Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Increase the force area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

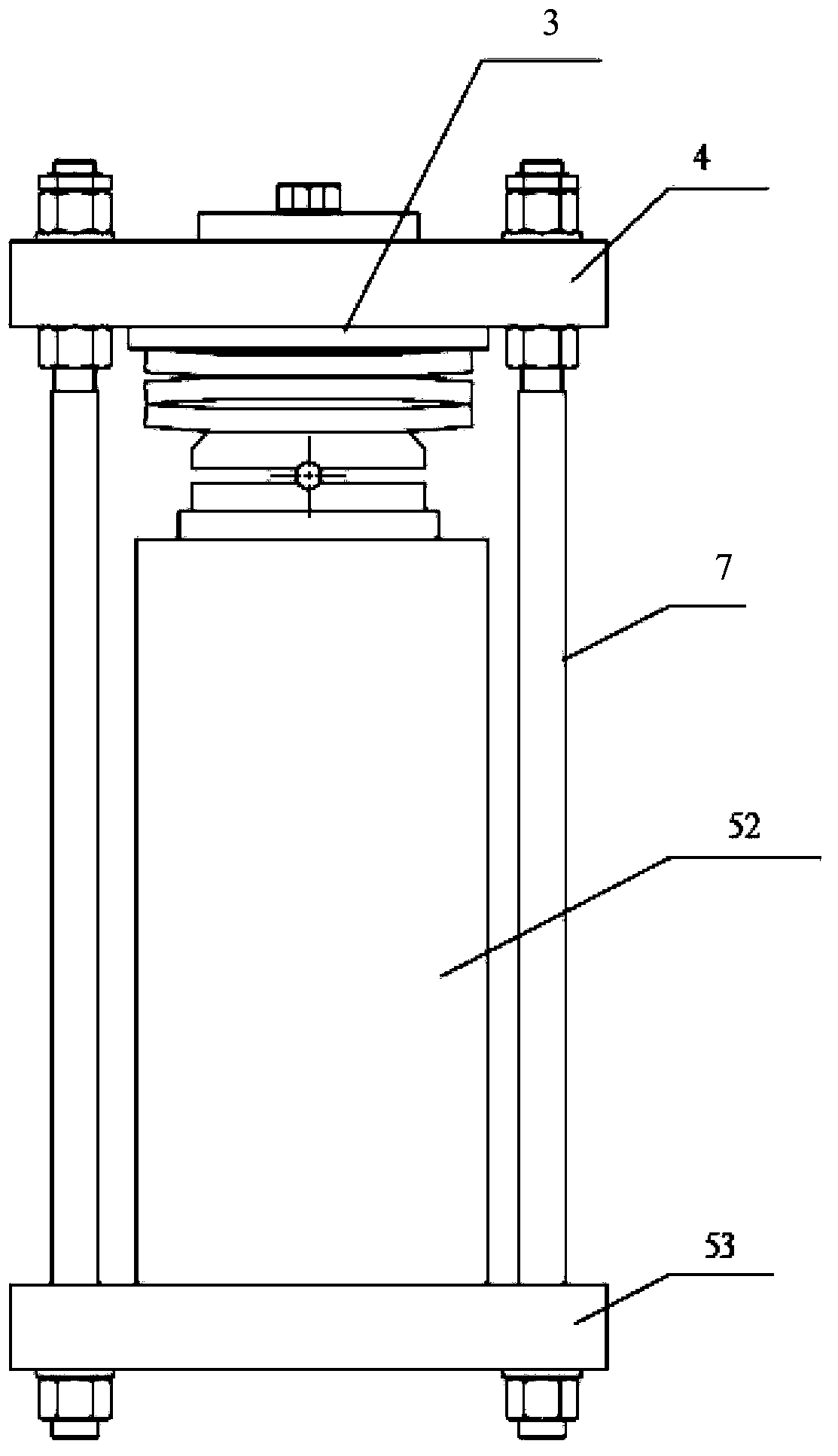

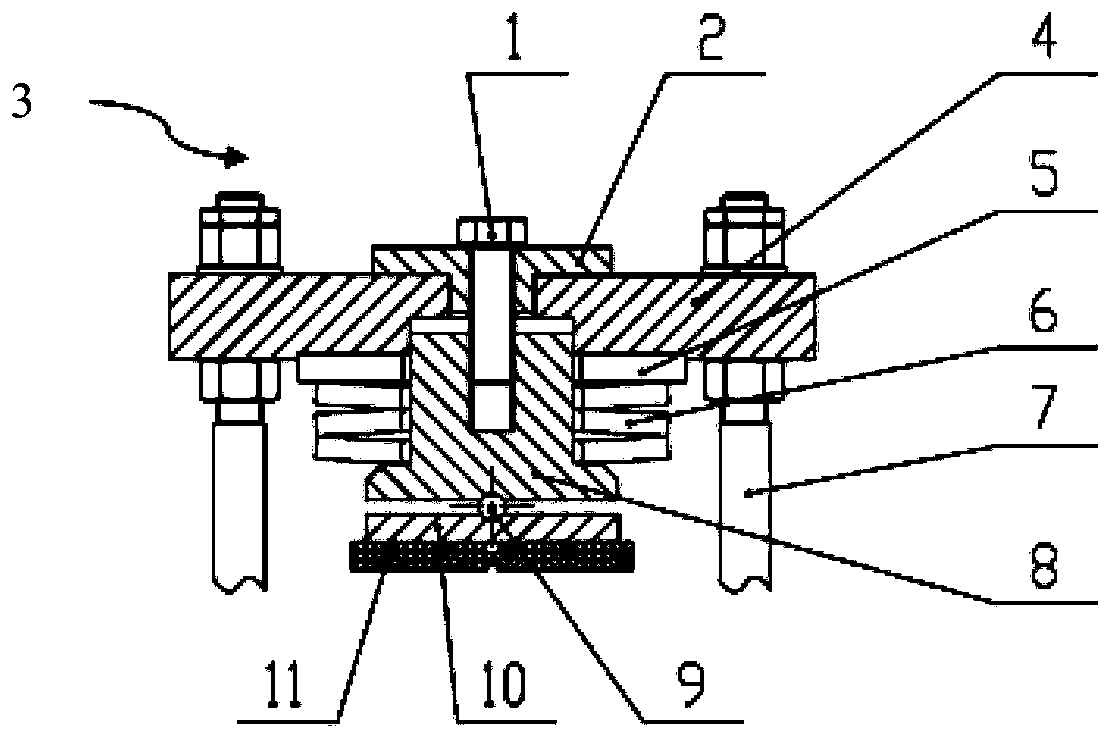

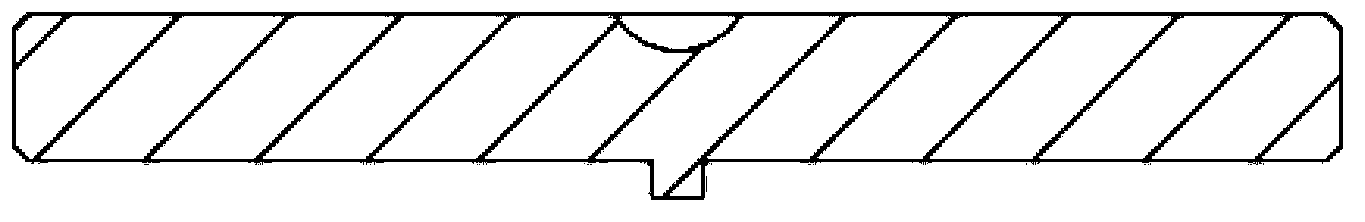

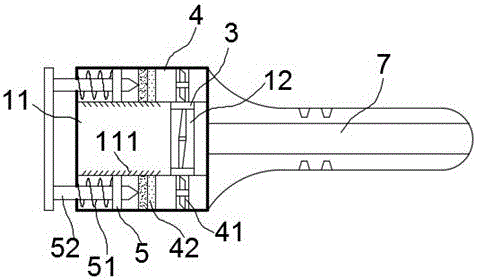

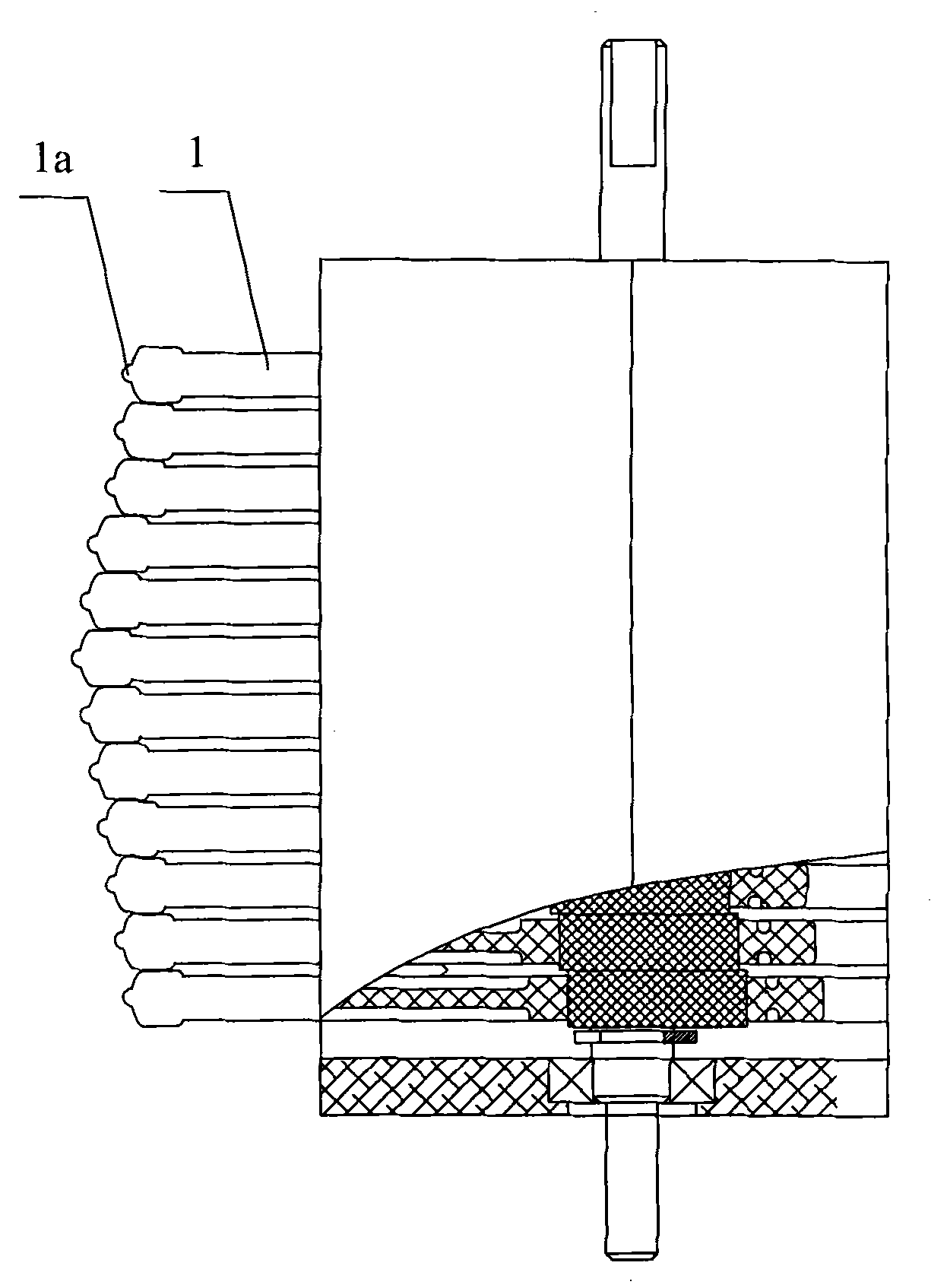

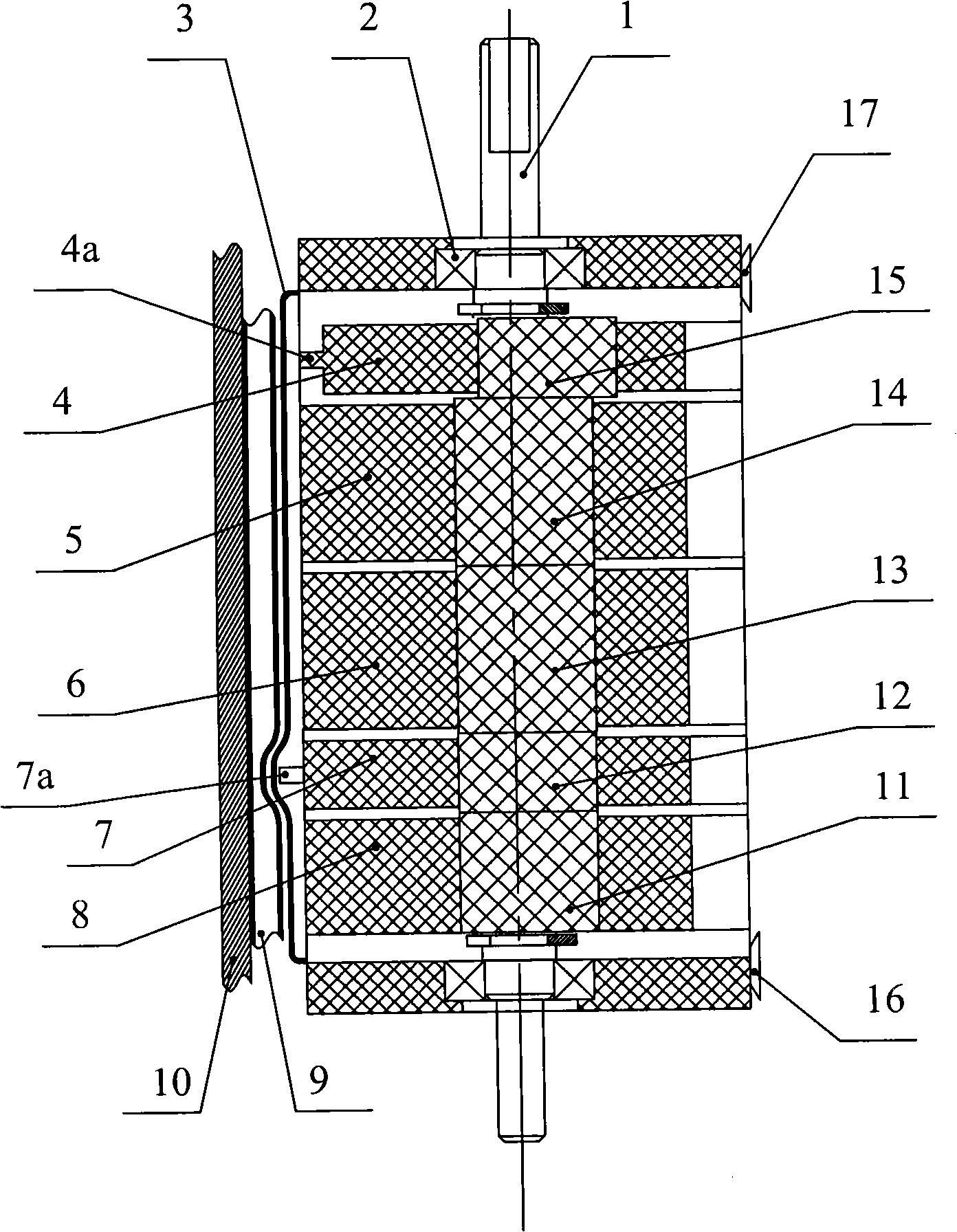

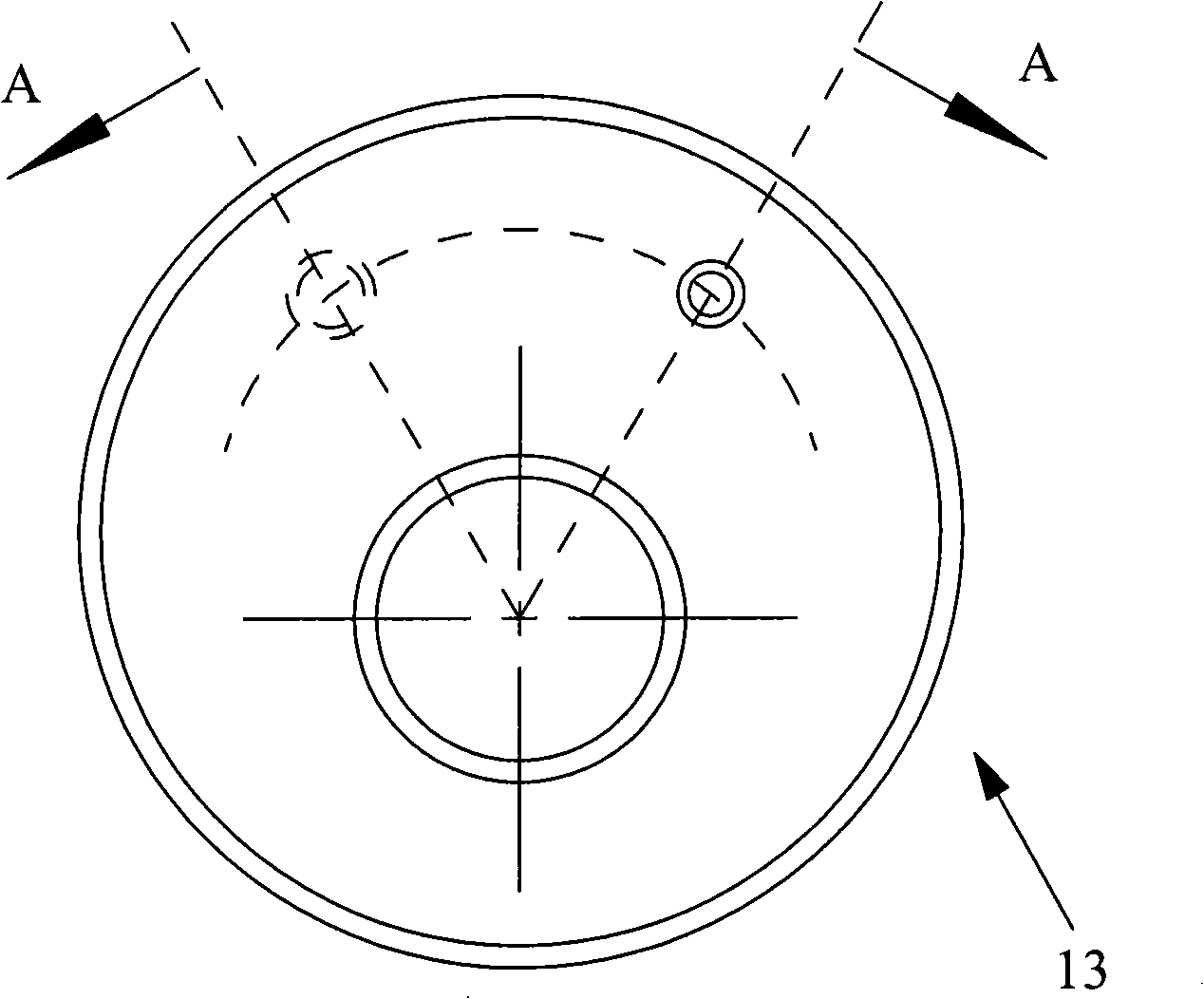

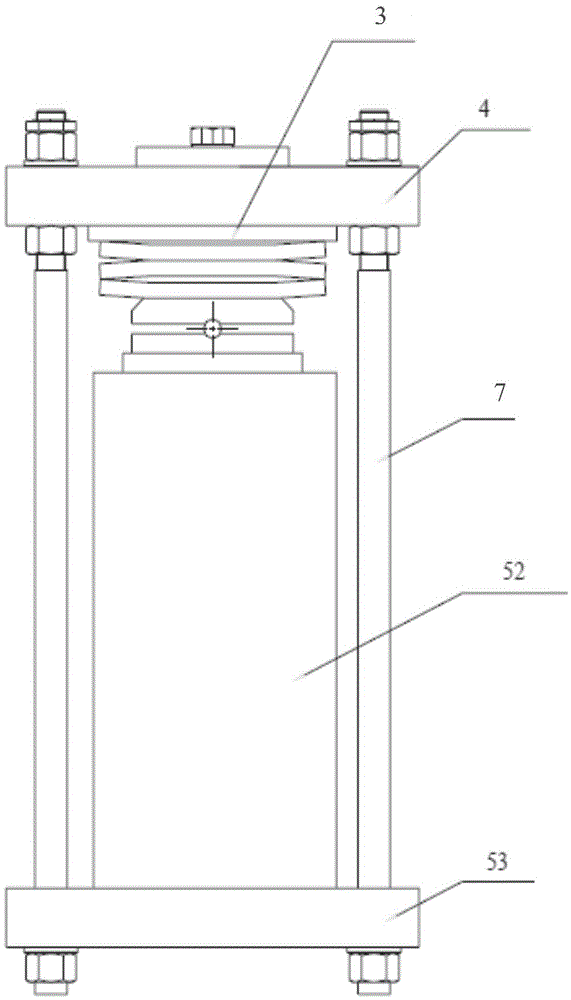

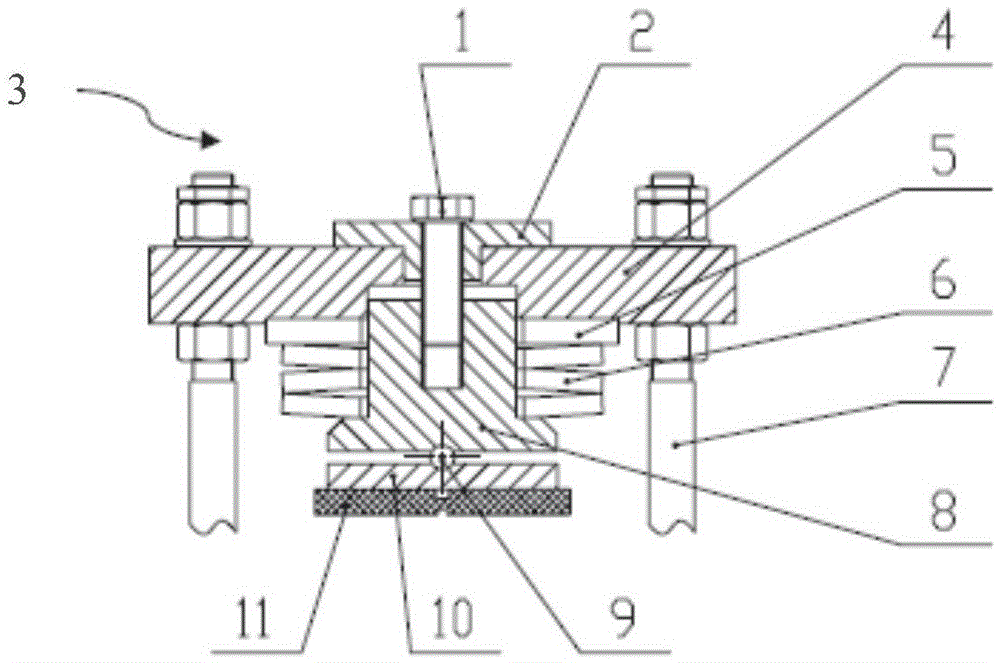

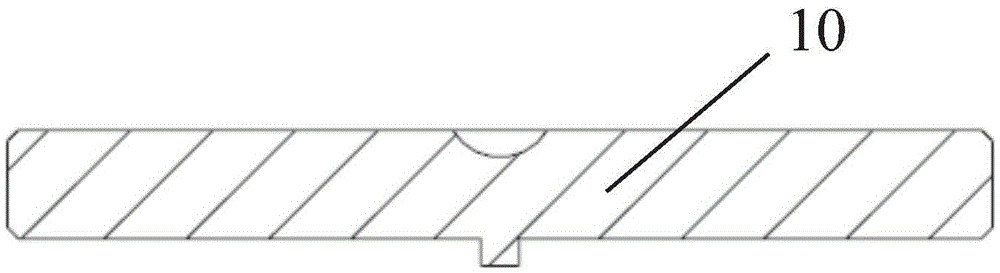

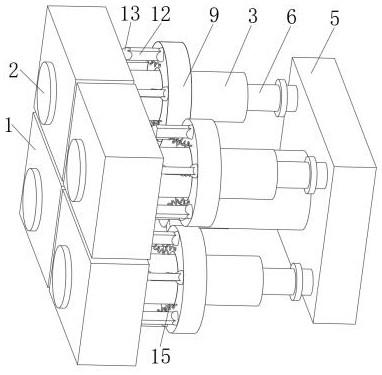

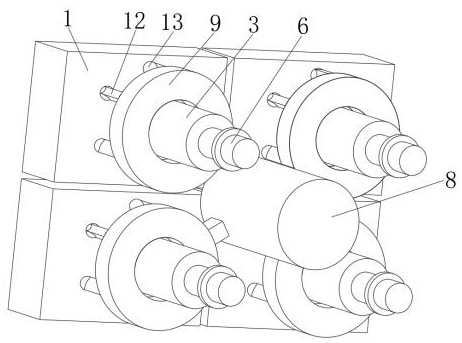

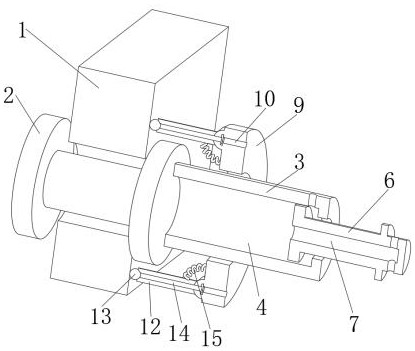

Device and method for press-fitting flat plate type semiconductor element on press-fitting equipment

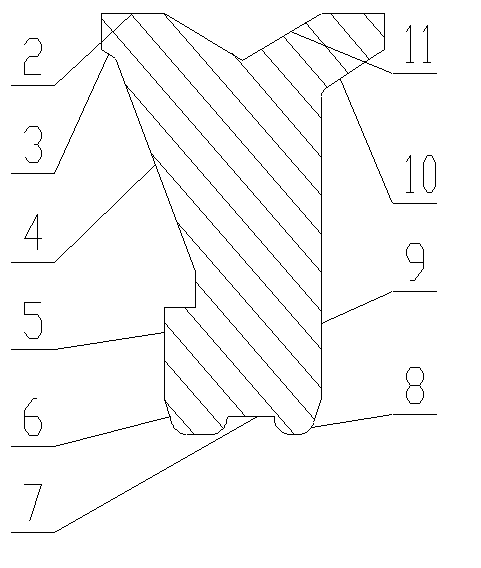

ActiveCN103367276AIncrease the force areaPrecisely control the size of the pressing forceSemiconductor/solid-state device detailsSolid-state devicesEngineeringFlange

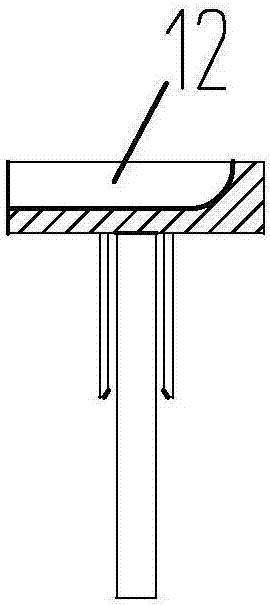

The invention provides a device for press-fitting a flat plate type semiconductor element on press-fitting equipment. The device comprises a pressing plate, a pressing mechanism which is arranged on the pressing plate and comprises a central column body provided with an end flange, and an elastic element which is arranged between the end flange and the pressing plate, wherein the central column body can move along the direction vertical to the pressing plate by means of an adjusting element so that the elastic element remains under a preset pretightening force; the device is connected with the press-fitting equipment through the pressing plate so that the surface of the pressing mechanism is contacted with the surface of the flat plate type semiconductor element to be press-fitted; and the pretightening force of the elastic element is transferred onto the flat plate type semiconductor element through the pressing mechanism by releasing the adjusting element. The invention also provides a corresponding method. According to the method and the device disclosed by the invention, the accuracy of press-fitting force is ensured; and when the semiconductor element works normally, the influence on the press-fitting force caused by strong external vibration is prevented.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

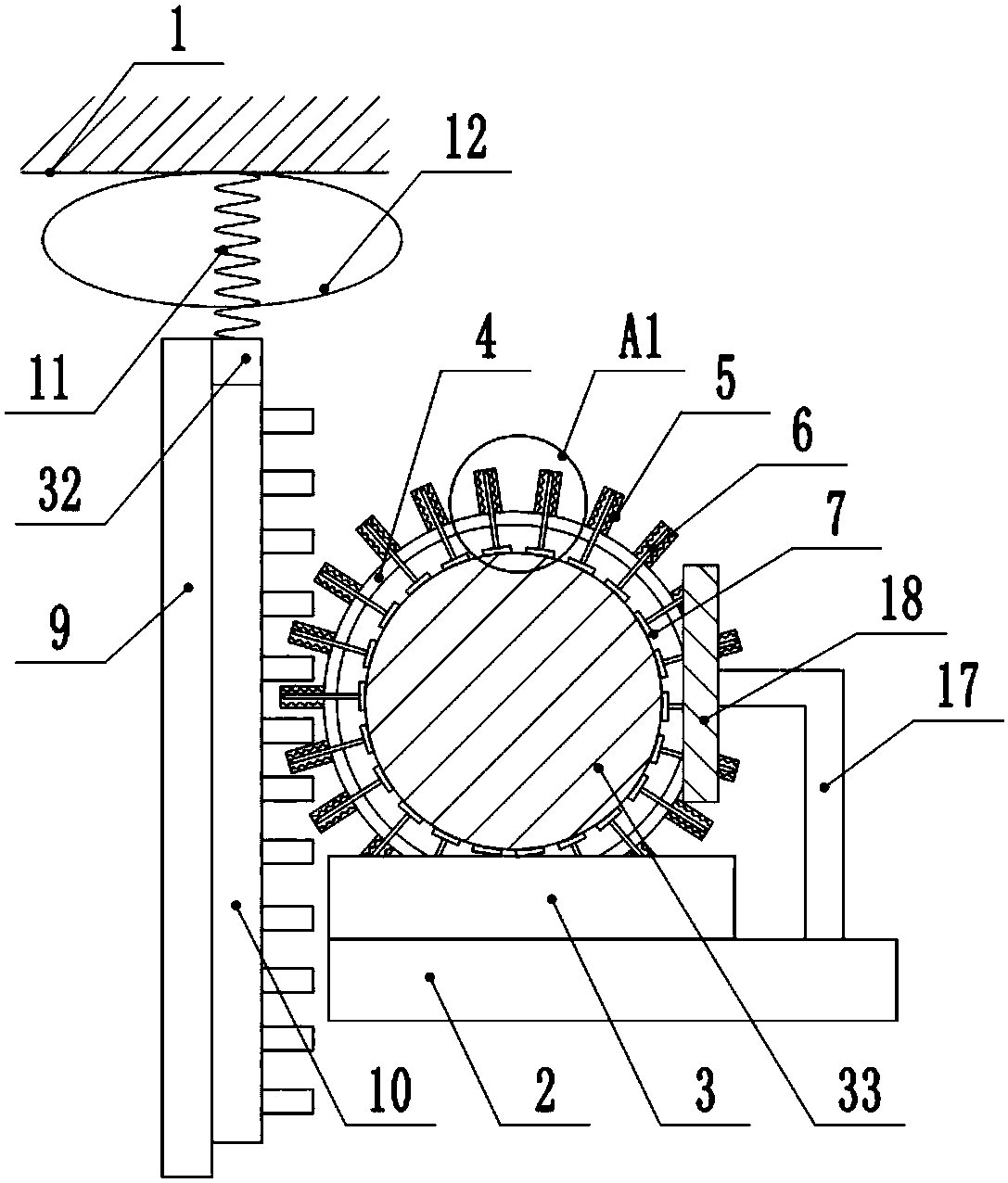

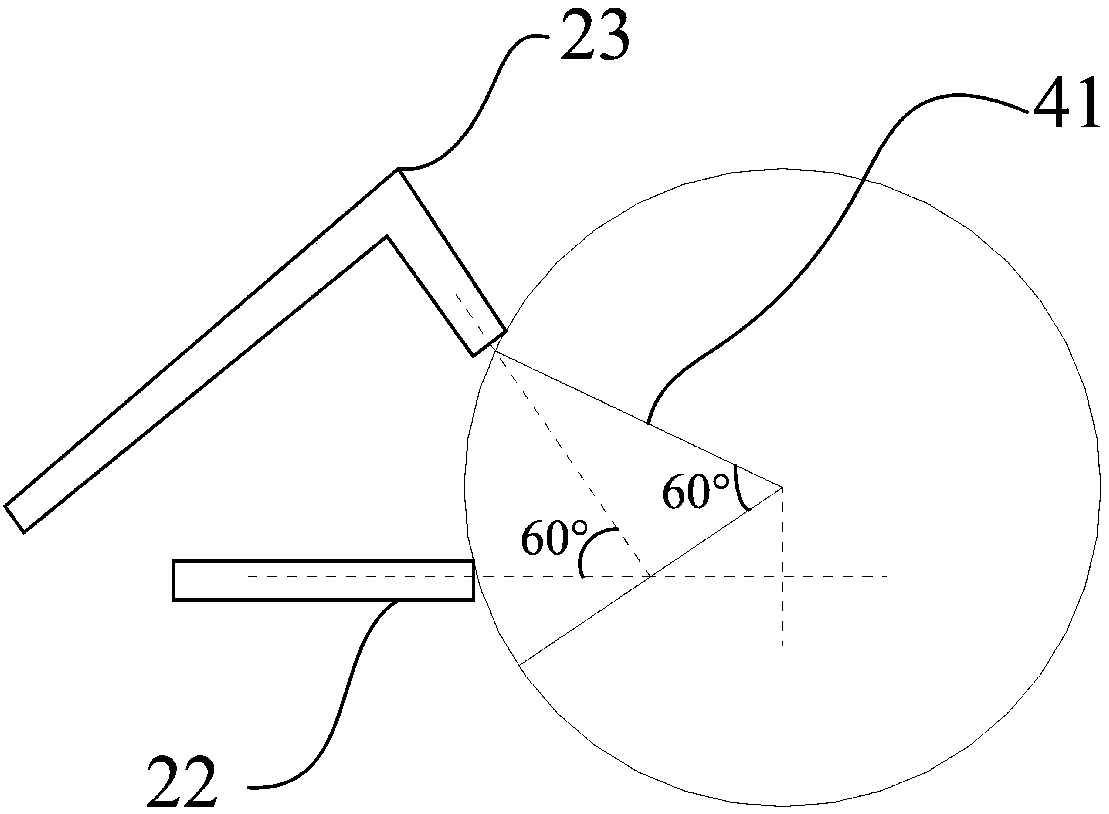

Pipe fitting polishing device

InactiveCN108515403AAvoid over sandingAvoid the problem of uneven sandingEdge grinding machinesGrinding carriagesPipe fittingEngineering

The invention relates to the field of pipe fitting polishing, and discloses a pipe fitting polishing device. The pipe fitting polishing device comprises a machine frame and a supporting table, a conveying roller is rotationally connected to the supporting table, a clamping ring is rotationally connected to the supporting table, a through hole is formed in the middle portion of the clamping ring, driving teeth are arranged on the outer wall of the clamping ring, the interiors of the driving teeth are hollow, abutting-against rods are fixedly connected to the top ends of the interiors of the driving teeth, the other ends of the abutting-against rods are fixedly connected with abutting-against blocks, first supporting springs are fixedly connected between the top ends of the interiors of thedriving teeth and the outer wall of the clamping ring, a rack is in sliding connection to one side of the supporting table, a reset spring is fixedly connected to the upper portion of the rack, and anair bag is arranged above the rack and is opposite to the rack; and an air cylinder is in sliding connection to the supporting table, a guide pipe is connected between the air cylinder and the air bag, polishing strips are fixedly connected to the supporting table and are located on the opposite sides of the supporting plate, and the supporting table is further provided with a pushing mechanism used for pushing and abutting against the air cylinder. By means of device, the problem that a traditional polishing device cannot evenly polish a pipe fitting or local polishing is excessive is solved.

Owner:NINGBO HAIMAN AUTOMOTIVE TECH CO LTD

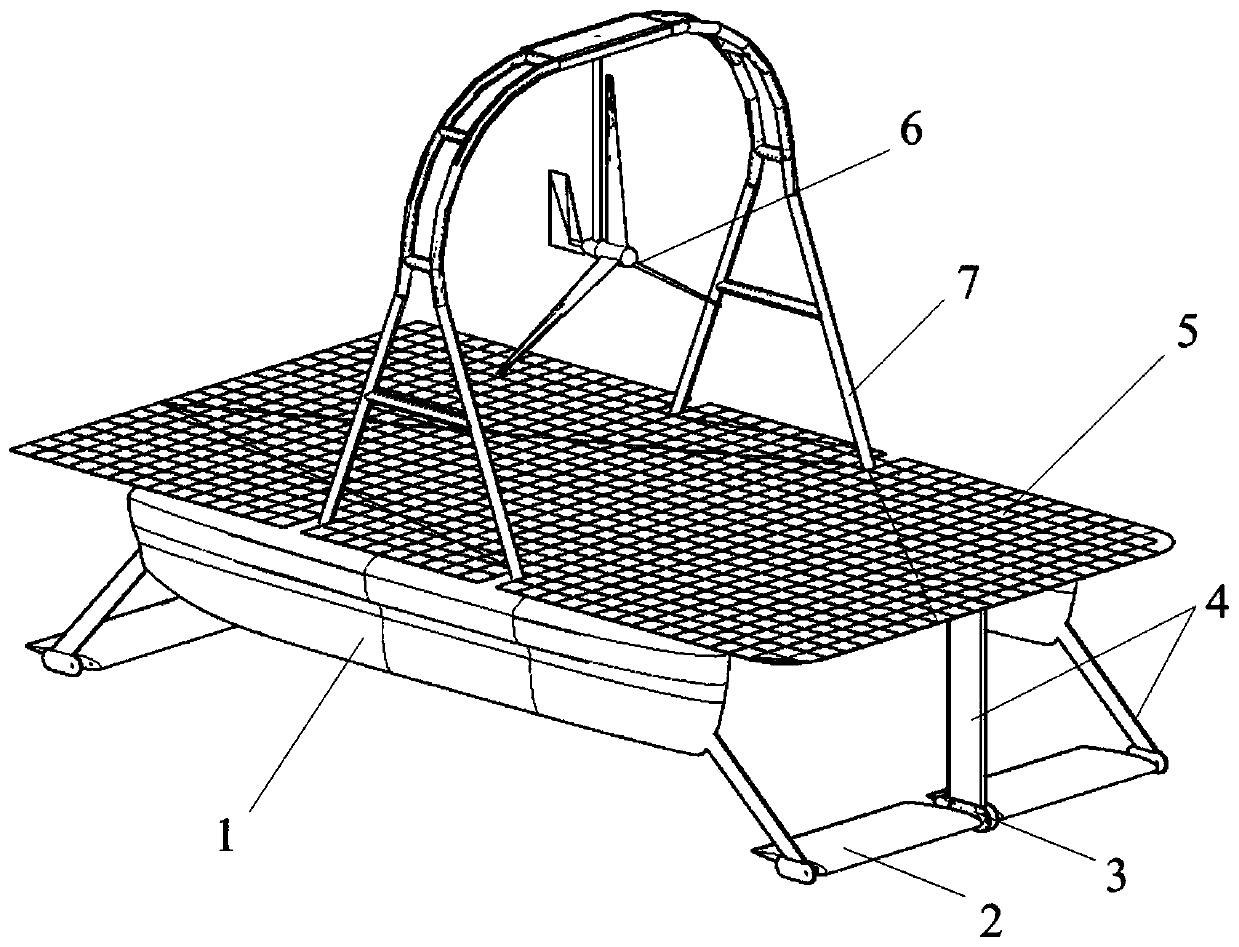

Natural-energy-driven wing-rudder linkage long-endurance twin-hull unmanned boat

ActiveCN109733544AUps and downsBig-amplitudePower plants using propulsion unit combinationsSteering by propulsive elementsSternRudder

The invention relates to a naturally-energy-driven wing-rudder linkage long-endurance twin-hull unmanned boat, and belongs to the field of unmanned boats. The naturally-energy-driven wing-rudder linkage long-endurance twin-hull unmanned boat comprises a twin-hull sheet body, four wave swinging hydrofoils, wing-rudder linkage mechanisms, hydrofoil mounting plates, a solar panel, a wind generator and a fan bracket. Two of the swinging hydrofoils are arranged at the bow and two of the swinging hydrofoils are arranged at the stern, and the swinging hydrofoils are arranged side by side in the widthdirection of a hull. The arrangement method overcomes the structural weight gain burden when the wings are greatly expanded. The front and rear hydrofoils extend towards the bow and the stern correspondingly, so that the hydrofoils utilize the longitudinal motion of the hull in waves and the heave amplitude is larger than the heave amplitude of the bow and the stern of the sheet body, and thus the thrust generated by the hydrofoils is effectively improved. The wing-rudder linkage mechanisms adopt hydraulic transmission devices, the thrust of the hydrofoils on the left side and the right sideof the hull is changed by limiting the rotation range of the swinging hydrofoils on the left side and right side of the hull, a thrust difference is generated to drive the unmanned boat to rapidly rotate the bow, and when the rotation of all the hydrofoils are limited at the same time so that the unmanned boat cannot generate thrust, the unmanned boat can quickly stop, and therefore, the unmannedboat has the capability of rapidly rotating the bow and stopping in an emergency.

Owner:HARBIN ENG UNIV

Plug adapter type infusion hose joint seal ring

InactiveCN103216693AFixed tightlyWon't rotateCouplingsHose connectionsEngineeringMechanical engineering

Owner:XINXING HEAVY IND HUBEI 3611 MECHANICAL

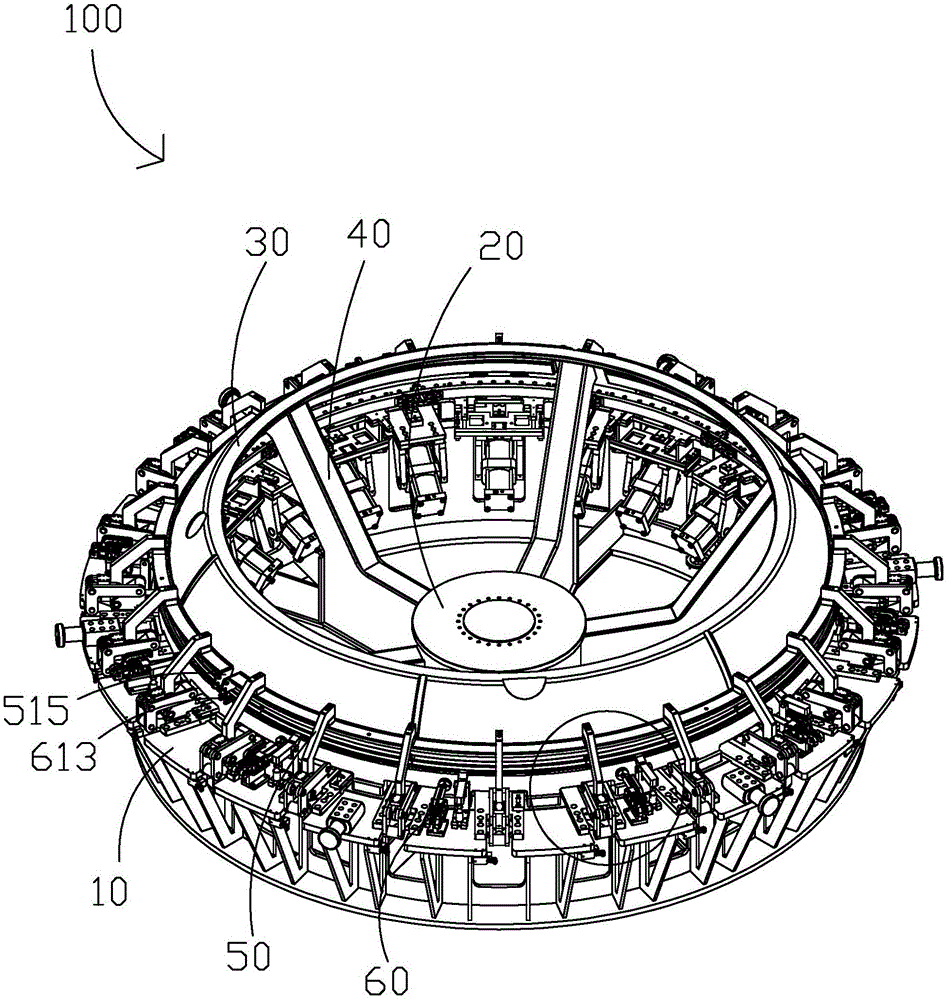

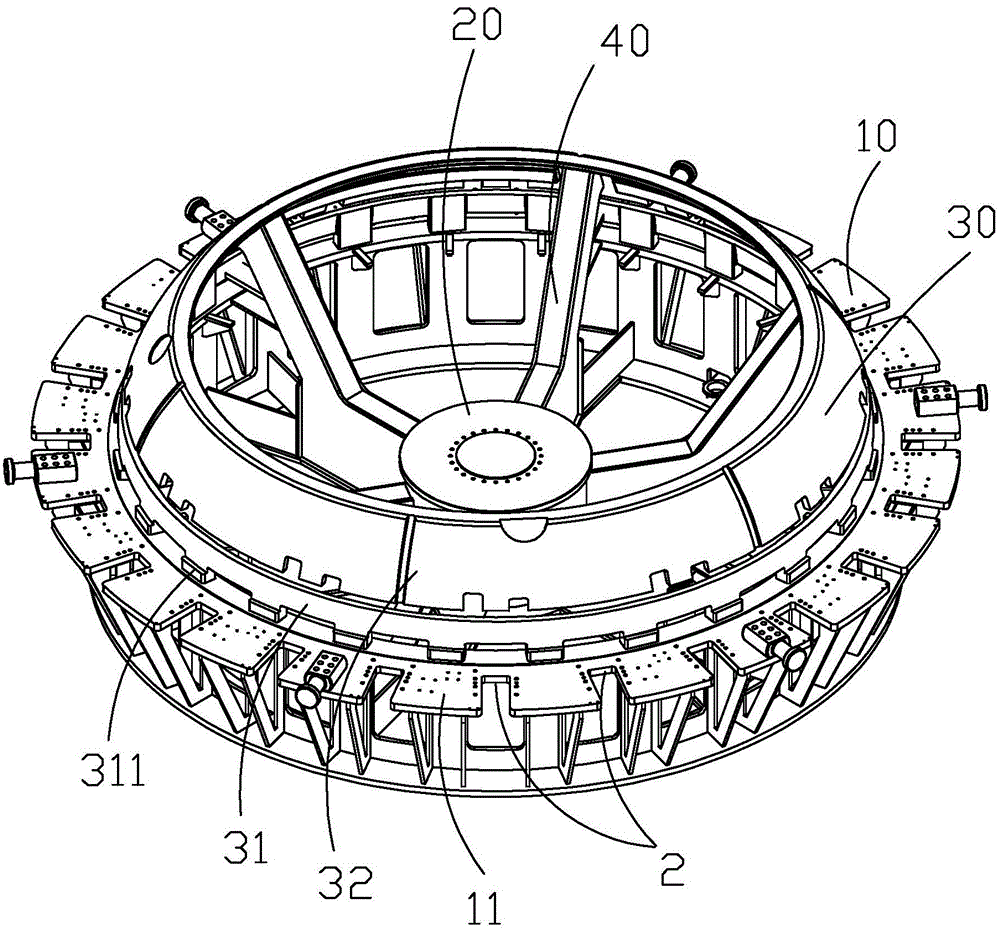

Positioning fixture and storage case girth welding equipment

ActiveCN105127656AAvoid deformationPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention provides a positioning fixture for positioning a circular ring and a section frame at the bottom of a storage case. The positioning fixture comprises a base, a mould fixed on the base and used for positioning the circular ring and the section frame from the inner side, a first pressing assembly used for pressing the circular ring from the outer side and a second pressing assembly used for pressing the section frame; the first pressing assembly comprises a first pressing ring sleeving the circular ring from the outer side and a first pressing mechanism acting on the first pressing ring; the second pressing assembly comprises a second pressing ring sleeving the section frame from the outer side, a second pressing mechanism acting on the second pressing ring, and a third pressing mechanism used for pressing the section frame inwards from the outer side; the first pressing mechanism, the second pressing mechanism and the third pressing mechanism are fixed on the base and positioned on the outer side of the mould. The positioning fixture has good positioning effect on the circular ring and the section frame, cannot affect welding, and can provide guarantee for achieving high-quality welding.

Owner:JIANGSU BEIREN ROBOT SYST CO LTD

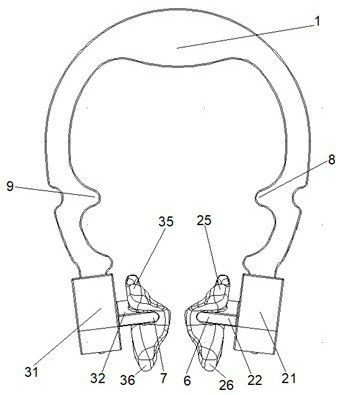

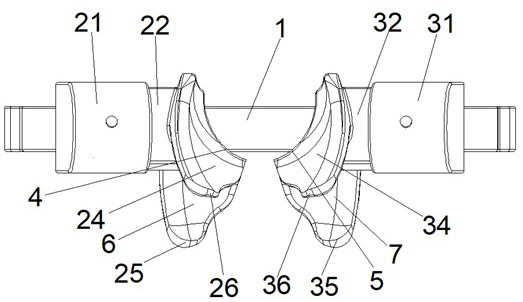

Invisible orthodontic tooth socket, buccal side multi-curved spring matched with invisible orthodontic tooth socket and buccal side multi-curved spring invisible orthodontic appliance with invisible orthodontic tooth socket

ActiveCN113057747AEasy to assemble and disassembleEasy to replaceOthrodonticsEngineeringBiomedical engineering

Owner:桂林医学院附属口腔医院

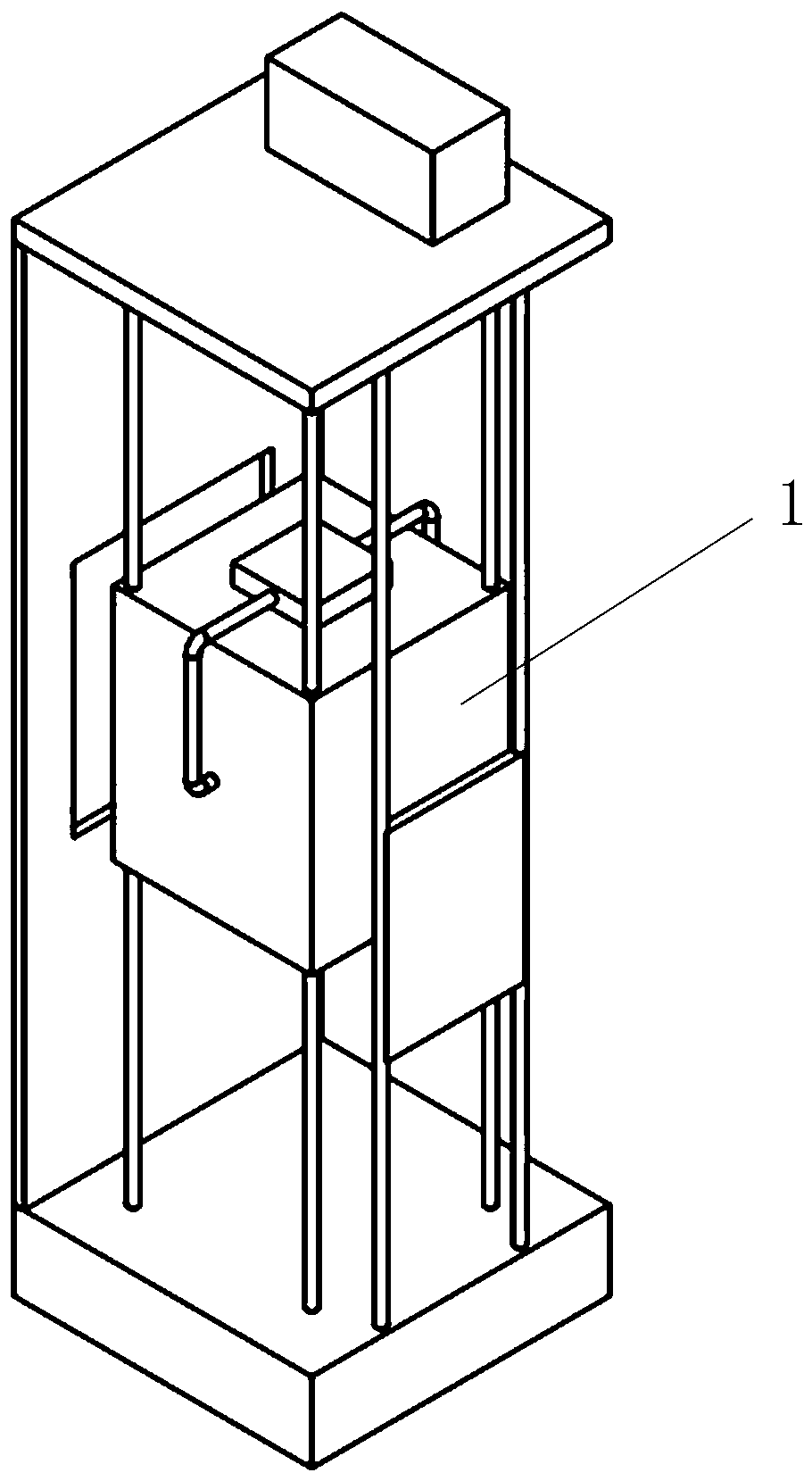

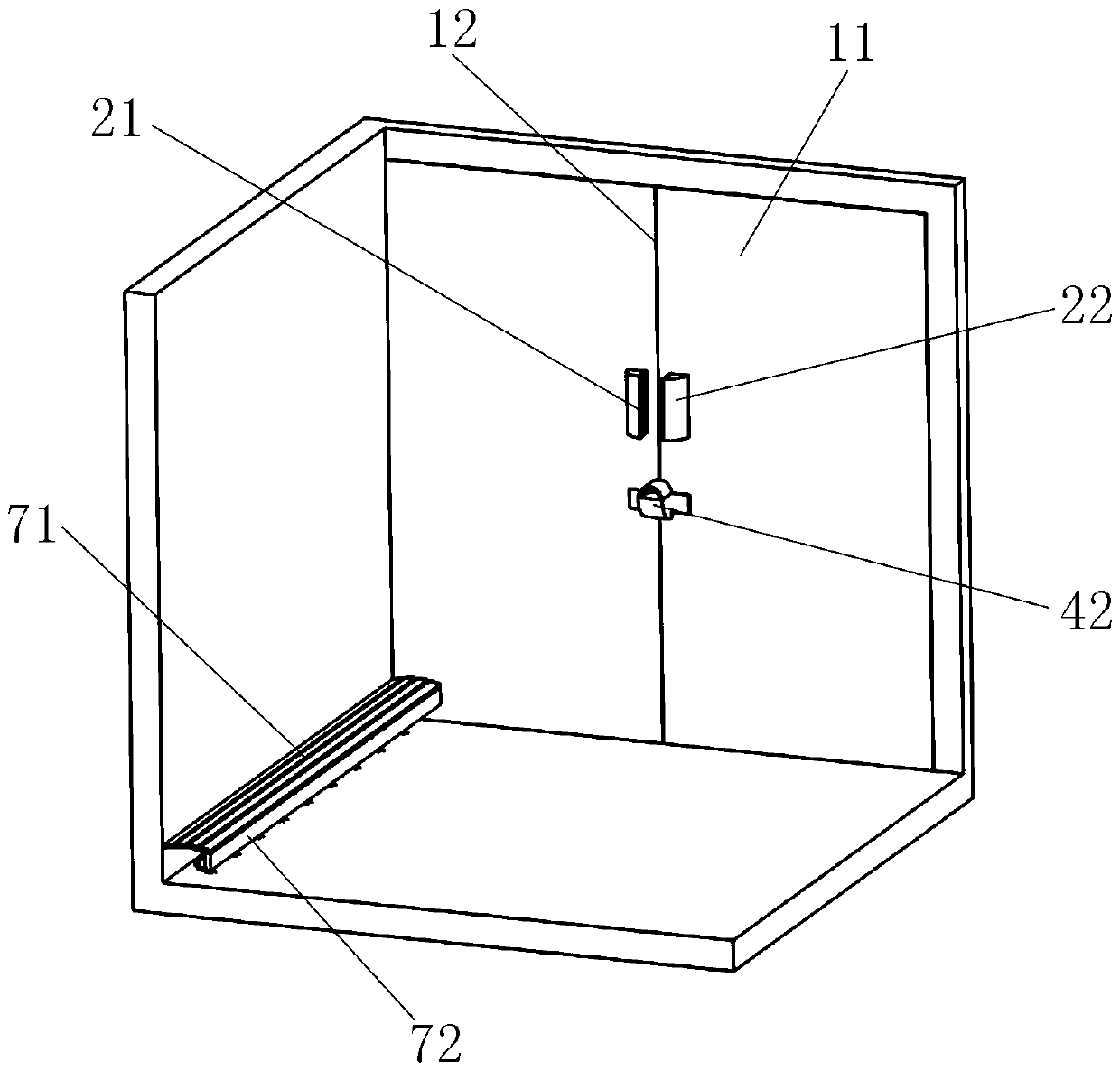

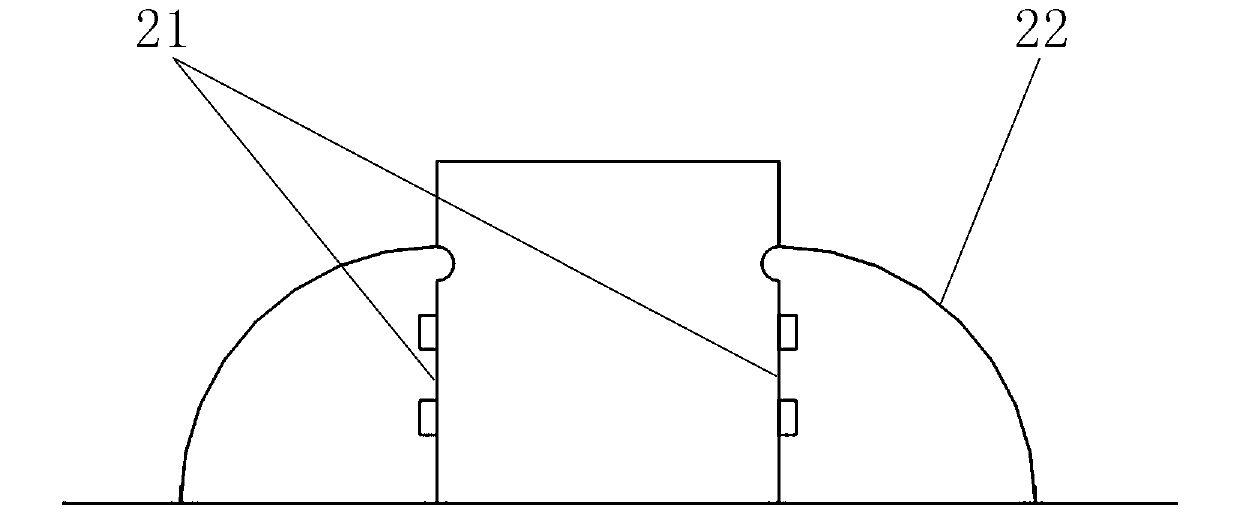

Energy absorption traction elevator

ActiveCN107628514AAvoid personal injuryReduce bump damageElevatorsBuilding liftsEnergy absorptionWire rope

The invention discloses an energy absorption traction elevator, and relates to the field of elevator manufacturing. The energy absorption traction elevator comprises a lift car, a steel wire rope, a counter-weight and a traction machine; the lift car comprises a car door, a control opening part used for controlling opening of the car door is arranged on the surface of the side, close to internal space of the lift car, of the car door, and the control opening part comprises a handle containing part and a collision buffering part; the handle containing part is a plane extending in the directionof the internal space in a manner of being vertical to the surface of the car door, and the collision buffering part is an arc-shaped convex face extending from the edge of the tail end of the hand containing part to the side far away from the door connection position and gradually getting close to the surface connected with the car door, and therefore passengers inside the lift car can open the car door from the interior of the lift car at dangerous moment, and self rescue is achieved; on one aspect, the safety of the traction elevator when unforeseen circumstances occur is improved; and on the other aspect, more self rescue force can be give to the passengers, and life and personal injury losses caused by the fact that accidents happen to the traction elevator are reduced.

Owner:苏迅电梯有限公司

Mark printing device for inner walls of U-shaped parts

ActiveCN108528016ALow costClamping effect is goodRotary pressesOther printing apparatusEngineeringAirbag

The invention relates to a mark printing device for inner walls of U-shaped parts. The mark printing device comprises an operating platform and a driving shaft. A support plate is arranged on the operating platform, a first sliding groove and a second sliding groove are formed in the support plate, a first mark printing tube and a second mark printing tube are slidably connected into the first sliding groove and the second sliding groove respectively, a protrusion block is arranged in the middle of each of the first mark printing tube and the second mark printing tube, a rotating shaft is arranged on the support plate, and is located between the first sliding groove and the second sliding groove, a driving plate is connected to the rotating shaft coaxially, a first driving groove and a second driving groove are formed in the driving plate, the protrusion blocks are connected into the first driving groove and the second driving groove in a sliding manner. A first connection rod is fixedly connected to the driving shaft, a second connection rod is connected to the other end of the first connection rod rotationally, the other end of the second connection rod is connected to the protrusion block of the first mark printing tube rotationally; an airbag is fixedly connected to the support plate fixedly, an air cylinder, directly facing the airbag, is arranged on one side of the airbag, an air guide tube is connected between the air cylinder and the airbag. The mark printing device has the advantages that additional fixtures are not needed, and convenience in operation is achieved.

Owner:宁波隆锐机械制造有限公司

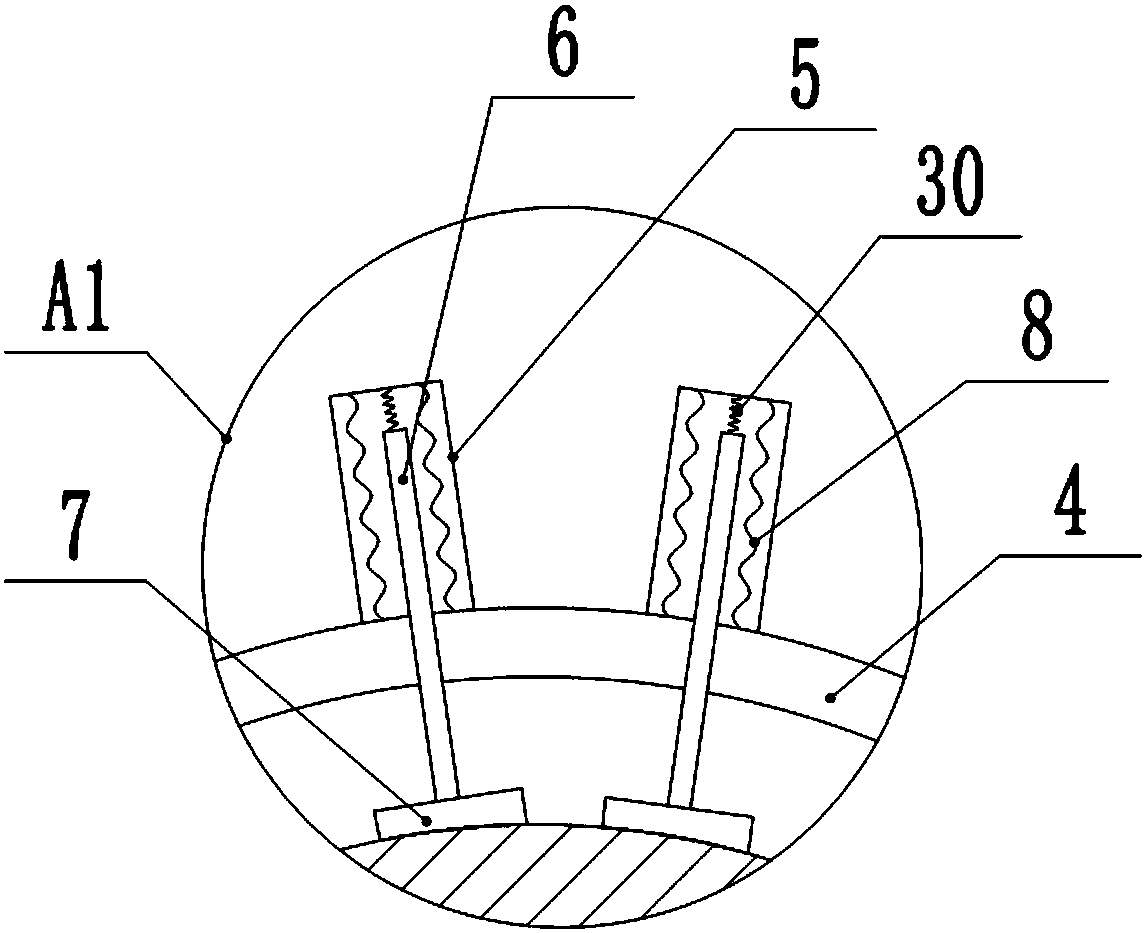

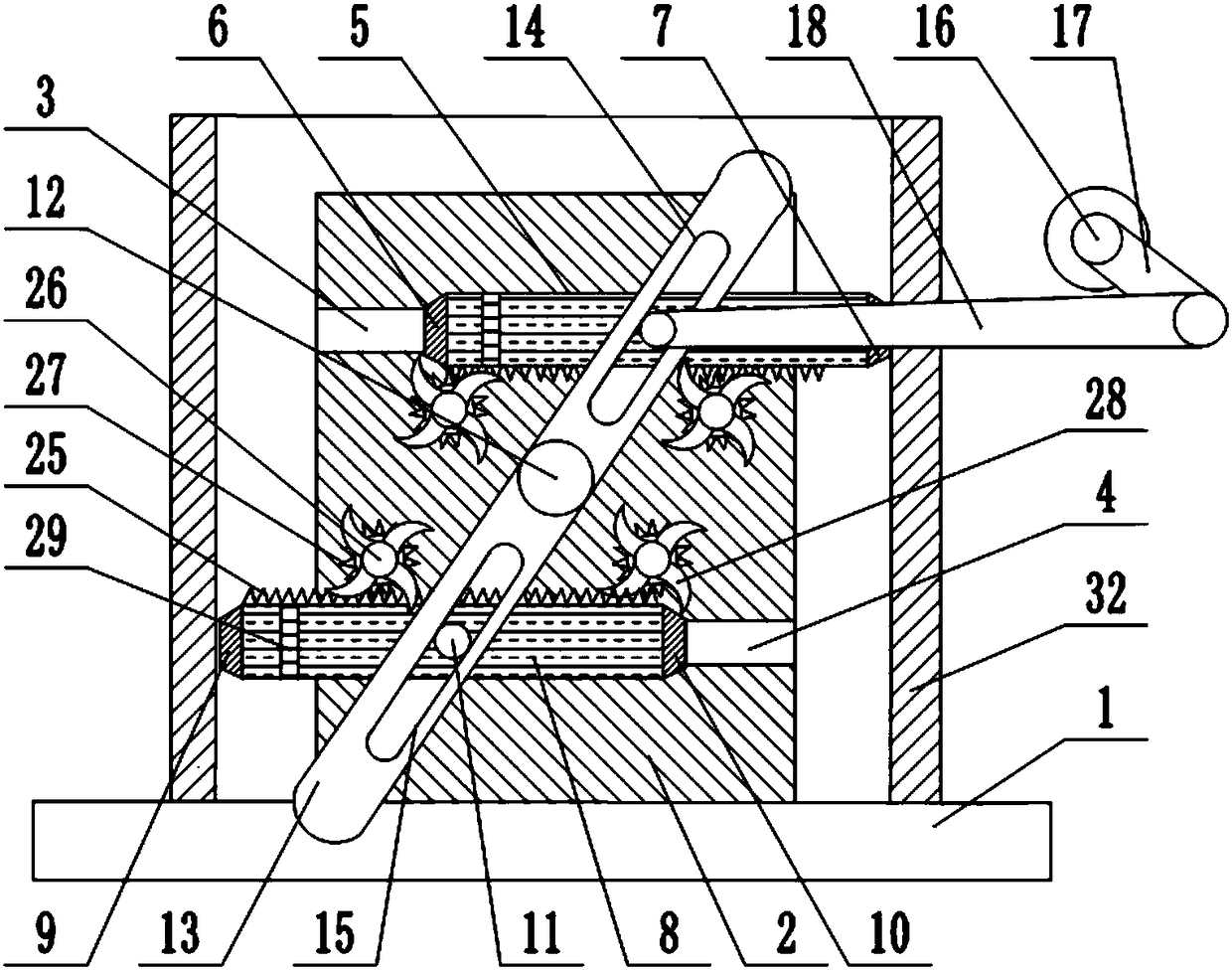

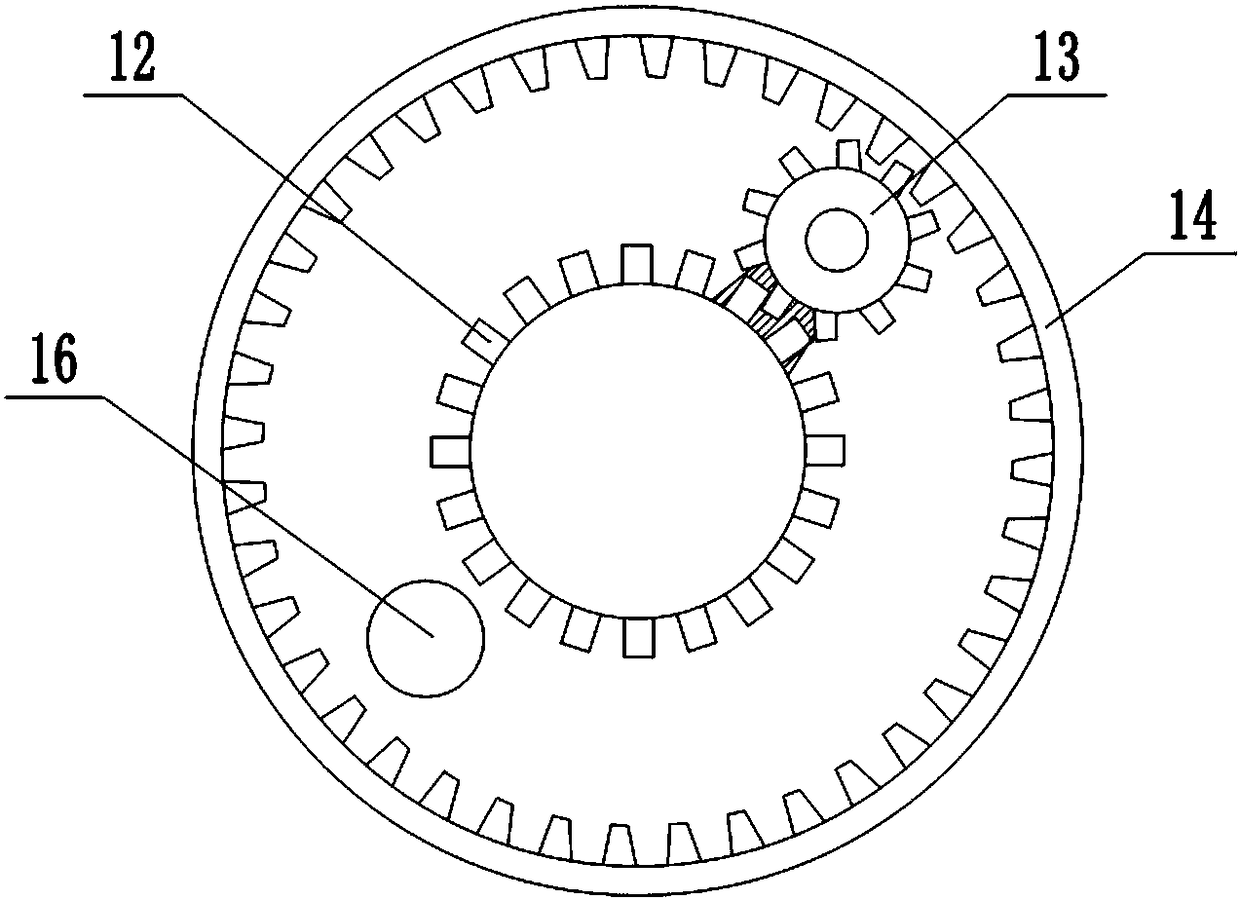

Gear polishing device

ActiveCN108326651AAvoid affecting the grinding accuracyGuaranteed cleanlinessGrinding carriagesRevolution surface grinding machinesPolishing teethMagnet

The invention relates to a gear polishing device. The gear polishing device comprises a rack, support tables are arranged on the rack, clamping blocks are glidingly connected with the support tables,and support springs are arranged between the clamping blocks and the support tables; the gear polishing device also comprises a polishing shaft, polishing teeth are glidingly connected onto the polishing shaft, a cavity is formed in the polishing shaft, an air bag is arranged in the cavity, a downward press rod glidingly connected onto the rack is arranged above the air bag, connecting rods are hinged to two sides of the downward press rod respectively, and the other ends of the connecting rods are hinged to the clamping blocks; a collecting plate is arranged on the polishing shaft, a first magnet is arranged at the bottom of the collecting plate, a falling port is formed in the collecting plate, a baffle is rotationally connected at the falling port, a second magnet is arranged on the baffle, and magnet poles of opposite sides of the first magnet and the second magnet are opposite; a conveying belt and a conveying wheel are arranged below the collecting plate, a third magnet is arranged on the conveying belt, magnet poles of opposite sides of the third magnet and the second magnet are opposite, and the magnetic force of the third magnet is larger than that of the first magnet. Thedevice solves the problem of small application range of traditional polishing devices.

Owner:重庆台华传动技术有限公司

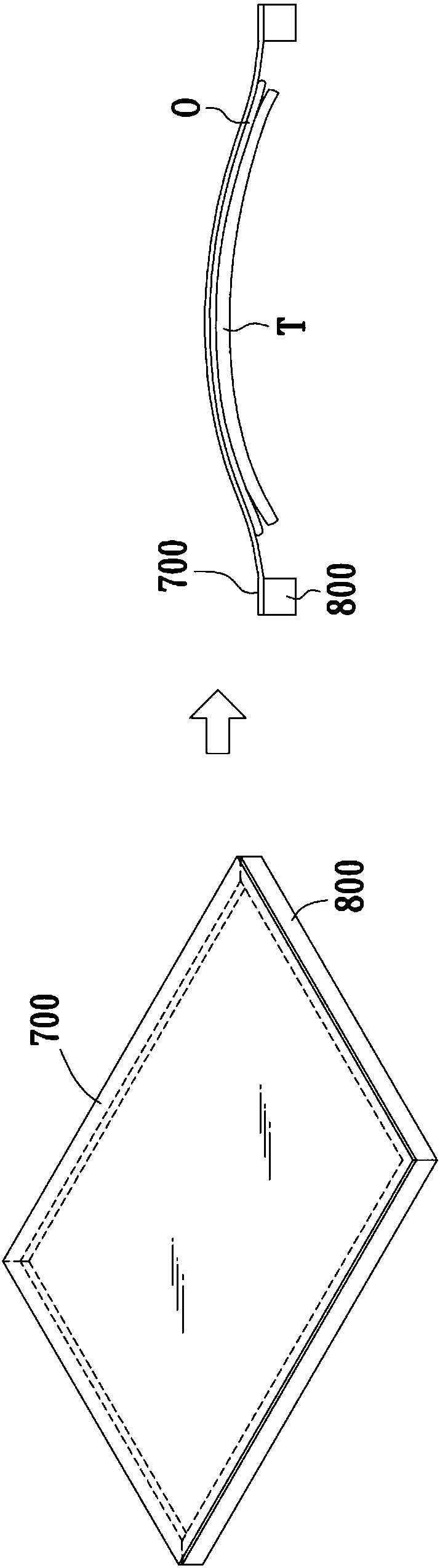

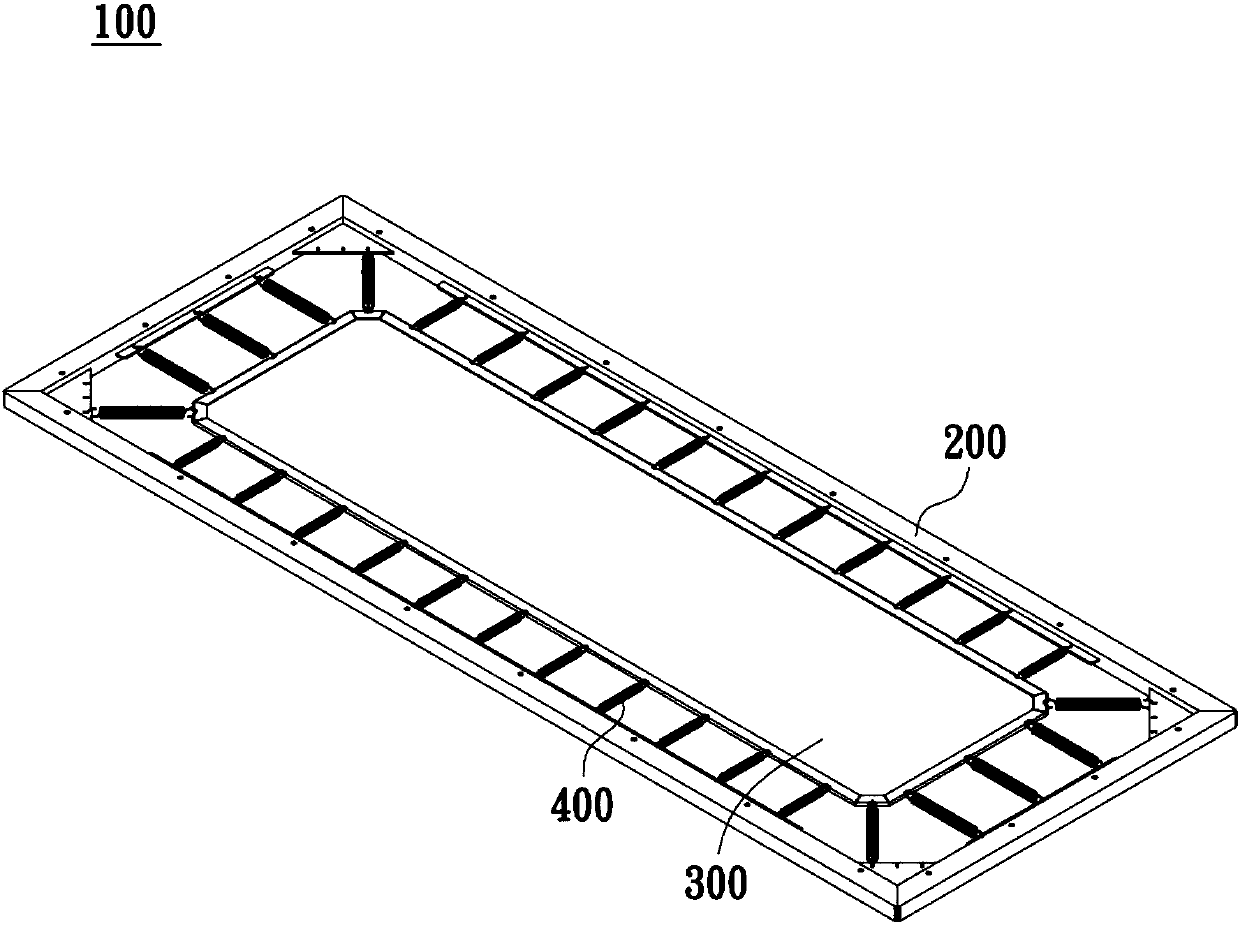

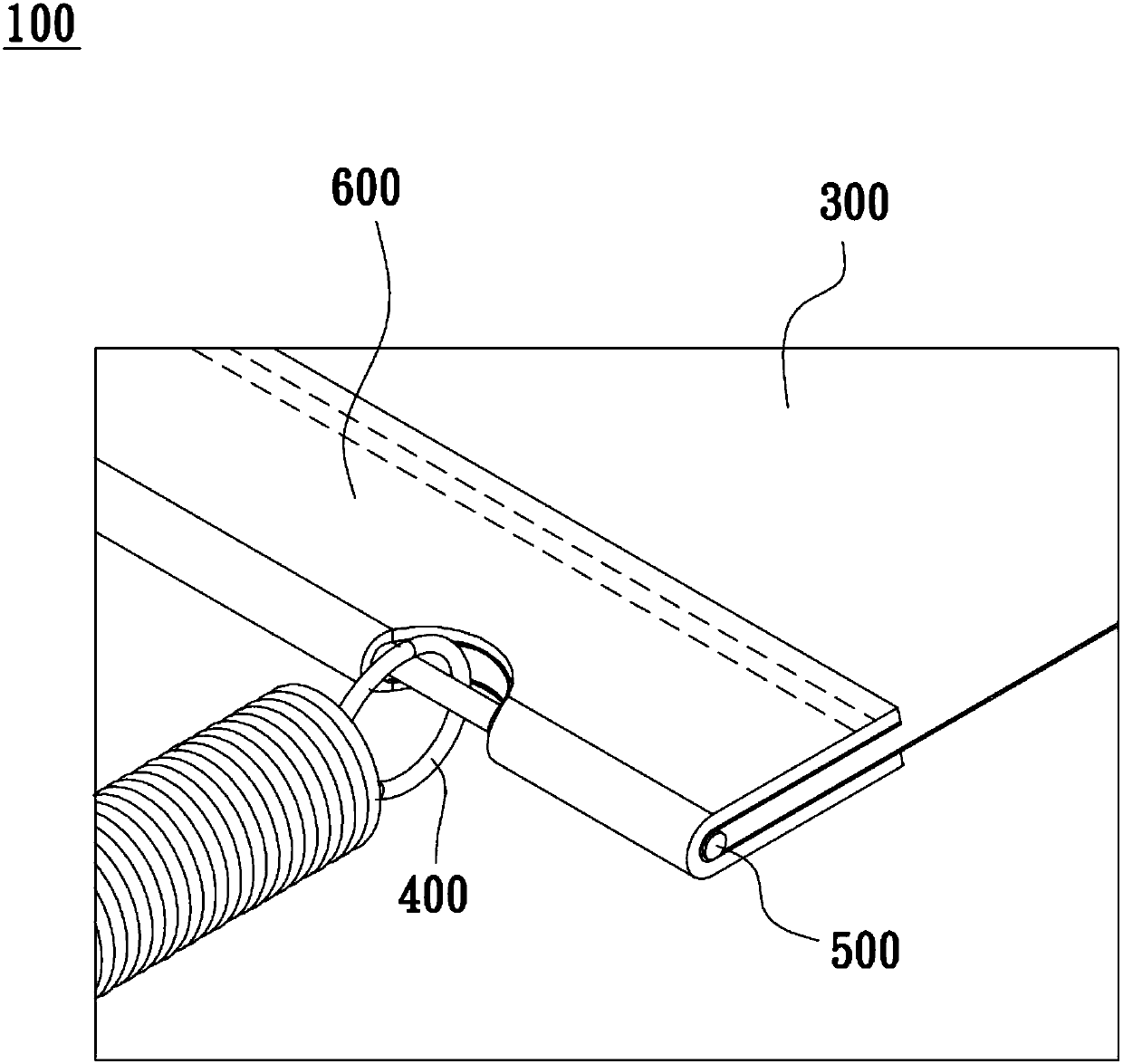

Three-dimensional fitting device of touch display panel device

ActiveCN109532189AReduced deformation restraintHigh densityLaminationLamination apparatusEngineeringSurface plate

The invention provides a three-dimensional fitting device of a touch display panel device. The fitting device includes a frame body, an elastic film and multiple elastic members; the frame body is arranged on pad pasting equipment; the elastic film is located on the inner side of the frame body; the multiple elastic members are annularly distributed on the periphery of the elastic film; one end ofeach elastic member is connected to the elastic film, and the other end of each elastic member is connected to the frame body; and the controlling and moving of the pad pasting equipment can be realized through the frame body so that the pad pasting equipment can be aligned with a pasted object, and therefore, the elastic film can fit with the pasted object according to the shape deformation of the pasted object. As the elastic film is not directly connected to the frame body, different parts of the elastic film can freely telescope and deform by depending on each elastic member; and as the elastic members has elasticity, the fitting device can accurately fit with three-dimensional pasted objects with higher height.

Owner:非翌股份有限公司

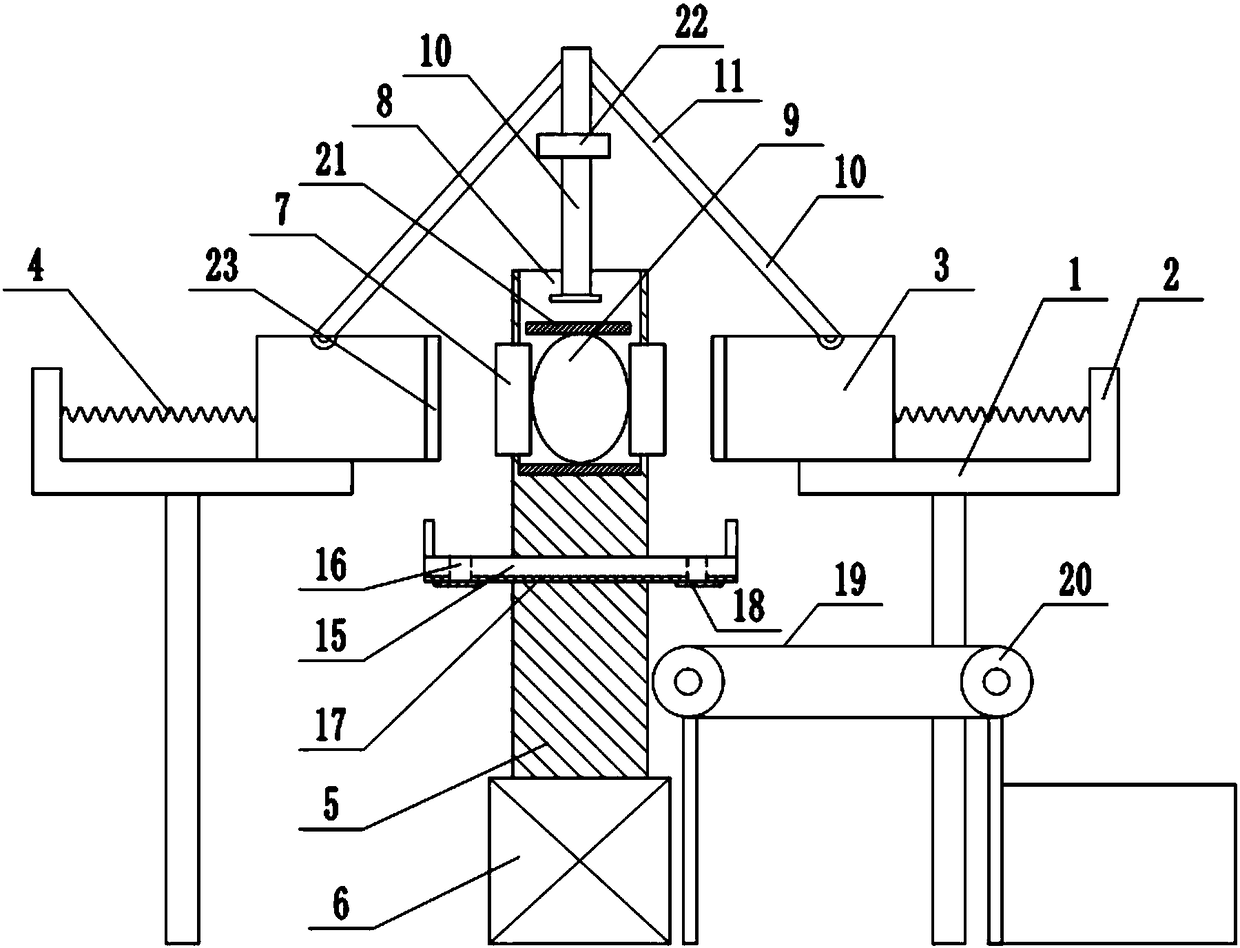

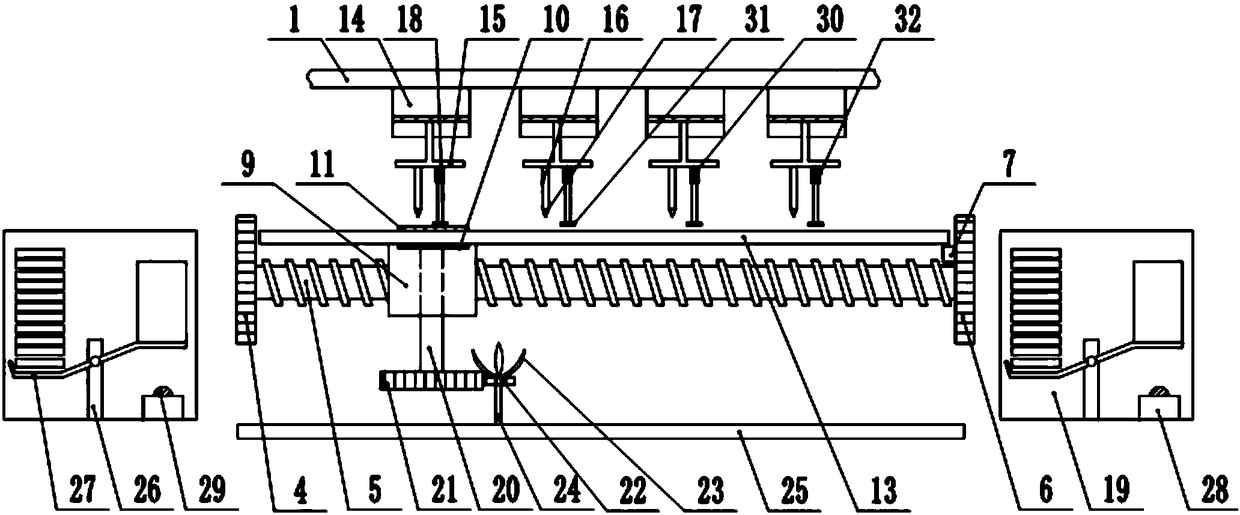

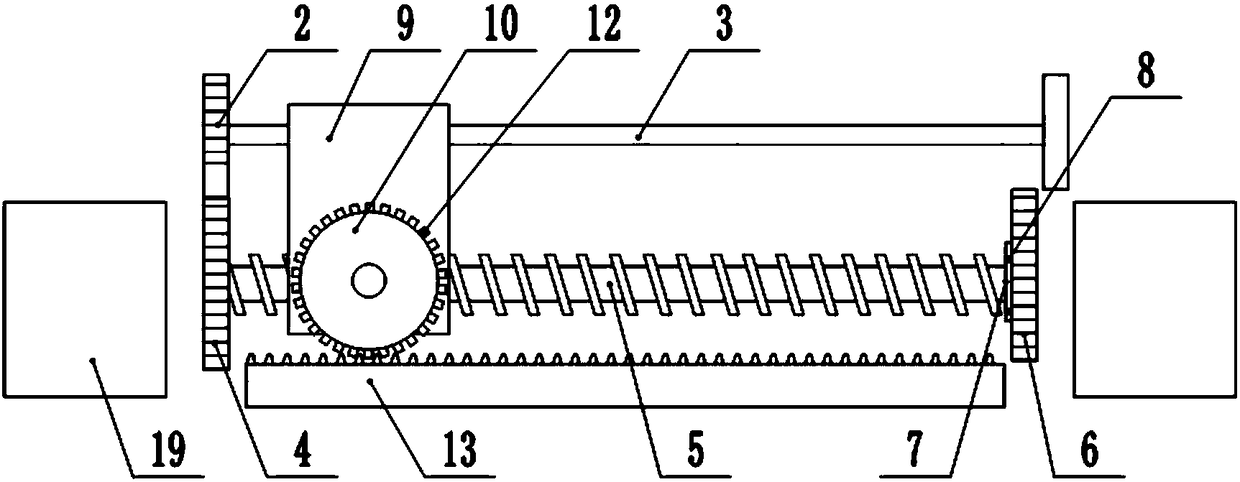

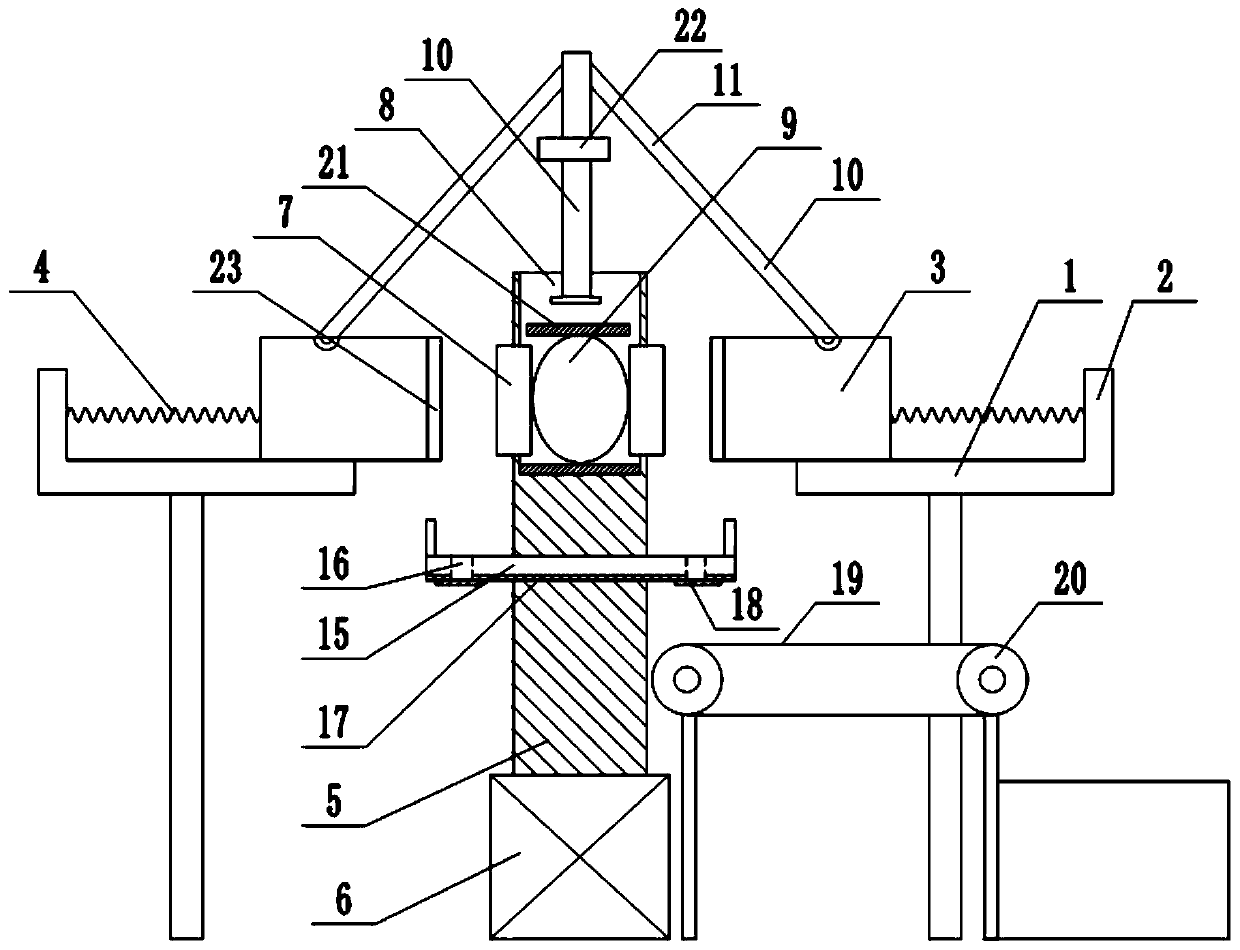

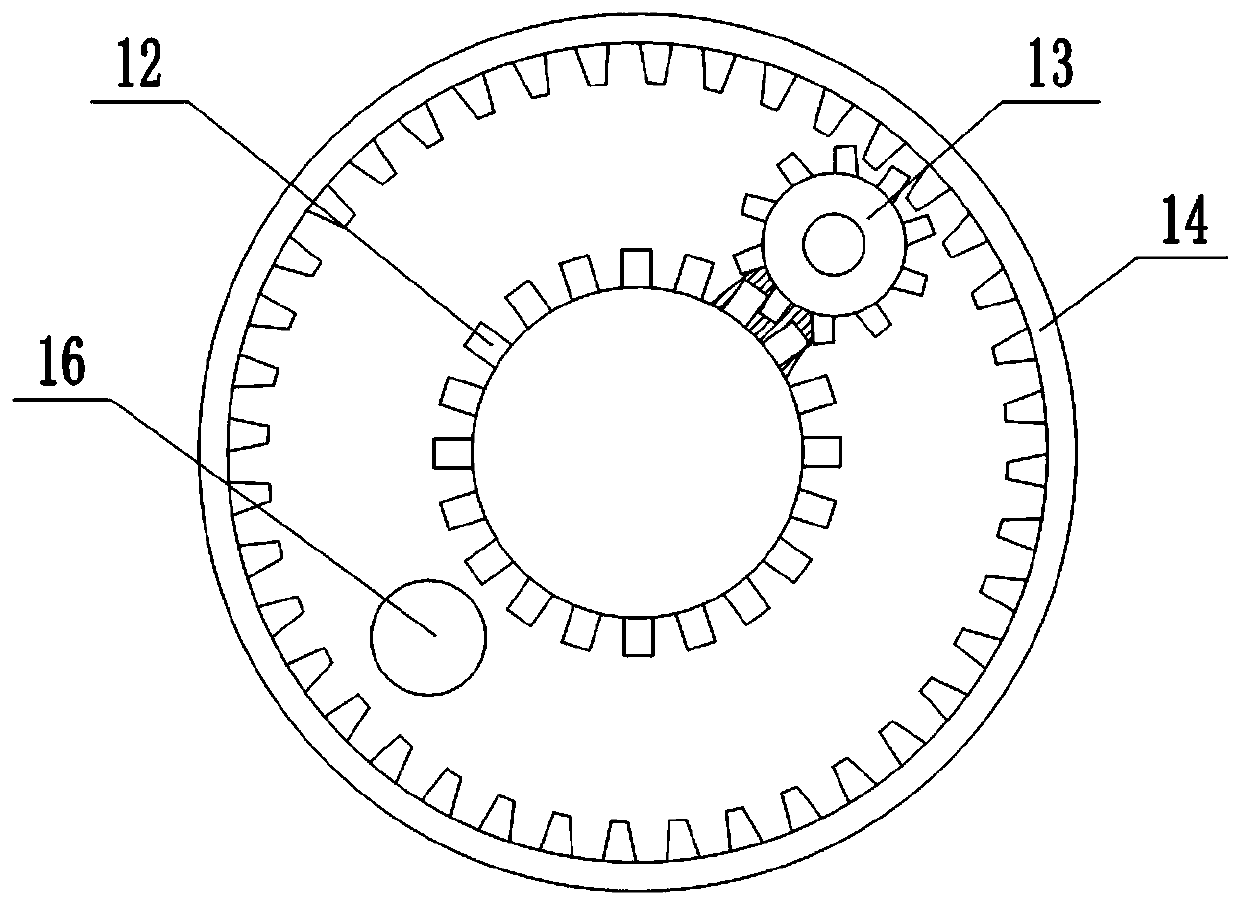

Flange drilling device

ActiveCN108500327AAvoid security issuesImprove consistencyLarge fixed membersBoring/drilling machinesDrive shaftGear wheel

The invention relates to the field of drilling, and discloses a flange drilling device. The flange drilling device comprises a machine frame and a driving shaft. The driving shaft is coaxially and fixedly connected with a driving gear, and the driving gear is a sector-shaped gear. The driving shaft is rotatably connected with a supporting rod, and the other end of the supporting rod is fixedly connected to the machine frame. The driving gear meshes with a transmission gear. A lead screw is coaxially and fixedly connected to the transmission gear, and the other end of the lead screw is rotatably connected with a supporting gear. An alarming apparatus and a control switch which controls the alarming apparatus are arranged on the transmission gear and the supporting gear. A reset spring is arranged on the control switch. A supporting platform is connected to the lead screw in a threaded mode. A transfer plate is rotatably connected to the supporting platform. A positioning groove is formed in the transfer plate. Driving teeth are evenly distributed in the circumferential direction of the transfer plate. A rack is fixedly connected with the machine frame, and the rack meshes with the driving teeth. A cylinder is arranged above the supporting platform, a drilling plate is fixedly connected to the bottom of a piston rod of the cylinder, and a drill bit is arranged on the drilling plate. The flange drilling device solves the problem of hidden danger caused by the mobile drilling equipment.

Owner:重庆博创知识产权运营有限公司

A flange drilling device

ActiveCN108500327BAvoid security issuesImprove consistencyLarge fixed membersBoring/drilling machinesGear driveGear wheel

Owner:重庆博创知识产权运营有限公司

Gear grinding device

ActiveCN108326651BAvoid affecting the grinding accuracyGuaranteed cleanlinessGrinding carriagesRevolution surface grinding machinesGear grindingGear wheel

The invention relates to a gear polishing device. The gear polishing device comprises a rack, support tables are arranged on the rack, clamping blocks are glidingly connected with the support tables,and support springs are arranged between the clamping blocks and the support tables; the gear polishing device also comprises a polishing shaft, polishing teeth are glidingly connected onto the polishing shaft, a cavity is formed in the polishing shaft, an air bag is arranged in the cavity, a downward press rod glidingly connected onto the rack is arranged above the air bag, connecting rods are hinged to two sides of the downward press rod respectively, and the other ends of the connecting rods are hinged to the clamping blocks; a collecting plate is arranged on the polishing shaft, a first magnet is arranged at the bottom of the collecting plate, a falling port is formed in the collecting plate, a baffle is rotationally connected at the falling port, a second magnet is arranged on the baffle, and magnet poles of opposite sides of the first magnet and the second magnet are opposite; a conveying belt and a conveying wheel are arranged below the collecting plate, a third magnet is arranged on the conveying belt, magnet poles of opposite sides of the third magnet and the second magnet are opposite, and the magnetic force of the third magnet is larger than that of the first magnet. Thedevice solves the problem of small application range of traditional polishing devices.

Owner:重庆台华传动技术有限公司

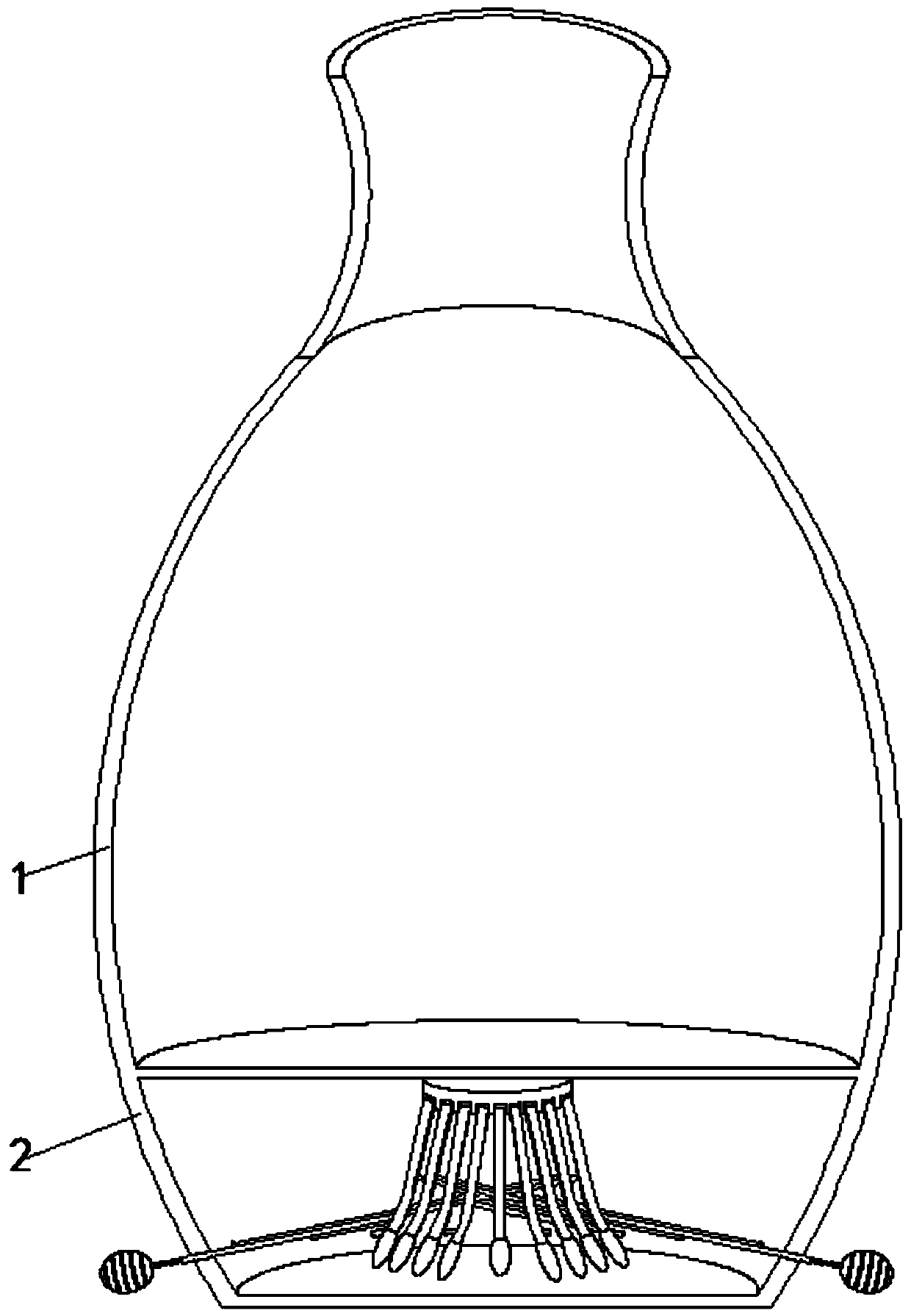

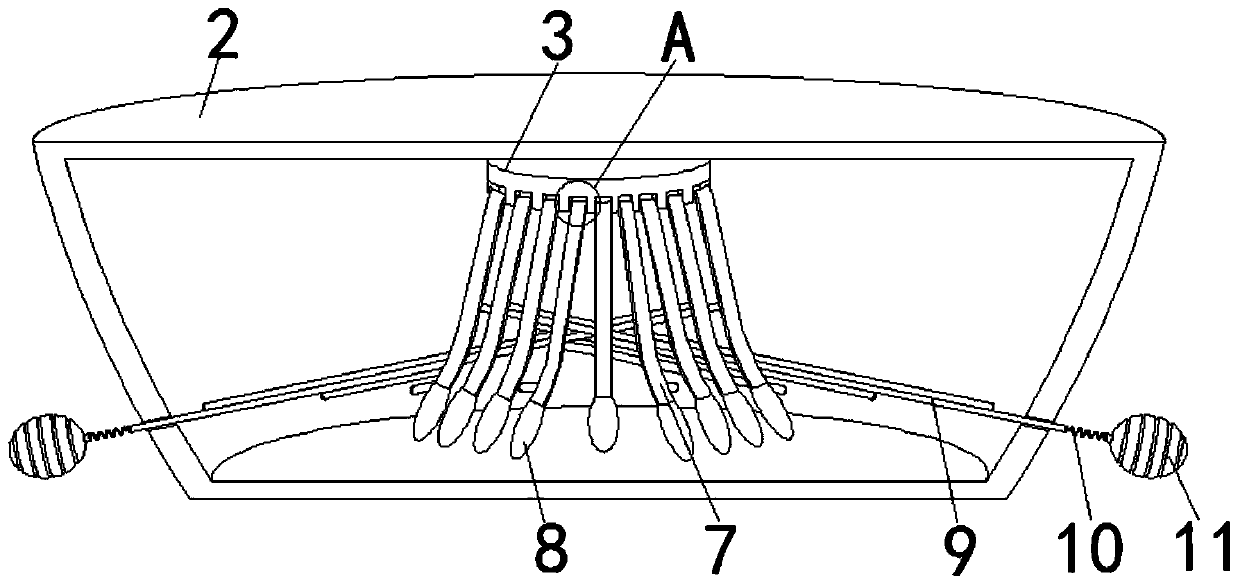

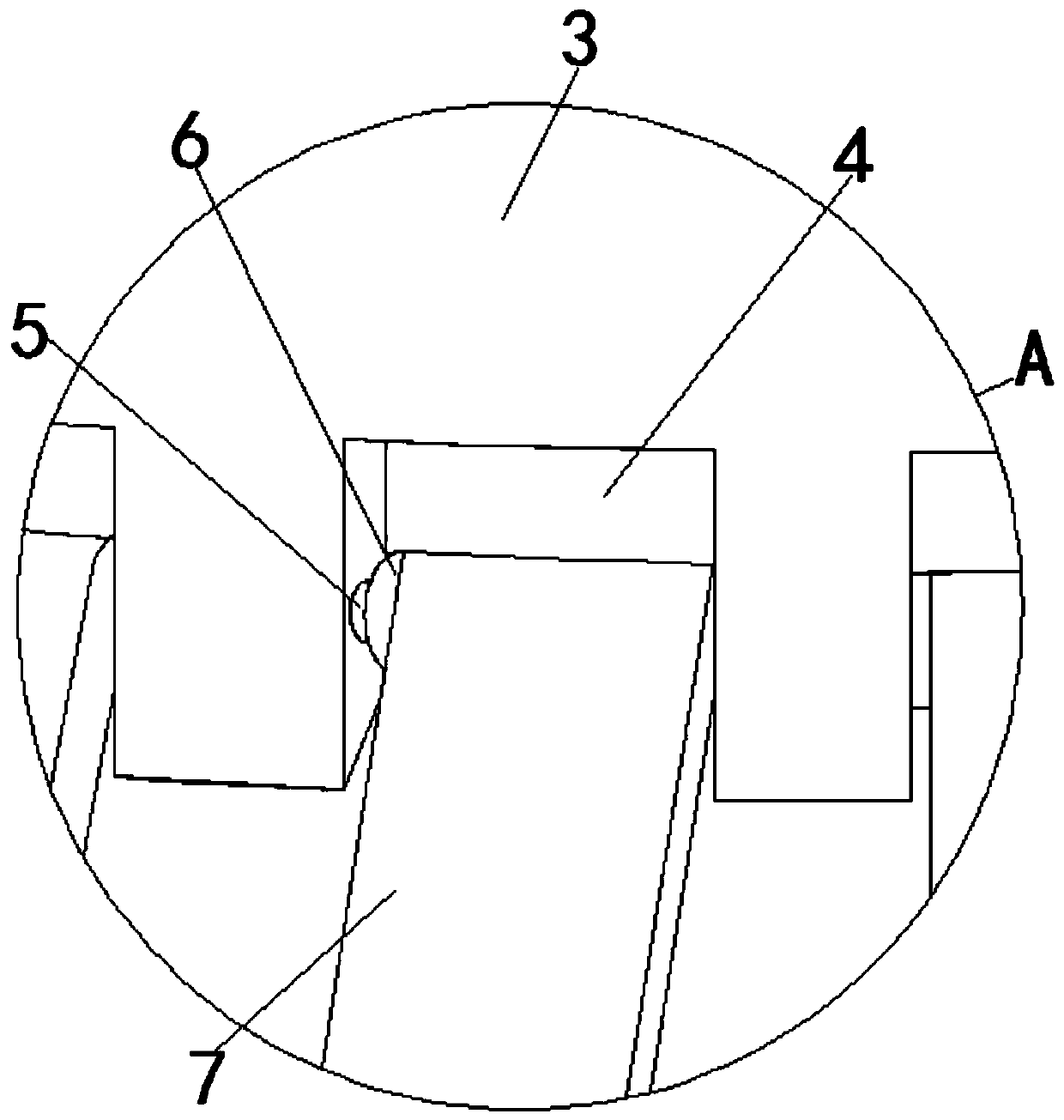

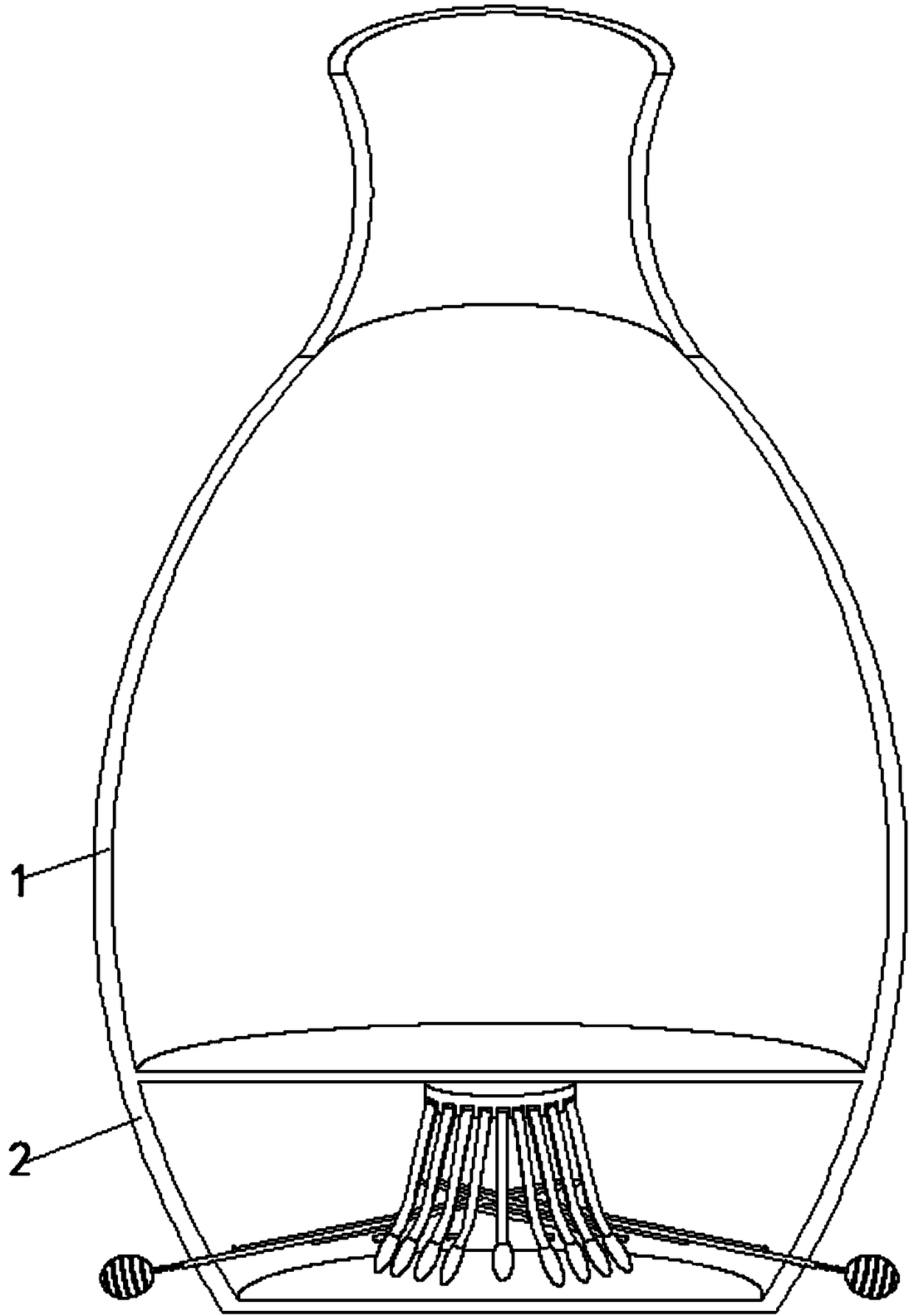

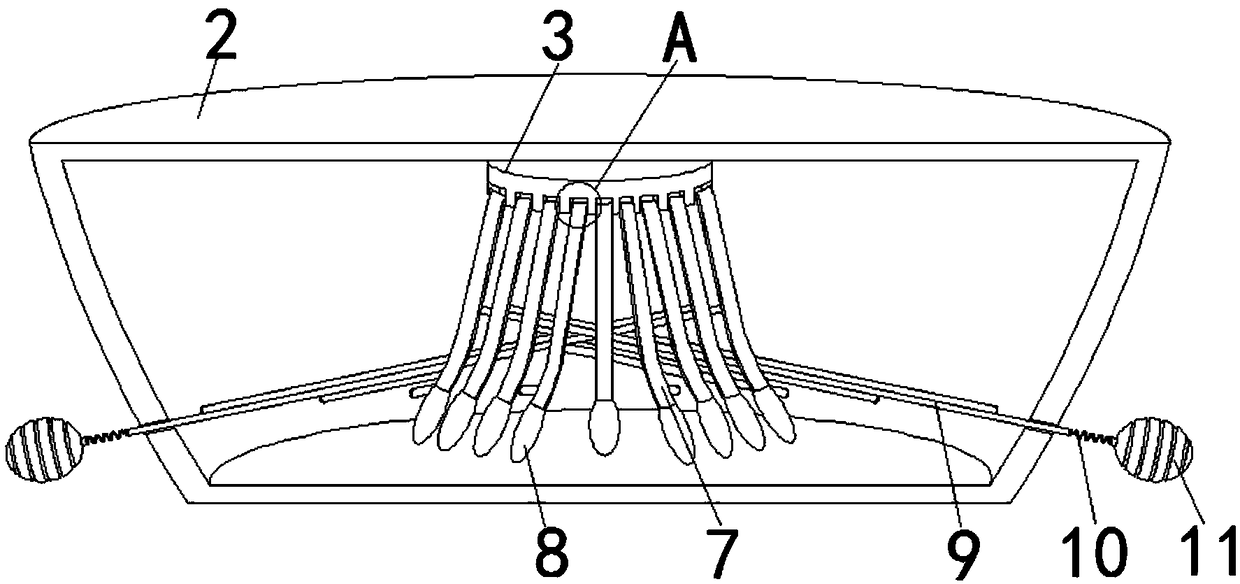

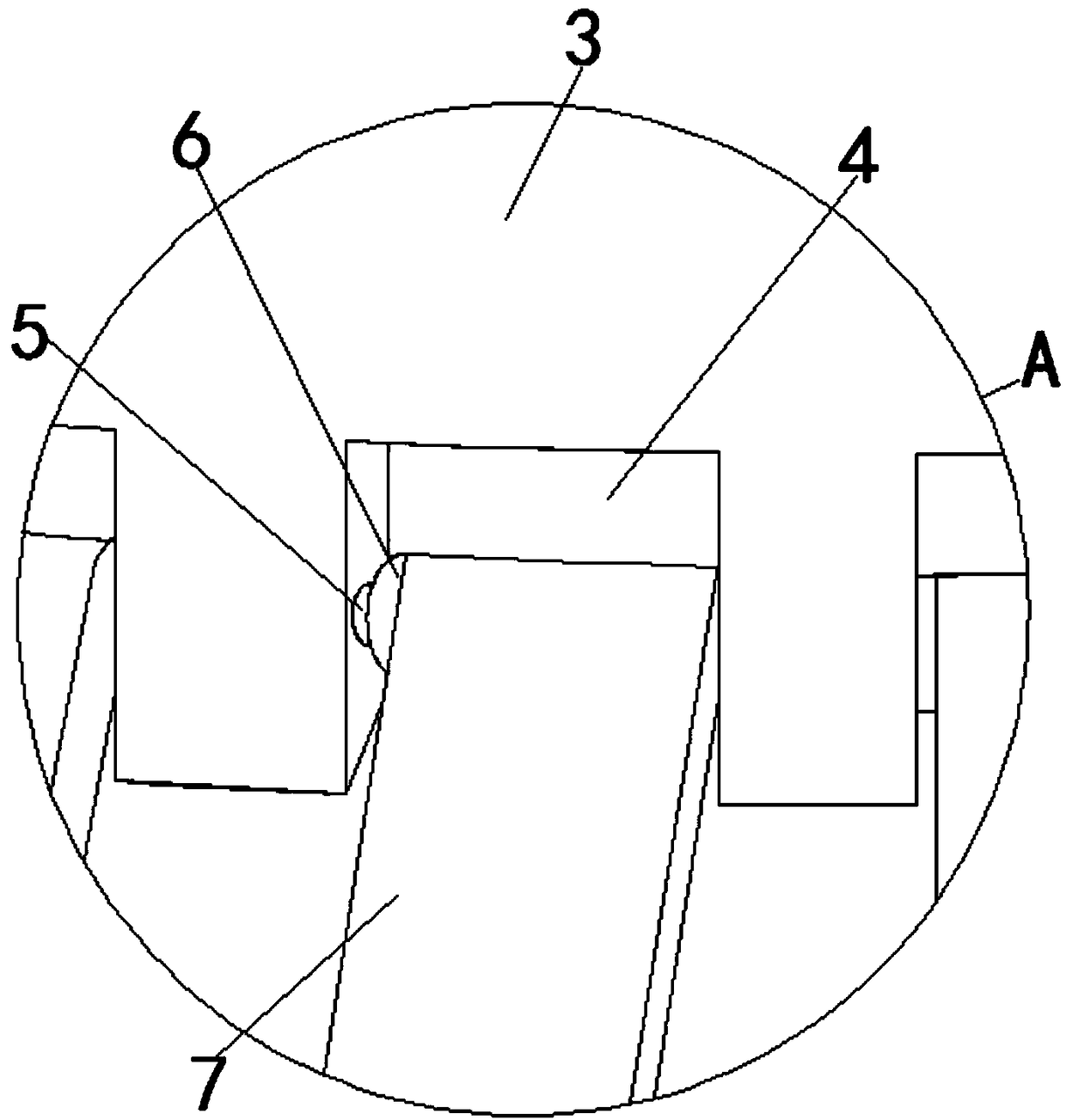

a vase

InactiveCN109222532BLess pouring forceImprove stabilityFlower vasesEngineeringStructural engineering

The invention relates to the technical field of vases, in particular to a vase. The technical problem to be solved by the invention is that it is not convenient to automatically return to the startingposition after the vase is dumped. In order to solve the above technical problems, A vase include a vase body, the bottom of the vase body is fixedly connected with a hollow base, The top of the inner wall of the hollow base is fixedly connected with a round block, the surface of the round block is provided with a plurality of through grooves, the through groove is inserted with a rotating shaft,a circular sleeve is movably sleeved on the rotating shaft, the surface of the circular sleeve is fixedly connected with a pendulum plate, and the bottom end of the pendulum plate is fixedly connected with a counterweight block. As that vase body of the invention is incline, any several touching the earth contact with the table top, at this time, the incline bar can push any several swing platesto rotate, and the counterweight block can move with the swing plate, the vase body is inclined in the opposite direction to the counterweight block, and therefore, the vase is erected on the table top again.

Owner:南京菲兰化妆品有限公司

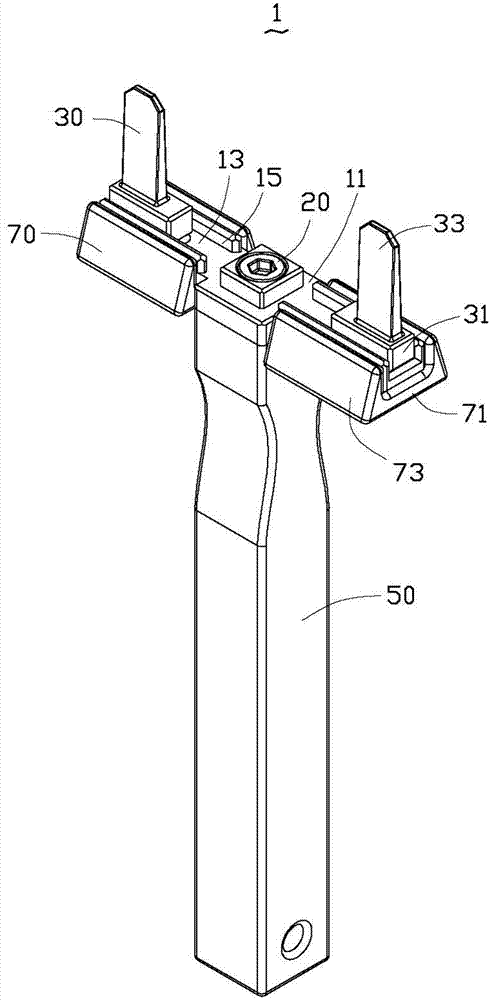

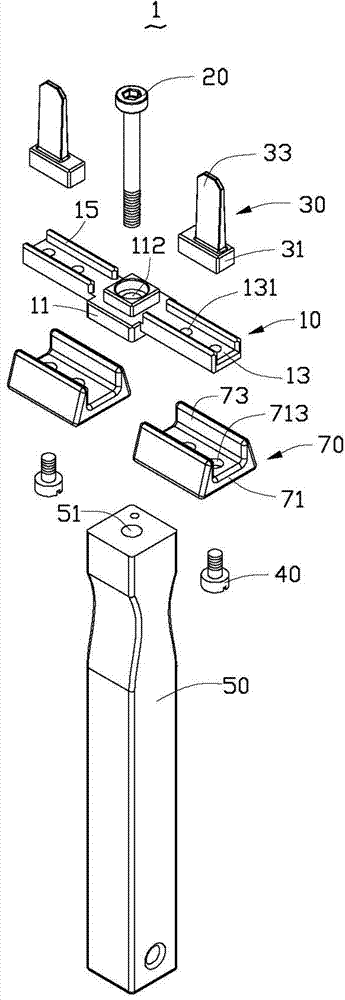

Separation blade dismantling jig

InactiveCN103085022AIncrease the force areaThe force area is large and relatively uniformMetal-working hand toolsWork performanceEngineering

A separation blade dismantling jig is used for dismantling separation blades with openings on a computer case and comprises a support and a handle installed at the bottom surface of the support. The separation blade dismantling jig further comprises two separated prizing sheets installed at the top of the support, wherein the two prizing sheets are used for being inserted into two openings of the separation blades. The separation blade dismantling jig is matched with one separation blade simultaneously through two prizing sheets, and the action force exerted onto the separation blades by the separation blade dismantling jig is large in area and relatively even, so that the separation blades can be dismantled from the computer case by slightly swinging the separation blade dismantling jig for a small angle. The separation blade dismantling jig is easy to operate, saves working hour, can reduce the collision opportunity between the separation blade dismantling jig and the computer case and prevents the appearance and the working performance of the case from being damaged.

Owner:HONG FU JIN PRECISION IND WUHAN CO LTD +1

A reinforced support structure for construction works

ActiveCN112878733BAvoid the problem of difficulty in fully clamping the columnStrong clamping forceBuilding repairsPhotovoltaic energy generationArchitectural engineeringHydraulic pressure

The invention discloses a reinforced support structure for construction engineering, comprising a reinforced support structure connecting frame and a reinforced support structure main body, the reinforced support structure main body includes a right reinforced support structure main body and a left reinforced support structure main body, the One end of the reinforcement support structure connecting frame is fixedly provided with the right reinforcement support structure main body, the other end of the reinforcement support structure connection frame is fixedly provided with the left reinforcement support structure main body, the left reinforcement support structure main body and the right reinforcement support structure main body Symmetrically arranged, the main body of the reinforced support structure is composed of a support plate, a hydraulic telescopic cylinder mounting frame, a hydraulic telescopic cylinder and a fixed splint. One end of the top surface of the support plate is vertically fixed with a hydraulic telescopic cylinder mounting frame, and the hydraulic telescopic cylinder There are two sets; the present invention is composed of a reinforced support structure connecting frame and a reinforced support structure main body, which is convenient for installation and disassembly.

Owner:康建

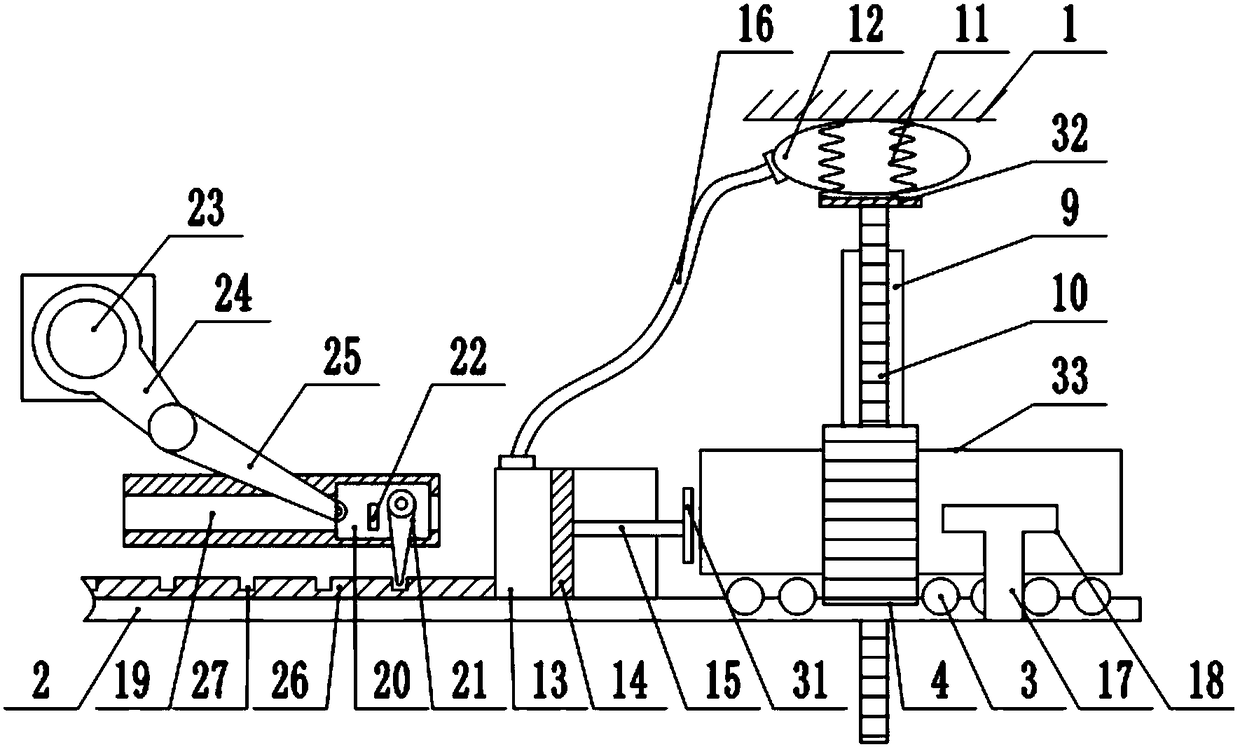

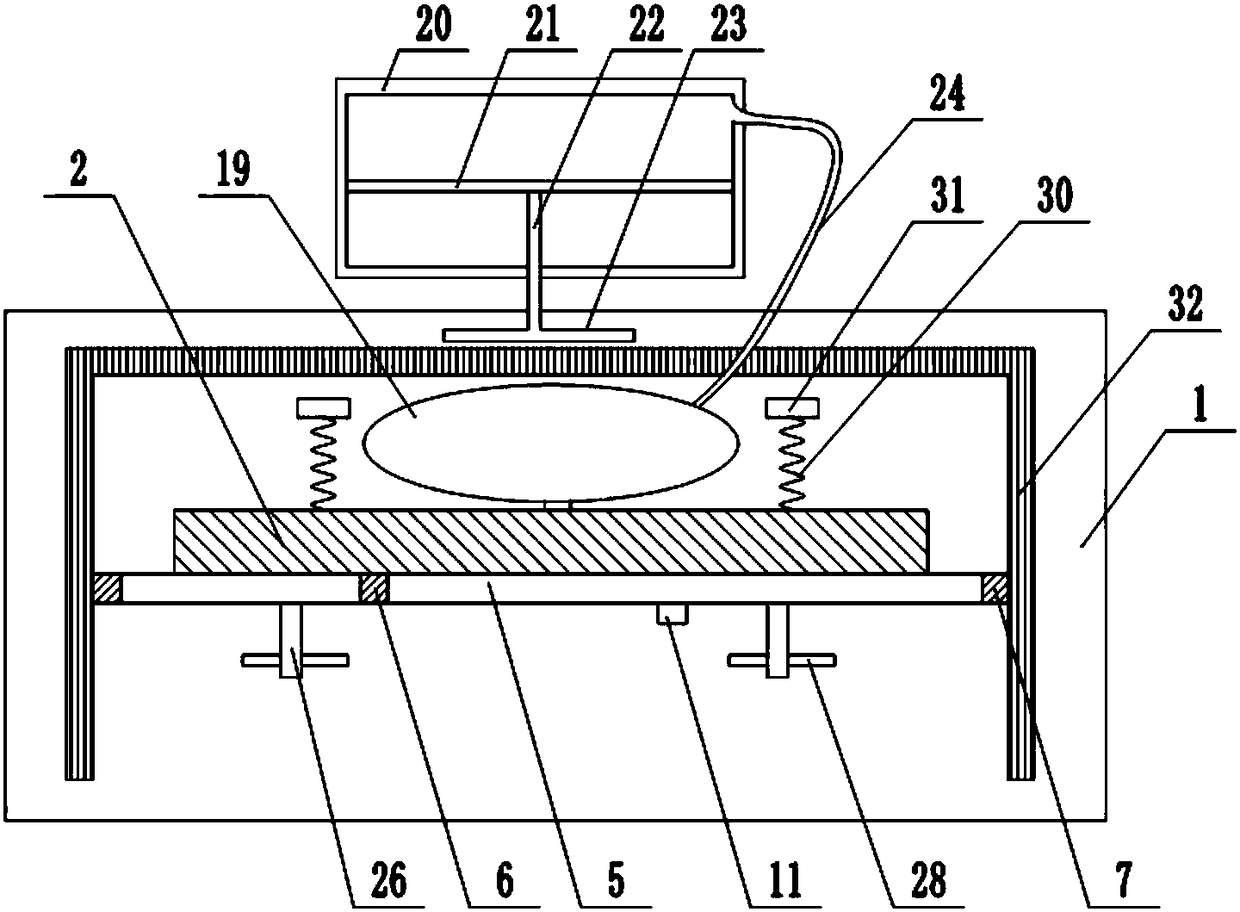

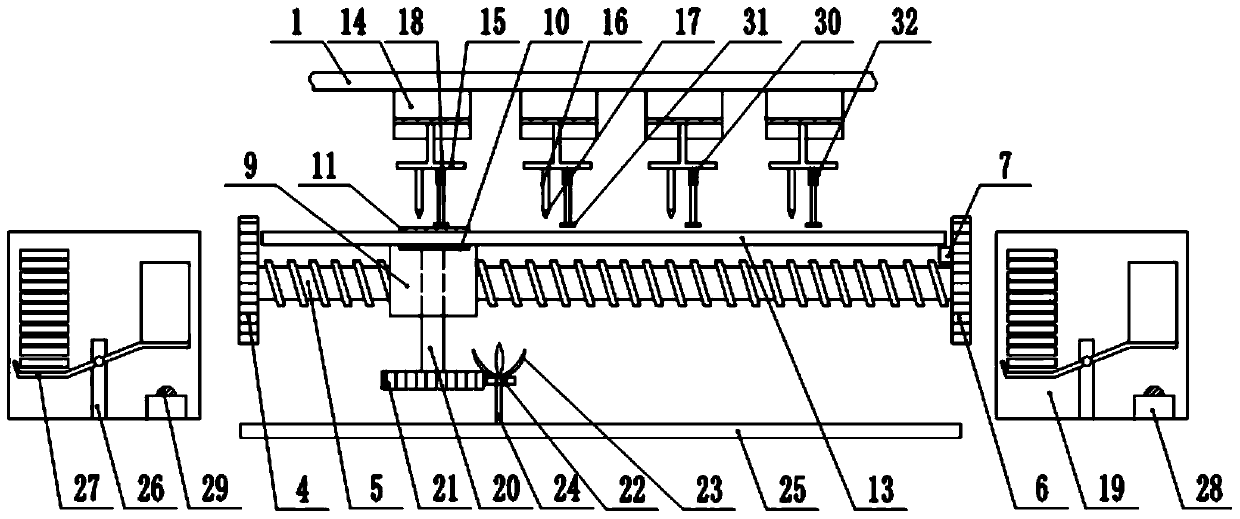

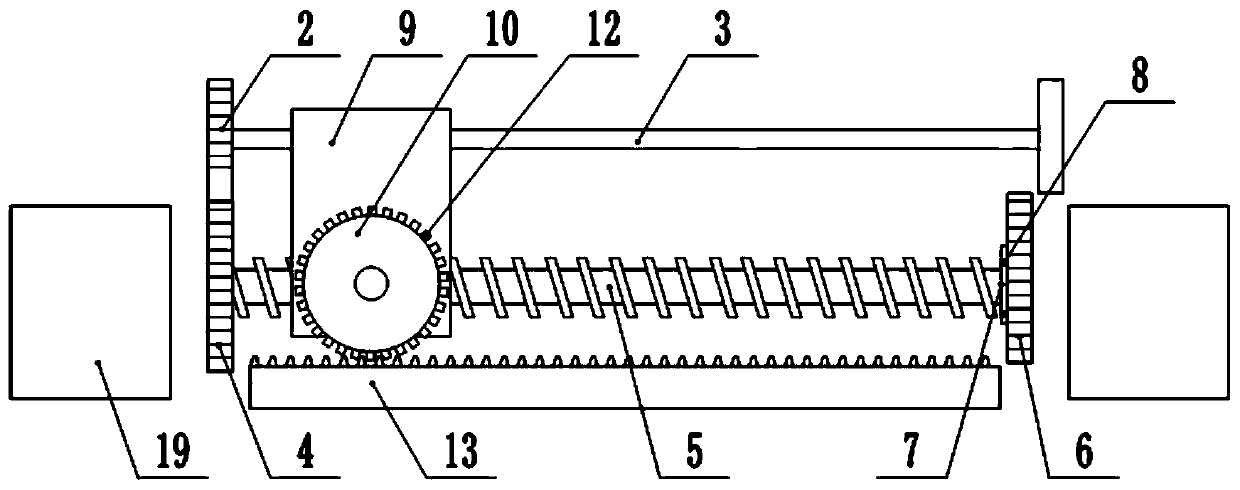

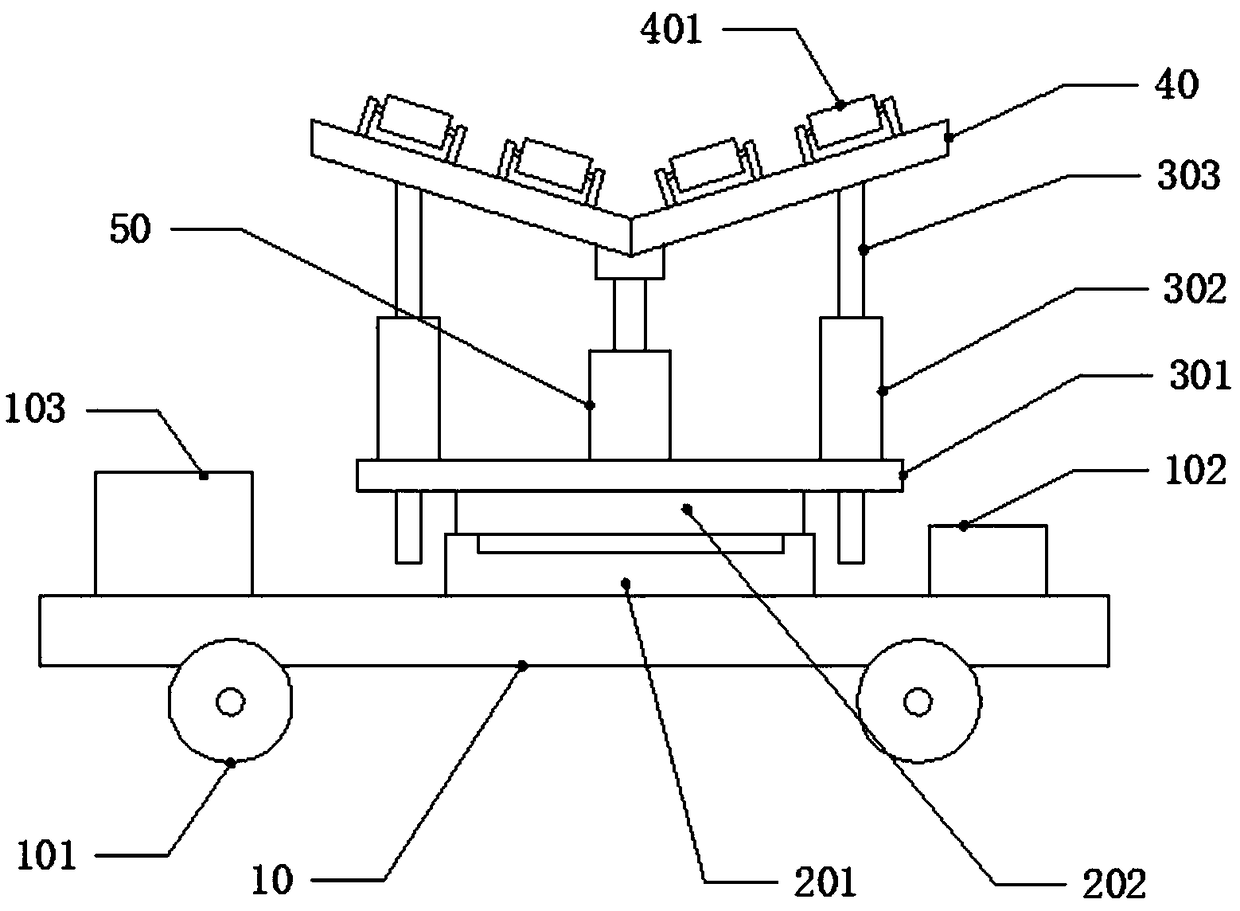

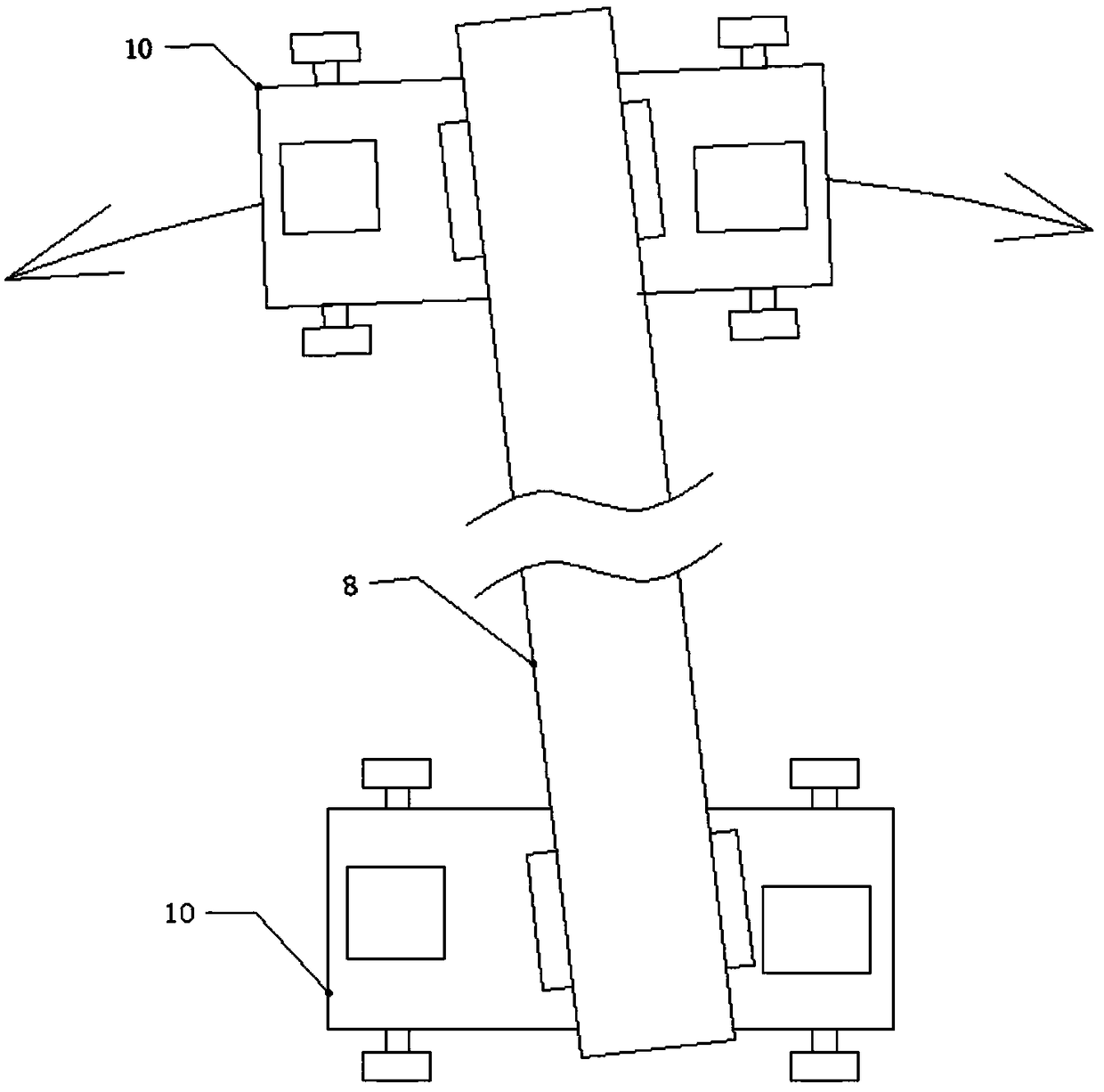

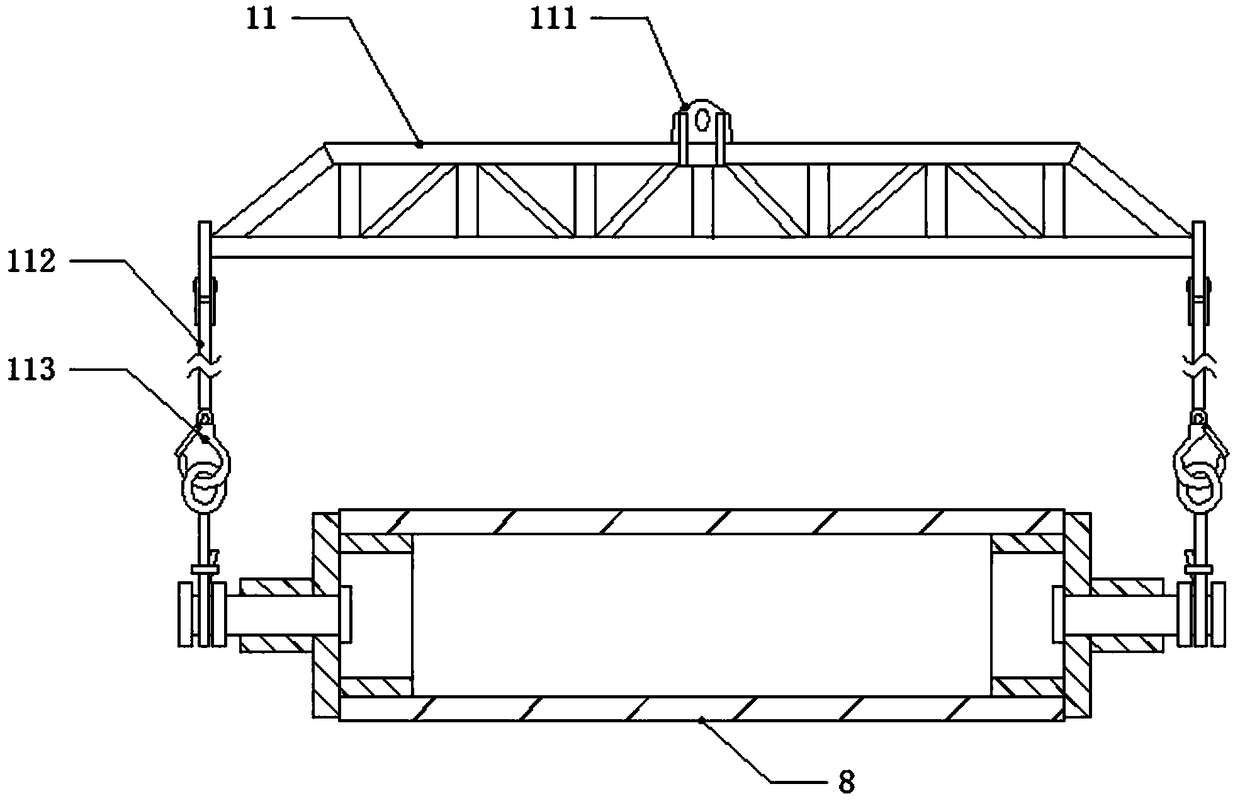

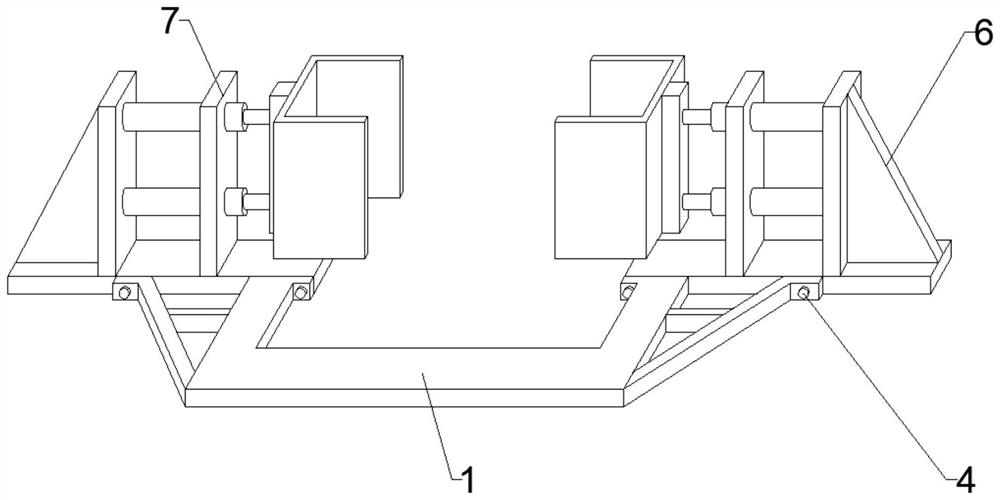

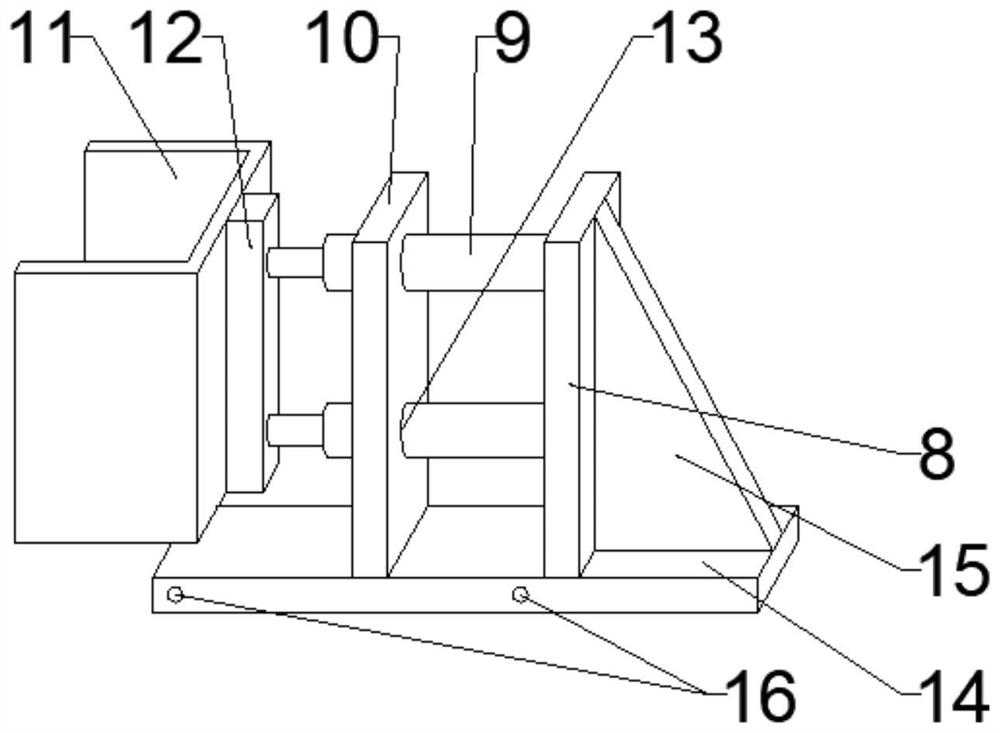

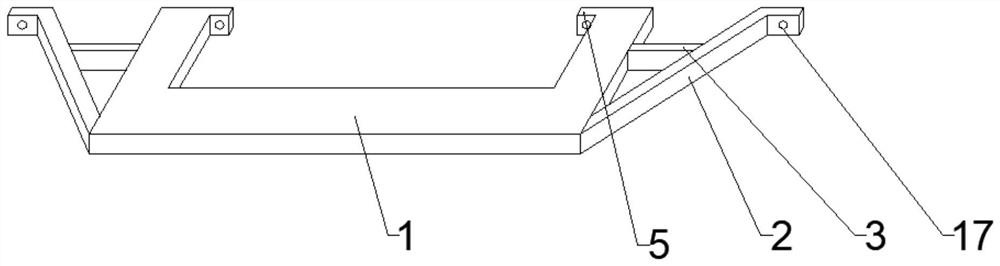

Direct-buried pipe sleeving process production line

InactiveCN109019427AIncrease productivityEasy to operateLifting framesLoad-engaging elementsProduction lineHydraulic cylinder

The invention discloses a direct-buried pipe sleeving process production line. The direct-buried pipe sleeving process production line comprises a conveying vehicle, a loading lifting appliance and aworkbench; the conveying vehicle comprises a trolley, running wheels, a running driving mechanism, a hydraulic station, a rotary supporting base, a rotating disc, a V-shaped bracket and a hydraulic cylinder; the running wheels are arranged on the trolley; the running driving mechanism drives the running wheels to rotate to drive the trolley to run; the rotary supporting base is fixedly mounted onthe upper side of the trolley; the rotating disc is rotationally connected with the rotary supporting base; and a bottom plate is fixedly mounted on the rotating disc. The direct-buried pipe sleevingprocess production line has the beneficial effects that a whole set of special direct-buried pipe sleeving process production line is provided; special equipment is provided for conveying, hoisting, pre-treatment and sleeving of a steel pipe; the operation is convenient and fast; the sleeving production efficiency is enhanced; and as a rotating support is arranged under the V-shaped bracket, eventhough the running speeds of the two trolleys has a difference, a direct-buried pipe cannot fall off from the trolleys so that the direct-buried pipe sleeving process production line is safer and morereliable.

Owner:青岛恒科瑞新信息科技有限公司

Intelligent first-aid mouth opener

InactiveCN107174388AIncrease the force areaReduced pressure damageIntravenous devicesNon-surgical orthopedic devicesPistonFirst aid

The invention relates to an intelligent first-aid mouth opener. The intelligent first-aid mouth opener comprises a handle and an elastic mouth opening bag; a guiding tube is formed in the handle, a suction wheel is coaxially installed in the guiding tube and engaged with an inner wheel of one corresponding one-way bearing, operating cylinders are distributed on the periphery of the guiding tube in parallel, and a pneumatic wheel is coaxially installed in each operating cylinder; pistons are arranged at the front ends of the operating cylinders in a sliding mode, and puncture needles are fixed to the pistons; the tip ends of the puncture needles face towards liquid storage cavities and partition membranes, and the tail ends of the puncture needles come out of the operating cylinders and are fixed to a pushing plate; through holes are formed in the rear ends of the operating cylinders and communicated with the mouth opening bag; a suction tube is arranged in the mouth opening bag in a penetrating mode, and the tube wall of the suction tube is connected with the mouth opening bag in an airtight mode. According to the mouth opener, the structure is original and unique, the mouth of a patient can be maintained open, the teeth of the patient are protected, damage to the mouth is reduced, and smooth breathing is guaranteed at the same time.

Owner:THE FIRST AFFILIATED HOSPITAL OF ZHENGZHOU UNIV

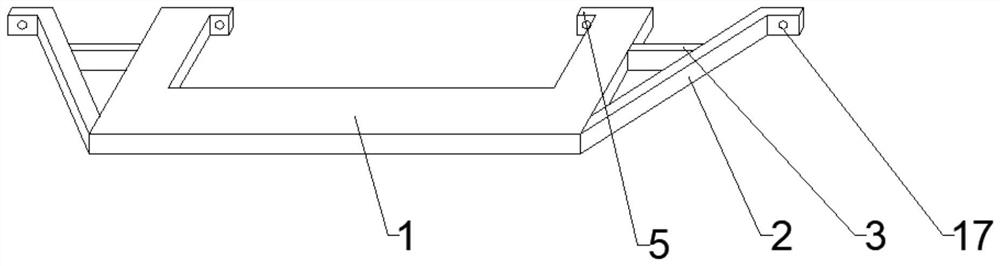

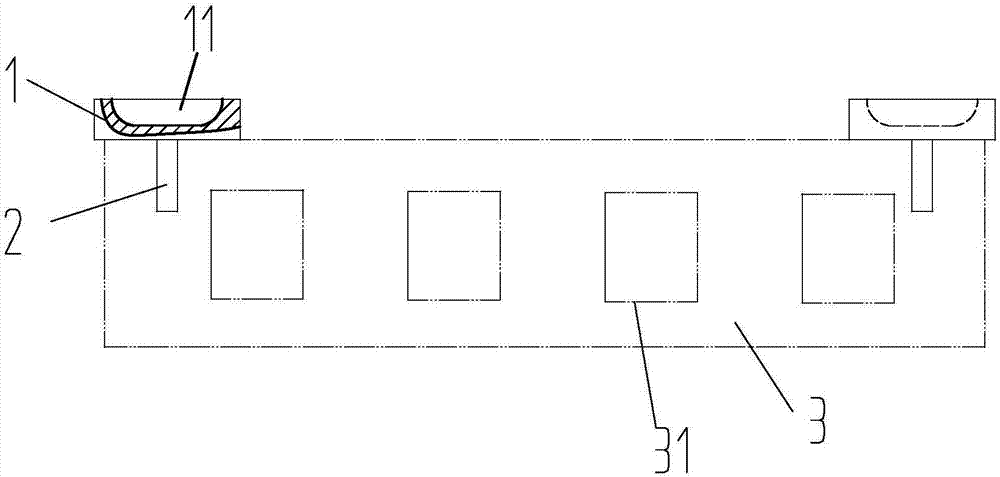

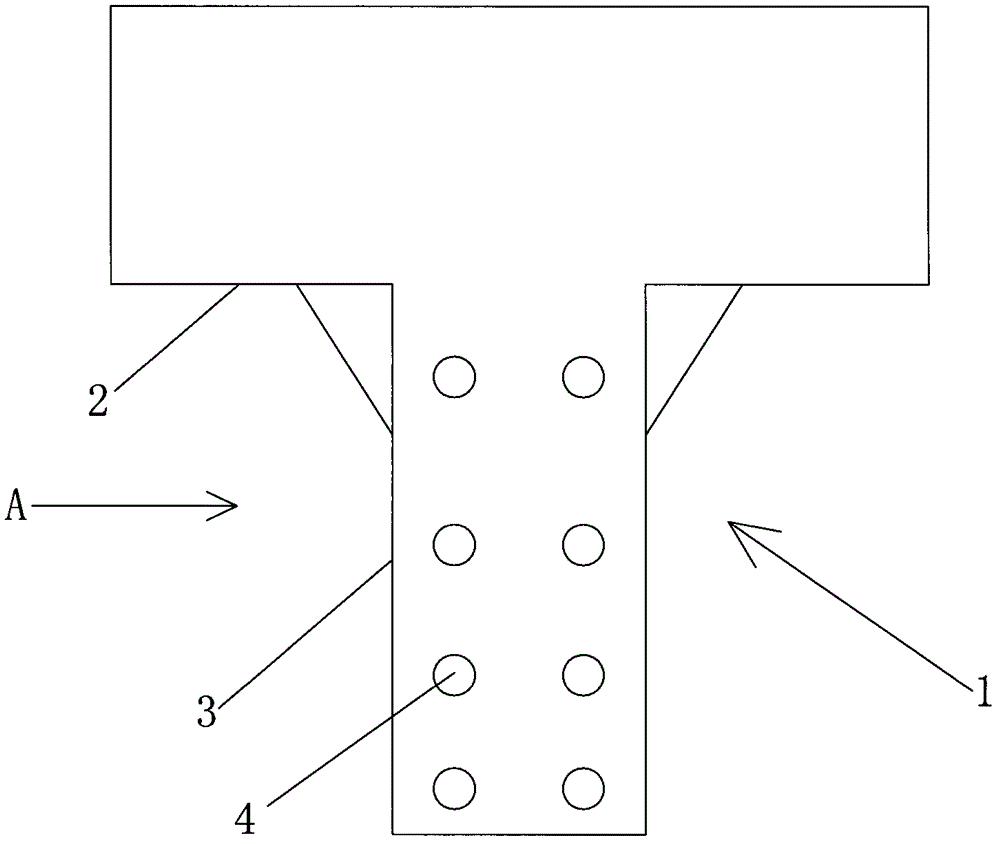

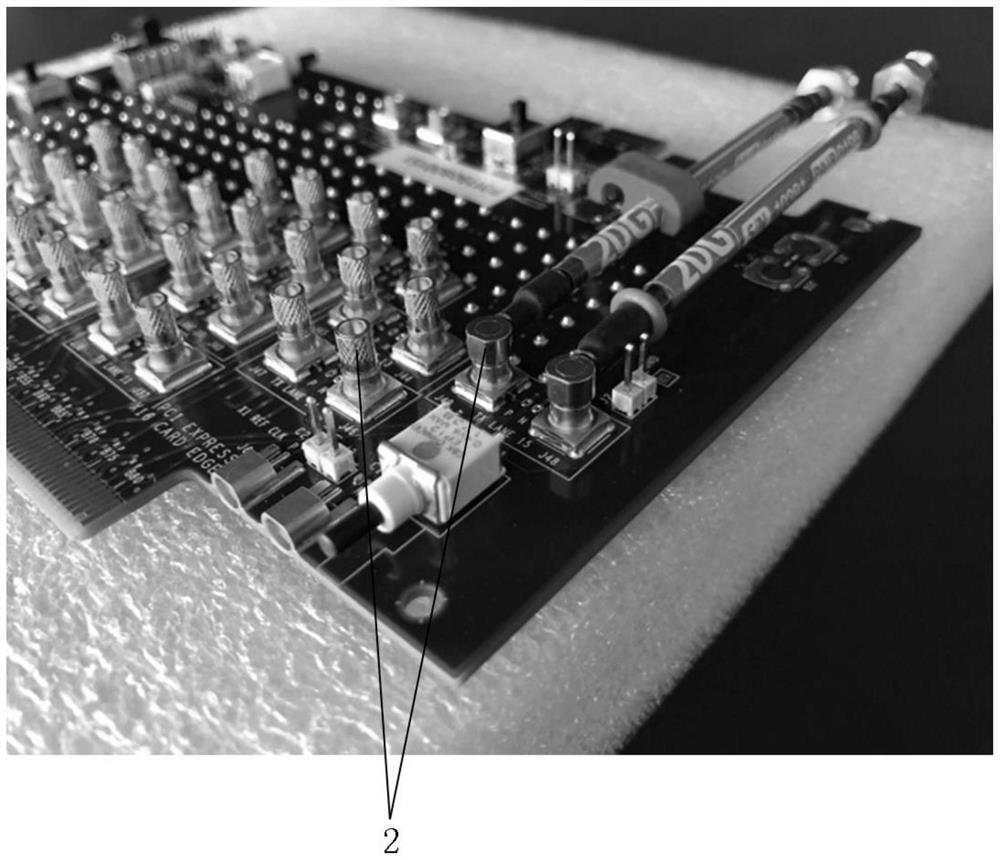

Device for inserting computer memory bank into slot

InactiveCN107263388AImprove work efficiencyEasy to operateMetal-working hand toolsMemory bankEngineering

The invention discloses a device for inserting a computer memory bank into a slot. The device for inserting the computer memory bank into the slot comprises a pressing plate and a positioning block which comprises a first positioning plate and a second positioning plate; the upper ends of the first positioning plate and the second positioning plate are connected with the inner end face of the pressing plate; the inner end face of the pressing plate is matched with the upper end portion of the memory bank; the inner side end faces of the first positioning plate and the second positioning plate are planes, and are arranged in parallel; and the distance between the two inner side end faces is matched with the width of the memory bank. The device for inserting the computer memory bank into the slot is compact in structure, small in weight, convenient to hold and capable of saving labor, reducing the labor intensity of an operator and improving the work efficiency of the operator.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

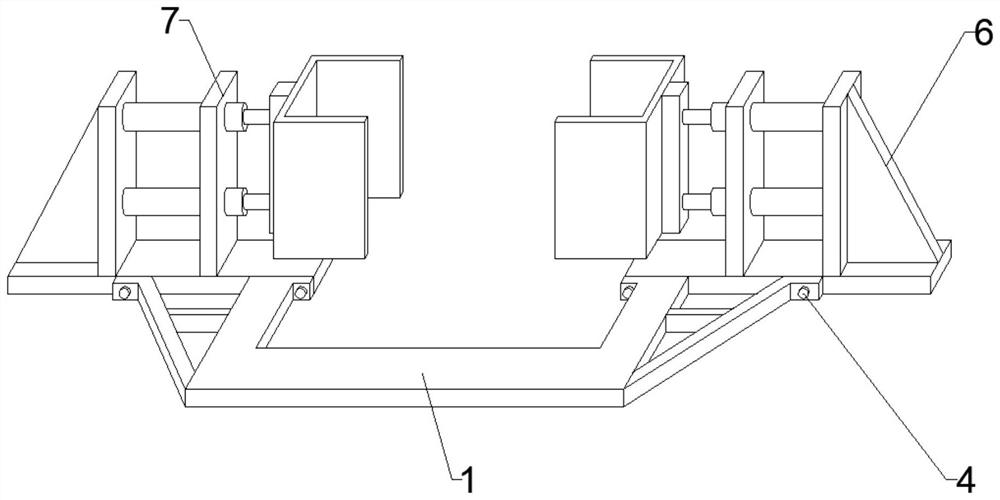

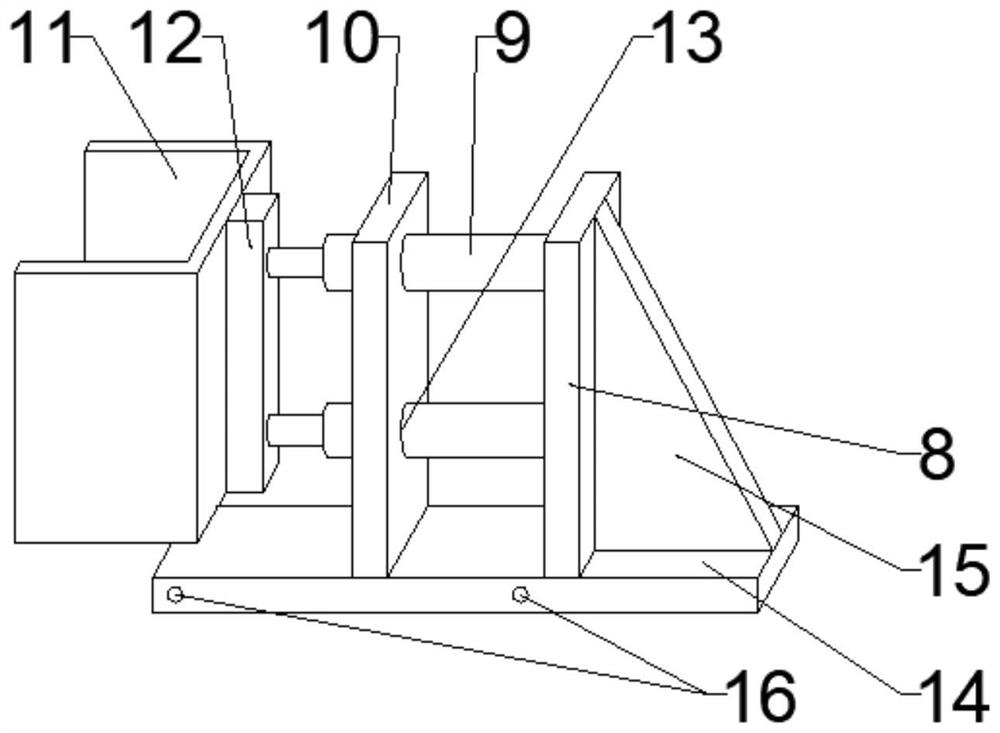

Reinforcing and supporting structure for constructional engineering

ActiveCN112878733AAvoid the problem of difficulty in fully clamping the columnStrong clamping forceBuilding repairsPhotovoltaic energy generationArchitectural engineeringHydraulic pressure

The invention discloses a reinforcing and supporting structure for constructional engineering. The reinforcing and supporting structure comprises a reinforcing and supporting structure connecting frame and reinforcing and supporting structure main bodies, the reinforcing and supporting structure main bodies comprise a right reinforcing and supporting structure main body and a left reinforcing and supporting structure main body, the right reinforcing and supporting structure main body is fixedly arranged at one end of the reinforcing and supporting structure connecting frame, the left reinforcing and supporting structure main body is fixedly arranged at the other end of the reinforcing and supporting structure connecting frame, and the left reinforcing and supporting structure main body and the right reinforcing and supporting structure main body are symmetrically arranged, the reinforcing and supporting structure main bodies are composed of supporting plates, hydraulic telescopic cylinder mounting frames, two hydraulic telescopic cylinders and fixed clamping plates, and the hydraulic telescopic cylinder mounting frames are vertically and fixedly arranged at one end of the top surface of a supporting plate. The reinforcing and supporting structure is formed by assembling the reinforcing and supporting structure connecting frame and the reinforcing and supporting structure main bodies, and is convenient to mount and dismount.

Owner:康建

Vase

The invention relates to the technical field of vases, in particular to a vase. The technical problem to be solved by the invention is that it is not convenient to automatically return to the startingposition after the vase is dumped. In order to solve the above technical problems, A vase include a vase body, the bottom of the vase body is fixedly connected with a hollow base, The top of the inner wall of the hollow base is fixedly connected with a round block, the surface of the round block is provided with a plurality of through grooves, the through groove is inserted with a rotating shaft,a circular sleeve is movably sleeved on the rotating shaft, the surface of the circular sleeve is fixedly connected with a pendulum plate, and the bottom end of the pendulum plate is fixedly connected with a counterweight block. As that vase body of the invention is incline, any several touching the earth contact with the table top, at this time, the incline bar can push any several swing platesto rotate, and the counterweight block can move with the swing plate, the vase body is inclined in the opposite direction to the counterweight block, and therefore, the vase is erected on the table top again.

Owner:南京菲兰化妆品有限公司

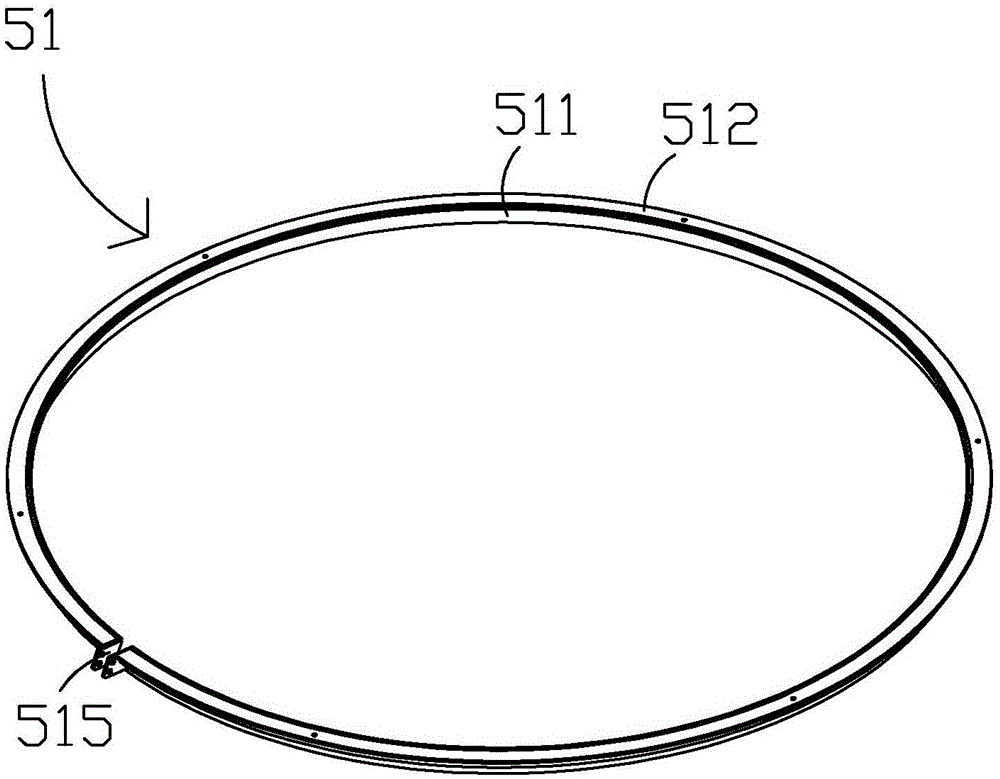

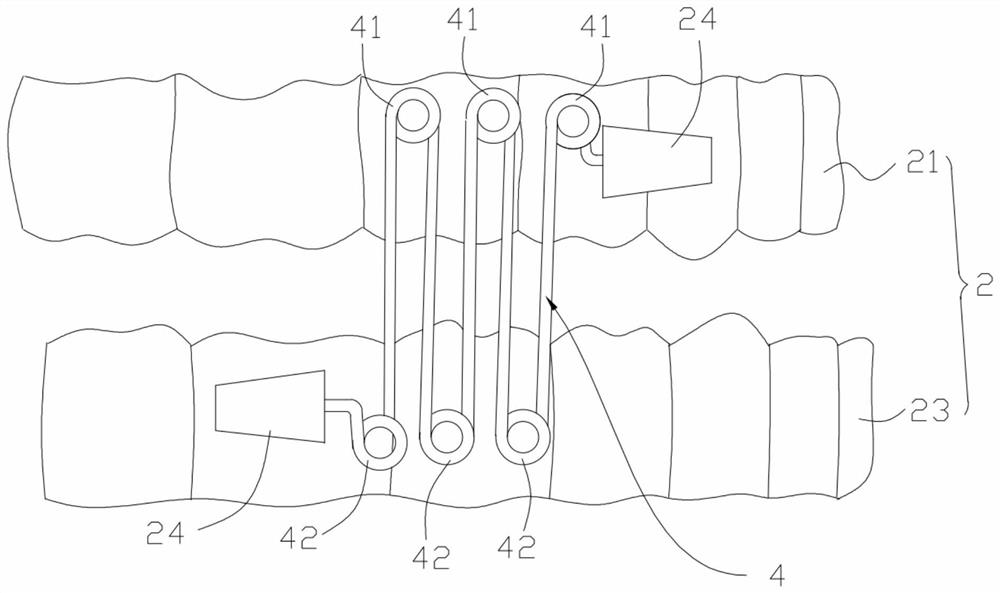

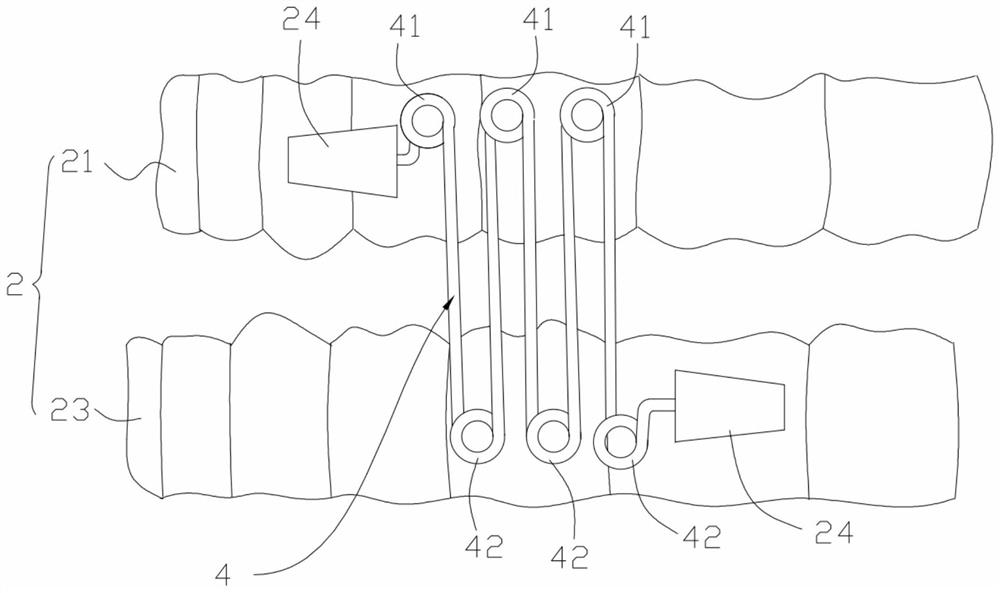

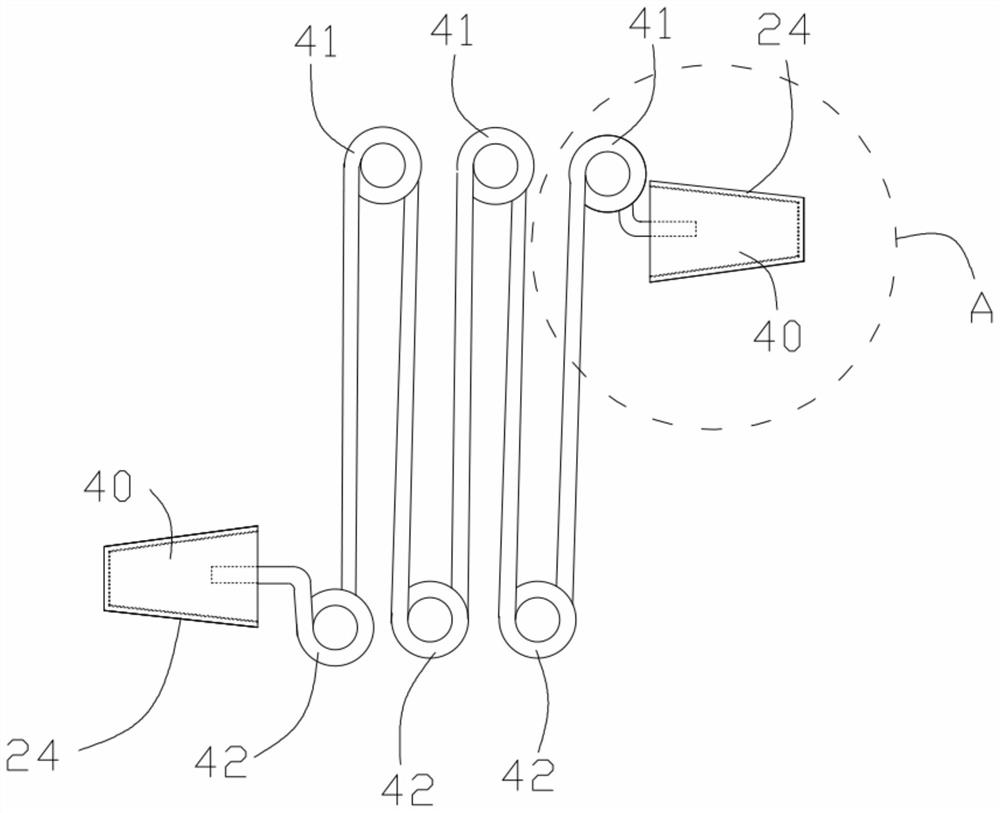

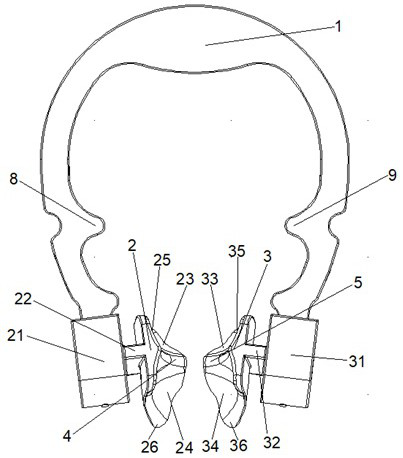

Self-adaptive forming sheet clamping ring

PendingCN114271965AIncrease clamping strengthPrevent collapseDental aidsTeeth cappingTooth fillingEngineering

The self-adaptive forming piece clamping ring comprises a ring body, the ring body is provided with an opening, the two ends of the opening are a first clamping end and a second clamping end, the first clamping end comprises a first fixing part and two first arc-shaped clamping faces, and the first fixing part is fixed to one side of the opening of the ring body; the second clamping end comprises a second fixing part and two second arc-shaped clamping surfaces, and the second fixing part is fixed on the other side of the opening of the ring body; a first elastic connecting part is arranged between the first fixing part and the two first arc-shaped clamping surfaces, one side of the first elastic connecting part is connected with the first fixing part, and the other side of the first elastic connecting part is connected with the two first arc-shaped clamping surfaces. The self-adaptive forming piece clamping ring can adaptively adjust the fitting state of each arc-shaped clamping surface and a tooth wall along with the tooth state to improve the fitting degree of the forming piece and the tooth, is firm in clamping, not easy to fall off, good in tooth filling effect, free from fighting for space with a clearance wedge, and convenient to use.

Owner:唐山恒新医疗器材有限公司

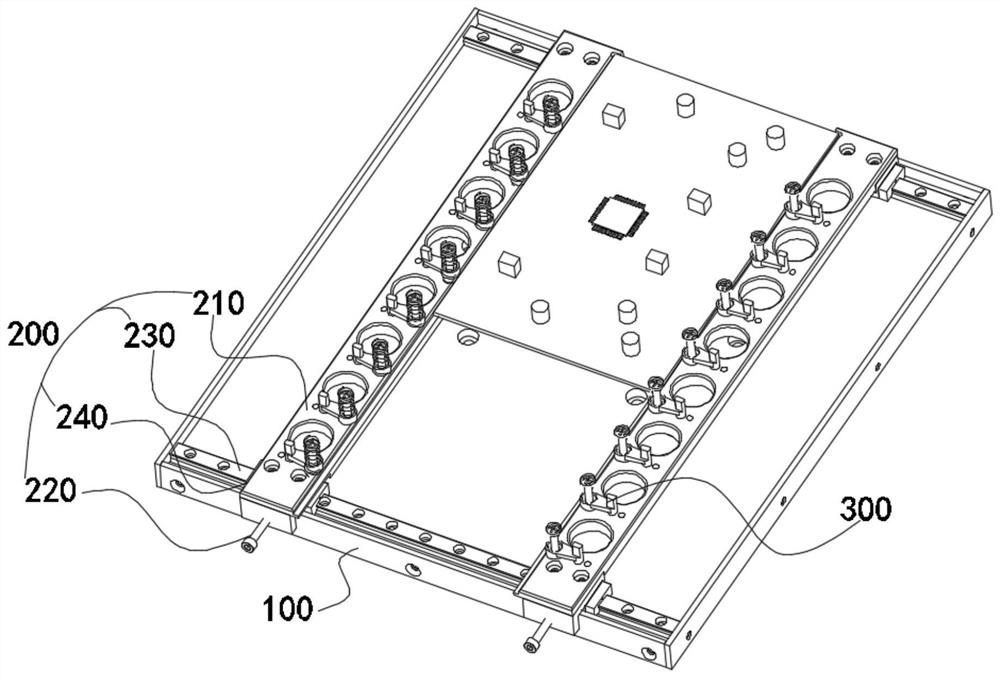

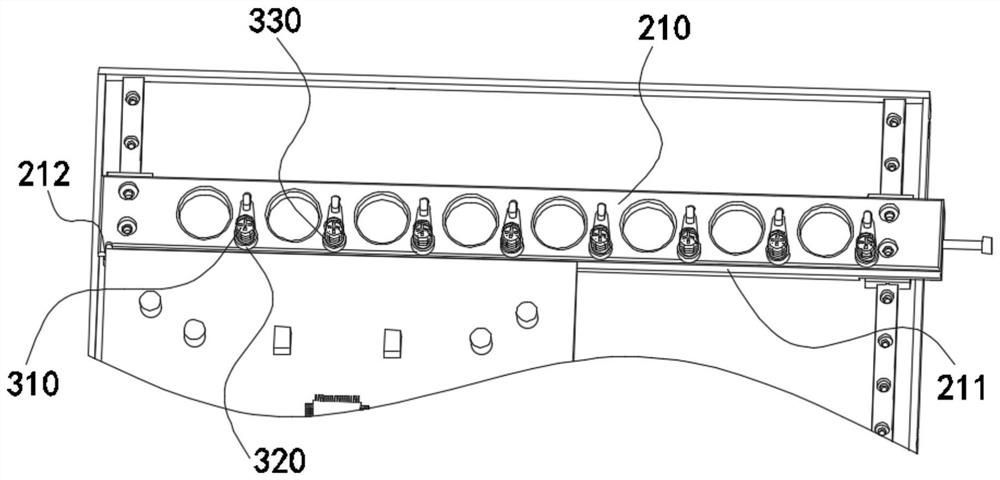

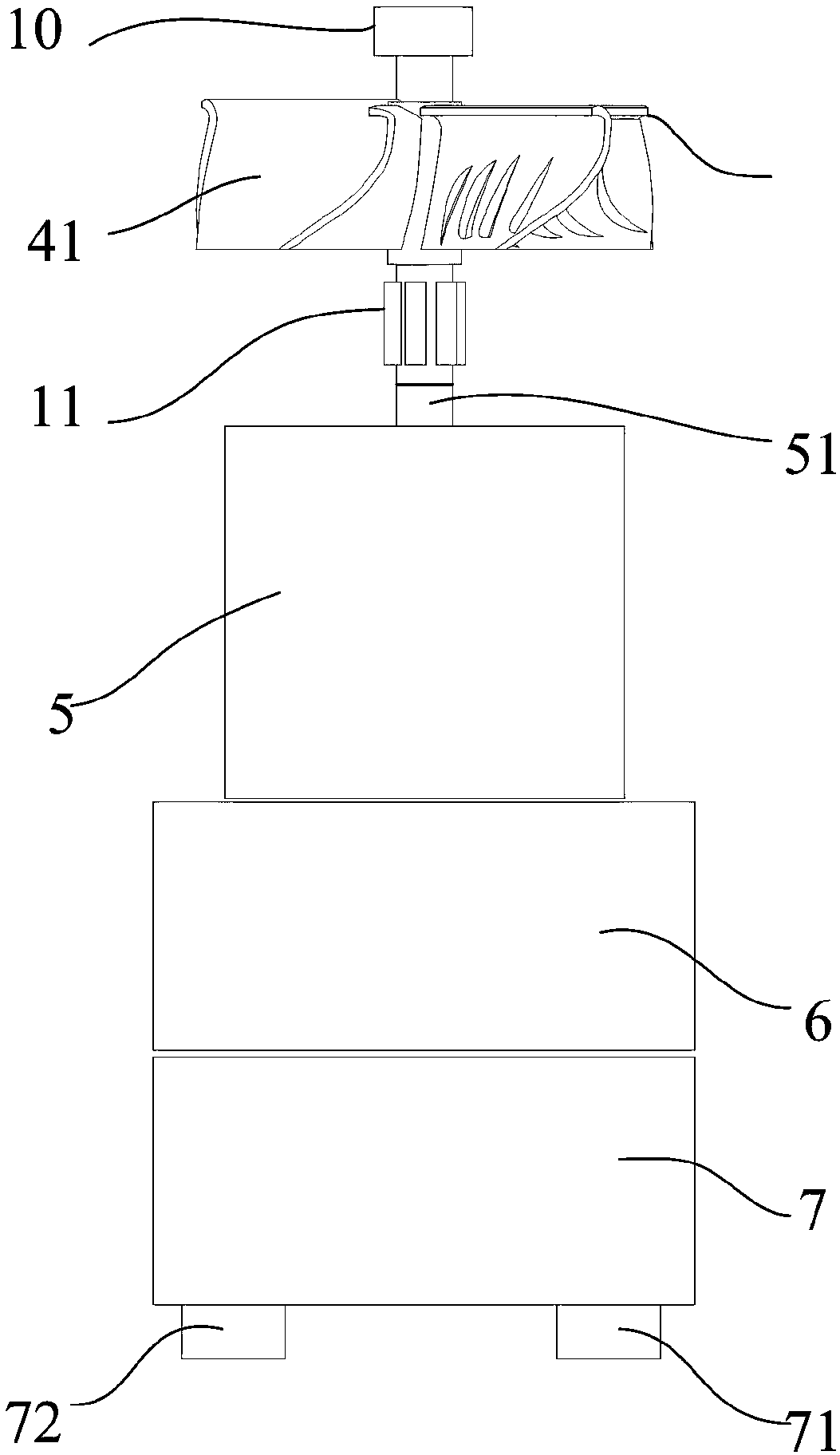

Laser tin soldering working platform

PendingCN114473264AIncrease the force areaPrecise positioningPrinted circuitsMetal working apparatusSolderingMechanical engineering

The invention relates to a laser tin soldering working platform which comprises a bottom plate, a positioning assembly and a fixing assembly. The bottom plate is provided with a working plane; the positioning assembly comprises two positioning plates which are oppositely arranged on the working plane, the two positioning plates are both in sliding connection with the bottom plate, the two positioning plates slide oppositely or oppositely, the opposite sides of the two positioning plates are provided with bearing parts, and the two bearing parts are used for being connected with the two sides of a workpiece in a clamped mode; the fixing assembly comprises two fixing ends in one-to-one correspondence with the two bearing parts, the two fixing ends are connected with the two positioning plates respectively and can move in the direction perpendicular to the working plane, and a clamping gap is formed between the two fixing ends and the corresponding bearing parts and used for clamping a workpiece; the problem that a workpiece is difficult to position accurately under the condition that the workpiece is not damaged by an existing working platform is solved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

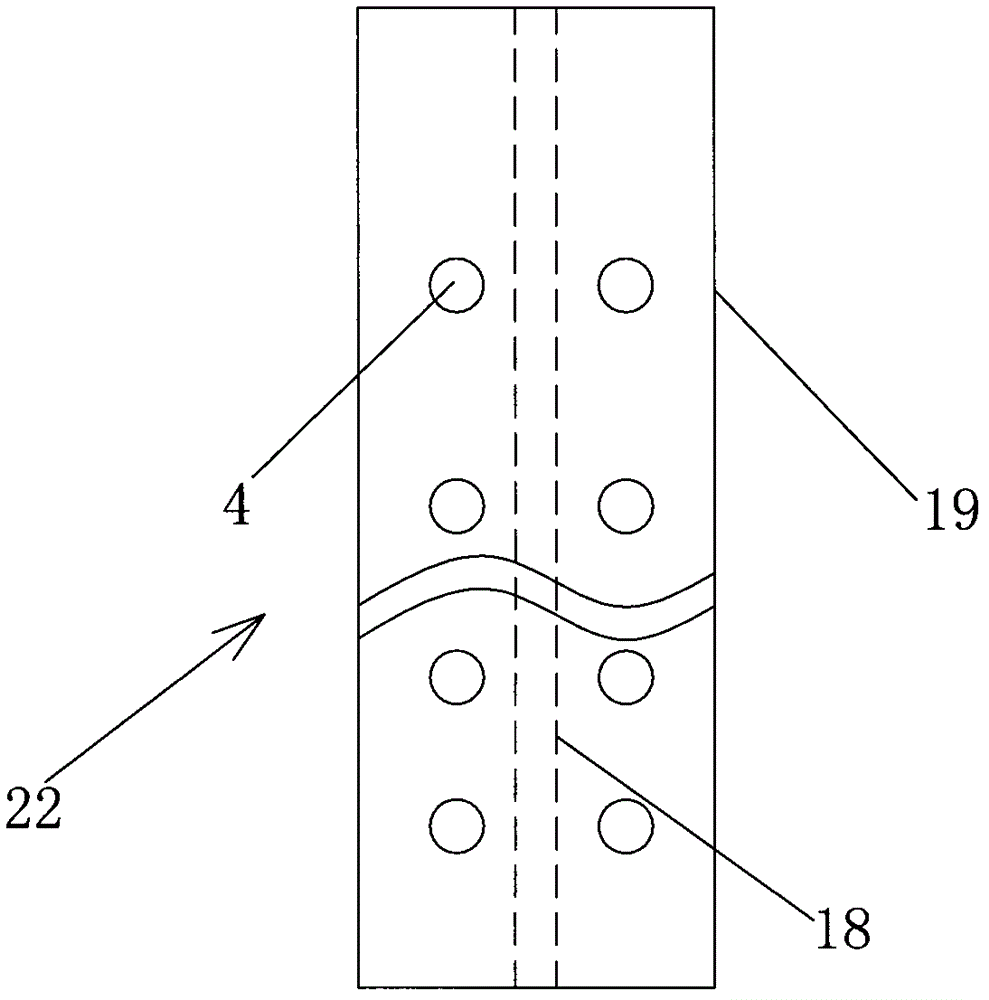

Pile extracting clamp

The invention discloses a pile extracting clamp which is integrally of a T shape. The pile extracting clamp comprises a horizontally-arranged hollow transverse tube and a vertically-arranged hollow longitudinal tube; wherein the upper end and the lower end of the hollow longitudinal tube are opened; the upper end of the hollow longitudinal tube is communicated with the hollow transverse tube; a front side plate and a rear side plate of the hollow longitudinal tube are provided with a plurality of rows of preserved holes from top to bottom; a horizontal moving chuck is arranged in a left half section of the hollow transverse tube; and a horizontal fixed chuck is arranged in a right half section of the hollow transverse tube. According to the clamp, actions forces are applied onto an H-shaped steel flange plate and a web plate; the area of the action forces is large; the centralized stress is reduced; the damage to the pile is reduced; in addition, the clamp is very convenient to operate.

Owner:ZHEJIANG GEOFORE GEOTECHN TECH

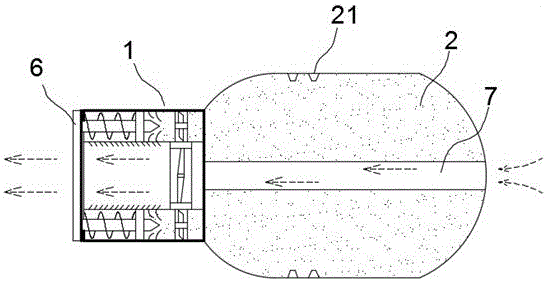

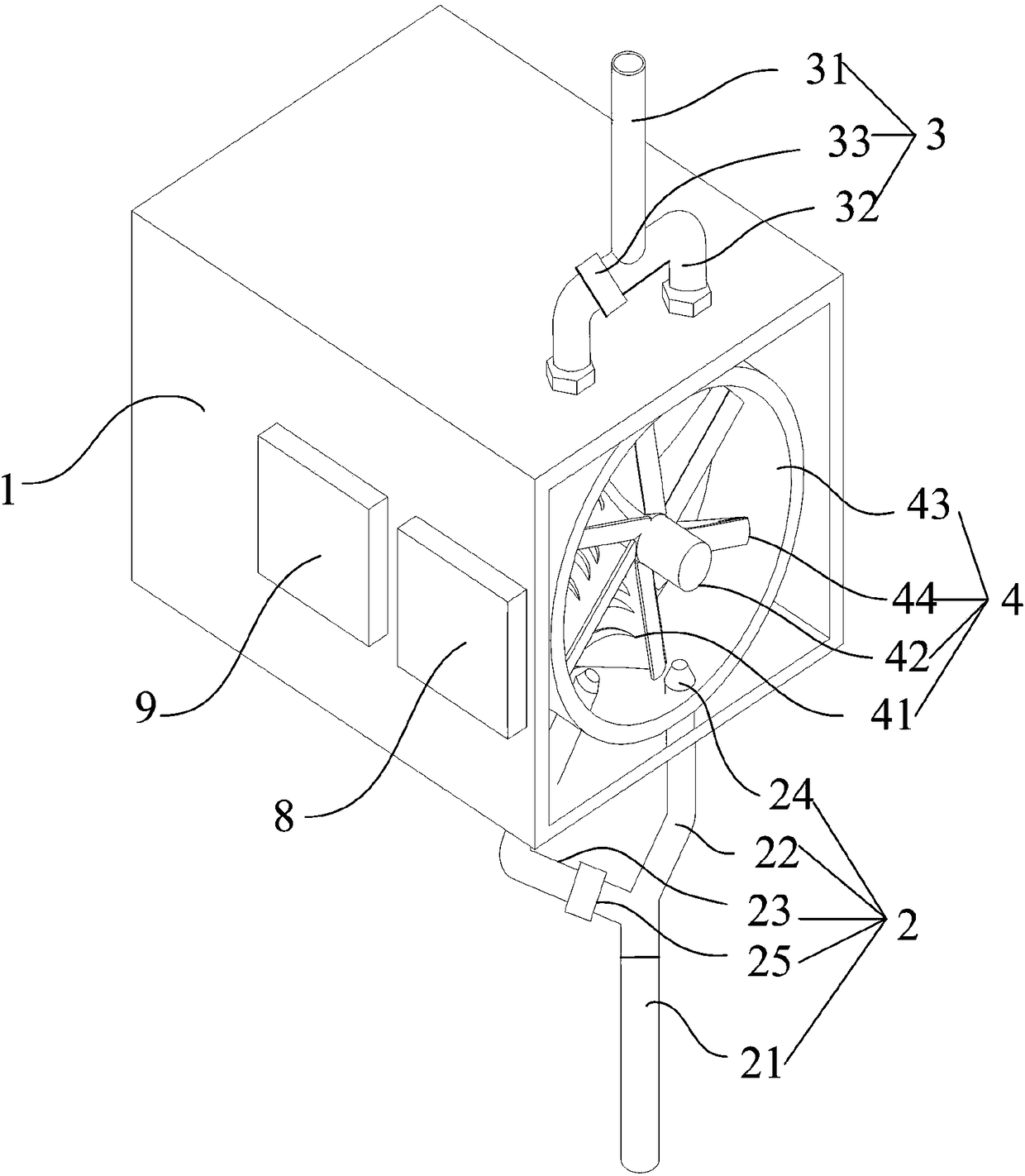

Tap water power generating device

InactiveCN108223246AIncrease water pressureImprove rotation efficiencyHydro energy generationSafety/regulatory devicesAutomatic controlWater discharge

The invention provides a tap water power generating device. The tap water power generating device comprises a case which is internally provided with an impeller, a power generator, a rectifier and a storage battery; the case is connected with a water feeding three-way pipe and a water discharging three-way pipe which are provided with solenoid valves; blades comprise the six rotary blades, and a plurality of half-moon impact grooves are formed in the rotary blades; an automatic control display device and a wireless charging panel are arranged on the case and are electrically connected with thestorage battery; the automatic control display device comprises a pressure sensor and controllers of the solenoid valves; and the storage battery is provided with a USB interface and a mains supply interface. According to the tap water power generating device, the blades are impacted to rotate through the water feeding three-way pipe and the water discharging three-way pipe so that the power generator can be driven to generate power, when water pressure is insufficient, the power generator can serve as a motor to drive the impeller to rotate so that the water pressure can be increased, electricity can be supplied to external electric appliances through the storage battery and the wireless charging panel, and the mains supply can be connected to the storage battery so that the storage battery can be charged.

Owner:王桐冉

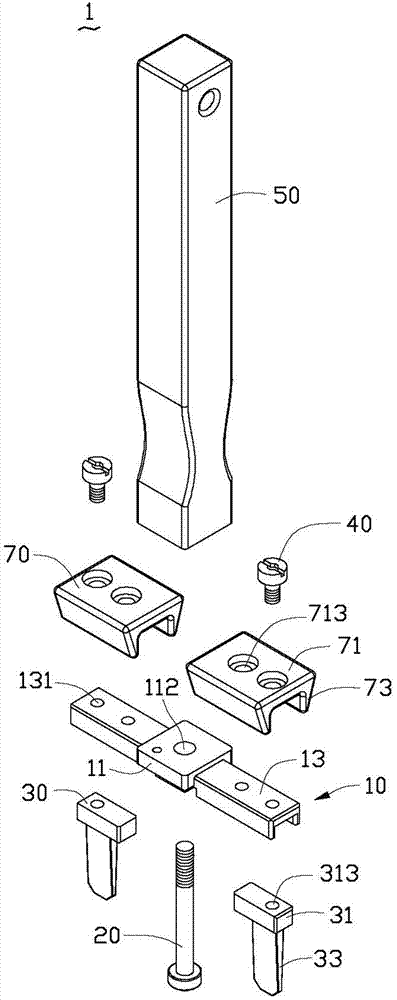

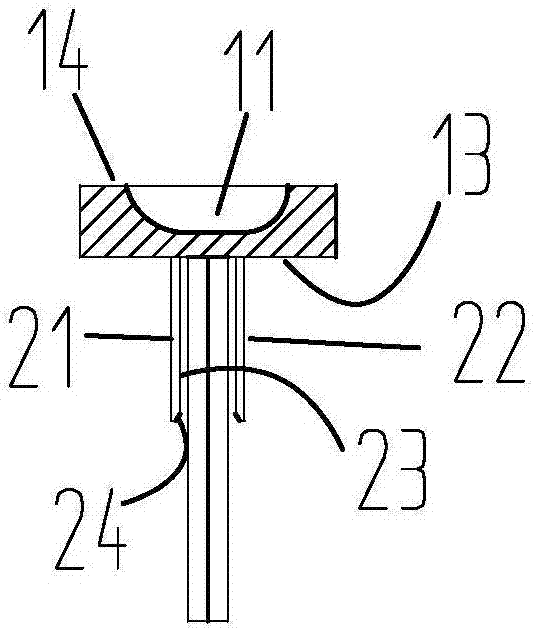

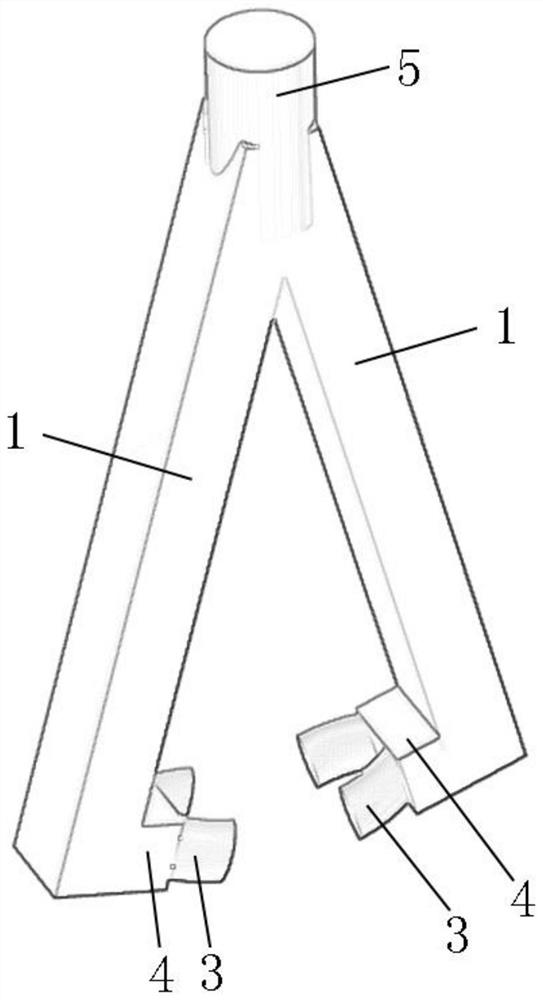

Connector pull-out jig

InactiveCN111628391AIncrease the force areaIncrease vertical frictionCoupling device engaging/disengagingComputer periphery connectorsEngineeringMechanical engineering

The invention discloses a connector pull-out jig which comprises two clamping supporting legs and clamping arms, one ends of the two clamping supporting legs are connected with each other, a preset included angle is formed between the two clamping supporting legs, and the clamping arms are arranged at the tail ends of the clamping supporting legs and used for clamping the outer surface of a connector plug in the circumferential direction. Therefore, an operator can firstly arrange the two clamping supporting legs at the two sides of an SMP connector in a spanning manner, then adjusts the relative positions of the tail ends of the two supporting legs and the outer surface of the SMP connector so that the clamping arms at the tail ends of the two supporting legs abut against and clamp the outer surface of the connector plug inserted in the SMP connector, and finally applies a tightening force by pinching the two clamping supporting legs by palms and fingers at the same time and then applies vertical upward force, so that the connector plug can be pulled out of the SMP connector. Compared with the prior art, when the SMP connector plug puller is used, the force application area of theoperator on the two clamping supporting legs is greatly increased, so that the SMP connector plug can be conveniently and quickly pulled out, and meanwhile, the SMP connector is prevented from beingdamaged in the pulling-out process.

Owner:GUANGDONG INSPUR BIG DATA RES CO LTD

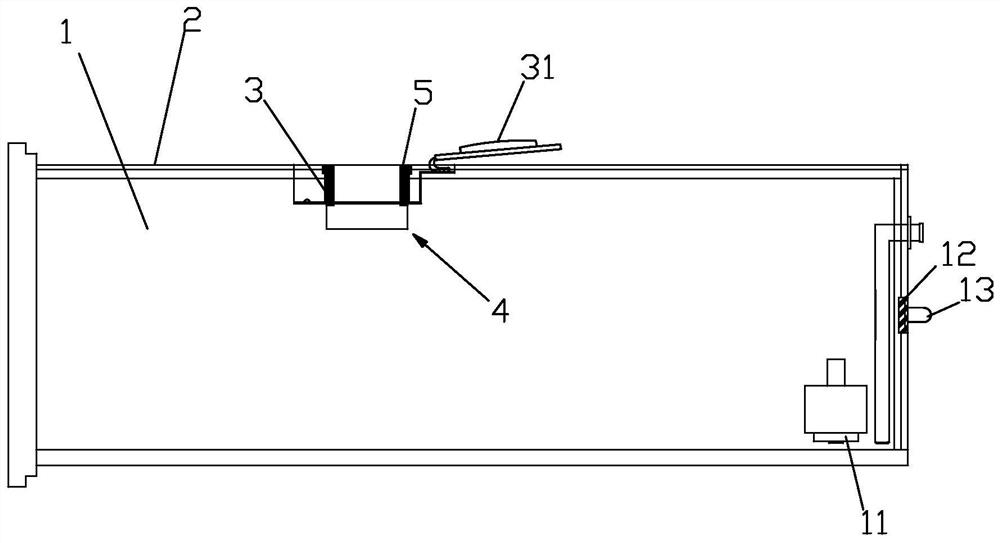

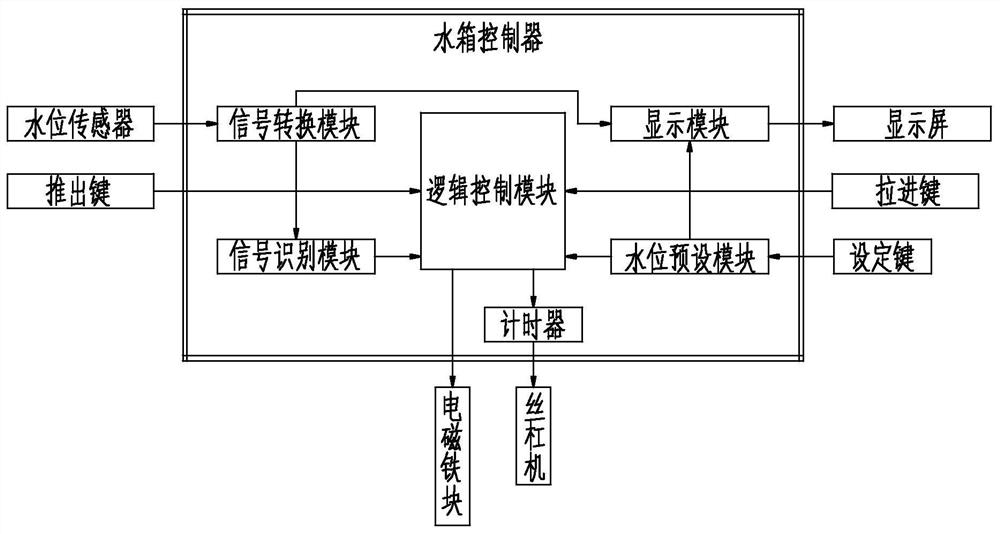

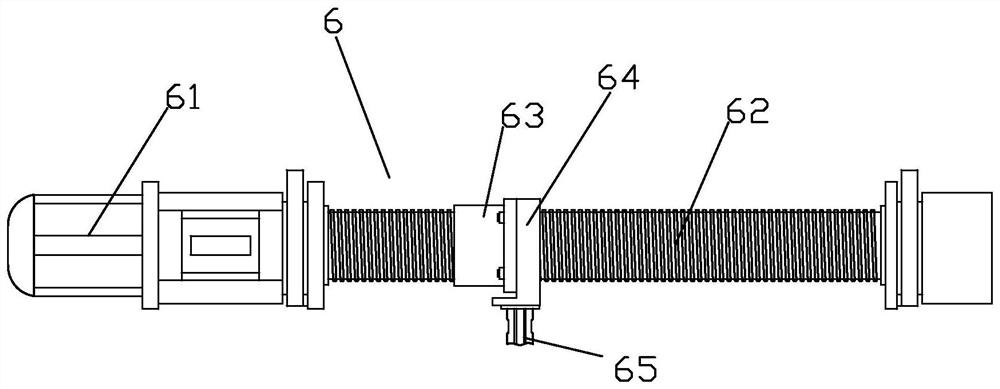

Intelligent water tank for steam oven and water adding method thereof

InactiveCN112515486AAvoid falling overAvoid problems such as water tank jammingSteam cooking vesselsRoasters/grillsSmart waterProcess engineering

The invention discloses an intelligent water tank for a steam oven and a water adding method thereof. The intelligent water tank is installed in a water tank opening of the steam oven and further comprises a water tank controller, a water level sensor and an intelligent push-pull mechanism, the water tank controller is connected with a water level sensor and receives a water level signal detectedby the water level sensor, and the water tank controller controls the intelligent push-pull mechanism; the water level sensor is installed in the tank body, and the intelligent push-pull mechanism isconnected with a water tank shell and pushed out of or pulled into the intelligent water tank. The water tank is designed to be an intelligent water tank and provided with the water tank controller, the water level sensor and the intelligent push-pull mechanism, the water tank controller automatically controls the intelligent push-pull mechanism according to a water level signal detected by the water level sensor, and water in the water tank is automatically pushed out after being used up and reminds a user to add water; the water tank is automatically controlled and does not need to be manually taken, and the problems of water tank turnover, water tank jamming and the like caused by human errors are avoided; and the water tank is pushed out and pulled in more safely and reliably.

Owner:浙江大坤电器科技有限公司

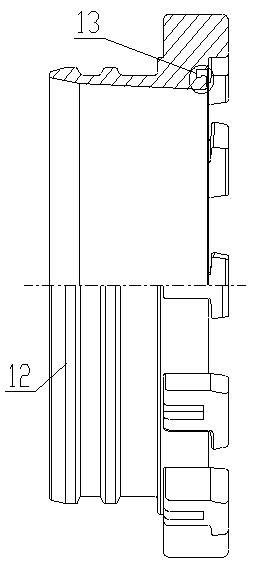

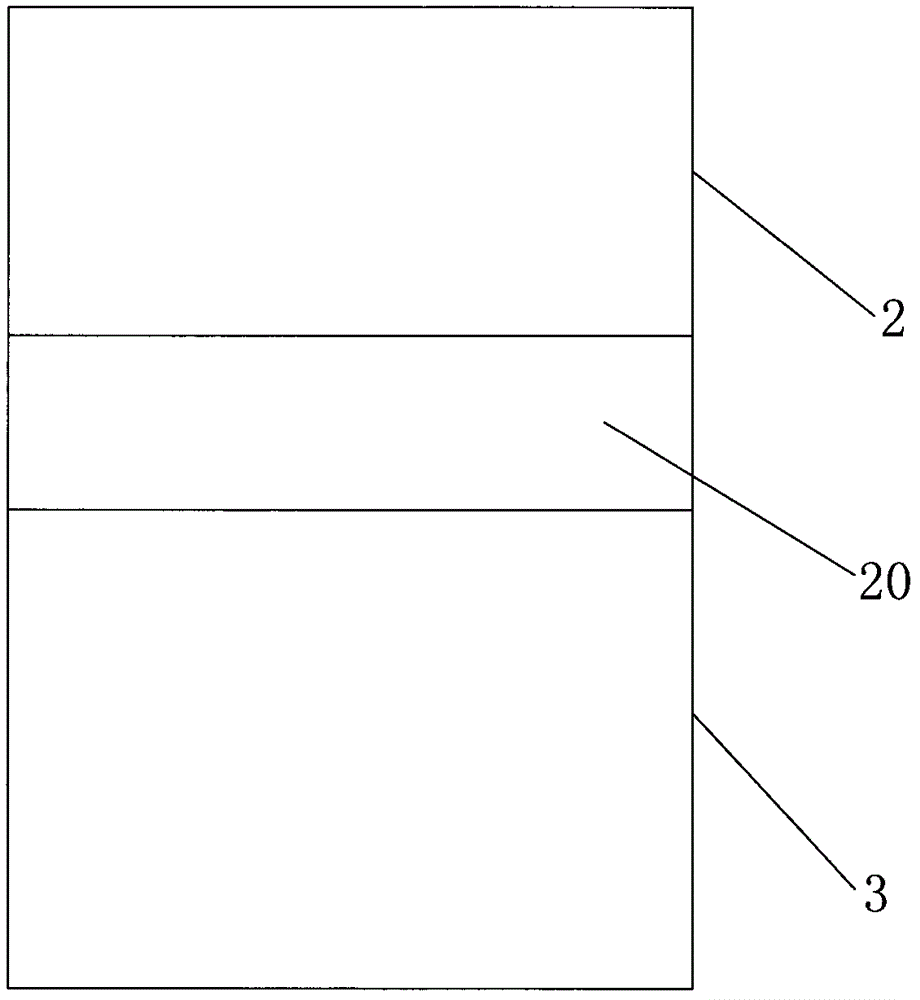

Infusion set

The invention provides an infusion device, which can be used for an infusion pump and comprises a transmission shaft, a liquor stopping block and at least one liquor pushing block, wherein the transmission shaft is connected with a driving device; the liquor stopping block comprises a first liquor stopping block and a second liquor stopping block and can be sleeved to the transmission shaft in a rotating way and periodically extrude an infusion tube along with the rotation of the transmission shaft so as to temporarily stop the flowing of liquor in the infusion tube; the at least one liquor pushing block is sleeved to the transmission shaft in the rotating way, periodically extrudes the infusion tube so as to push the liquor to flow in the infusion tube and is positioned between the first and second liquor stopping blocks; and the lateral end face of the liquor pushing block extruding the infusion tube is a flat end face.

Owner:BEIJING AEONMED

Device and method for press-fitting flat-plate semiconductor components on press-fitting equipment

ActiveCN103367276BIncrease the force areaPrecisely control the size of the pressing forceSemiconductor/solid-state device detailsSolid-state devicesEngineeringMechanical engineering

The invention provides a device for press-fitting a flat plate type semiconductor element on press-fitting equipment. The device comprises a pressing plate, a pressing mechanism which is arranged on the pressing plate and comprises a central column body provided with an end flange, and an elastic element which is arranged between the end flange and the pressing plate, wherein the central column body can move along the direction vertical to the pressing plate by means of an adjusting element so that the elastic element remains under a preset pretightening force; the device is connected with the press-fitting equipment through the pressing plate so that the surface of the pressing mechanism is contacted with the surface of the flat plate type semiconductor element to be press-fitted; and the pretightening force of the elastic element is transferred onto the flat plate type semiconductor element through the pressing mechanism by releasing the adjusting element. The invention also provides a corresponding method. According to the method and the device disclosed by the invention, the accuracy of press-fitting force is ensured; and when the semiconductor element works normally, the influence on the press-fitting force caused by strong external vibration is prevented.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

Multi-angle glass curtain wall keel connecting device

The invention relates to the technical field of glass curtain walls, and discloses a multi-angle glass curtain wall keel connecting device which comprises a panel, clamping pieces are fixedly installed at the corners in the panel, sliding rods are fixedly installed at the right ends of the clamping pieces, sliding cavities are formed in the sliding rods, the sliding cavities are filled with gas, and the clamping pieces are fixedly installed at the right ends of the clamping pieces. A keel is installed on the right side of the sliding rod, a supporting rod is fixedly installed on the side, close to the sliding rod, of the keel, and the piston end of the supporting rod is movably connected with the sliding cavity and divides the sliding cavity into a left cavity located on the left side of the piston end and a right cavity located on the right side of the piston end. An air distribution hole is formed in the supporting rod, and the left cavity can communicate with the external environment through the air distribution hole. Through the arrangement of the sliding rods and the supporting rods, the contact area of the air bag and the panel is increased, part of thrust applied to the clamping piece by the panel can be transferred to the air bag, therefore, force application concentration of the panel is avoided, and the probability that the panel is broken is reduced.

Owner:江苏华发装饰有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com