A variable camber trailing edge and leading edge for an aircraft wing

A wing leading edge and wing technology, applied in wing adjustment, aircraft transmission, aircraft power transmission, etc., can solve the problem of poor invisibility, difficulty in adapting to a wide range of flight conditions, difficulty in wing skin installation, and reduced aircraft safety To achieve the effect of improving combat maneuverability and safety, improving cruising capability, and reducing radar echoes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

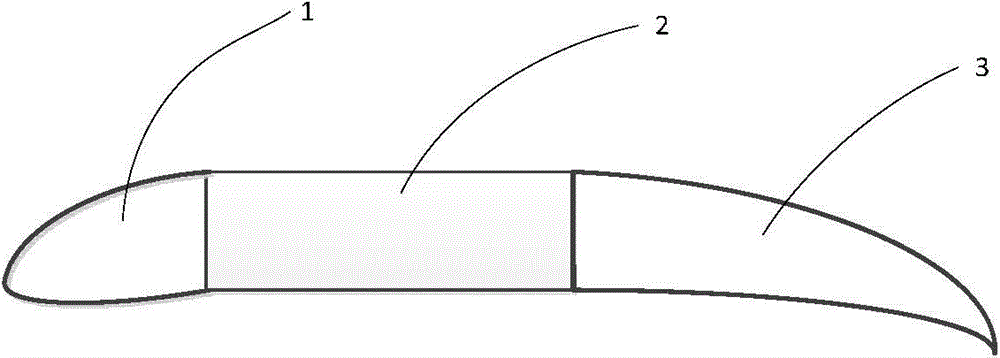

[0035] Such as Figure 1-2 As shown, the present embodiment provides a kind of aircraft wing, and this aircraft wing comprises wing leading edge 1, wing middle part 2, wing trailing edge 3, wing skin 4; Wherein, wing leading edge 1 camber Variable, 2 cambers in the middle of the wing are not variable, and 3 cambers at the trailing edge of the wing are variable.

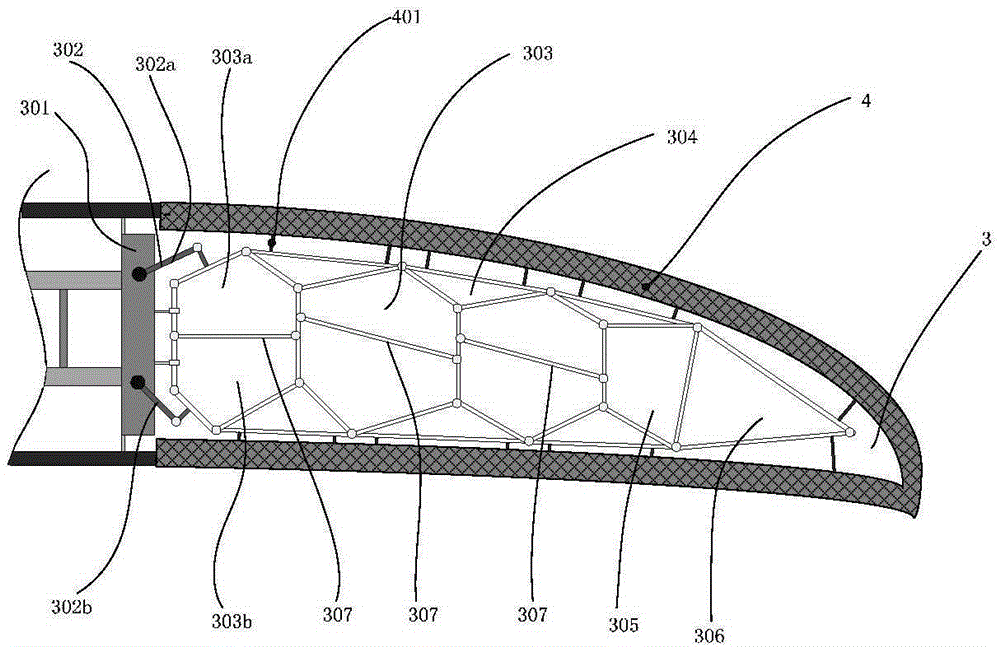

[0036] Such as image 3 As shown, the wing middle part 2 with constant camber includes a main beam; the trailing edge 3 with a variable camber includes a rear beam 301, multiple groups (for example, four groups) of trailing edge rod group structures and trailing edge drive mechanisms arranged in parallel; the rear beam 301 is connected to the rear end of the main beam; the rear edge drive mechanism includes a rocker 302 driven by the driving device, one end of the rocker 302 is rotatably connected to the rear beam 301, and the other end of the rocker 302 is rotatably connected to the rear edge rod group structure; T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com