Method for designing special wind turbine airfoil profile and special wind turbine airfoil profile

A design method and technology of wind turbines, applied in the direction of wind engines, wind turbine components, mechanical equipment, etc., can solve the problems of limited research work on special airfoils for wind turbines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

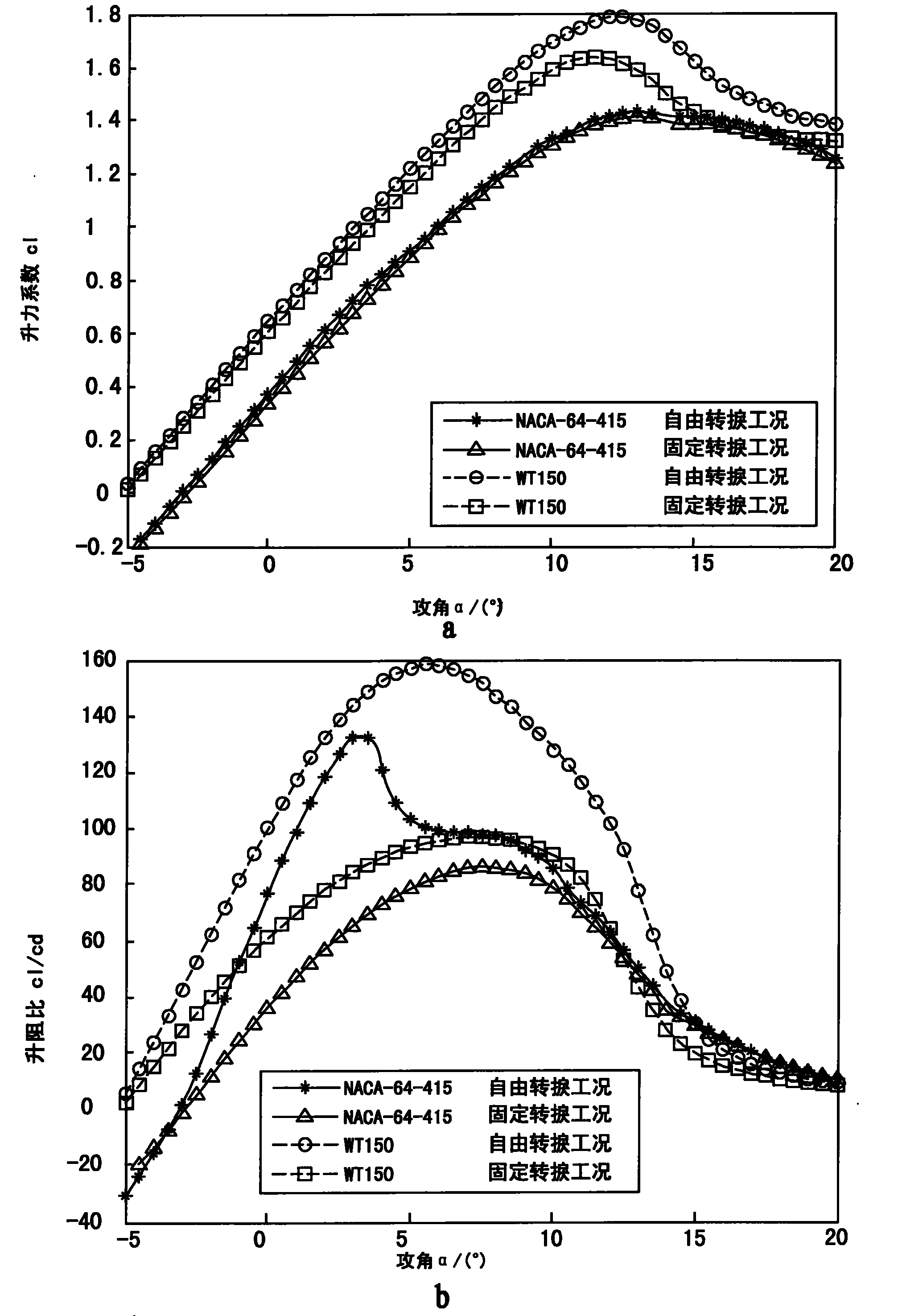

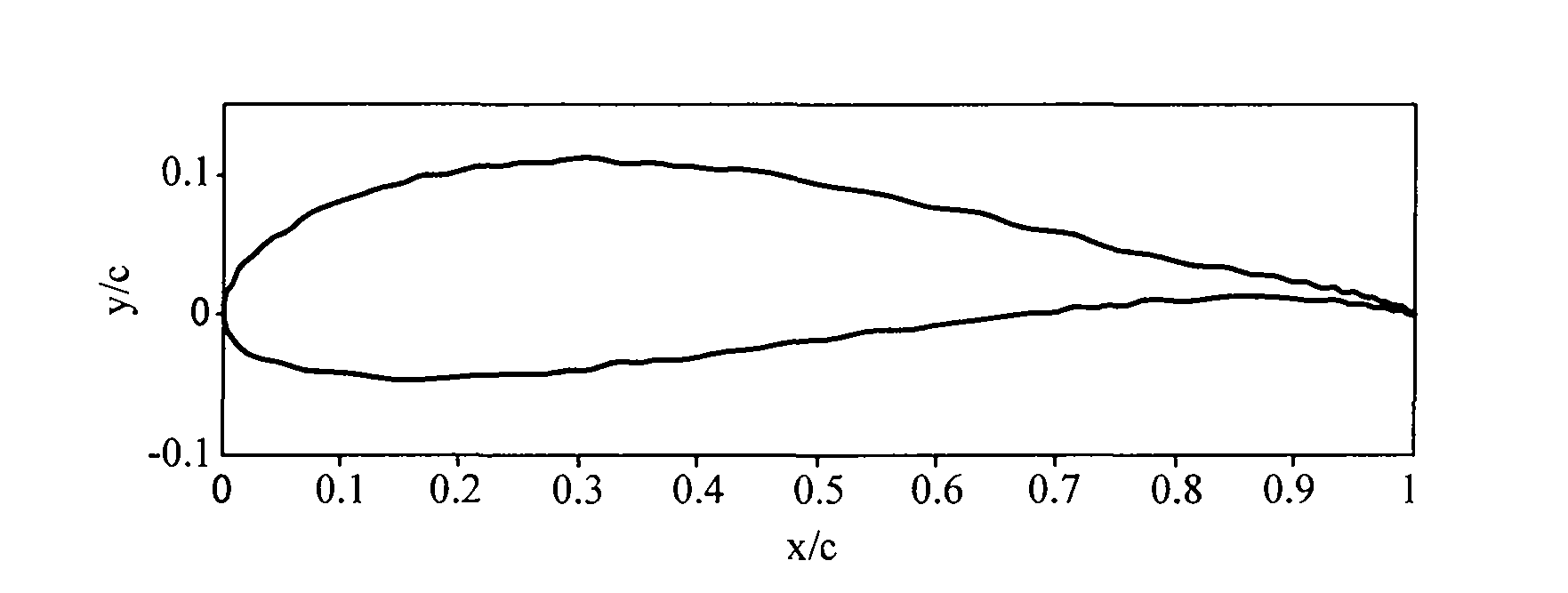

[0109] Such as figure 1 with figure 2 As shown, the special airfoil WT150 for wind turbines is obtained by selecting the thickness constraint of the airfoil thickness of 0.15, which is obtained by optimizing the design method of the special airfoil for wind turbines described in claim 1, and the maximum thickness of the airfoil is located in the chord direction At x / c=0.254, the maximum camber is cam / c=0.037385, and the chord position is x / c=0.443. The following table shows the coefficients of the shape function equation of the airfoil WT150.

[0110] airfoil

[0111] Use the special analysis software RFOIL 3D airfoil for wind turbine airfoil to conduct detailed aerodynamic characteristics analysis. The analysis results of the airfoil WT150 can be found in figure 2 . It can be seen from the figure that the airfoil WT150 has low roughness sensitivity and is not sensitive to external pollution, foreign object damage and processing; it has a high lift coefficient a...

Embodiment 2

[0113] Such as image 3 with Figure 4 As shown, the special airfoil WT170 for wind turbine is obtained by selecting the thickness constraint of the airfoil thickness as 0.17, which is obtained by optimizing the design method of the special airfoil for wind turbine according to claim 1, and the position of the maximum thickness of the airfoil is in the chord direction At x / c=0.289, the maximum camber is cam / c=0.029445, and the chord position is x / c=0.460. The following table shows the coefficients of the shape function equation of the airfoil WT170.

[0114] Airfoil name

[0115] Use the special analysis software RFOIL 3D airfoil for wind turbine airfoil to analyze the detailed aerodynamic characteristics. The analysis results of the airfoil WT170 are shown in Figure 4 . It can be seen from the figure that the airfoil WT170 has low roughness sensitivity and is not sensitive to external pollution, foreign object damage and processing; it has a high lift coefficien...

Embodiment 3

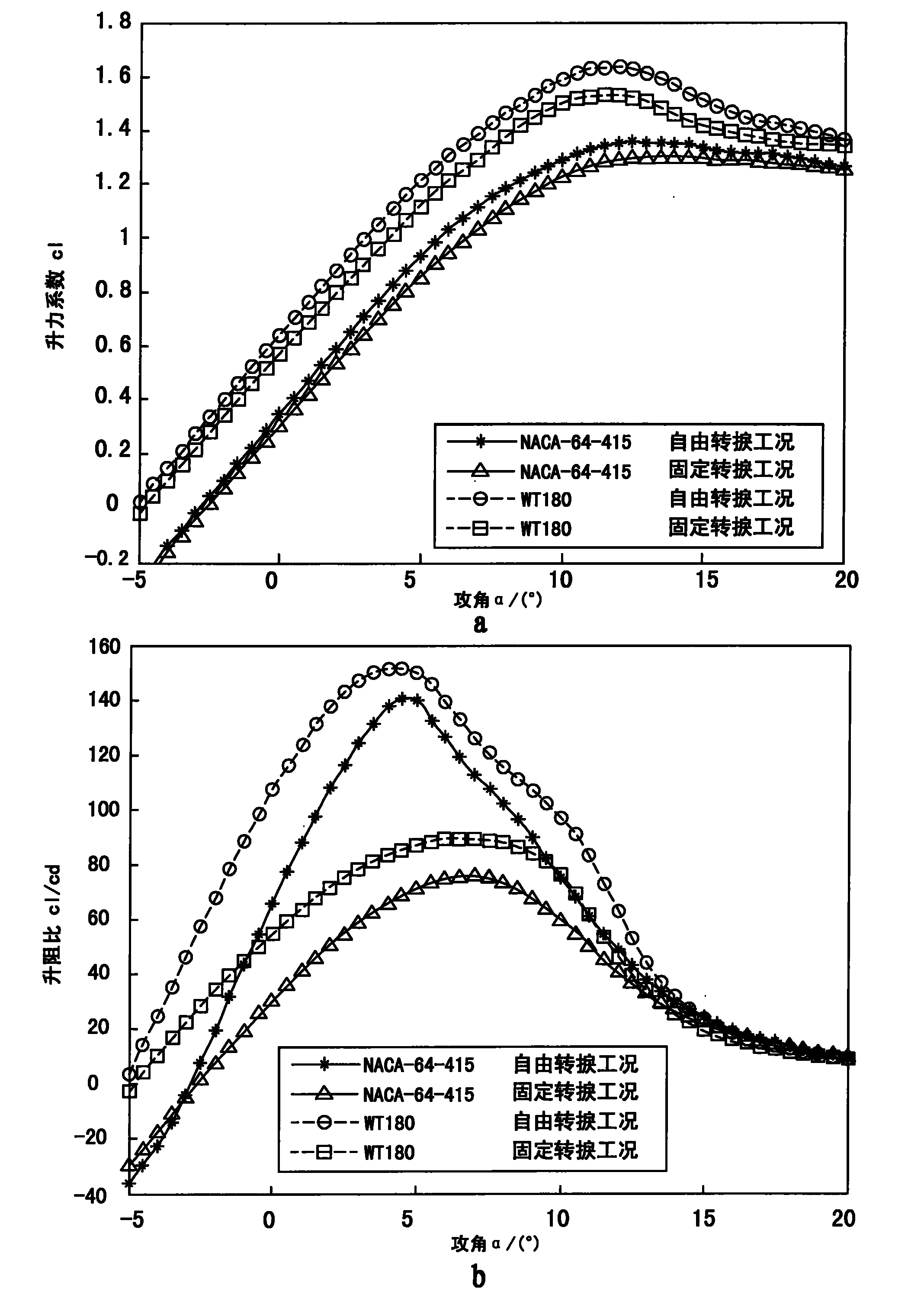

[0117] Such as Figure 5 with Image 6 As shown, the special airfoil WT180 for wind turbines is obtained by selecting the thickness constraint of the airfoil thickness of 0.18, which is obtained by optimizing the design method of the special airfoil for wind turbines described in claim 1, and the maximum thickness of the airfoil is in the chord direction At x / c=0.289, the maximum camber is cam / c=0.029445, and the chord position is x / c=0.460. The following table shows the coefficients of the shape function equation of the airfoil WT180.

[0118] Airfoil name

[0119] Use the special analysis software RFOIL 3D airfoil for wind turbine airfoil for detailed analysis of aerodynamic characteristics, the analysis results of the airfoil WT180 are shown in Image 6 . It can be seen from the figure that the airfoil WT180 has low roughness sensitivity and is not sensitive to external pollution, foreign object damage and processing; it has a high lift coefficient and maximum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com