Device and method for press-fitting flat plate type semiconductor element on press-fitting equipment

A semiconductor, flat-panel technology, applied in the field of press-fitting devices, can solve problems such as inconvenient engineering application of flat-panel semiconductor components, and achieve the effects of avoiding human error, ensuring accuracy, and facilitating mechanical structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

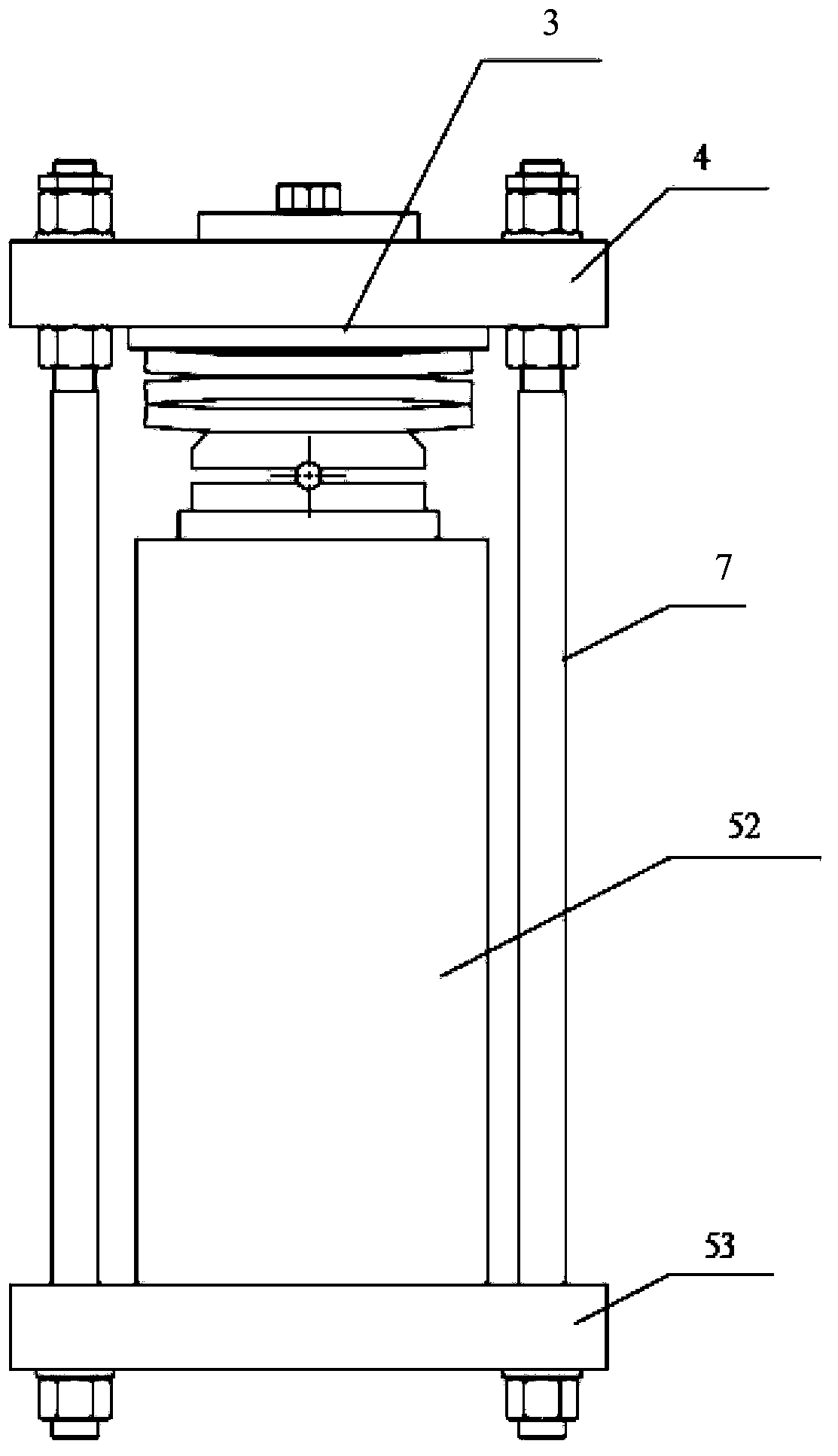

[0037] figure 1 A press-fitting installation equipped with a device 3 according to the invention is schematically shown.

[0038] Wherein the device 3 is arranged on the upper part of the equipment in the figure, and the device 3 is fixed relative to the lower pressing plate 53 by the screw rod 7 . The power device series of the planar semiconductor element 52 to be pressed is placed between the pressing device 3 and the lower pressing plate 53 , and the device 3 is used to apply a pressing force to the semiconductor element 52 .

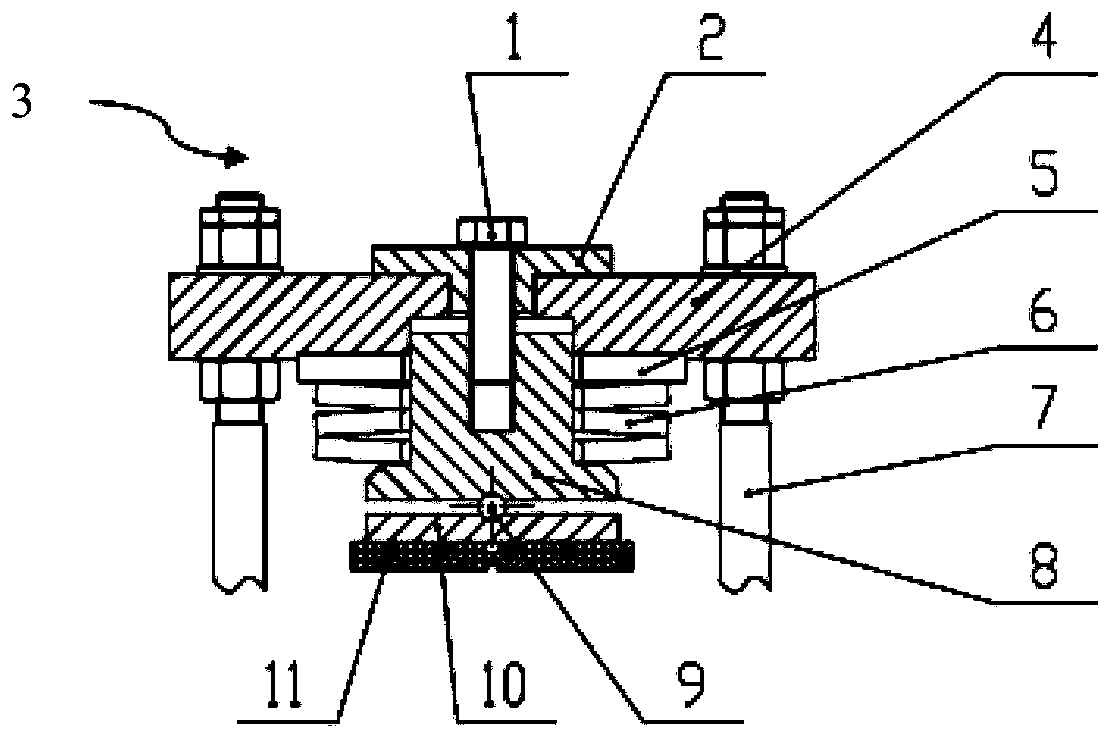

[0039] figure 2 The press-fitting device 3 is shown in detail.

[0040] The device 3 comprises a pressure plate 4 for fixing the device 3 to the whole apparatus.

[0041] The device 3 also includes a guide post 8 connected to the pressure plate 4 through the disc spring 6 , the guide post 8 can move relative to the press plate 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com