High lift and low torque characteristic 12%-thickness rotor-wing airfoil suitable for all working conditions

A full-condition, rotor-wing technology, applied to rotorcraft, aircraft, motor vehicles, etc., can solve the problems that cannot meet the design requirements of high-performance rotors of helicopters, and the lift-to-drag ratio and maximum lift coefficient need to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

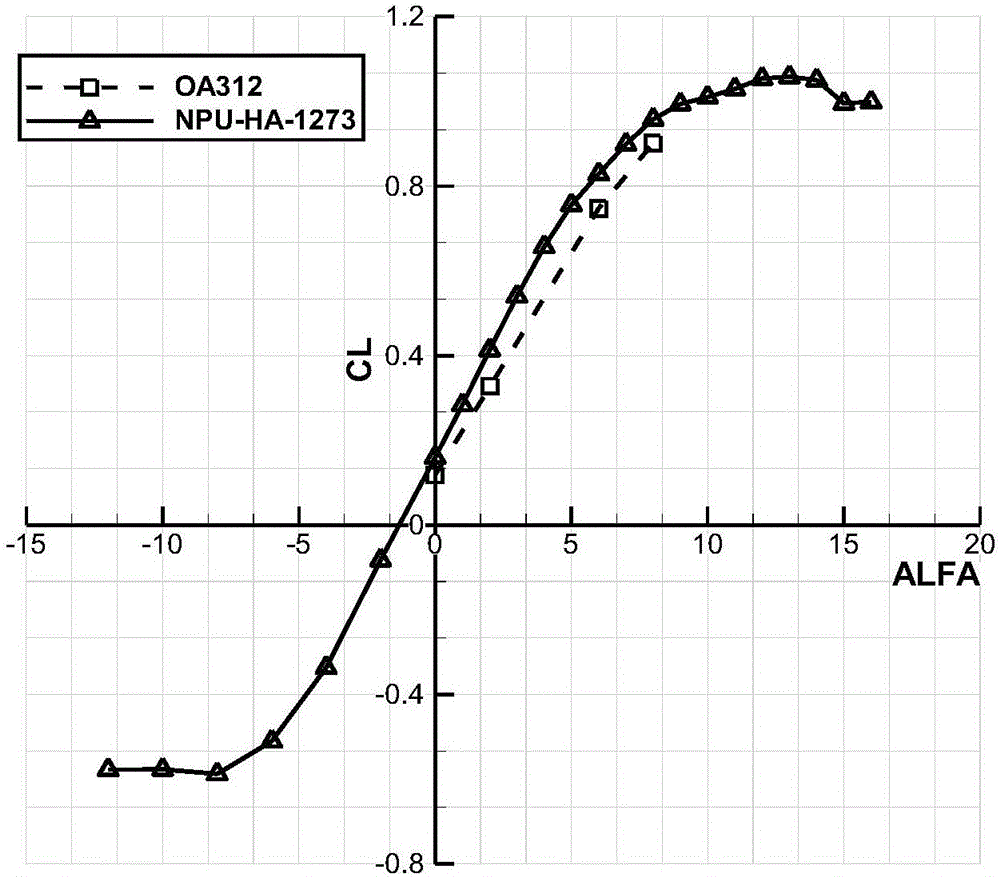

[0036] With the development of new high-performance helicopters, more stringent requirements are put forward for the design of high-performance helicopter rotor airfoils, which require high lift-to-drag ratio, high maximum lift coefficient, and low moment characteristics under multiple working conditions.

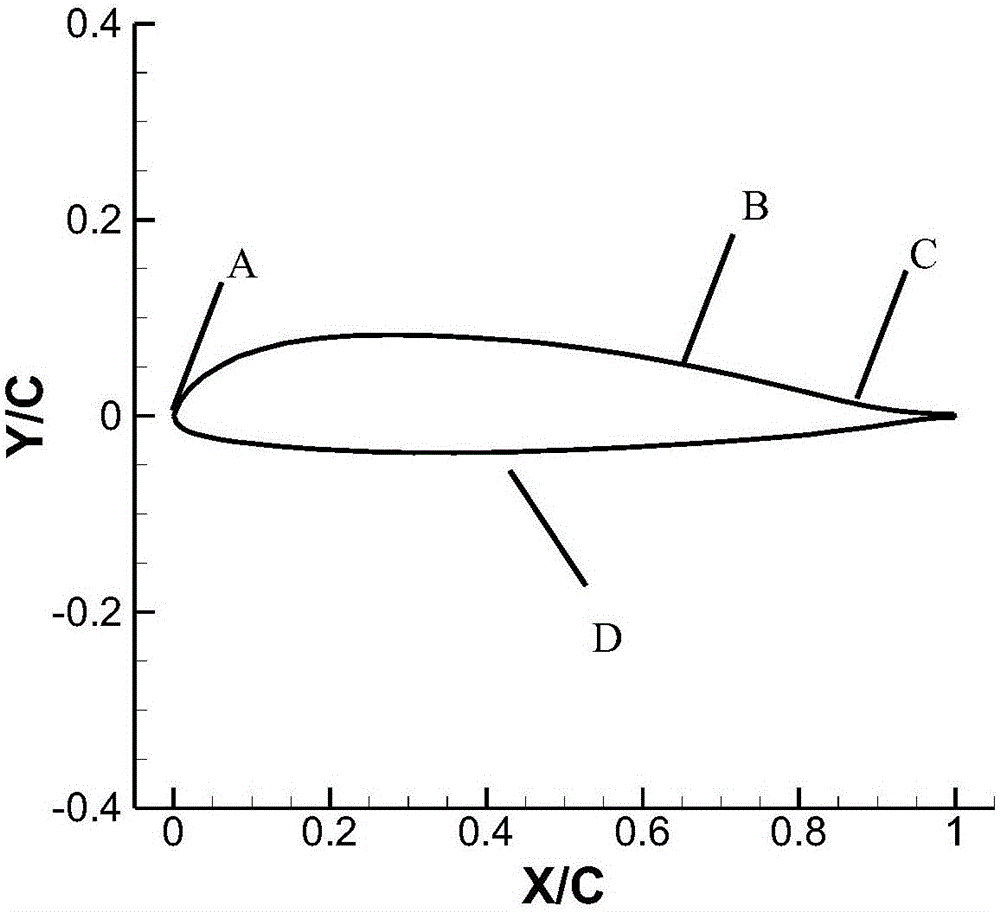

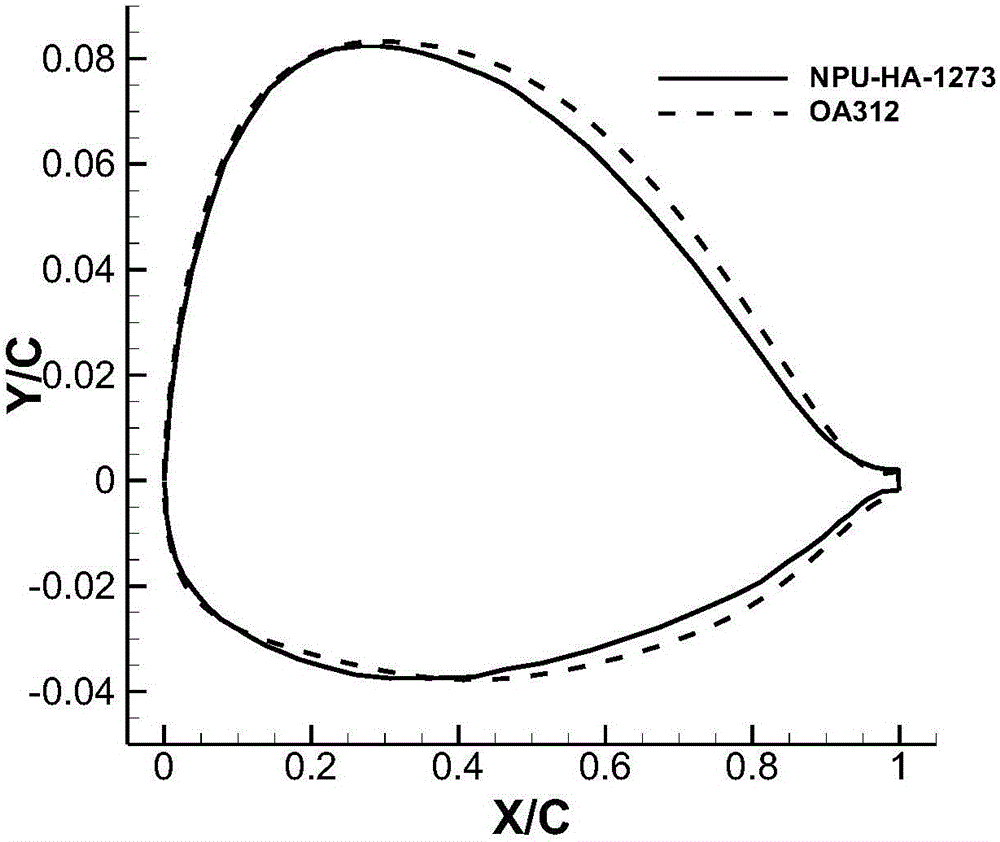

[0037] Based on the above purpose, the present embodiment designs a 12% thick airfoil with high lift-to-drag ratio, high maximum lift coefficient and lower zero-lift drag coefficient. The full working conditions mentioned in this article refer to all the working conditions of the helicopter rotor airfoil in actual use. For the airfoil proposed by the present invention, it refers to the working conditions where the Mach number ranges from 0.3 to 0.6.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com