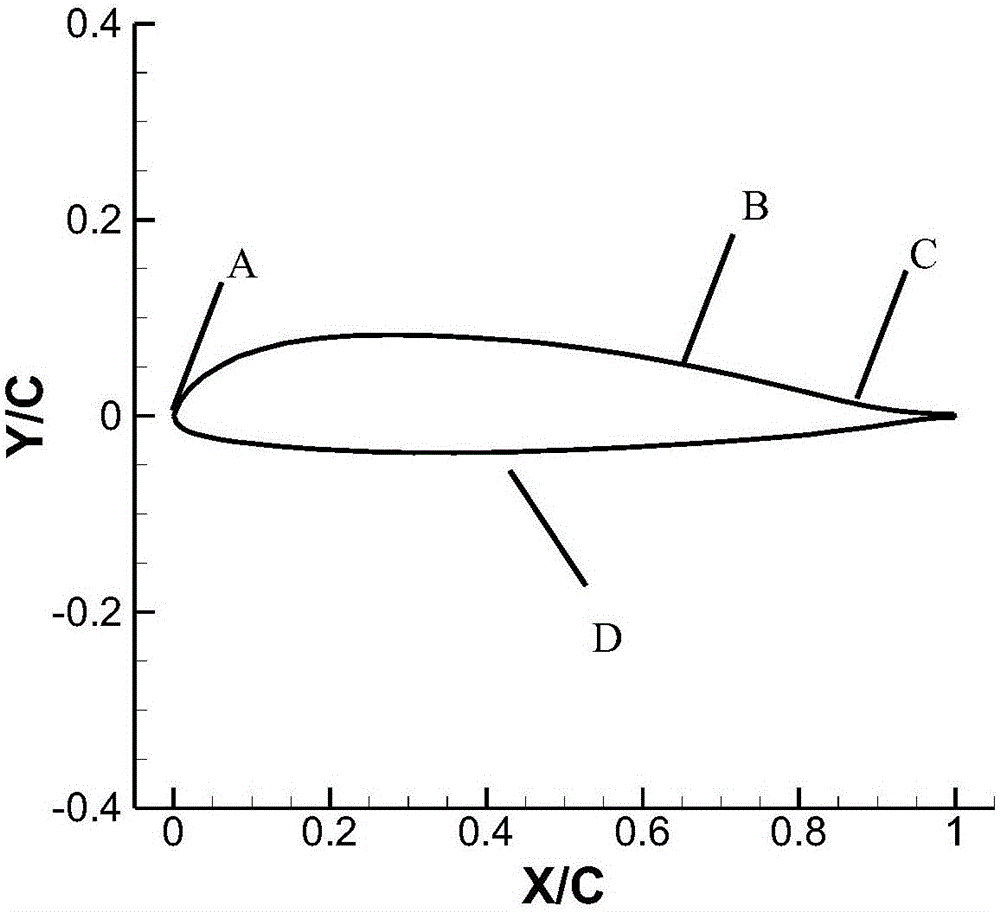

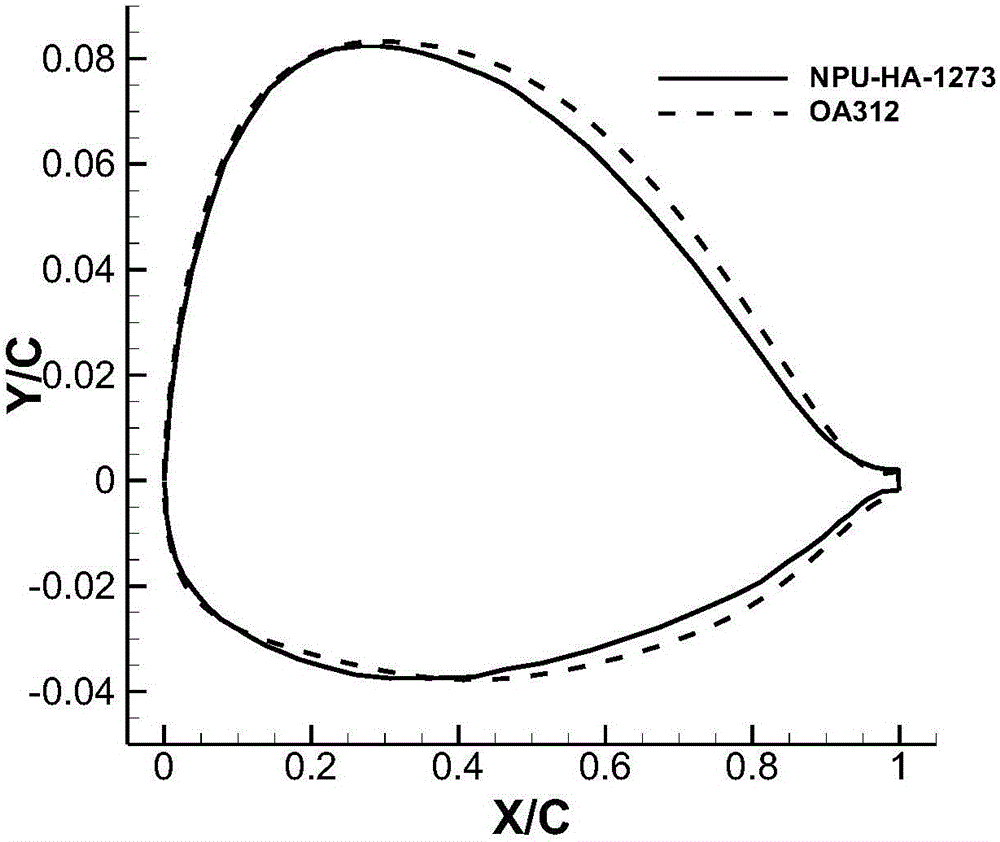

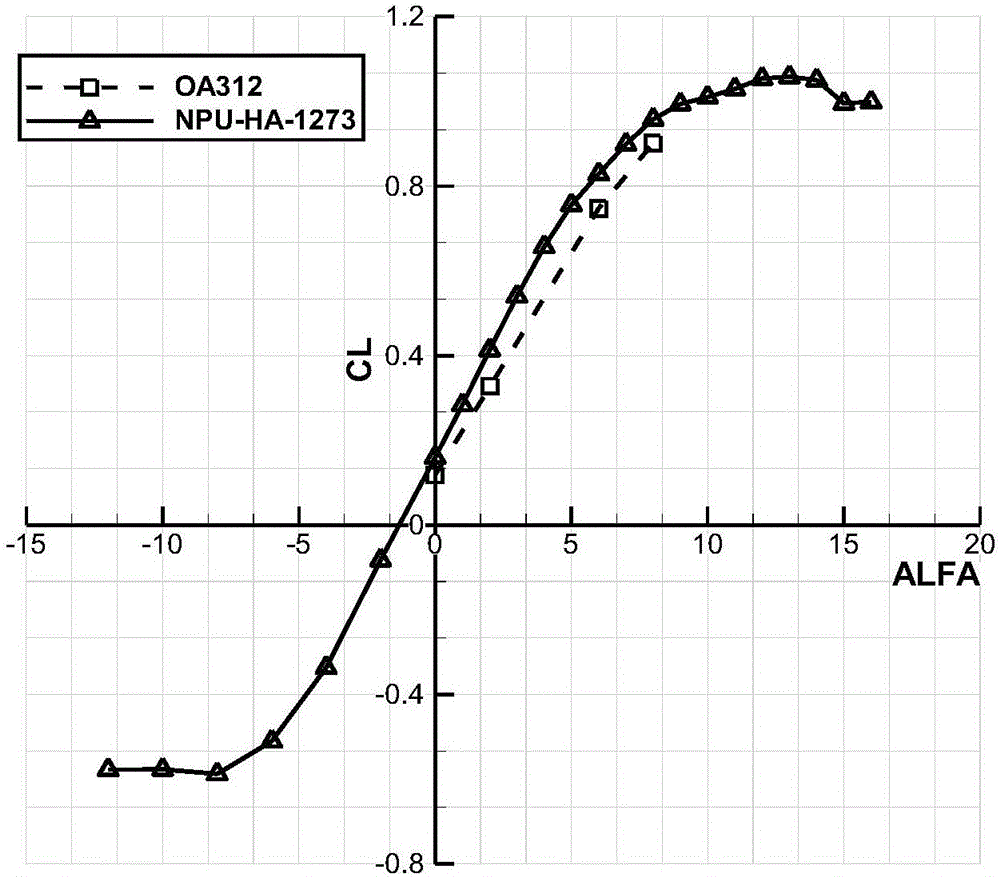

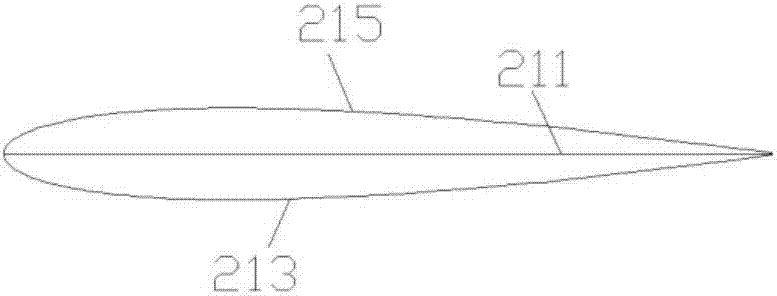

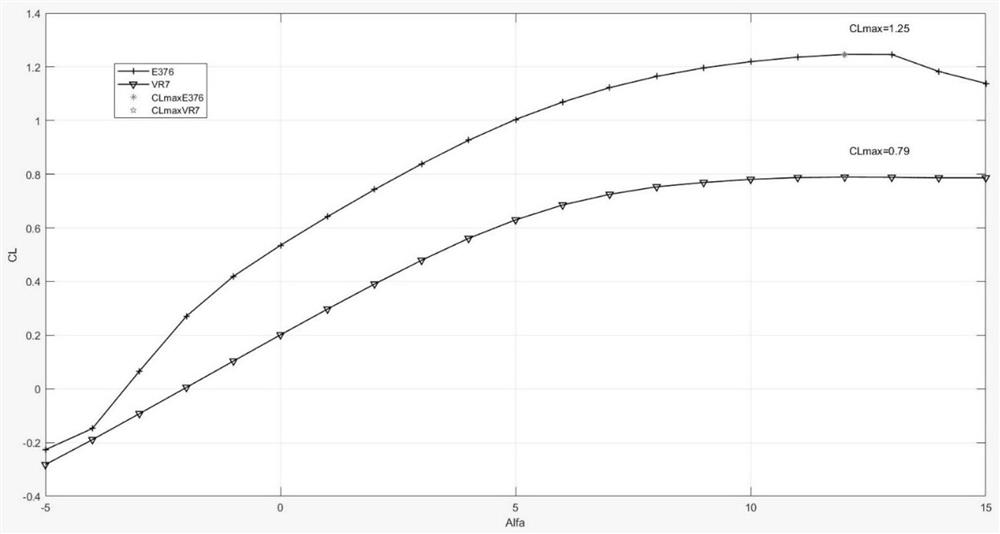

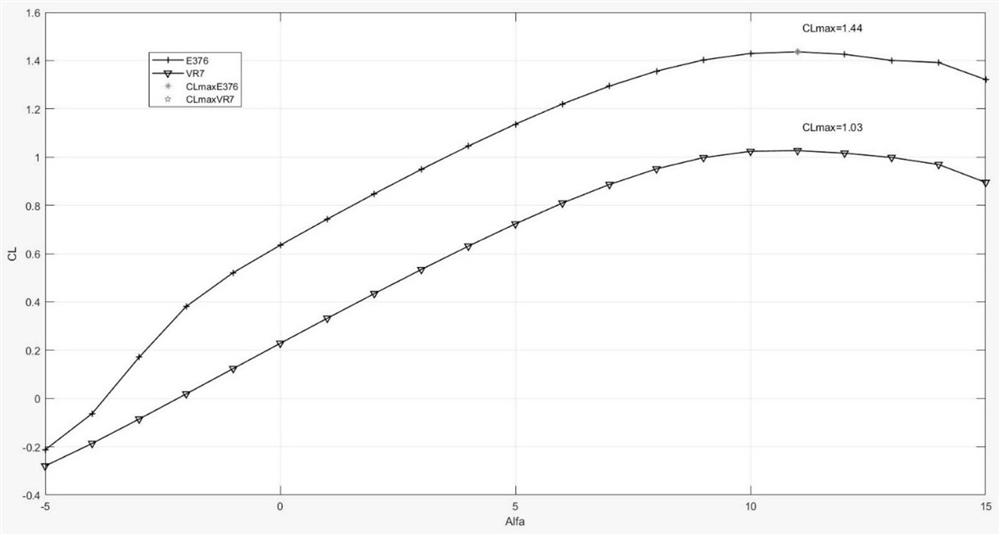

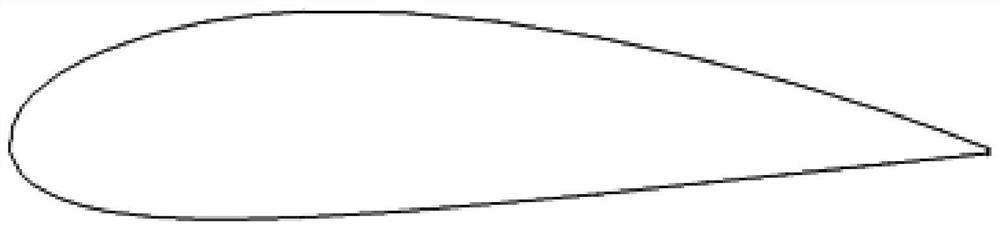

High lift and low torque characteristic 12%-thickness rotor-wing airfoil suitable for all working conditions

InactiveCN106741925AImprove the lift-to-drag ratioIncrease the maximum lift coefficientRotocraftShock waveHigh resistance

The invention provides a high lift and low torque characteristic 12%-thickness rotor-wing airfoil suitable for all working conditions, The 12%-thickness rotor-wing airfoil is characterized in that the radius of a front edge is reduced, so that shock-wave strength is reduced, the resistance is further reduced, and a lift-drag ratio is increased; the thickness of the lower part of the airfoil is increased to some extent, so that the torque is reduced. Compared with a high lift drag ratio and high resistance divergence Mach number 12%-relative-thickness rotor-wing airfoil OA312 disclosed abroad at present, the rotor-wing airfoil provided by the invention completely meets design indexes under multiple working conditions, and has a high lift drag ratio, a high resistance divergence Mach number, a high maximum lift coefficient and a smaller torque coefficient; when Ma is equal to 0.77, the zero lift drag is lower, so that the performance requirements of a high performance helicopter rotor blade design can be met.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

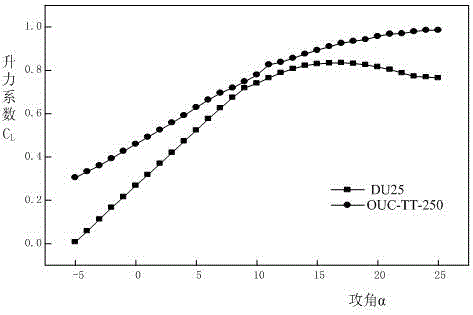

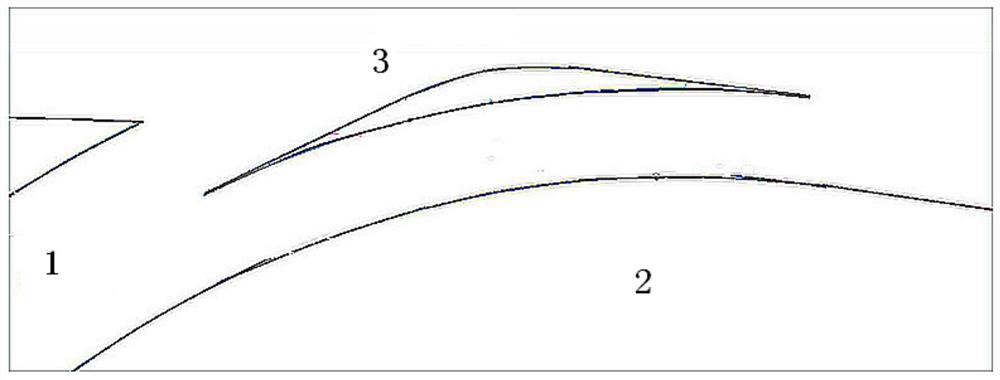

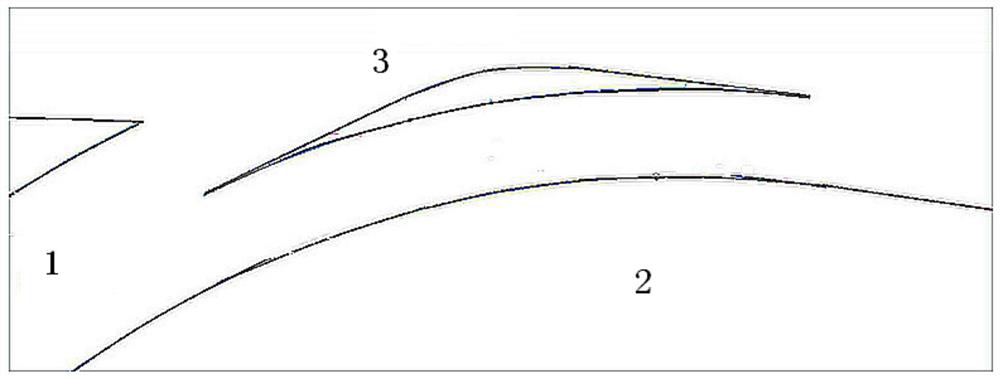

Wind turbine blade wing section group

InactiveCN104819106AImprove structural performanceIncrease the swept areaMachines/enginesEngine componentsSuction forceTurbine blade

The invention discloses a wind turbine blade wing section group which comprises a first wing section, a second wing section and a third wing section. The outlines of the first wing section, the second wing section and the third wing section are formed by smoothly connecting non-dimensional two-dimensional coordinates, the non-dimensional two-dimensional coordinates are obtained by using horizontal coordinates and longitudinal coordinates of all points on the pressure faces and suction force faces of the first wing section, the second wing section and the third wing section to divide the chord lengths of the wing sections. The relative thicknesses of the first wing section, the second wing section and the third wing section are respectively 23%, 27% and 32%, and the maximum camber positions are respectively located at the positions of the chord lengths of 67.6%, 74.1% and 64.4% of the front edges of the wing sections. The demands for thick wing sections of large wind turbine blades applied to a low-wind-speed wind field are met, the aerodynamic characteristics of the thick wing sections are effectively improved, the maximum lift coefficient and maximum lift-drag ratio of the thick wing sections are improved, and front edge roughness sensibility of the wing sections is reduced. Compared with existing thick wing sections, the structural performance of the blades is obviously improved, and static load under the limiting condition is reduced, so that the blades are lengthened, wind diffusion area is increased, and more wind energy is captured.

Owner:NANJING BEIDA GONGDAO INNOVATION +1

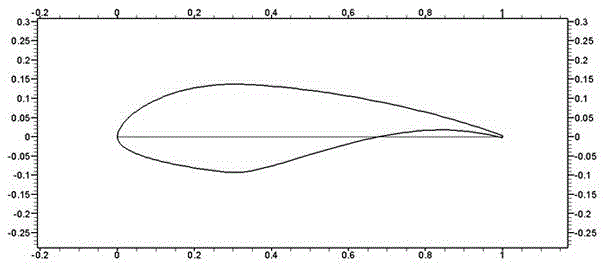

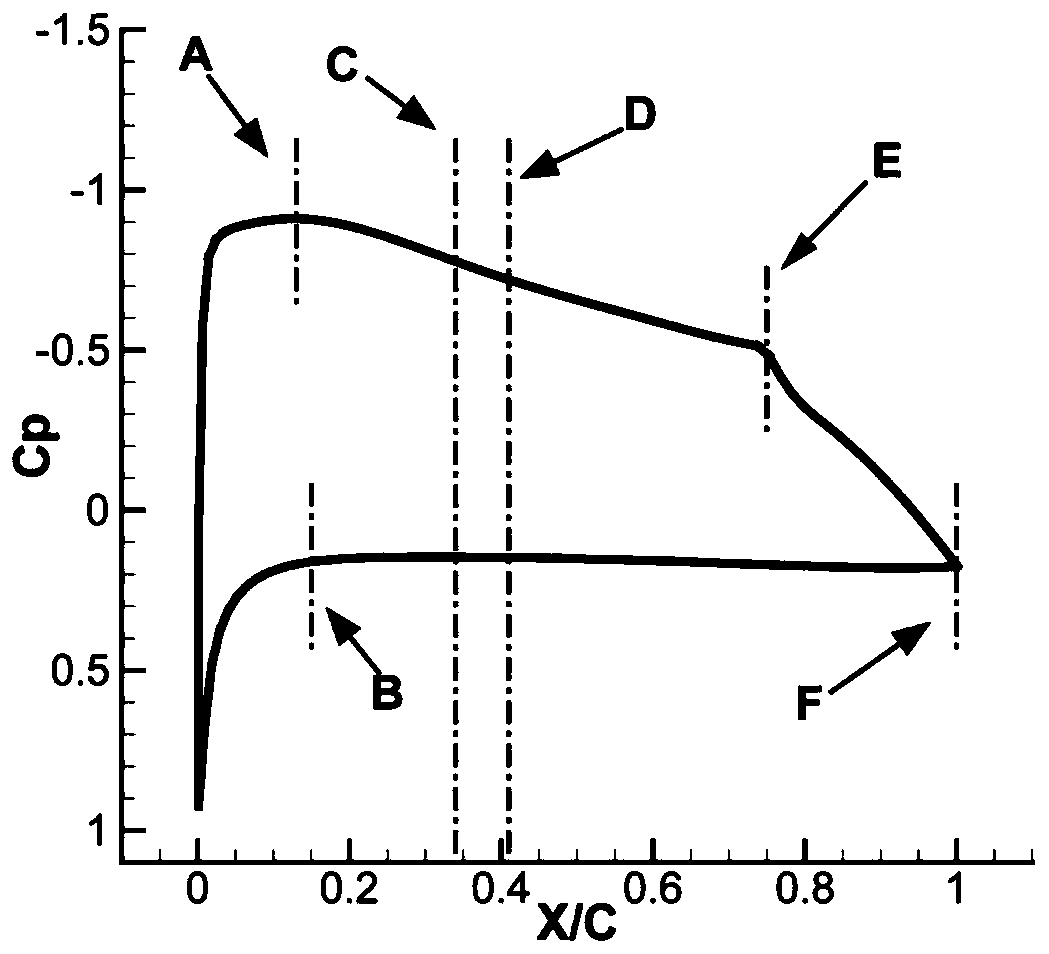

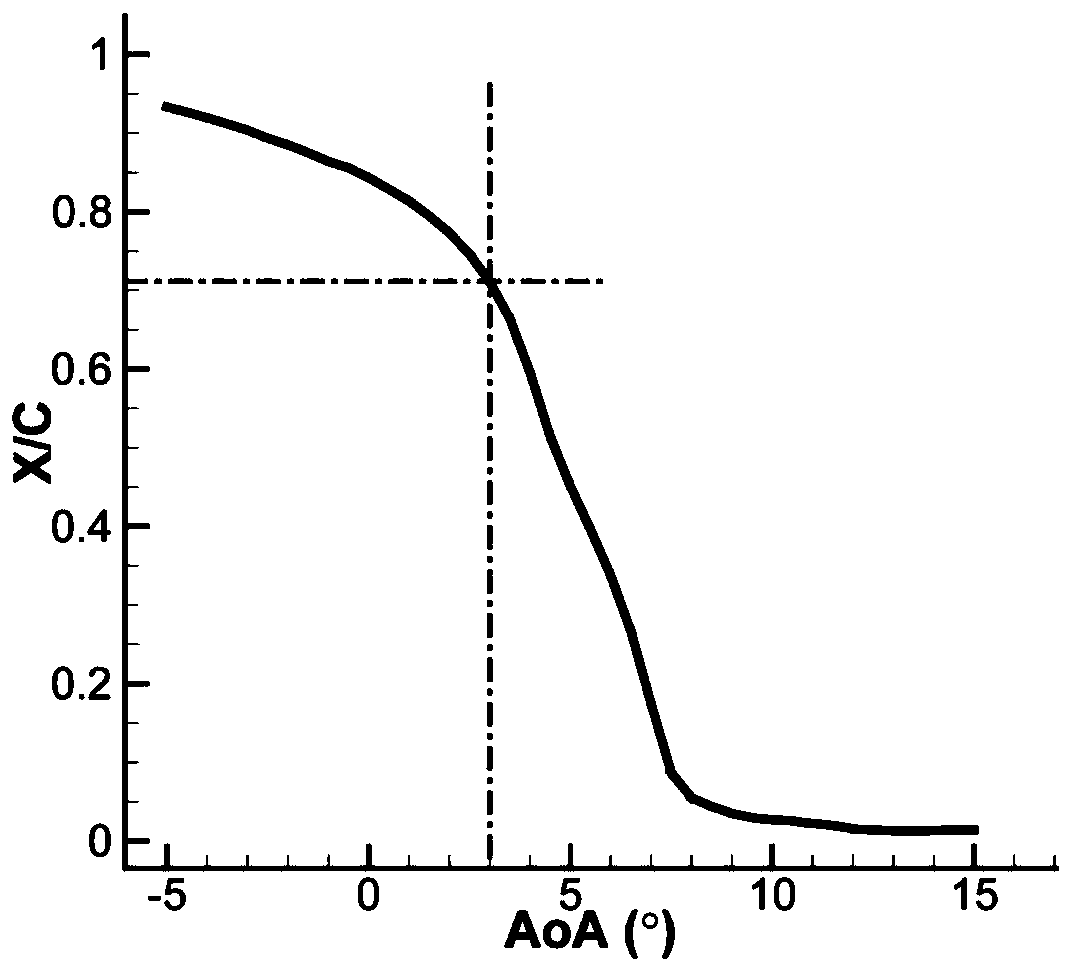

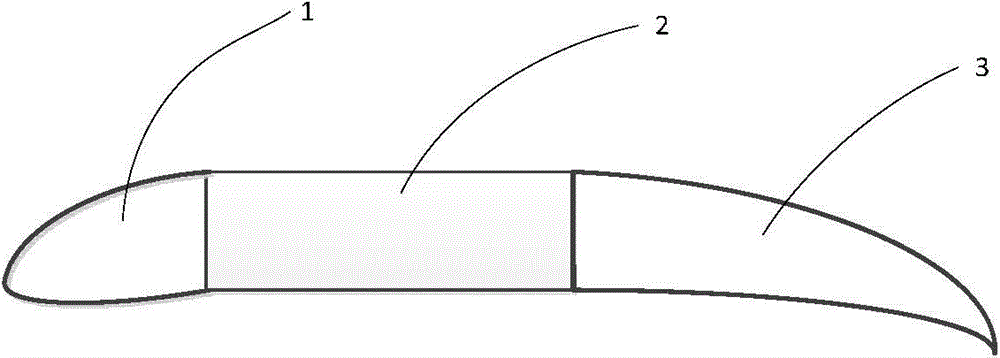

High lift-drag ratio laminar flow aerofoil profile suitable for low altitude and low speed unmanned aerial vehicle

ActiveCN110498037AMeet performance needsImproved stall characteristicsWing shapesLow speedEngineering

The invention belongs to the technical field of unmanned aerial vehicle aerofoil profile design and specifically relates to a high lift-drag ratio laminar flow aerofoil profile suitable for a low altitude (H is less than 5000 m) and low speed (Ma is less than 0.1) unmanned aerial vehicle. The maximum thickness of the aerofoil profile is 10%C, the chord position corresponding to the maximum thickness is 34%C, the maximum camber is 3.76%C, the chord position corresponding to the maximum camber is 41%C, and the thickness of a trailing edge is 0.3% C, wherein C is the chord length of the aerofoilprofile. According to the high lift-drag ratio laminar flow aerofoil profile suitable for the low altitude and low speed unmanned aerial vehicle, the upper surface of the aerofoil profile can generateflow transition at the 70-80% chord length under a working condition of 500 thousand order of Reynolds number; laminar flow gradually evolves into turbulent flow, namely, is transitioned first and then is separated; laminar flow separating bubbles are not generated; in a design state, the aerofoil profile has low resistance and high lift-drag ratio and possesses stable stalling characteristic andexcellent torque characteristic; and each performance index of the light unmanned aerial vehicle during low altitude and low speed long flight can be satisfied.

Owner:西安探索鹰航空科技有限公司

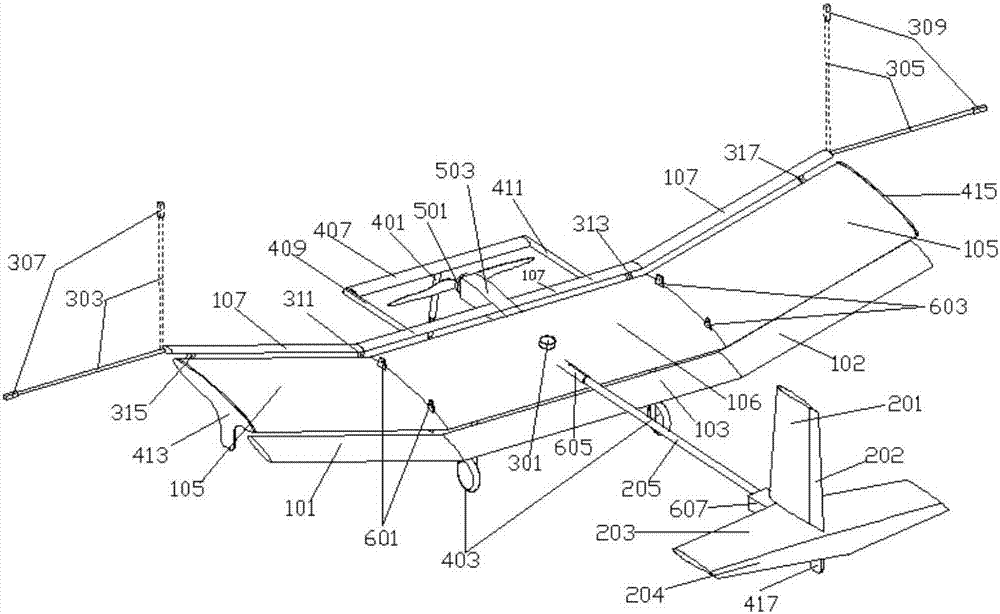

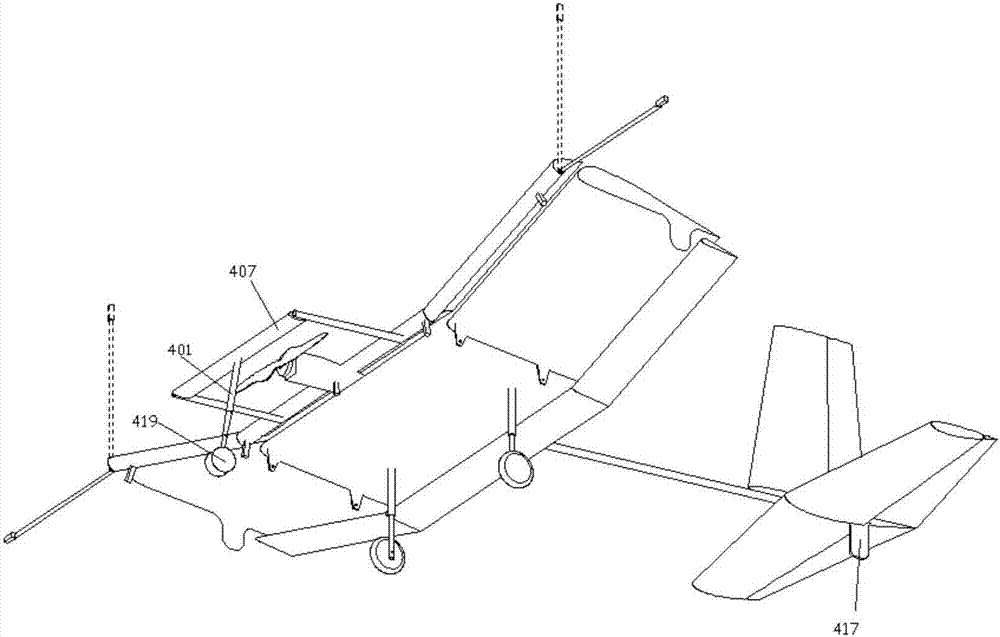

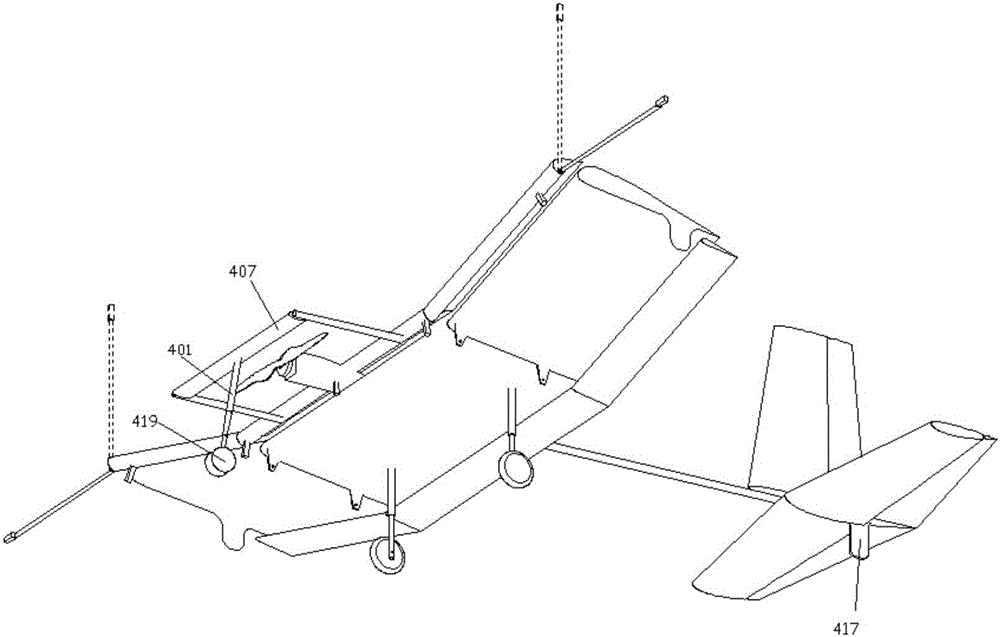

Three-section type fixed wing unmanned aerial vehicle provided with sprinkling system

PendingCN107054624AExtended spraying areaImprove spray performanceAircraft stabilisationWing shapesTrailing edgeAirplane

The invention relates to a three-section type fixed wing unmanned aerial vehicle provided with a sprinkling system. Each wing of the unmanned aerial vehicle is of a three-section type wing-type structure and comprises a slat arranged at the front edge of the wing, a main wing arranged in the middle of the wing and a wing flap arranged at the rear edge of the wing. Each main wing comprises a central wing body and outer wing bodies arranged on the two sides of the central wing body, and each wing flap comprises a wing flap body arranged at the rear edge of the corresponding central wing body and flaperons arranged at the rear edges of the corresponding outer wing bodies; and the sprinkling system comprises a container, a pump, a spray pipe and a spray head, the spray head is connected with the pump through the spray pipe, and the pump is connected with the container through the spray pipe. The three-section type fixed wing unmanned aerial vehicle provided with the sprinkling system has the higher maximum lift coefficient so as to have higher maximum lift; and meanwhile, the weight-carrying, flying and sprinkling performance of the fixed wing unmanned aerial vehicle is improved, and thus the fixed wing unmanned aerial vehicle has the higher sprinkling efficiency.

Owner:西安神骑航空科技有限公司

Wing with pits

InactiveCN104139846AWide range of effective angle of attackIncrease the maximum lift coefficientWingsAir-flow influencersEffective angleFront edge

The invention belongs to the technical field of aircrafts, and particularly relates to a wing with pits. The wing comprises a front edge, an upper surface, a lower surface, a rear edge and a wing body. The front edge is thick and round, the upper surface is an upwards-protruding curved surface, the lower surface of a plane or a curved surface which slightly protrudes downwards or a curved surface which is slightly concaved upwards, the identical small pits are evenly distributed in all the area, from the thickest portion of the wing to the rear edge, of the upper surface in the wing chord direction, the average depth of the small pits is about 0.25 mm, the largest boundary dimension of the small pits is between 1 mm and 10 mm, and the clear distance between every two adjacent small pits is between 1 mm and 3 mm. The largest lift-drag ratio of the wing is large, the range of the effective angle of incidence is large, and the wing is not prone to stalling, high in efficiency and high in strength.

Owner:FOSHAN SHENFENG AVIATION SCI & TECH

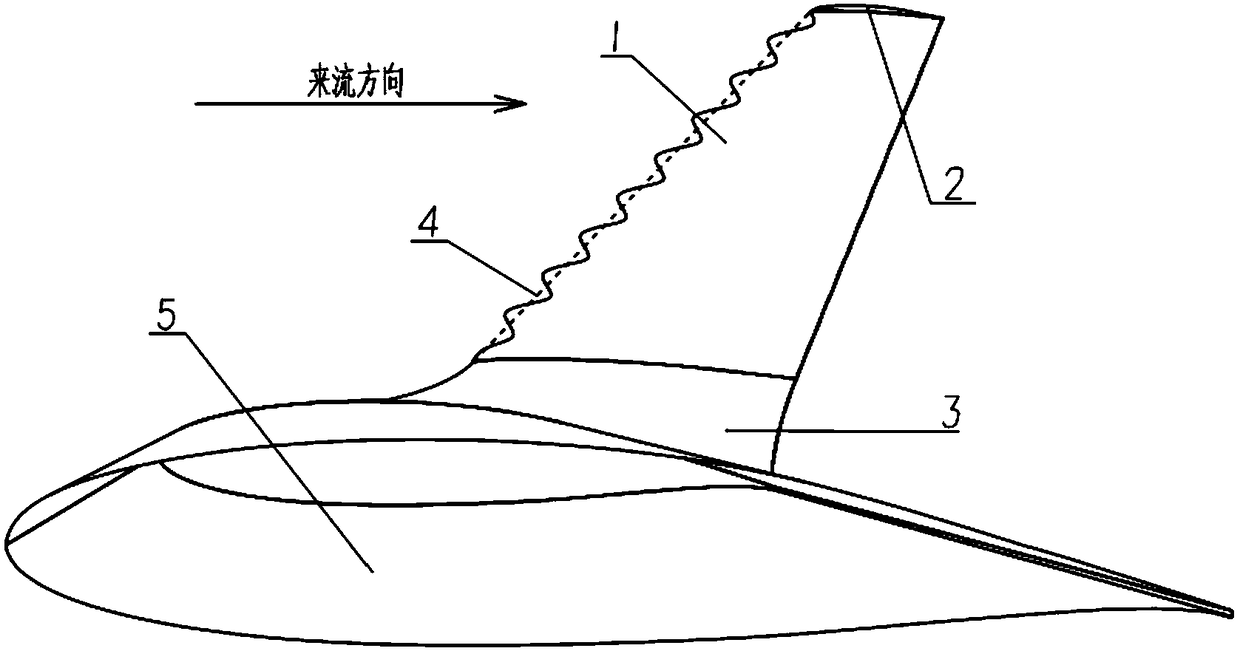

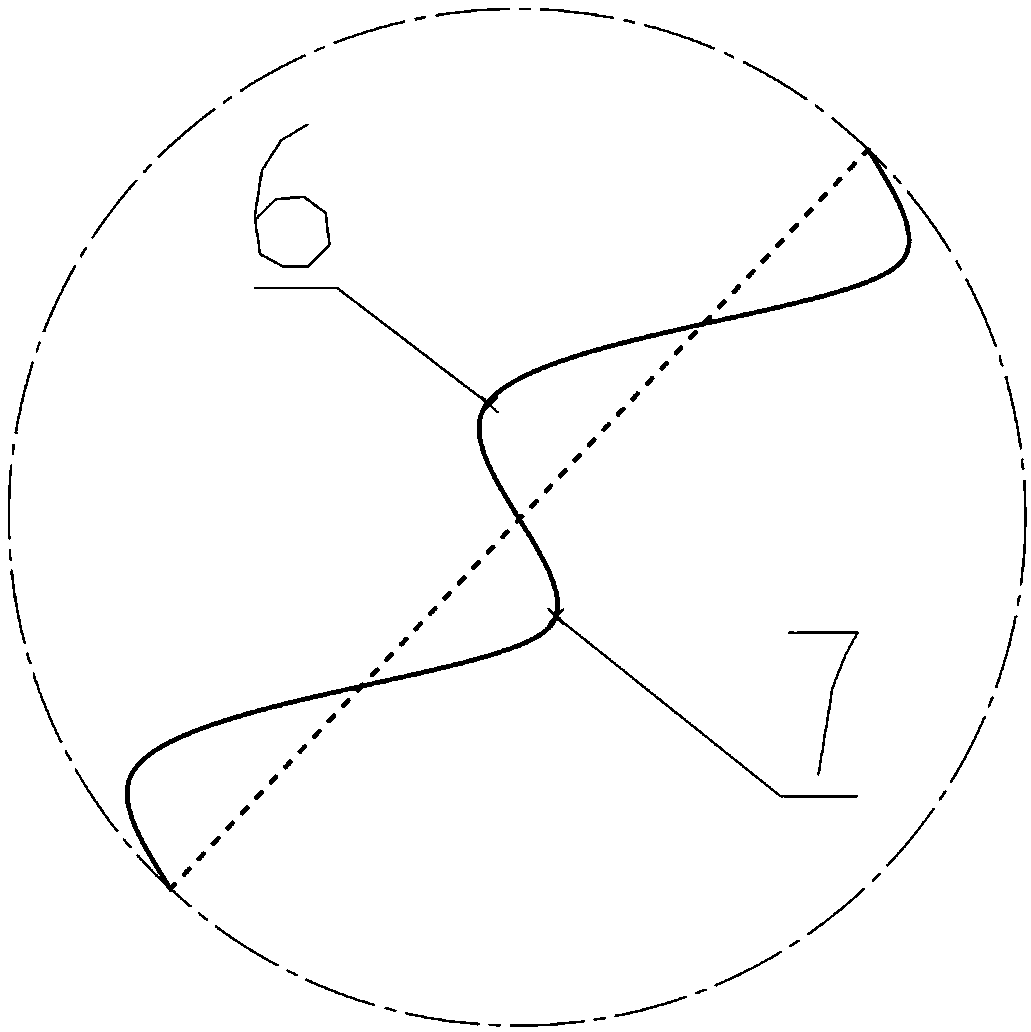

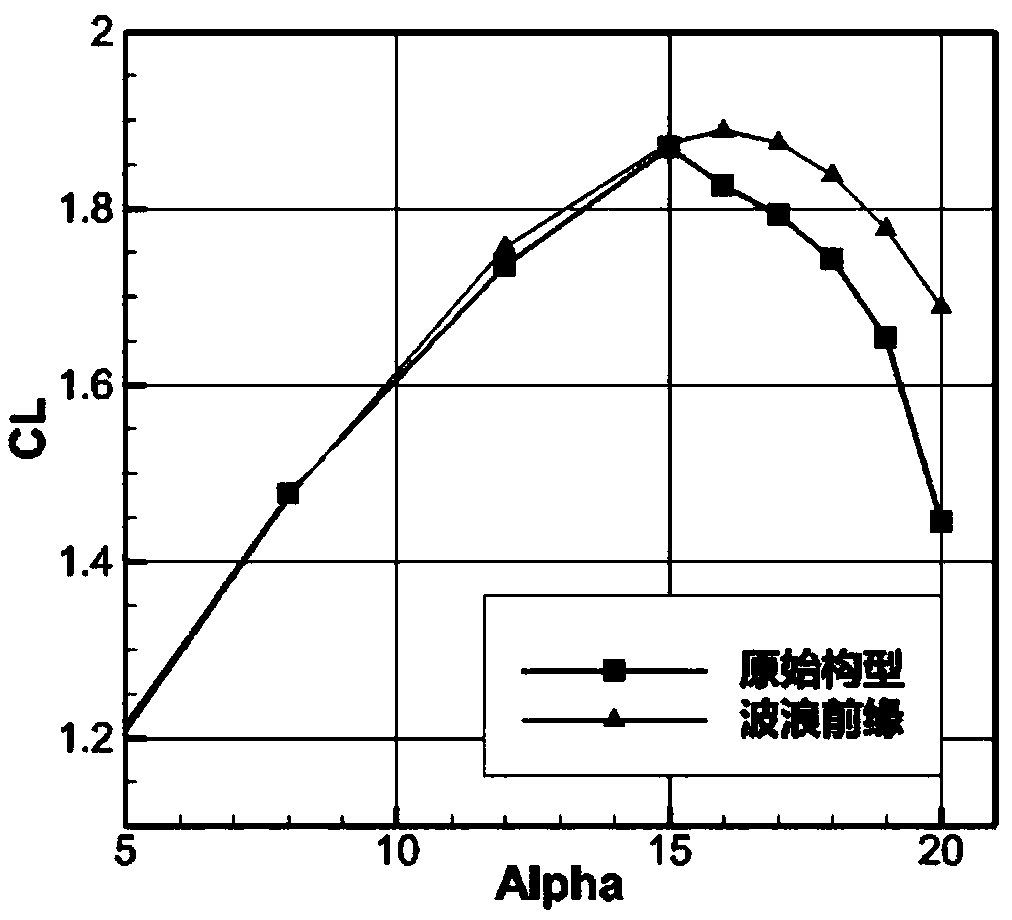

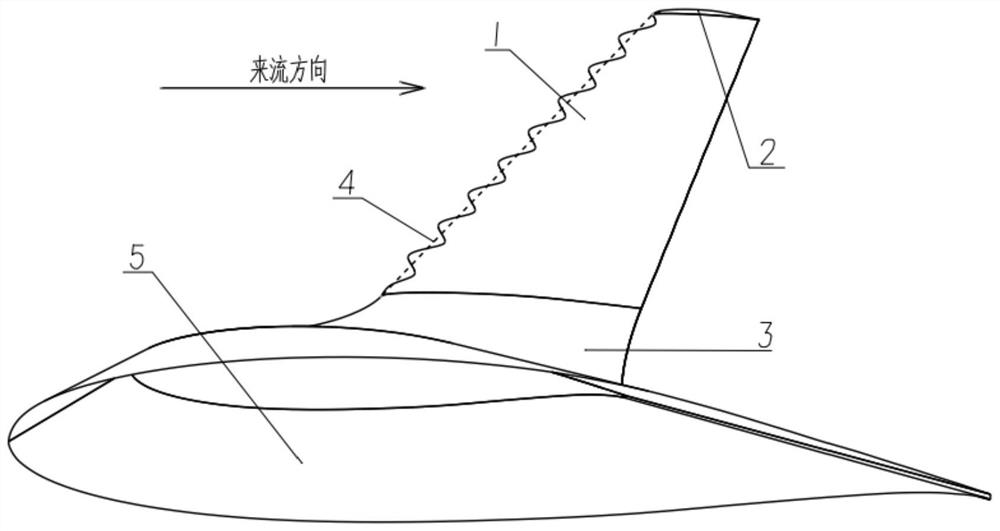

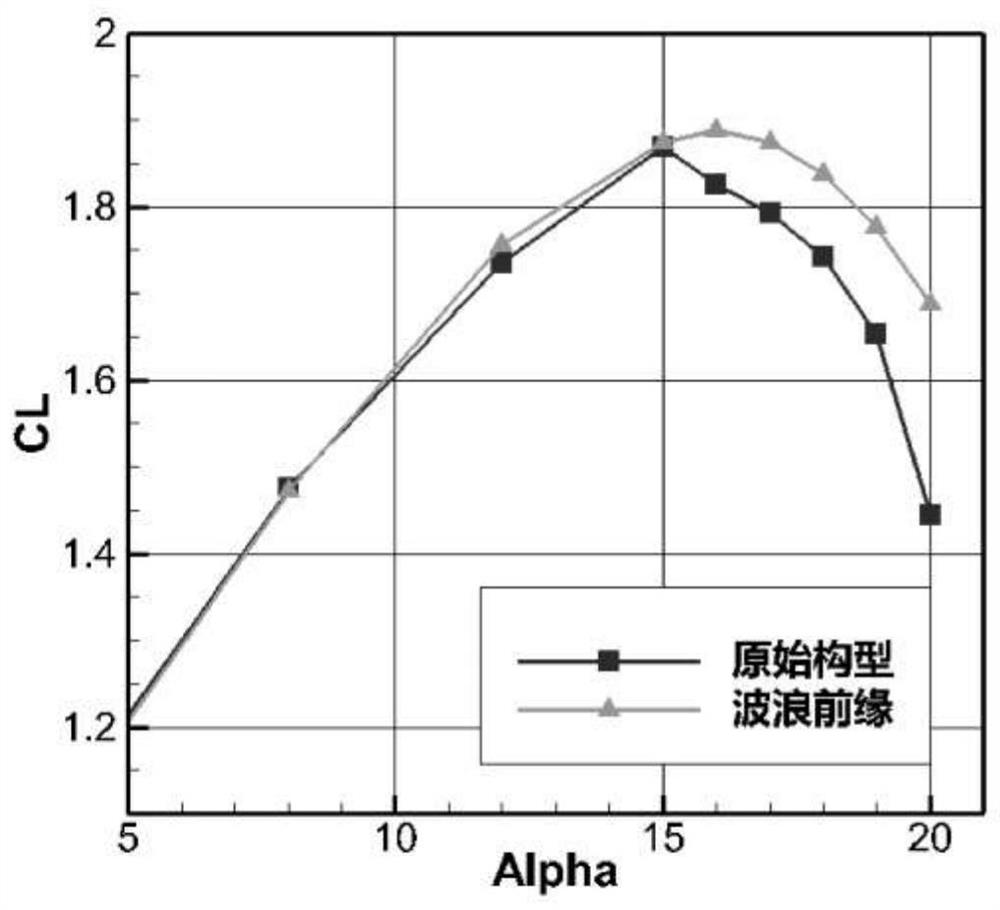

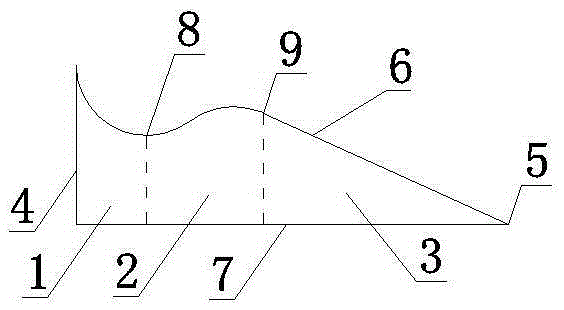

A biomimetic wave leading edge wing tip winglet device

ActiveCN108974326AEnhanced Momentum ExchangeIncrease the maximum lift coefficientAircraft stabilisationWing adjustmentsLeading edgeWave structure

A biomimetic wave leading edge wing tip winglet device includes a fin leading edge segment, a top rectifier section and a transition section, The leading edge section of the fin is a multi-sectional curved surface with two opened ends, one side of the leading edge section of the fin is of a wave structure, the top rectifier section is fixed on the top of the leading edge section of the fin to close the top of the leading edge section of the fin, the bottom of the leading edge section of the fin is provided with a transition section, and the transition section is arranged on the wing, the leading edge section of the fin, the top rectifier section and the transition section form a wing tip small wing. As that lead edge of the tip winglet forms regular bump, the uniform incoming flow can generate vortices with opposite rotational directions and high energy at high angle of attack, thereby maintaining airflow adhesion on the winglet, delay airflow separation and development, finally delaying the stall angle of attack of the wing, increasing the maximum lift coefficient, and achieving the purpose of shortening the takeoff distance.

Owner:XI AN JIAOTONG UNIV

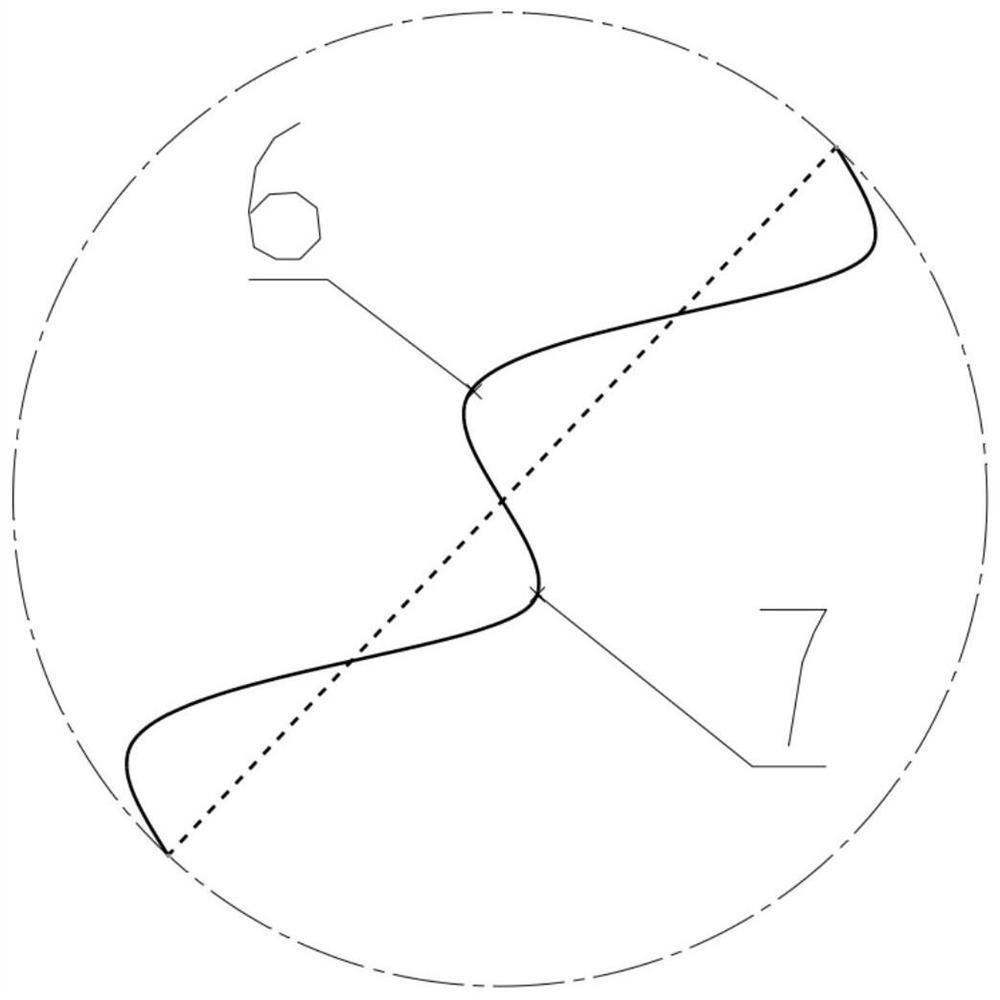

Special-shaped wing profile

ActiveCN104097763AWide range of effective angle of attackIncrease the maximum lift coefficientWing shapesLeading edgeTrailing edge

The invention discloses a special-shaped wing profile, belongs to the technical field of air vehicles and particularly relates to a wing. The special-shaped wing profile comprises a leading edge, an upper surface, a lower surface, a trailing edge, a wing root, a wing tip and a wing body, wherein the leading edge is a combination of an oblique S-shaped curve and a straight line, the trailing edge is straight, and the wing tip is sharp. A wing is divided into three portions by a plane parallel to the wing root end face along the wingspan direction: the first portion refers to a portion close to the wing root and is roughly a profile with a convex upper and a flat lower and with medial relative thickness, the radius of the leading edge is medial, and a position with maximum thickness is in the back; a second portion refers to a middle portion and is a thick profile with a convex upper and a concave lower, the radius of the leading edge is large, and a position with maximum thickness is in the front; a third portion is a portion close to the wing tip and is roughly a thin profile with double convex surfaces, the radius of the leading edge is small, and a position with maximum thickness is in the middle; the three portions are in smooth connection. The wing with the special-shaped wing profile is large in effective incidence, less prone to stalling and high in efficiency.

Owner:SUZHOU MAICHUANG INFORMATION TECH

Double-slit flap with flap body fixedly connected with additional wing

ActiveCN112339987AIncreased maximum lift coefficientImprove performanceWingsClassical mechanicsHigh lift

The invention belongs to the technical field of aircraft wings, and particularly relates to a double-slit flap with a flap body fixedly connected with an additional wing. The double-slit flap comprises the additional wing and the flap body, the additional wing and the flap are fixedly connected through a connecting rod, and the fixedly-connected additional wing and flap are taken as a whole to beretracted and released under the effect of a driving connecting mechanism; when the double-slit flap is in a put-down state, a gap exists between the main wing and the additional wing, a gap exists between the additional wing and the flap, and the high lift effect of the double-slit flap is achieved. According to the double-slit flap, through the additional wing flap structure in rigid connection,the high lift effect of the double-slit flap is achieved when the flap body is put down, meanwhile, the structural complexity of the double-slit flap is kept to be equivalent to that of a single-slit / fullerene flap, lift force is improved under the condition of the same structural complexity, and therefore the area requirements of wings and flaps are reduced, the weight of an airplane is reduced,and the aircraft performance is improved.

Owner:中电科芜湖通用航空产业技术研究院有限公司 +1

Efficient control method of high-altitude airscrew collaborative jet

ActiveCN104691744AIncrease stall angle of attackImproved stall characteristicsPropellersJet flowPropeller

The invention provides an efficient control method of high-altitude airscrew collaborative jet. The efficient control method comprises the following steps: setting configuration parameters and working parameters of collaborative jet devices; and configuring each collaborative jet device for propeller blades in a spanwise sectional type according to the configuration parameters; enabling each collaborative jet device to work according to the configured working parameters, so that the airfoil profile of each station reaches the best lift-drag ratio and the minimum energy loss. The operation process of each collaborative jet device is that an air pump simultaneously drives a front-edge negative-pressure region to spray air and a rear-edge high-pressure region to suck air, and actively controls the air stream on the surface of the airfoil profile in a flow mode, wherein the counter acting force of jet flow generated by air spraying and suction is decomposed to two directions, one is the rotation direction of a propeller, and further the rotation of the propeller is boosted, and the resistance is reduced; and the other one is the thrust direction of the propeller, the thrust of the propeller is enhanced, and finally the pneumatic efficiency of the propeller is improved. According to the invention, the operating efficiency of the propelling system of the high-altitude airscrew can be improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

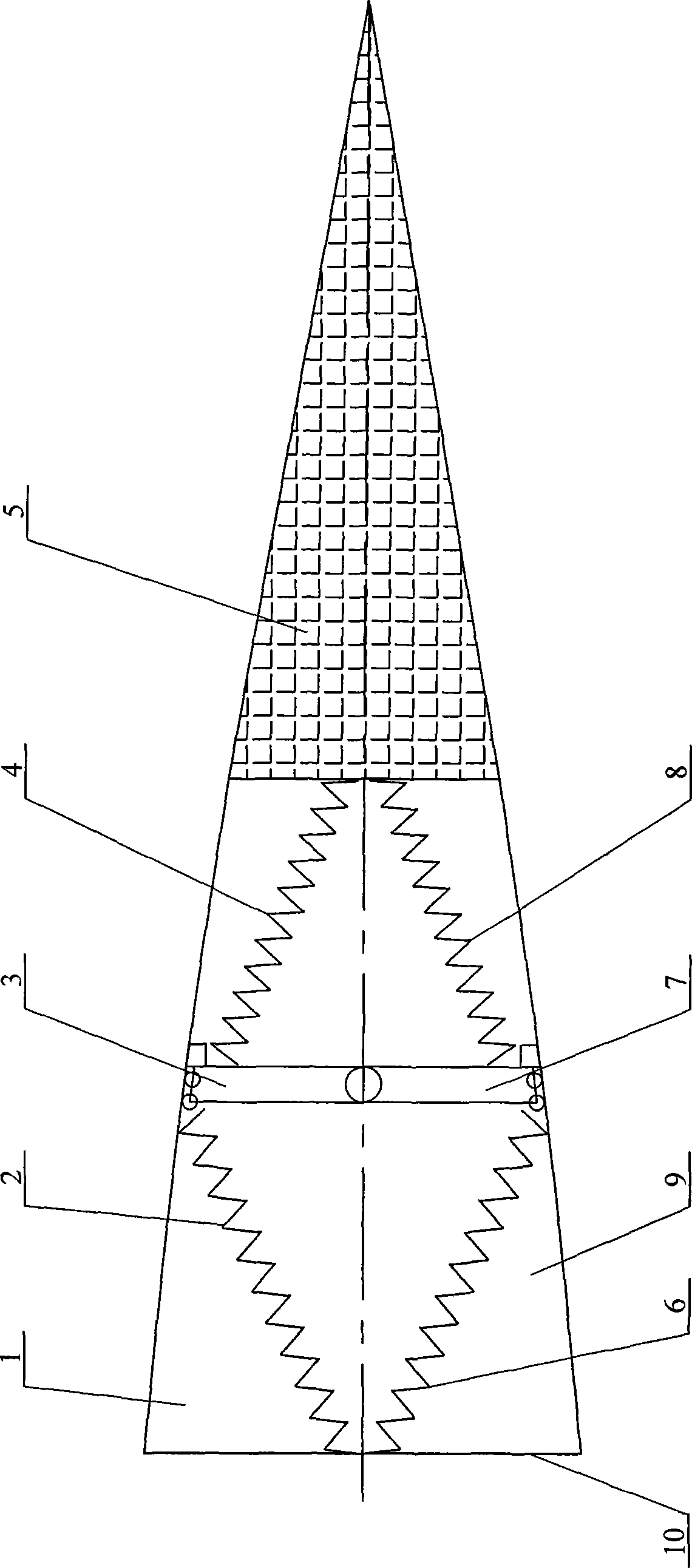

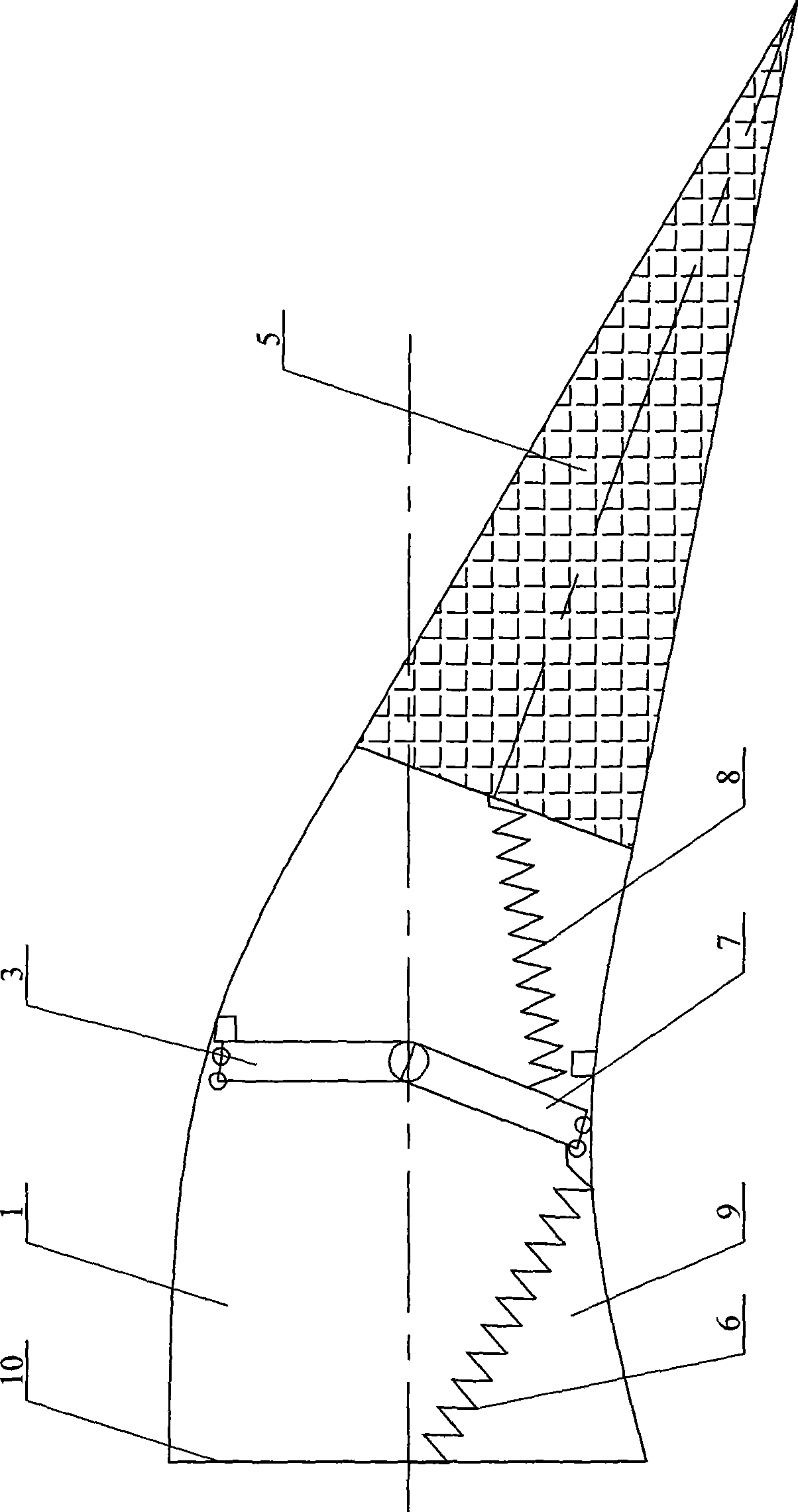

Three-section type fixed-wing unmanned aerial vehicle provided with protection device

The invention relates to a three-section type fixed-wing unmanned aerial vehicle provided with a protection device. A wing of the fixed-wing unmanned aerial vehicle is of a three-section type wing-shaped structure and comprises a slat which is arranged at the front edge of the wing, a main wing which is arranged in the middle of the wing and a wing flap which is arranged at the rear edge of the wing; the main wing comprises a central wing and outer wings located at two sides of the central wing; the wing flap comprises a wing flap arranged at the rear edge of the central wing and secondary wing flaps arranged at the outer edges of the outer wings; a forward pull type screw propeller is arranged at the front end of a fuselage; a protection device comprises a screw propeller protection device, a wingtip protection device and an empennage protection device. The three-section type fixed-wing unmanned aerial vehicle provided by the invention has the advantages that the three-section type fixed-wing unmanned aerial vehicle has a higher lift coefficient and the aerial vehicle has higher maximum lift; meanwhile, the fuselage and the screw propeller can be reasonably protected.

Owner:西安神骑航空科技有限公司

Method for designing special wind turbine airfoil profile and special wind turbine airfoil profile

InactiveCN101923584BReduce roughness sensitivityLess impact from rough conditionsWind energy generationSpecial data processing applicationsSurface roughnessTurbine

The invention discloses a method for designing a special wind turbine airfoil profile and a special wind turbine wing profile obtained by the designing method. In the invention, a corresponding airfoil profile can be obtained by expressing the geometrical shape of an airfoil profile with a simple high-order polynomial shape function and altering the coefficient of the shape function polynomial according to a special constraint condition. The special wind turbine airfoil profile is in a Reynolds number range with Re=1*106-3*106, has low-airfoil profile surface roughness sensitivity, higher lift coefficient and maximum lift drag ratio, as well as high lift drag ratio and favorable structural property in a larger attack angle range, and has favorable compatibility and acoustical property compared with other wind turbine airfoil profiles.

Owner:CHONGQING UNIV

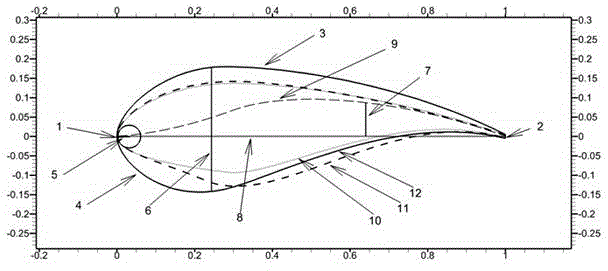

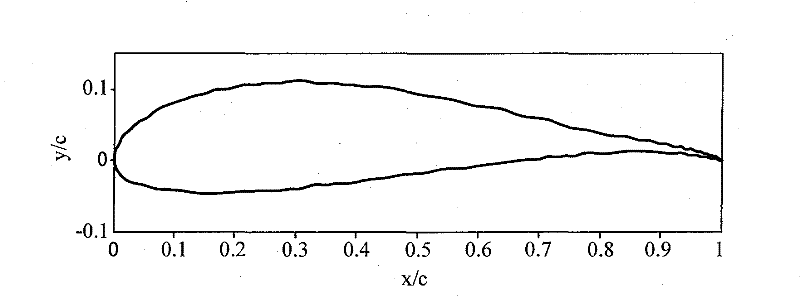

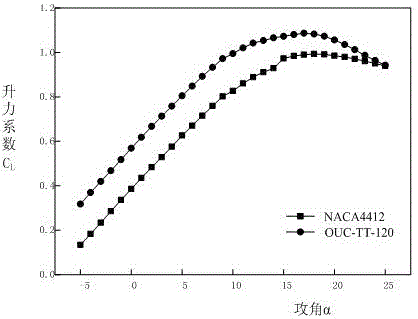

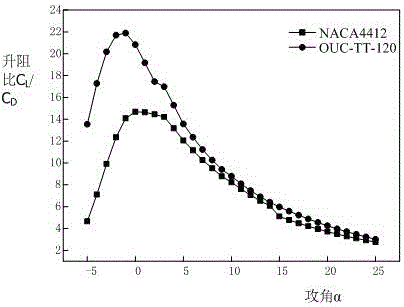

Blade airfoil family design method for tidal current energy horizontal shaft water turbine

InactiveCN106227985AImprove design efficiencyIncrease the maximum lift coefficientGeometric CADSpecial data processing applicationsWater turbineWater flow

The invention provides a blade airfoil family design method for a tidal current energy horizontal shaft water turbine. The blade airfoil family design method for the tidal current energy horizontal shaft water turbine is characterized in that an Hicks-Henne type function is used for performing parametric modeling on airfoil blades; the airfoil curve is controlled through controlling the upper airfoil surface and lower airfoil surface key points of the airfoil blades; in addition, the head and tail points of the airfoil blades are fixed and unchanged. The goal of improving the airfoil blade lift-drag ratio used by the tidal current energy water turbine is achieved; the structure of the airfoil blades is optimized to meet the requirements of water flow power generation; the use performance is improved.

Owner:OCEAN UNIV OF CHINA

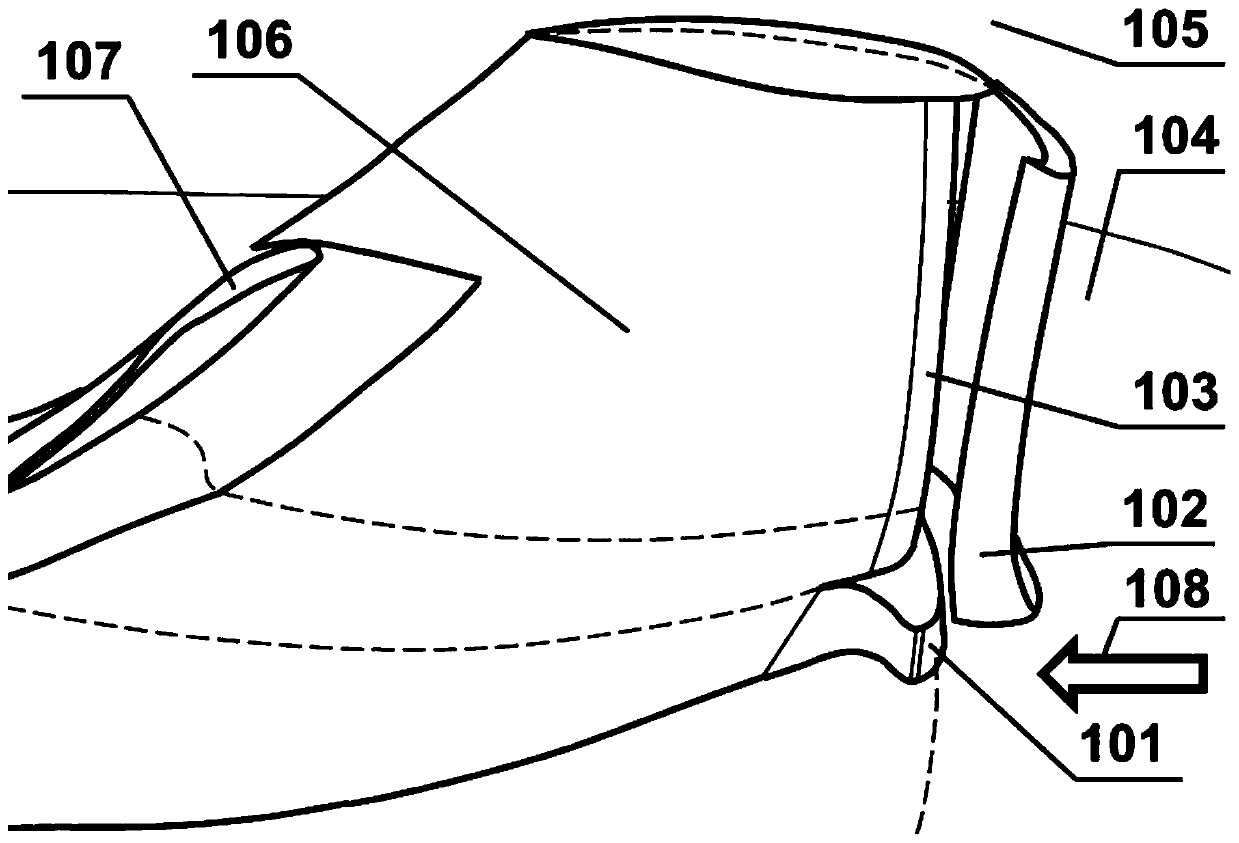

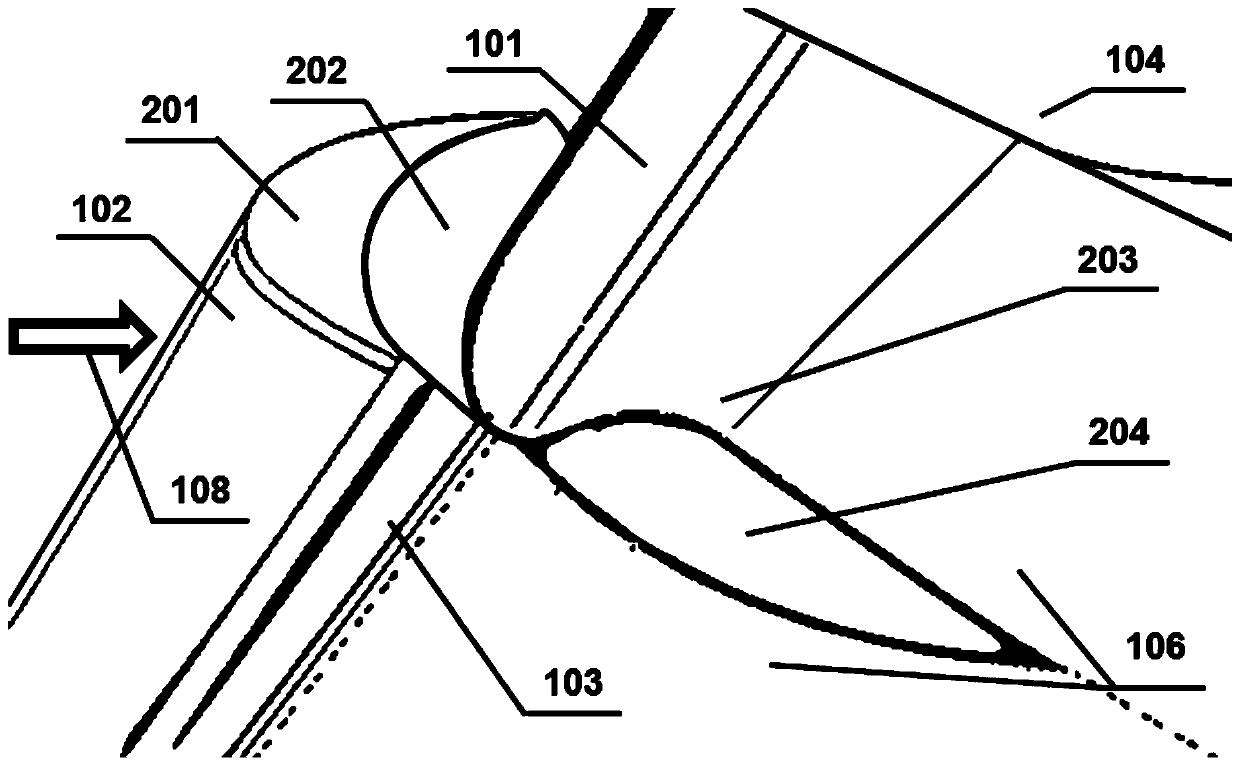

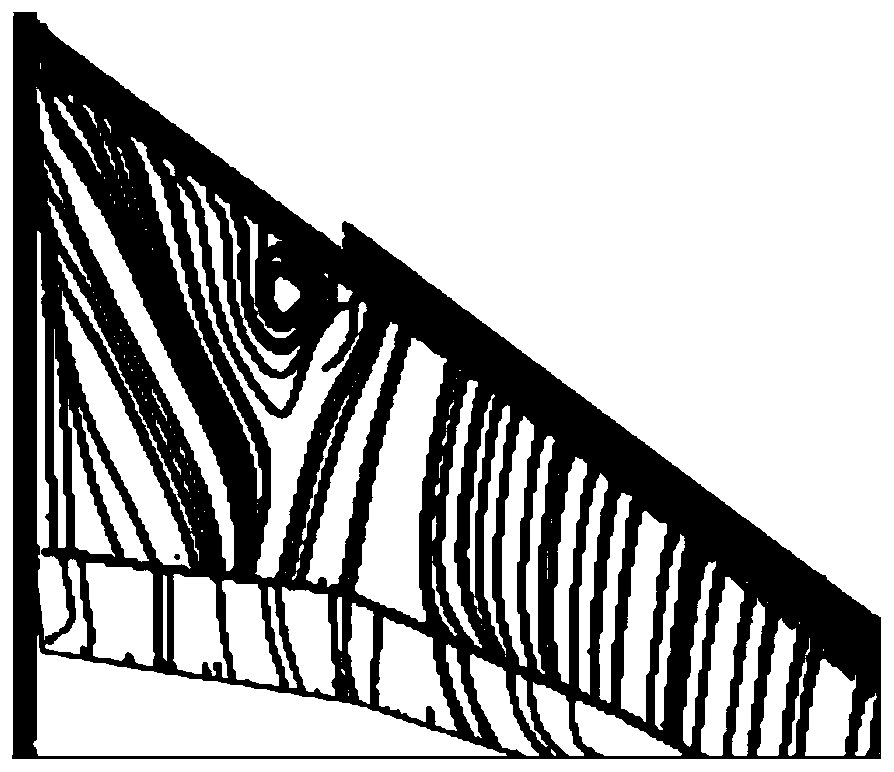

Method and device for optimizing flowing at junction of leading edge become-warped wing flap and leading edge slat

ActiveCN110539882AOvercome adverse flow disturbancesIncrease the maximum lift coefficientAir-flow influencersAviationLeading edge

The invention belongs to the technical field of flowing control and provides a method and device for optimizing flowing at the junction of a wing leading edge become-warped wing flap and a leading edge slat of an aviation flying machine and inhibiting and postponing flowing separation of the area. According to the method and device, due to the steps of flow field analyzing, pneumatic design, device installing, a wind tunnel test, result analyzing, relevant adjusting and the like, it is put forwards that in a wing inner side leading edge become-warped wing flap and outer side leading edge slatcombined construction, first flowing isolating pieces and second flowing isolating pieces are arranged. The first flowing isolating pieces are located between the leading edge become-warped wing flapand the leading edge slat, and arranged in the forward stretching direction of the slat; and the second flowing isolating pieces are also located at the junction of the leading edge become-warped wingflap and the leading edge slat, and arranged in the down flow direction of the lower surface of a wing. The flowing optimizing device effectively overcomes the flowing adverse disturbance at the junction of the leading edge become-warped wing flap and the leading edge slat, generation of flowing separation of the upper surface is postponed, and a maximum elevating force coefficient of an airplaneis increased. Besides, the method and device are clear in principle, simple in structure, and remarkable in effect and are verified by the wind tunnel test.

Owner:中国航空研究院

A variable camber trailing edge and leading edge for an aircraft wing

ActiveCN104139847BImprove pressure distributionImprove stealth performanceWing adjustmentsAircraft transmission meansLeading edgeClosed loop

The invention provides a trailing edge with adjustable degrees of curvature for an aircraft wing. The aircraft wing comprises a middle wing part with the fixed degree of curvature. The middle wing part comprises a main beam. The trailing edge with the adjustable degrees of curvature comprises a rear beam, a plurality of trailing edge pole group structures and a trailing edge driving mechanism, wherein the trailing edge pole group structures are arranged in parallel. The rear beam is connected with the rear end of the main beam. The trailing edge driving mechanism comprises rockers driven by a driving device. One ends of the rockers are connected with the rear beam in a rotatable mode, and the other ends of the rockers are connected with the trailing edge pole group structures in a rotatable mode. The trailing edge pole group structures are plane pole group structures based on 5R closed-loop units and respectively have one degree of freedom. Each trailing edge pole group structure comprises a plurality of pairs of 5R closed-loop units, a plurality of networking triangular units, a tail-end 4R closed-loop unit and a tail-end triangular unit. Each pair of 5R closed-loop units comprises the upper 5R closed-loop unit and the lower 5R closed-loop unit. Meanwhile, the invention provides a leading edge with adjustable degrees of curvature for the aircraft wing.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

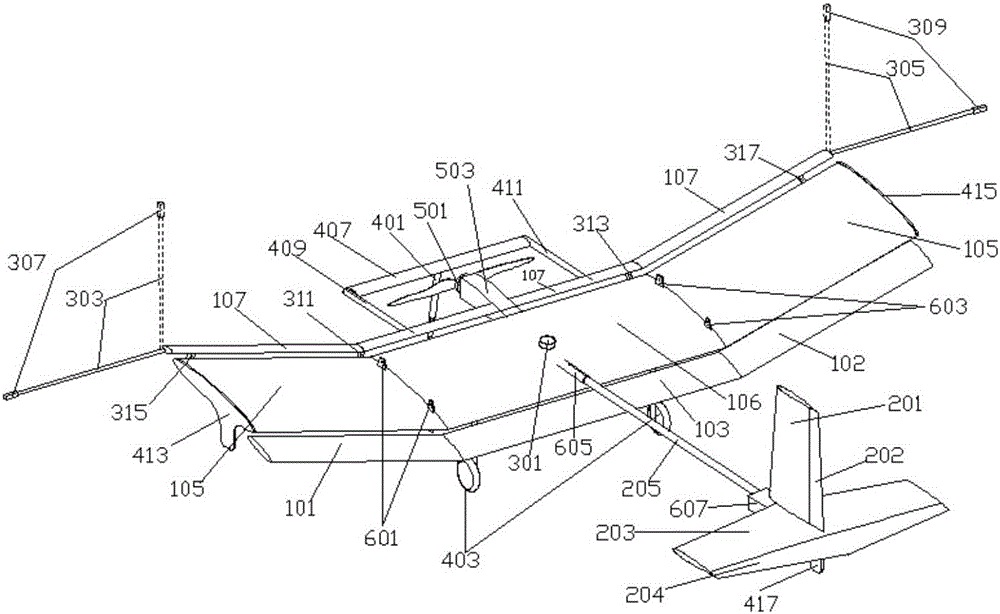

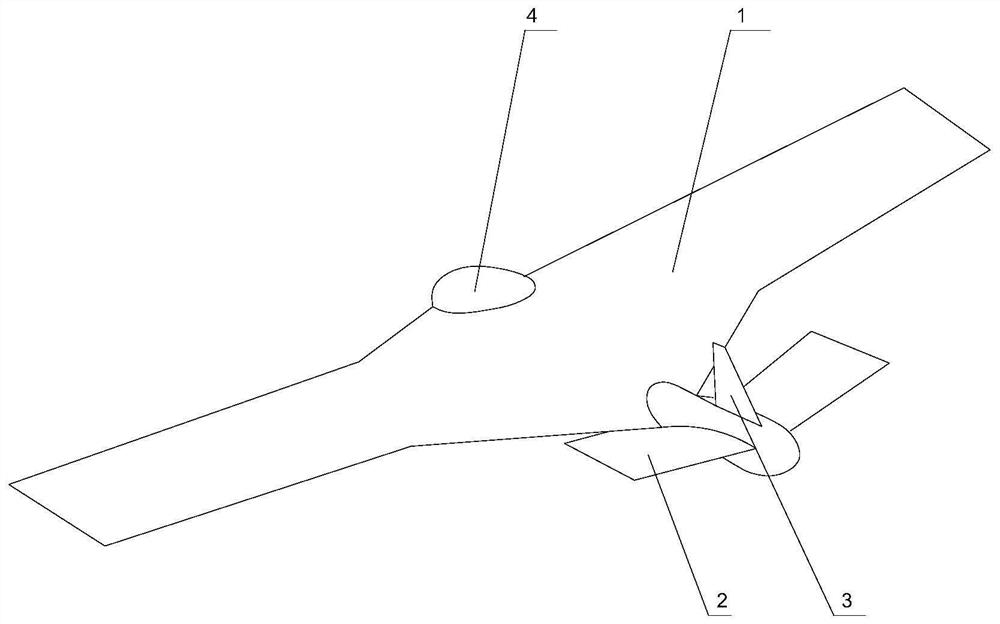

Canard flying wing aerodynamic layout unmanned aerial vehicle

PendingCN112319814AExtended pitch control rangeIncrease the maximum lift coefficientFuselage framesAircraft stabilisationFlight vehicleUncrewed vehicle

The invention discloses a canard flying wing aerodynamic layout unmanned aerial vehicle, and the unmanned aerial vehicle comprises main wings, full-motion canard wings, a full-motion vertical tail wing and a vehicle body, and the flying performance of a fixed wing aircraft is well improved by fusing flying wing aerodynamic layout and canard aerodynamic layout. The main wings adopt flying wing structures, so that the structural mass can be reduced, the effective lift area is increased, and the immersion area is reduced. The full-motion canard is added in front of the main wing, so that the pitching control range of the unmanned aerial vehicle is widened, and meanwhile, the maximum lift coefficient of the flying wing is increased. Compared with the performances of a conventional aerodynamiclayout fixed-wing unmanned aerial vehicle, the lifting force is improved by about 13.3%, the effective load is improved by about 8.6%, the unmanned aerial vehicle has outstanding performance in the aspect of low speed, the minimum flight speed can be reduced to 6 m / s, and the flight speed is reduced by about 37% compared with a single-flying-wing type aerodynamic layout unmanned aerial vehicle. Compared with a single-flying-wing type aerodynamic layout unmanned aerial vehicle, a pair of canard wings is additionally arranged on the structure, so that the lift-drag ratio of the unmanned aerial vehicle is reduced by about 5.25%.

Owner:珠海中科华创科技有限公司

Slotted flow guide piece type high lift device

ActiveCN112896489AImprove aerodynamic performanceImprove handling stabilityWing adjustmentsFlight vehicleStructural engineering

The invention provides a slotted guide vane type high lift device. A method comprises the steps: performing slotting on an airfoil upper surface and an airfoil lower surface; performing rounding and shaping treatment on the seam opening A1, the seam opening B1, the seam opening C1, the seam opening B2 and the seam opening C2; performing second-time rounding and shaping treatment on the slotted position, namely the position A1 of a slotted opening, of the wing type rear part of the slotted wing, the radius of an inscribed circle ranges from 0.05 c to 0.4 c, and forming a flow deflector by the cut rounding; enabling the flow deflectors to move upwards in the normal direction of the underground surface at the thickest positions of the flow deflectors, wherein the moving range is 0.005 c-0. 2 c; finally, forming the layout that the flow deflectors are additionally arranged at the seam opening, and obtaining the slotted flow deflector type high lift device. According to the slotted flow deflector type high-lift device, the maximum lift coefficient of the airfoil can be remarkably improved, the stall characteristic of the airfoil is greatly improved, the slotted flow deflector type high-lift device is a simple and efficient novel high-lift device, and then the aerodynamic performance and the control stability of an aircraft are effectively improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

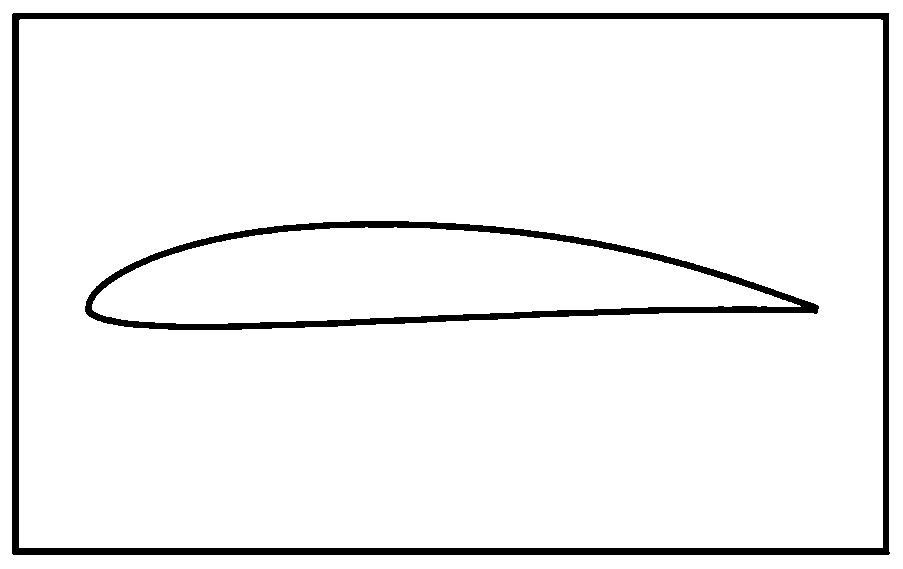

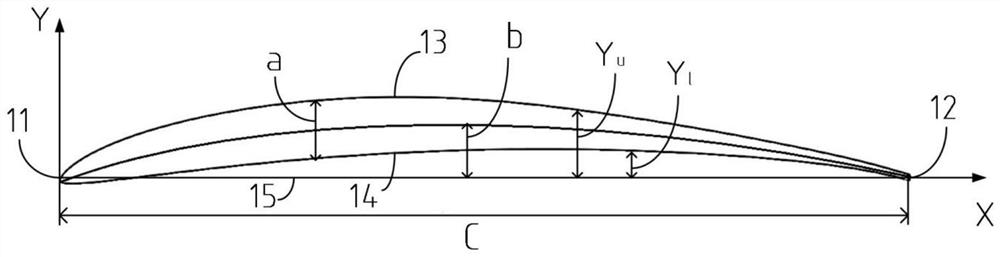

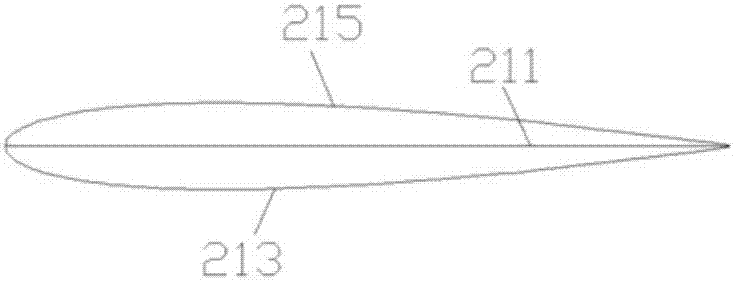

Rotor wing of rotorcraft and rotorcraft

ActiveCN112918668AIncrease the maximum lift coefficientImprove the lift-to-drag ratioWing shapesRotocraftLeading edgeFlight vehicle

The invention discloses a rotor wing of a rotorcraft and the rotorcraft. The rotor wing of the rotorcraft comprises blades and a propeller hub, the blades are installed on a driving assembly of the rotorcraft through the propeller hub, the wing section of each blade is composed of a front edge, a tail edge, an upper arc line and a lower arc line, and the upper arc line and the lower arc line are located between the front edge and the tail edge. The ratio a / c of the maximum thickness a of the airfoil of each blade to the chord length c of the airfoil is 6.85%, and the maximum thickness is located at the position where x / c is 30.5%; and the ratio b / c of the maximum camber b of the airfoil of each blade to the chord length c of the airfoil is 6.6%, and the maximum camber b is located at the position where x / c is 47.1%. The rotor wing obtained through the technical scheme has higher aerodynamic efficiency and lighter weight, and under the same lifting surface distribution design, the required rotating speed is lower, and a noise is lower.

Owner:BEIJING AIRLANGO TECH CO LTD

A variable camber wing

ActiveCN111907693BAchieve continuous bendingImprove pressure distributionWing adjustmentsClassical mechanicsEngineering

Owner:HARBIN INSTITUTE OF TECHNOLOGY SHENZHEN (INSTITUTE OF SCIENCE AND TECHNOLOGY INNOVATION HARBIN INSTITUTE OF TECHNOLOGY SHENZHEN)

A bionic wave leading edge winglet device

ActiveCN108974326BEnhanced Momentum ExchangeIncrease the maximum lift coefficientAircraft stabilisationWing adjustmentsLeading edgeWave structure

A biomimetic wave leading edge wing tip winglet device includes a fin leading edge segment, a top rectifier section and a transition section, The leading edge section of the fin is a multi-sectional curved surface with two opened ends, one side of the leading edge section of the fin is of a wave structure, the top rectifier section is fixed on the top of the leading edge section of the fin to close the top of the leading edge section of the fin, the bottom of the leading edge section of the fin is provided with a transition section, and the transition section is arranged on the wing, the leading edge section of the fin, the top rectifier section and the transition section form a wing tip small wing. As that lead edge of the tip winglet forms regular bump, the uniform incoming flow can generate vortices with opposite rotational directions and high energy at high angle of attack, thereby maintaining airflow adhesion on the winglet, delay airflow separation and development, finally delaying the stall angle of attack of the wing, increasing the maximum lift coefficient, and achieving the purpose of shortening the takeoff distance.

Owner:XI AN JIAOTONG UNIV

A profiled airfoil

ActiveCN104097763BWide range of effective angle of attackIncrease the maximum lift coefficientWing shapesLeading edgeTrailing edge

The invention discloses a special-shaped wing profile, belongs to the technical field of air vehicles and particularly relates to a wing. The special-shaped wing profile comprises a leading edge, an upper surface, a lower surface, a trailing edge, a wing root, a wing tip and a wing body, wherein the leading edge is a combination of an oblique S-shaped curve and a straight line, the trailing edge is straight, and the wing tip is sharp. A wing is divided into three portions by a plane parallel to the wing root end face along the wingspan direction: the first portion refers to a portion close to the wing root and is roughly a profile with a convex upper and a flat lower and with medial relative thickness, the radius of the leading edge is medial, and a position with maximum thickness is in the back; a second portion refers to a middle portion and is a thick profile with a convex upper and a concave lower, the radius of the leading edge is large, and a position with maximum thickness is in the front; a third portion is a portion close to the wing tip and is roughly a thin profile with double convex surfaces, the radius of the leading edge is small, and a position with maximum thickness is in the middle; the three portions are in smooth connection. The wing with the special-shaped wing profile is large in effective incidence, less prone to stalling and high in efficiency.

Owner:SUZHOU MAICHUANG INFORMATION TECH

Three-stage fixed-wing unmanned aerial vehicle

PendingCN106986001AHigh maximum liftIncrease the maximum lift coefficientAircraft stabilisationWing shapesFlaperonLeading edge

The invention relates to a three-stage fixed-wing unmanned aerial vehicle. A wing of the unmanned aerial vehicle is of a three-stage wing shaped structure, the wing comprises a slat arranged at the front edge of the wing, a main wing arranged in the middle of the wing and a flap arranged at the rear edge of the wing, the main wing comprises a central wing and outer wings arranged on both sides of the central wing, the flap comprises a flap body arranged at the rear edge of the central wing and auxiliary flaps arranged at the rear edges of the outer wings. An advantage of the three-stage fixed-wing unmanned aerial vehicle is that use of the three-stage wing airfoil is an innovate point. Compared with an existing single-stage or two-stage airfoil used in the unmanned aerial vehicle, the three-stage airfoil has a higher maximum lift coefficient, so that the unmanned aerial vehicle has a higher maximum lift. The increase in maximum lift allows the unmanned aerial vehicle to have a higher load and a lower stalling speed, take off and land on shorter runways, and have better low-speed flight performance.

Owner:西安神骑航空科技有限公司

Rotorcraft, rotorcraft blades and their airfoils

ActiveCN112977815BIncreasing the thicknessIncrease the maximum lift coefficientRotocraftLeading edgeFlight vehicle

The present disclosure relates to a rotorcraft, a blade of the rotorcraft, and an airfoil thereof, wherein the airfoil is composed of a leading edge, a trailing edge, and upper and lower arcs between the leading and trailing edges, and the wing The ratio of the maximum thickness of the airfoil to the chord length of the airfoil is, the maximum thickness is at; The trailing edge distances, , and values have a maximum error of ±3%, respectively. Through the above technical solutions, a higher lift-to-drag ratio can be provided for the rotorcraft at a low Reynolds number, thereby improving the aerodynamic efficiency of the rotorcraft. In addition, due to the improved aerodynamic efficiency of the rotorcraft, under the condition of the same lift surface distribution, the required rotational speed is lower, making it possible to reduce the noise generated during the flight of the rotorcraft.

Owner:BEIJING SANKUAI ONLINE TECH CO LTD

A dynamic base station for Auv recovery

ActiveCN110844027BReduced tow sailingIncrease the maximum lift coefficientVessel salvagingUnderwater vesselsMarine engineeringControl theory

A dynamic base station for AUV recovery belongs to the technical field of underwater robot recovery, and aims to solve the problems of unstable docking recovery, difficult operation, large dragging resistance and certain hidden safety hazards existing in the prior art. The present invention comprises the main body of the recovery base station; two attitude adjusters symmetrically arranged on the main body of the recovery base station; a connecting ring fixed on the main body of the recovery base station; The free end with an adjustable opening; one end is fixedly connected to the other end of the connecting ring, and the underwater robot that enters the dynamic base station is clamped or loosened by the locking device; the other end of the locking device is fixedly connected in place detector; and a main controller arranged in the main body of the recovery base station, through which the rotation speed of the two attitude regulators is controlled by the main controller, and the main controller receives the detection signal from the position detector to control the locking device to clamp or release the underwater robot.

Owner:JILIN UNIV

A slotted deflector type increasing lift device

ActiveCN112896489BImprove aerodynamic performanceImprove handling stabilityWing adjustmentsFlight vehicleStructural engineering

The invention provides a slotted deflector type lifting device, which is slotted on the upper surface of the airfoil and the lower surface of the airfoil; rounding is performed at points A1, B1, C1, B2, and C2 of the slot. Shape treatment; the slot position on the rear part of the slotted airfoil, that is, the position of the slot crossing A1, is subjected to the second rounding and shaping treatment. The radius of the inscribed circle is 0.05c ~ 0.4c, and the cut circle forms the deflector ;Move the deflector upward along the normal direction of the local subsurface at the thickest position of the deflector, and the moving range is 0.005c~0.2c, and finally form the layout of the slotted crossing to increase the deflector, that is, to obtain the slotted deflector Lifting device. The slotted deflector type high-lift device provided by the present invention can significantly improve the maximum lift coefficient of the airfoil, and the stall characteristic of the airfoil is greatly improved. It is a simple and efficient new high-lift device, and further Effectively improve the aerodynamic performance and control stability of the aircraft.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com