Separation blade dismantling jig

A technology of baffles and jigs, which is applied in the field of jigs, can solve the problems of affecting the appearance and performance of the chassis, time-consuming operation of dismantling the baffles, and high dismantling costs, so as to achieve undamaged appearance and working performance, saving man-hours, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

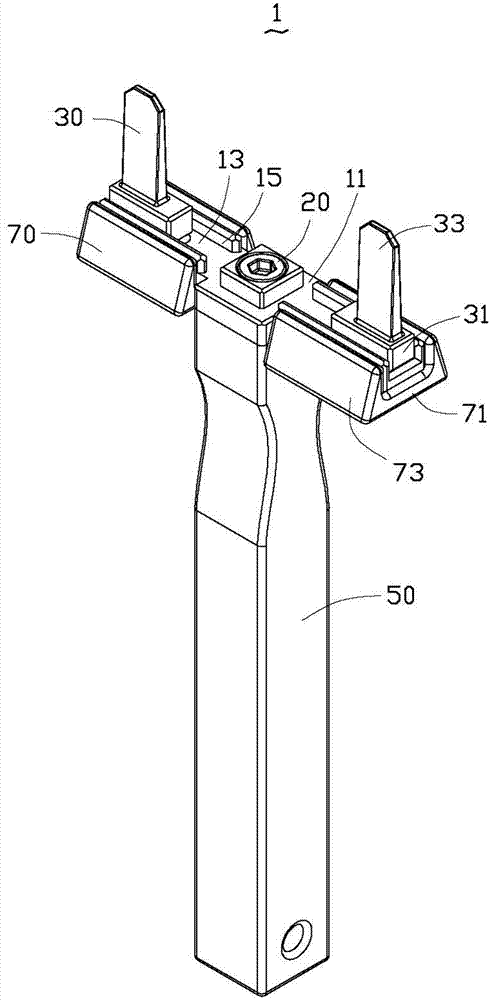

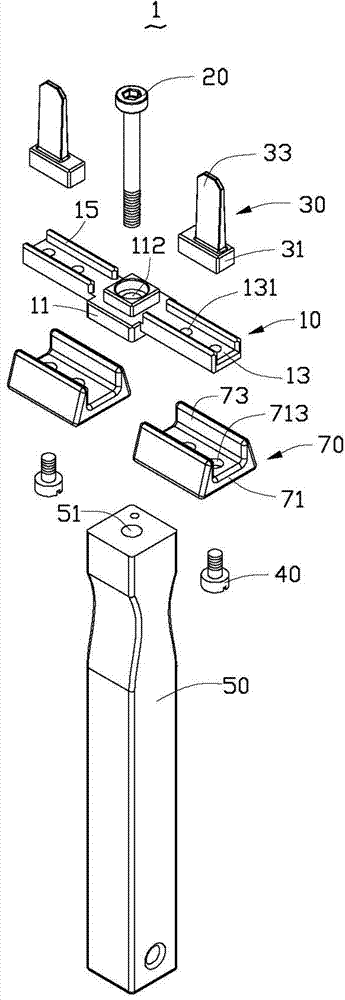

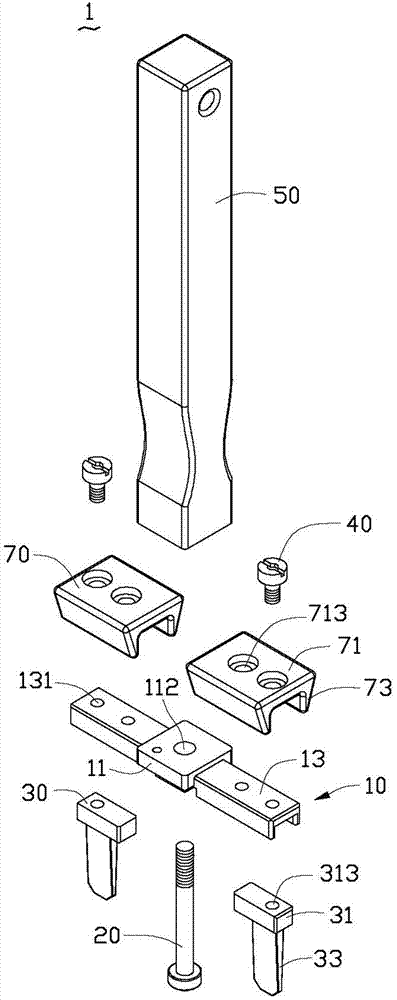

[0013] see figure 1 and Figure 4 , The block removal jig 1 of the present invention is used to remove the block 3 of the chassis 2 of the desktop computer, so as to install the expansion card port. The jig 1 for removing the baffle can also be used to remove the baffles of the cabinets of servers and other similar electronic products. The blocking piece removal jig 1 includes a bracket 10 , two picks 30 mounted on opposite ends of the top surface of the bracket 10 , and a handle 50 mounted on the middle of the bottom surface of the bracket 10 . The two skids 30 can be installed at different positions of the bracket 10 , so as to adjust the distance between the two skids 30 , so that the two skids 30 can fit the two openings 4 of the blocking pieces 3 of different sizes. The handle 50 is used for the convenience of the operator to operate the jig 1 for removing the blocking sheet.

[0014] Please also see figure 2 and image 3 , the bracket 10 includes a joint portion 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com