Rotorcraft, rotorcraft blades and their airfoils

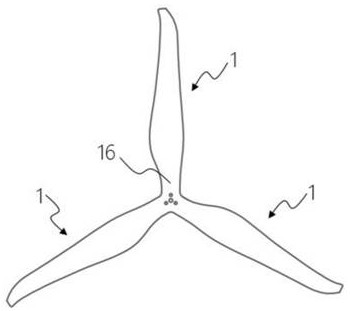

A technology for rotorcraft and blades, applied in the field of aircraft, can solve the problems of low Reynolds number, low aerodynamic efficiency, low lift coefficient and lift-to-drag ratio, etc., and achieve the effects of improving aerodynamic efficiency, improving aerodynamic efficiency, and increasing lift-drag ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Specific embodiments of the present disclosure will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present disclosure, and are not intended to limit the present disclosure. The orientation terms such as up and down in this embodiment refer to the conventional operating attitude of the rotor and the rotorcraft after the rotor is installed on the aircraft, and should not be regarded as limiting.

[0033] The airfoil used for the rotorcraft blade of the present disclosure will be described in detail below with reference to the accompanying drawings. In the case of no conflict, the features in the following embodiments and implementations can be combined with each other.

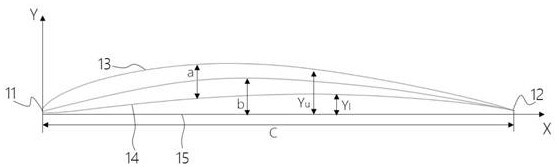

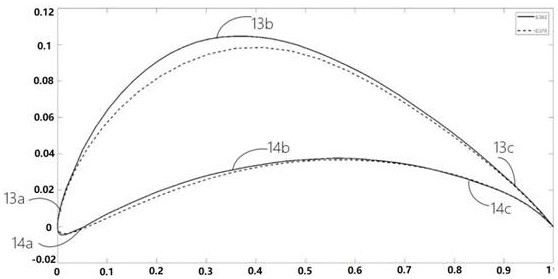

[0034] Such as figure 1 and figure 2 As shown, the present disclosure provides an airfoil for a rotorcraft blade consisting of a leading edge 11, a trailing edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com