Pressure equalizing fabric for hydraulic hot pressing installation

A hot pressing equipment and pressure technology, applied in the field of pressure pads, to achieve the effect of shape stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

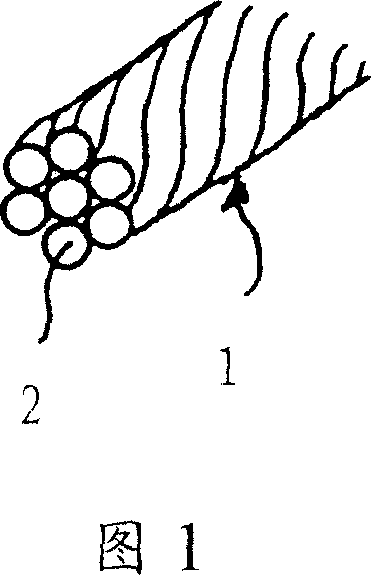

[0041] FIG. 1 shows a metal strand made from a single twisted brass fiber 2 , wherein the metal fiber 1 is processed both as the warp thread and the weft thread of the pressure-balancing fabric 6 .

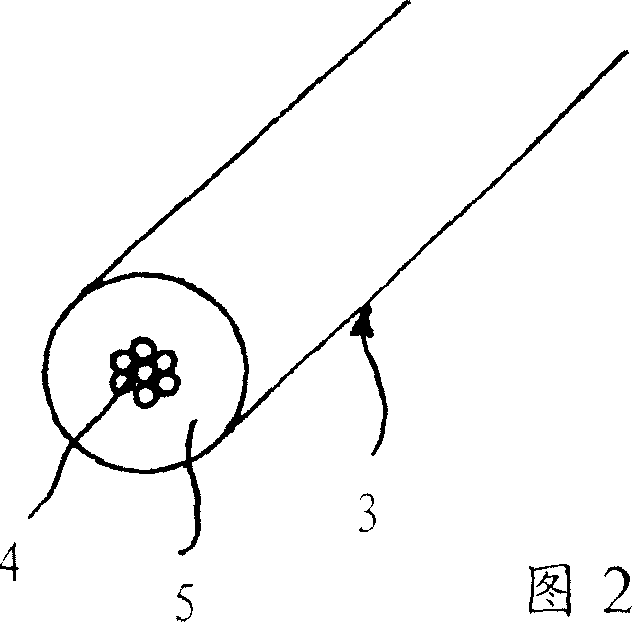

[0042] In FIG. 2 , an elastomeric fiber 3 is shown, which is composed of a core fiber 4 and an elastomeric sheath 5 , eg, of a copolymer fluorosilicone / silicone rubber. The core fiber 4 consists of twisted copper fibers. In the above example, the elastomeric fibers 3 are processed as wefts of the pressure-balancing fabric 6 .

[0043] In the top view of the pressure balancing fabric 6 according to the invention shown in FIG. 3 , it can be seen that the elastomeric fibers 3 are raised upward in the form of the weft yarns of the pressure pad fabric, and the elastomeric fibres 3 are raised in the form of the weft and warp yarns of the pressure pad fabric of metal fibers 1. The elastomeric fibers 3 have a significantly larger diameter than the metal fibers 1 , wherein the diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com