Self-adaptive forming sheet clamping ring

A self-adaptive, forming sheet technology, applied in the field of dental restoration, can solve the problems of no retention structure, no separation force, low fit between the forming sheet and the tooth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

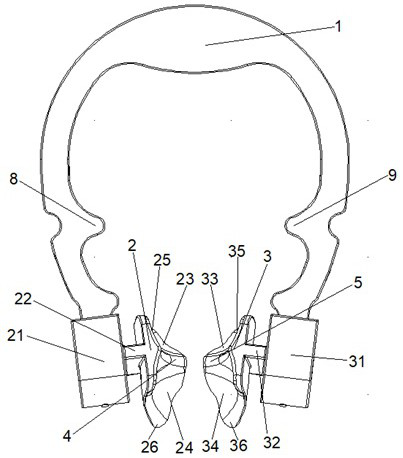

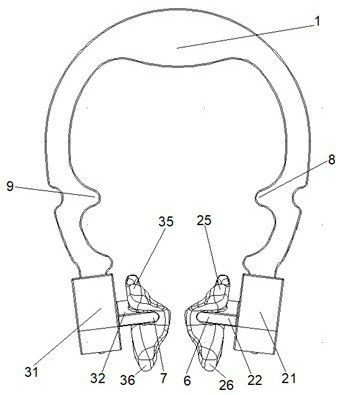

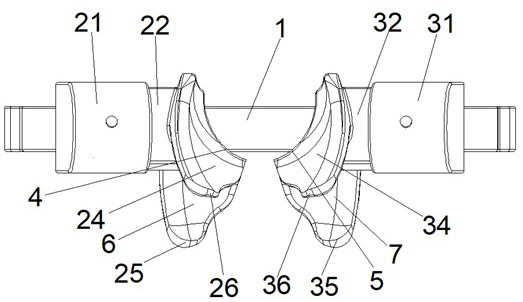

[0019] Below in conjunction with accompanying drawing, the present invention will be further described:

[0020] Such as Figure 1 to Figure 4 As shown, the self-adaptive forming sheet clamping ring includes a ring body 1, the ring body 1 has an opening, and the two ends of the opening are a first clamping end 2 and a second clamping end 3, and the first clamping end 2 includes The first fixing part 21, the first elastic connecting part 22, the first arc-shaped clamping surface 23 and the first arc-shaped clamping surface 24, the first fixing part 21 is fixed on the opening side of the ring body 1, and the first elastic connecting part One side of 22 is connected to the first fixing part 21, and the other side is connected to the first arc-shaped clamping surface 23 and the first arc-shaped clamping surface 24, and the first elastic connecting part 22 elastically deforms to make the first arc-shaped clamping surface Surface 23 and the first arc-shaped clamping surface 24 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com