Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Improve unstacking efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cargo unstacking method and device and unstacking system

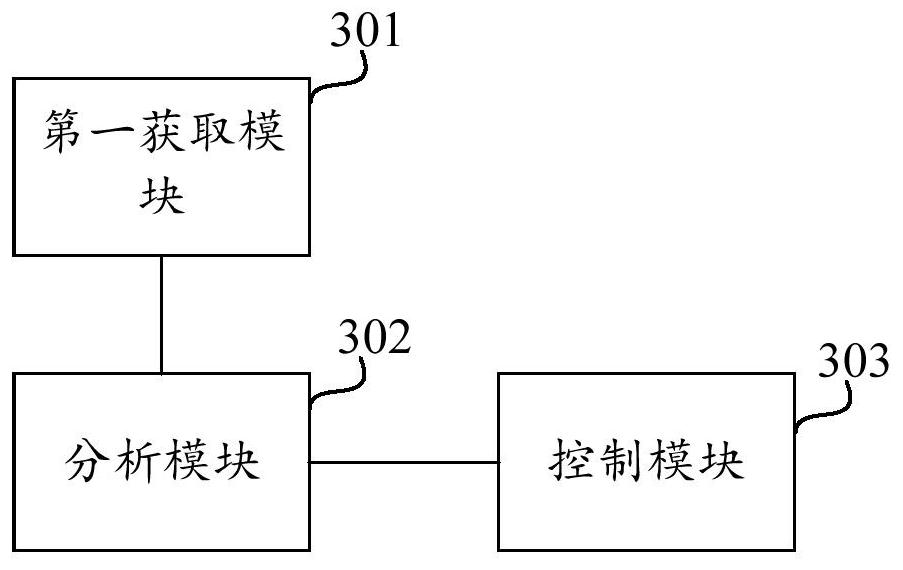

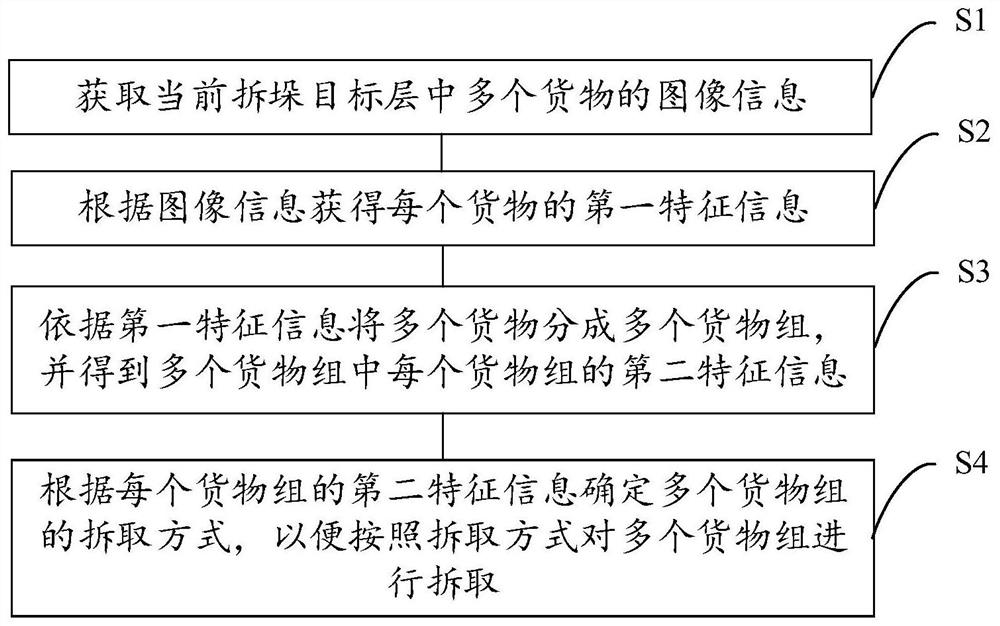

ActiveCN109592433APrecise positioningImprove unstacking efficiencyStacking articlesDe-stacking articlesComputer science

The embodiment of the invention provides a cargo unstacking method and device and an unstacking system, and relates to the technical field of material conveying. The cargo unstacking method comprisesthe steps of obtaining the image information of multiple cargos in a current unstacking target layer; obtaining the first characteristic information of each cargo according to the image information; dividing the multiple cargos into multiple cargo groups according to the first characteristic information, and obtaining the second characteristic information corresponding to each cargo group; and according to the second characteristic information of each cargo group, determining the unstacking mode of the multiple cargo groups, and thus unstacking the multiple cargo groups according to the unstacking mode. The cargo unstacking method can assist the unstacking system to carry out more accurate and efficient unstacking.

Owner:CHINA HEFEI TAIHE OPTOELECTRONICS TECH

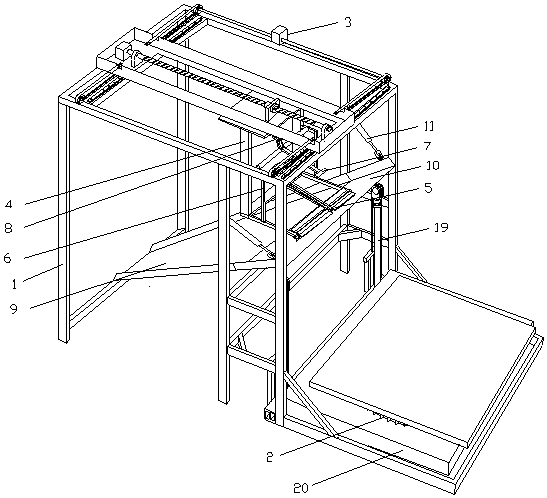

Un-stacking method and stack bag detachment device

InactiveCN102030194AImprove unstacking efficiencyImprove efficacyLifting framesDe-stacking articlesEngineeringDelivery system

The invention relates to an un-stacking method and a stack bag detachment device. The un-stacking method comprises the following steps of: A, conveying a stack disc into a stack bin of the stack bag detachment device through a forklift; B, dragging bags on the stack disc into corresponding chutes by an operator, continually promoting the stack in the stack detachment operation, shifting out the bags layer by layer, and making the bags entering the chutes fall on a subsequent conveying device in turn; and C till the whole stack disc is completely detached, resetting the stack bag detachment device to prepare for detaching the next stack disc. The stack bag detachment device designed by the invention can assist the operator in quickly detaching the bags in the stack bag into single bags, and is convenient for supplying materials to a conveying system or loading. During stack detachment, the top bag of the stack is at an easy-carrying position all the time, and the bags can be moved into the chutes along the dragging of the operator. The device for finishing the stack detachment operation can save manpower, greatly reduce the labor intensity of the operator, and remarkably improve the speed and efficiency of stack detachment.

Owner:CIMC ENRIC ENGINEERING TECHNOLOGY CO LTD

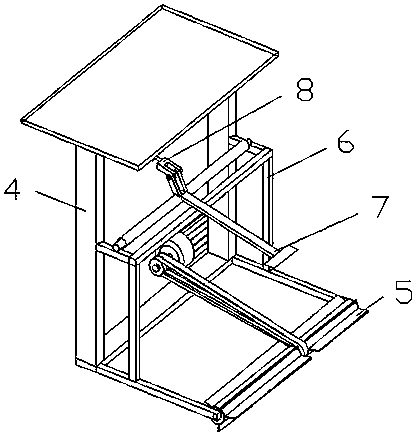

Unstacking machine

PendingCN110371692AFar adaptableCompact structureDe-stacking articlesHydraulic cylinderReciprocating motion

The invention provides an unstacking machine, and belongs to the technical field of unstacking devices. The unstacking machine aims at solving the problems that in the use process of an existing unstacking device, the unstacking efficiency is low and stability is poor. The unstacking machine comprises a base, a lifting platform, lifting devices, hydraulic cylinders and turnover shaft bases. The turnover shaft bases are installed on the base. Each lifting device is installed on the corresponding turnover shaft base in a hinged manner through a turnover center shaft. The cylinder body ends of the hydraulic cylinders are installed on the base. The output ends of the hydraulic cylinders are connected with the lifting devices. Under the push effect of the hydraulic cylinders, the lifting devices do the pitching action relative to the base. The lifting platform is installed on the lifting devices and linearly reciprocates on the lifting devices. The automatic operation of the unstacking workcan be conveniently completed, and the unstacking efficiency is improved.

Owner:HARBIN BOSHI AUTOMATION

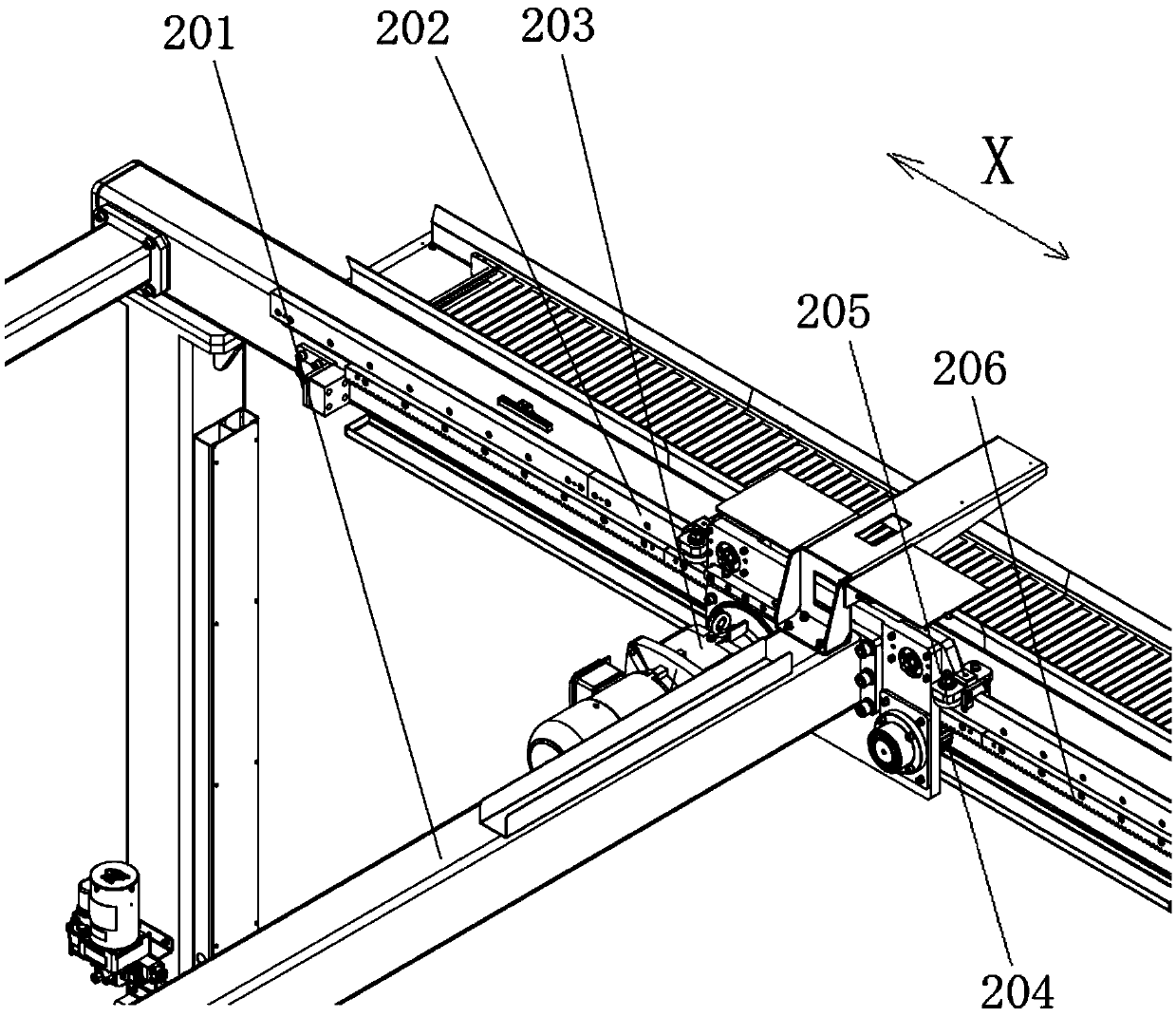

Bidirectional unstacking and taking device and bidirectional cargo unstacking equipment

PendingCN109484865ASimple structureLow costDe-stacking articlesVehicle dissasembly recoveryMarine engineering

Owner:CHINA HEFEI TAIHE OPTOELECTRONICS TECH

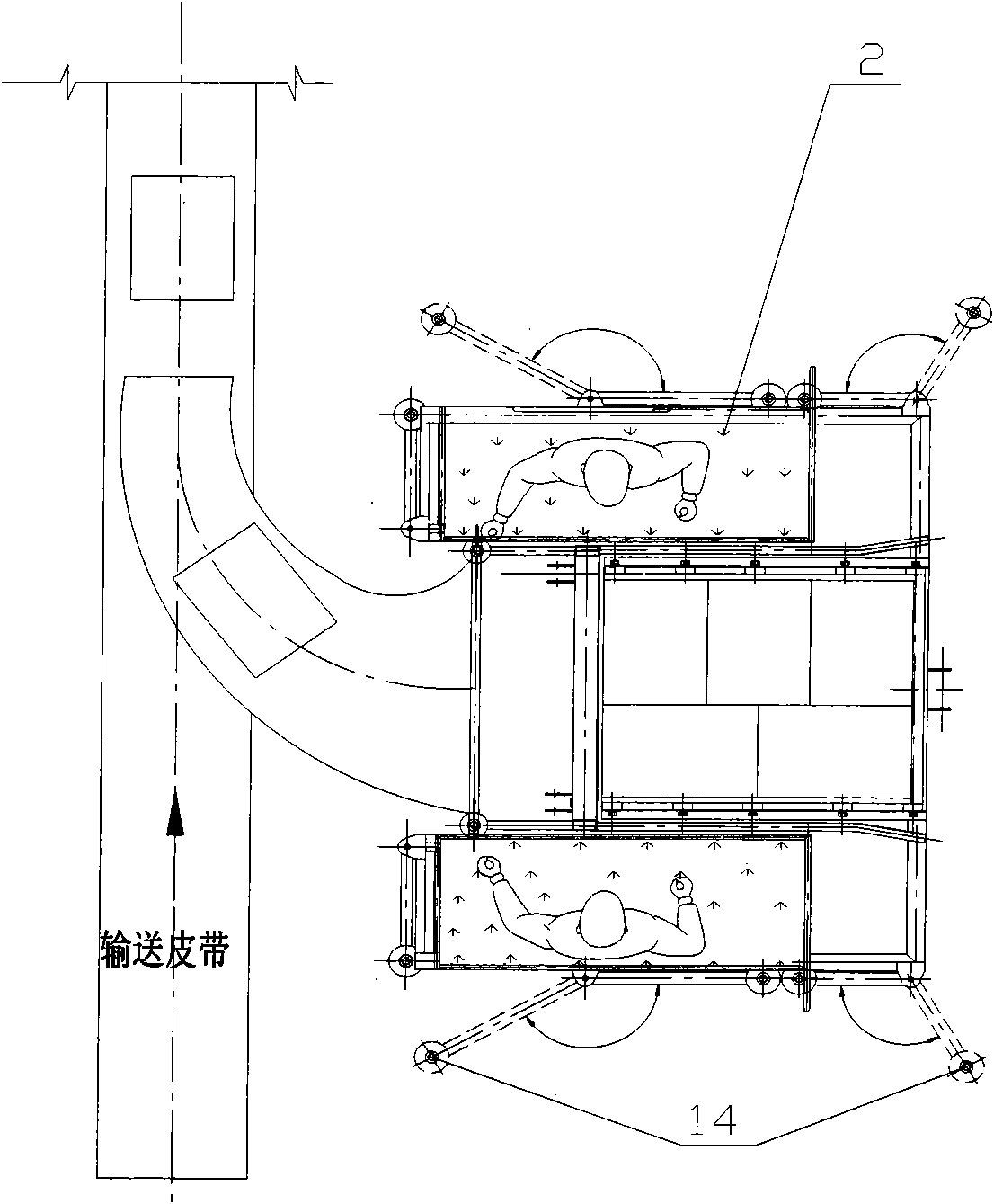

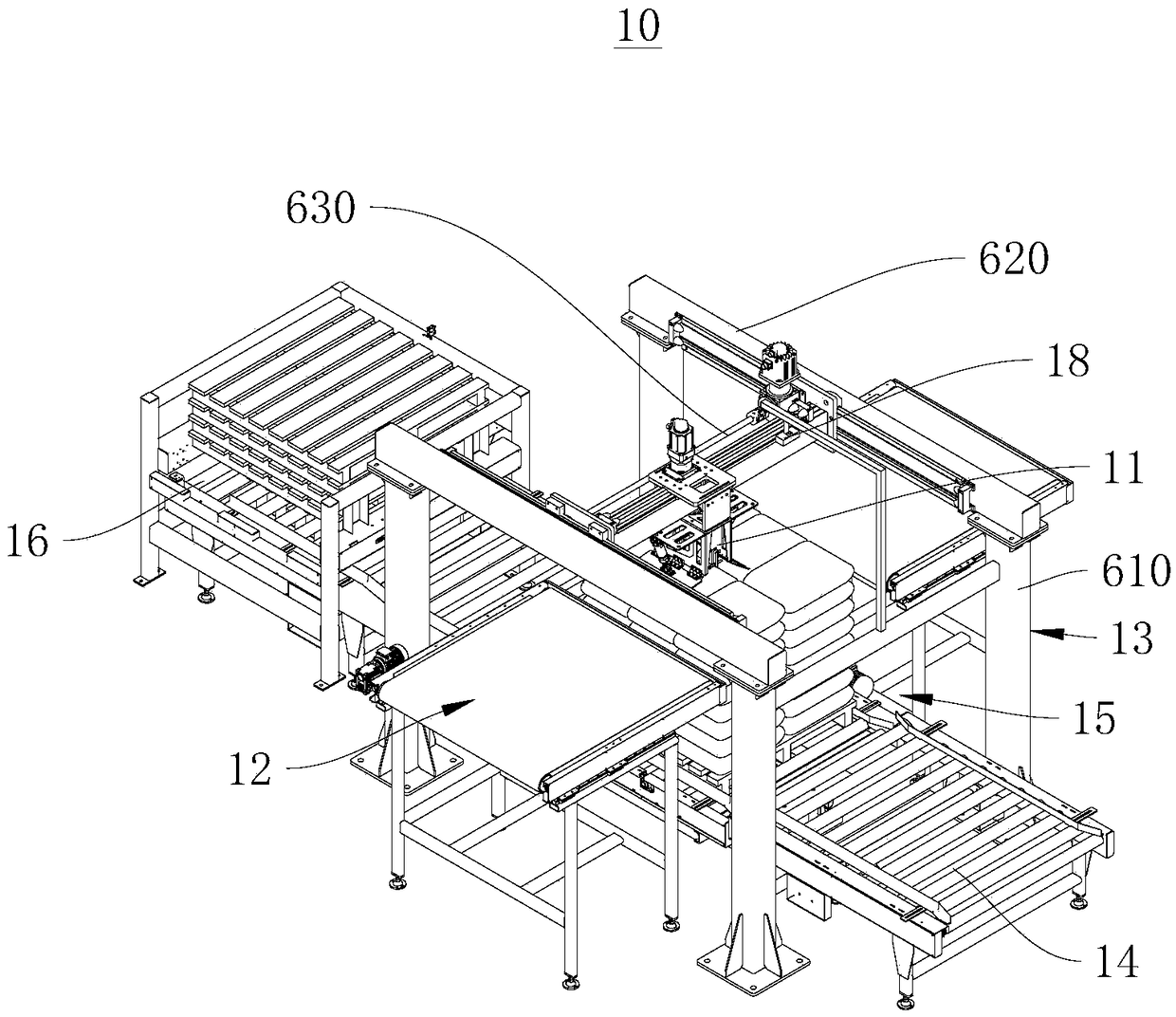

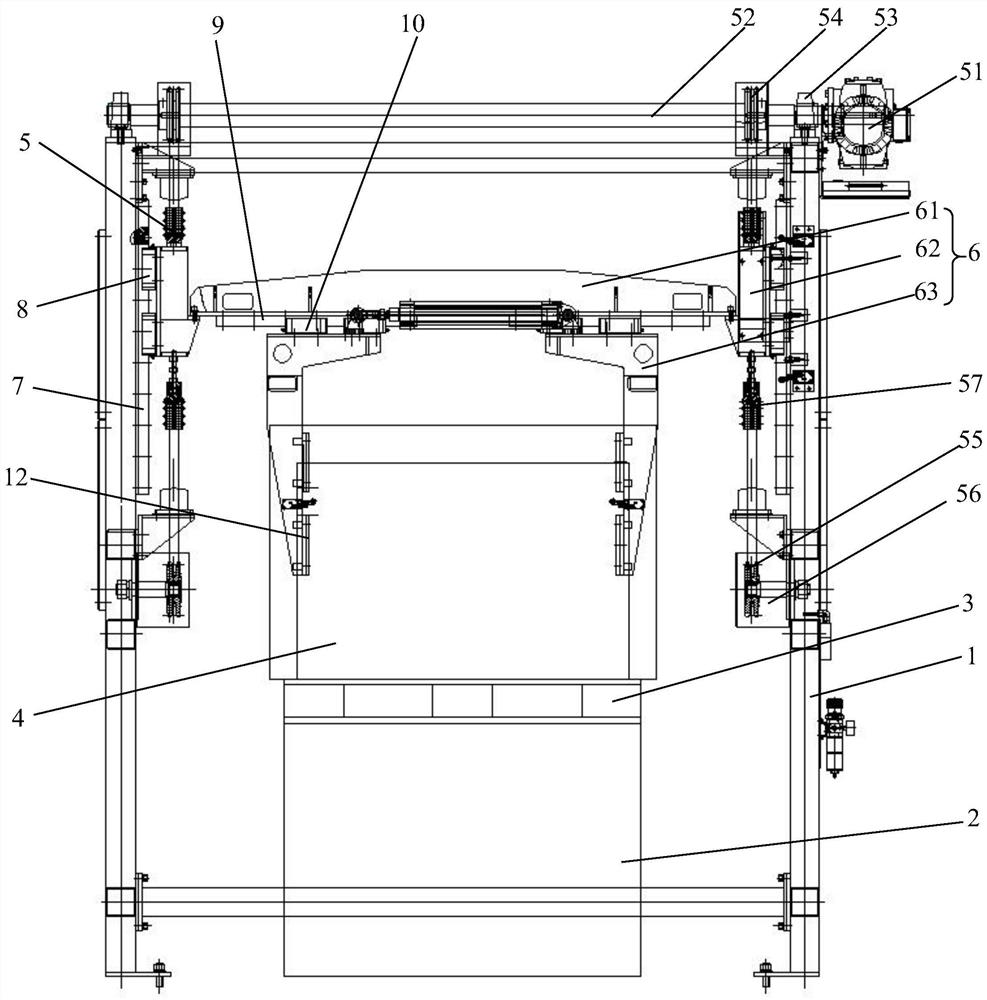

Automatic destacking system for bagged material packages

InactiveCN110775650ADepalletization to achieveImprove unstacking efficiencyStacking articlesDe-stacking articlesRobot handProcess engineering

The invention discloses an automatic destacking system for bagged material packages. The automatic destacking system includes an automatic destacking machine, an empty tray recovery device and a material transport and storage device. A lifting and rotating platform is arranged at the feeding end of the automatic destacking machine. One end of the lifting and rotating platform is arranged corresponding to the discharge end of the material transport and storage device, and the other end of the lifting and rotating platform is arranged corresponding to a tray inlet of the empty tray recovery device. A planar moving manipulator for grabbing materials on the lifting and rotating platform is arranged at the top of the discharge end of the automatic destacking machine corresponding to the liftingand rotating platform. The automatic destacking system has the beneficial effects of high destacking efficiency, high degree of automation, automatic recovery of trays, stable grabbing of the material packages and simple manipulator action.

Owner:MIANYANG LANAO HEAVY MACHINERY MFG

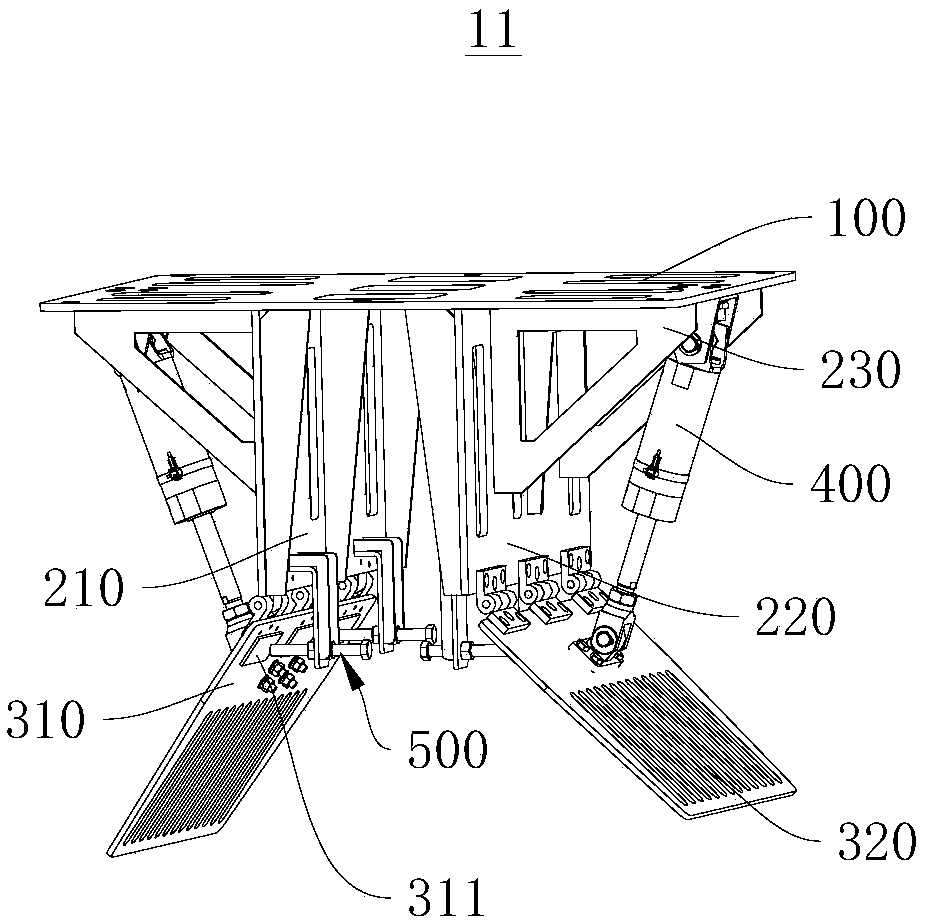

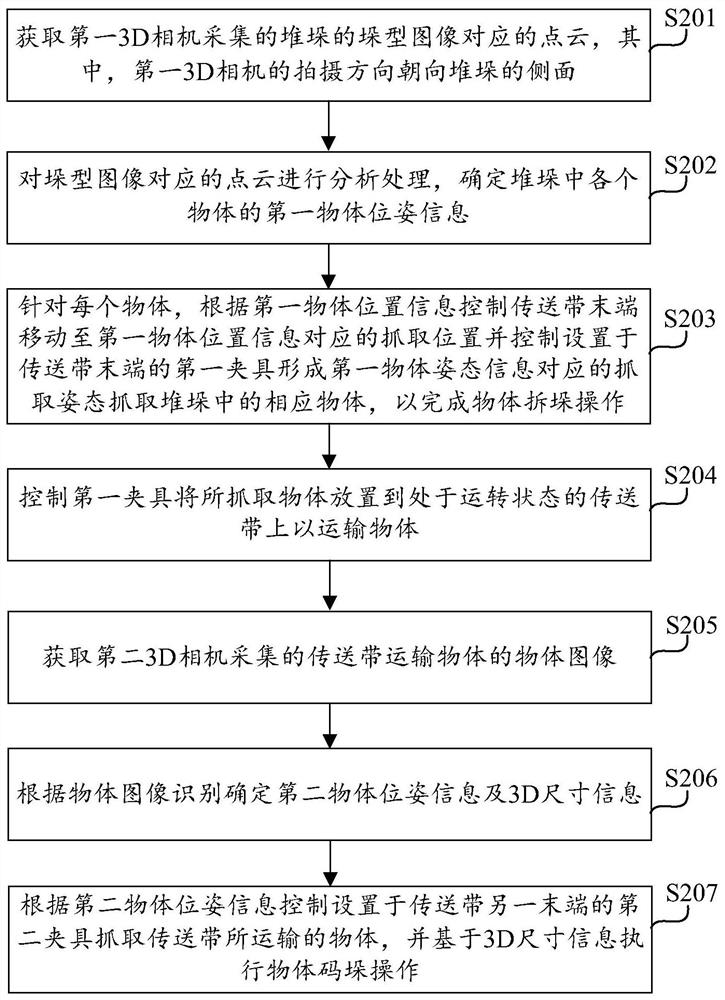

Object unstacking method and device based on conveyor belt, computing equipment and storage medium

ActiveCN113307042AAccurate captureImprove unstacking efficiencyImage enhancementImage analysisInformation controlPoint cloud

The invention discloses an object unstacking method and device based on a conveyor belt, computing equipment and a storage medium. The method comprises the steps that a point cloud corresponding to a stack type image, collected by a first 3D camera, of a stack is obtained, wherein the shooting direction of the first 3D camera faces the side face of the stack; analyzing and processing the point cloud corresponding to the stack type image, and determining first object pose information of each object in the stack; for each object, controlling a first clamp arranged at the tail end of the conveyor belt to grab the corresponding object in the stack according to the first object pose information, so that object unstacking operation is completed; and controlling the first clamp to place the grabbed objects on the conveyor belt in the running state to convey the objects. The objects can be accurately grabbed and efficiently conveyed through the conveyor belt, the unstacking efficiency is effectively improved, time is saved, and cost is reduced.

Owner:MECH MIND ROBOTICS TECH LTD

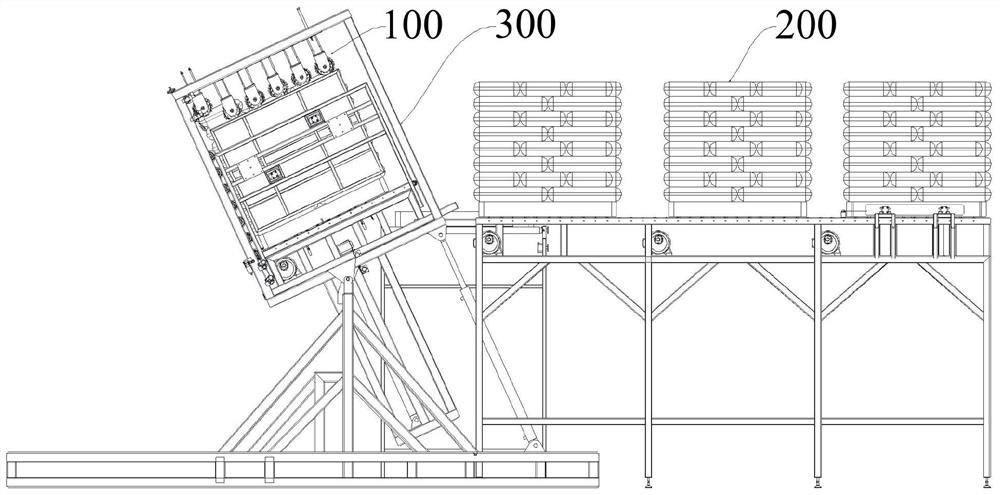

Array type gravity destacking device

InactiveCN111824785AContinuous and compact bag dropping actionReduce depalletizing timeConveyorsRollersSupport pointPhysics

Owner:山东伟豪思智能仓储装备有限公司

High-speed full-automatic double-station plastic bottle unstacker

PendingCN113371470AImprove unstacking efficiencyEfficient process flowStacking articlesDe-stacking articlesProduction lineEngineering

The invention discloses a high-speed full-automatic double-station plastic bottle unstacker. The high-speed full-automatic double-station plastic bottle unstacker comprises two bottle body unstacking units, a partition plate unstacking and stacking unit and a tray stacking unit. Each of the two bottle body unstacking units comprises a first lifting platform and a second lifting platform. The tray stacking unit comprises a tray stacking mechanism and a tray conveying mechanism. The partition plate unstacking and stacking unit comprises a partition plate stacking mechanism and a partition plate conveying mechanism. Under cooperation of the two bottle body unstacking units, the partition plate unstacking and stacking unit and the tray stacking unit, double stations are formed, multiple process steps of plastic bottle unstacking, tray stacking, partition plate unstacking and partition plate stacking can be conducted at the same time, traditional manual unstacking work is replaced, the high-speed full-automatic double-station plastic bottle unstacker is matched with a plastic bottle labeling and filling production line to form an efficient process flow, the labor cost is greatly reduced, and the unstacking efficiency of a whole stack of plastic bottles is improved.

Owner:沧州恒睿自动化设备科技有限公司

Vacuum suction cup whole-layer unstacker

PendingCN109319511AEasy loading and unloadingConvenient adsorption and destackingStacking articlesDe-stacking articlesMechanical engineeringEngineering

The invention discloses a vacuum suction cup whole-layer unstacker. The vacuum suction cup whole-layer unstacker comprises a metal rack and a cargo carrying table; a metal guard bar is arranged on theouter side of the metal rack, a guide rail is arranged on the inner side of the metal rack, the cargo carrying table is located in the metal rack, a guide wheel is arranged on the outer side of the cargo carrying table, a conveying mechanism is arranged above the cargo carrying table, a lifting mechanism is arranged above the side of the cargo carrying table, a vacuum suction cup device is arranged at the upper end of the inner side of the metal rack, a vertical moving mechanism is arranged above the vacuum suction cup device, a transverse moving mechanism is arranged above the vertical moving mechanism, and a servo motor is arranged on the inner side of the transverse moving structure. The vacuum suction cup whole-layer unstacker is provided with a vacuum suction cup device, in the use process of the device, a vacuum suction tool of the vacuum suction cup device can conveniently carry out absorbing and putting down on materials rapidly, the materials can be conveniently driven to bedisassembled and moved, and the unstacking efficiency is improved.

Owner:TAIYUAN FORTUCKY LOGISTICS EQUIP TECH CO LTD

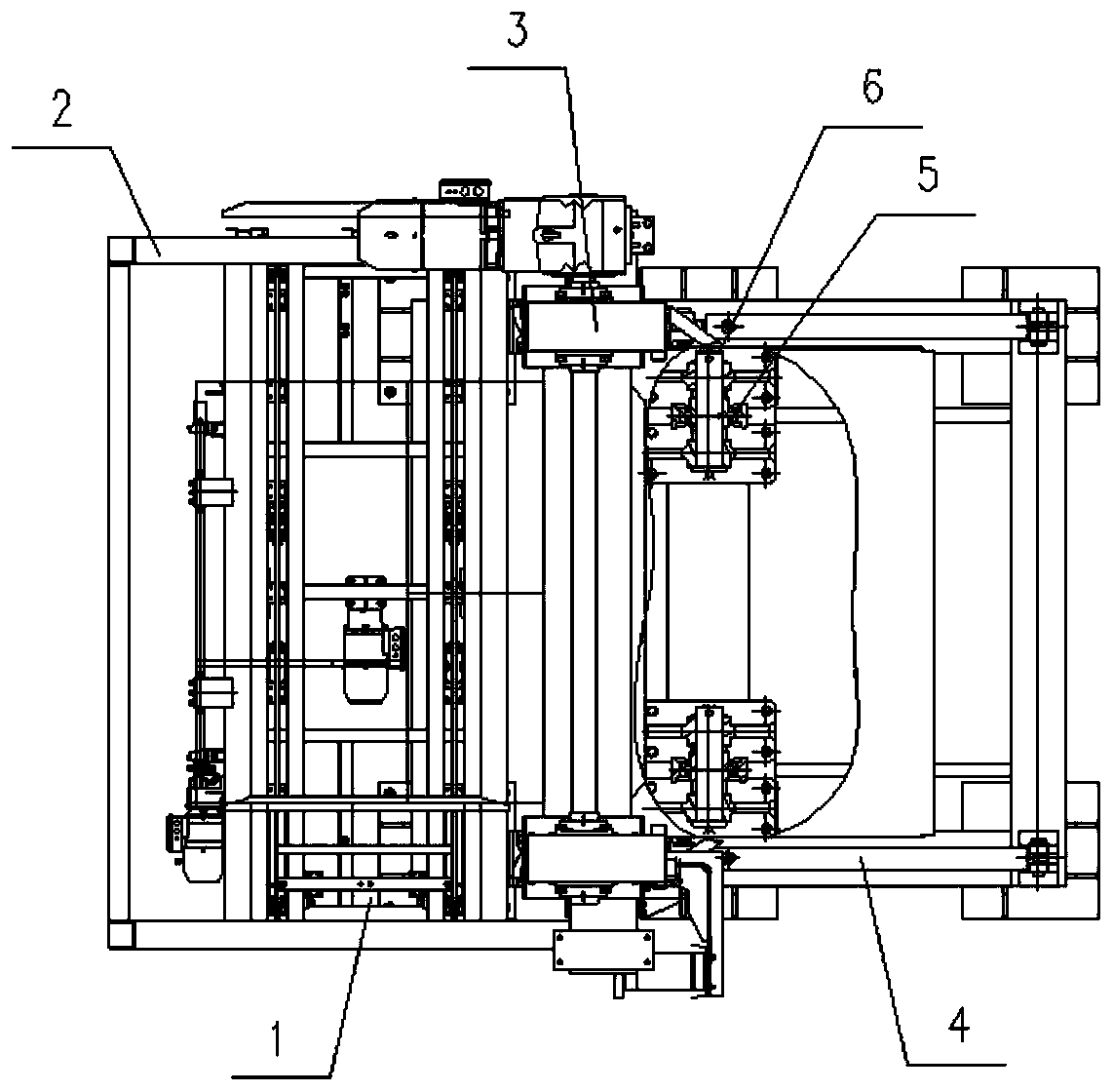

Cigarette packet tray unstacking device

PendingCN112777326AAchieve separationSimple structureStacking articlesDe-stacking articlesEngineeringMechanical engineering

The invention discloses a cigarette packet tray unstacking device. The cigarette packet tray unstacking device comprises a frame body, a lifting chain mechanism and a lifting type cigarette packet grabbing manipulator mechanism, wherein a conveying belt is arranged under the frame body, trays are conveyed on the conveying belt, and cigarette packets are placed on the trays; the lifting chain mechanism is arranged at the top of the frame body; and the lifting type cigarette packet grabbing manipulator mechanism is fixedly connected with the lifting chain mechanism and is used for grabbing cigarette packets. In the working process, the conveying belt conveys cigarette packets stacked on the trays to the position below the lifting type cigarette packet grabbing manipulator mechanism, the lifting chain mechanism acts to enable the lifting type cigarette packet grabbing manipulator mechanism to move downwards and grab the cigarette packets, separation of the trays and the cigarette packets is achieved, and then the cigarette packets are placed on corresponding bearing devices. The cigarette packet tray unstacking device is simple in structure, small in size, small in occupied area, low in equipment cost and high in unstacking efficiency.

Owner:TIANHAI OUKANG TECH INFORMATION XIAMEN

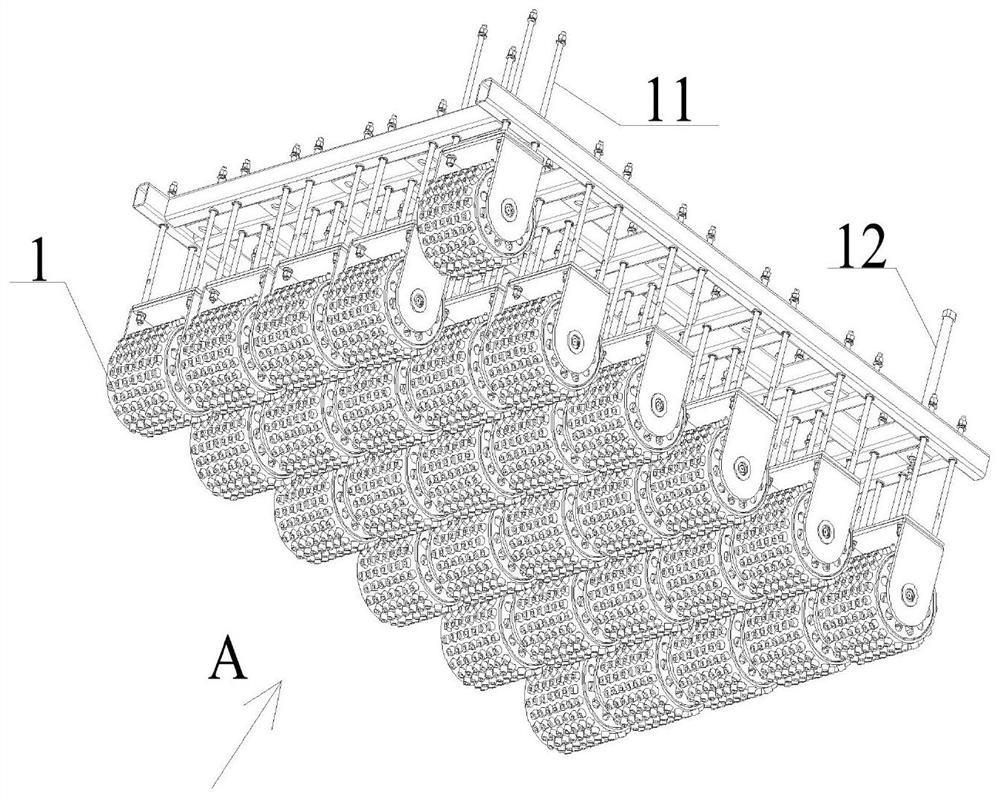

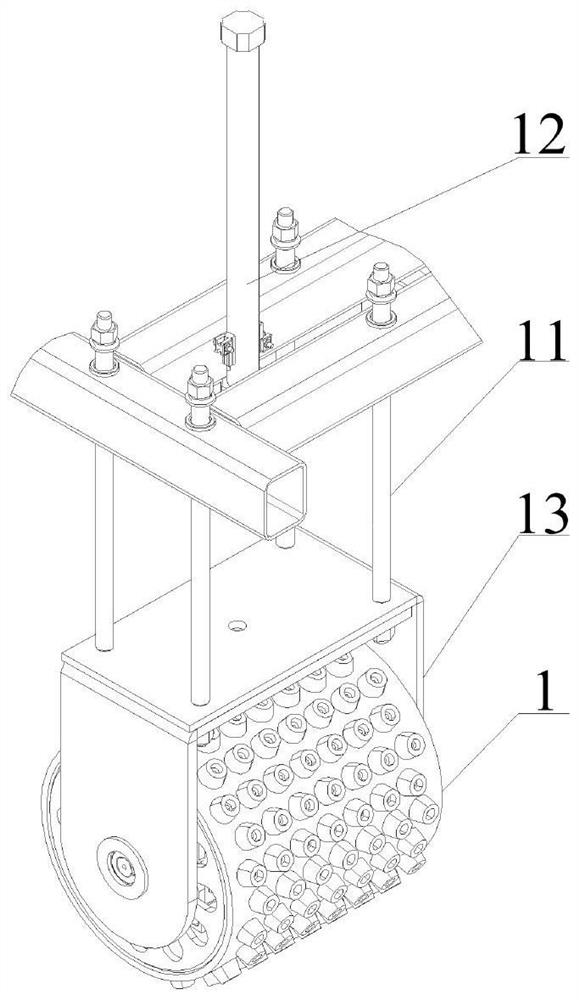

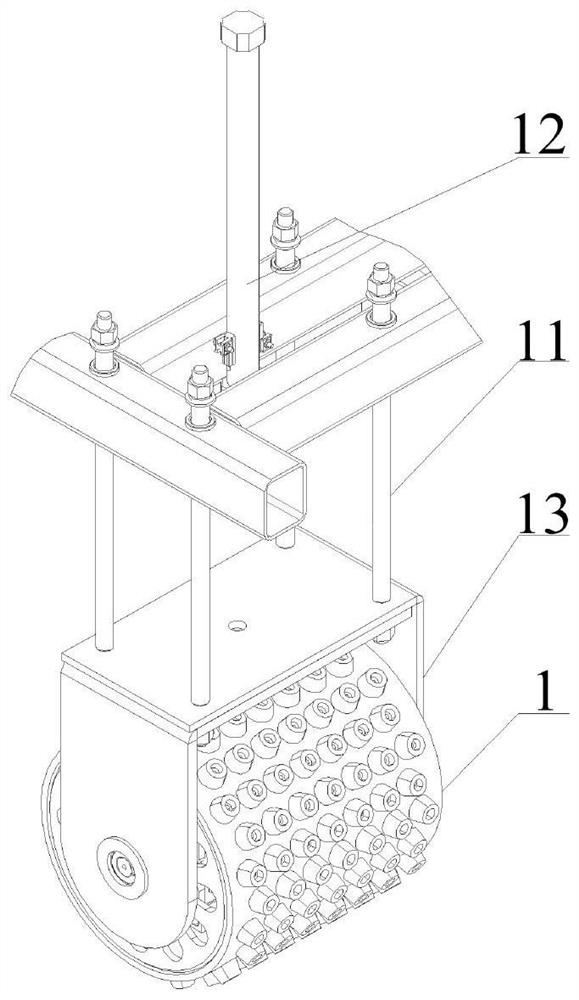

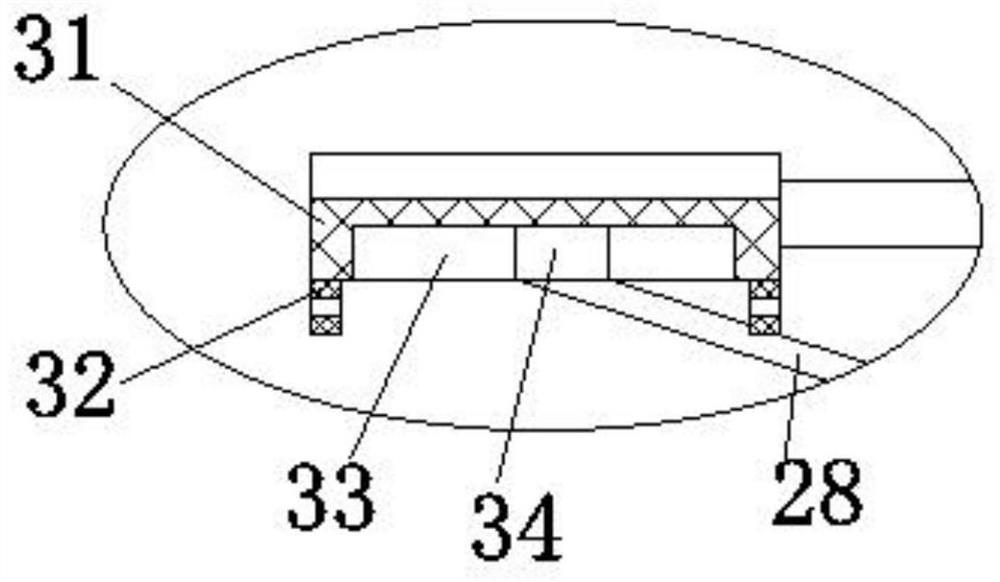

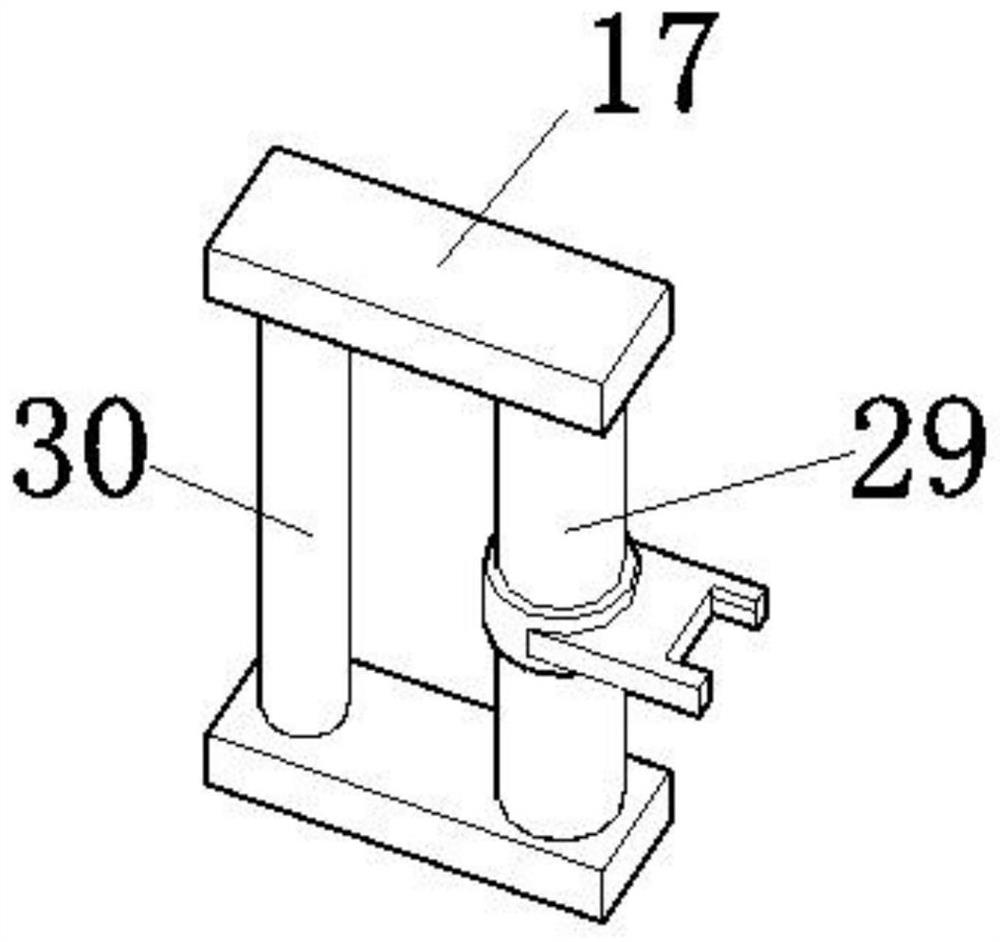

Array type bag shifting mechanism

InactiveCN111824784AContinuous and compact bag dropping actionShorten the timeConveyorsRollersControl theoryMechanical engineering

The invention relates to the technical field of unstacking equipment, and provides an array type bag shifting mechanism. The array type bag shifting mechanism comprises a roller assembly arranged on the upper portion of an overturning frame, wherein the roller assembly is provided with a plurality of rollers arranged in an array manner; each roller can independently rotate to shift a cargo bag, and the cargo bags are made to slide in the conveying direction; each roller is connected with a pre-pressing piece; the roller assembly is provided with a first drive area, a swing drive area and a second drive area which act according to a preset program; and the rollers in the swing drive area synchronously rotate with the first drive area and / or the second drive area according to the preset program or independently rotate. Thus, the rollers in all the drive areas rotate according to the preset program to shift the cargo bags, and the cargo bags are guided out one by one and rapidly fall onto equipment of the next procedure under the action of gravity. The array type bag shifting mechanism is continuous and compact in unpacking action, and the unstacking efficiency is improved.

Owner:山东伟豪思智能仓储装备有限公司

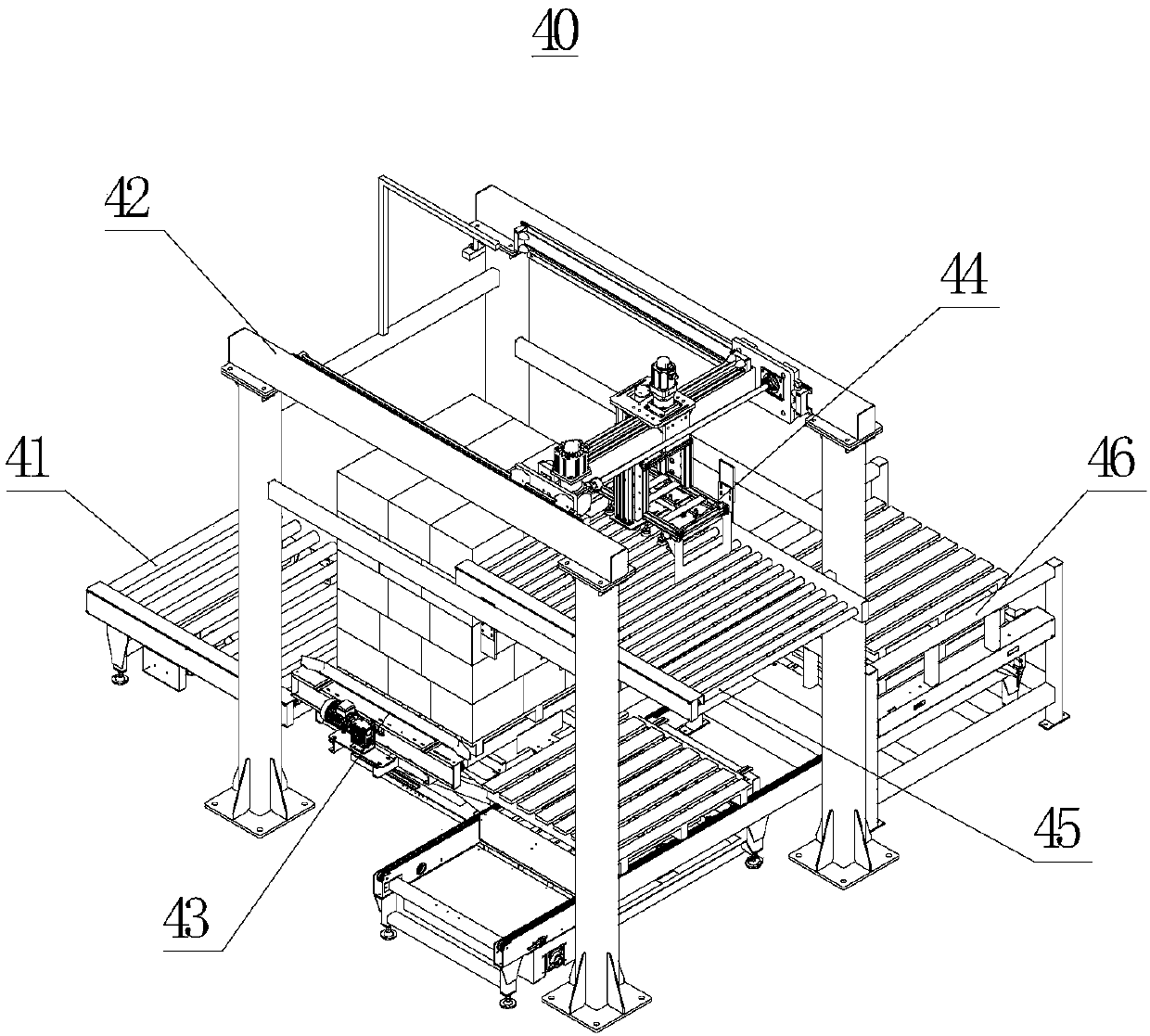

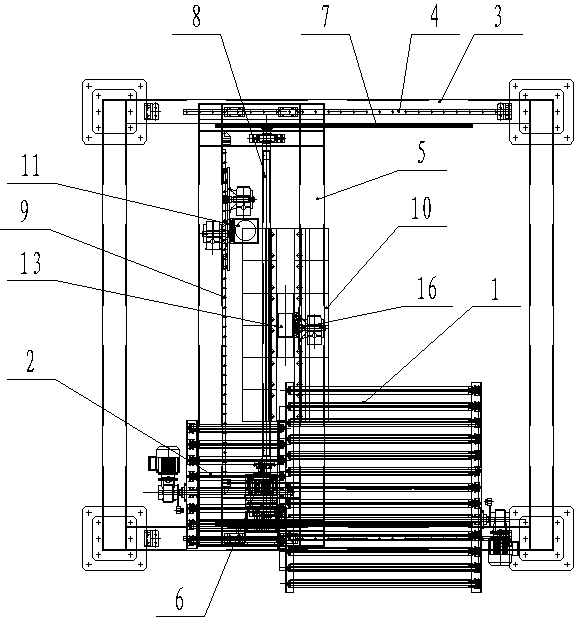

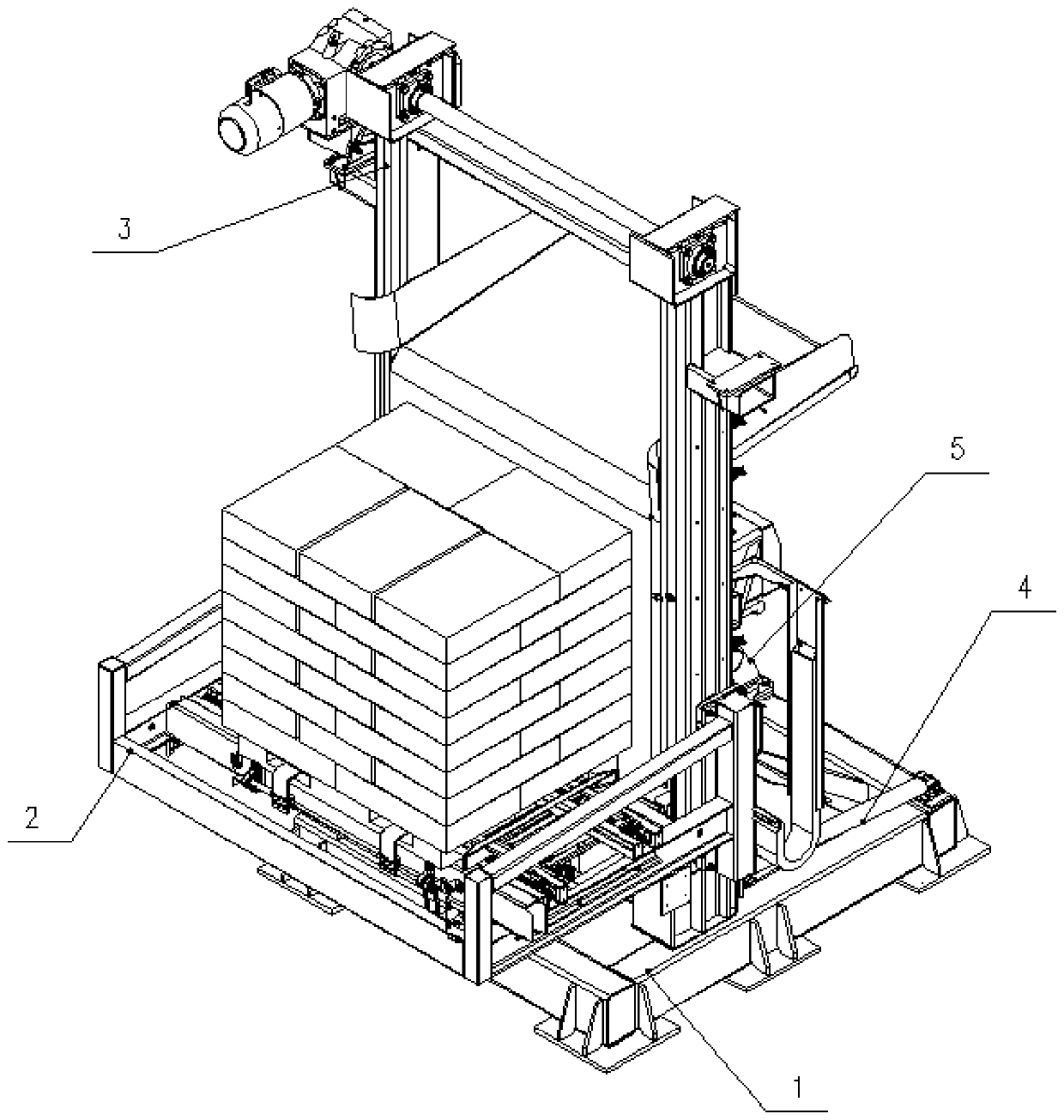

Automatic coordinate type unstacker

InactiveCN110077864AImprove unstacking efficiencyLow running costStacking articlesDe-stacking articlesEngineeringMechanical engineering

The invention discloses an automatic coordinate type unstacker. The automatic coordinate type unstacker comprises an unstacking working area. An unstacking station and a single box placing station arranged on one side of the unstacking station are arranged in the unstacking working area. The automatic coordinate type unstacker further comprises a supporting frame which is transversely erected andarranged above the unstacking working area. The supporting frame comprises two transverse beams which are equidistantly arranged front and back and extend along the left-right direction respectively.Left-right direction walking guide rails are respectively arranged on the two transverse beams. Movable bases cooperating with the guiding direction of the left-right direction walking guiding rails are arranged on the left-right direction walking guide rails. Left-right direction driving devices are connected to the movable bases. The movable bases are driven to move in the left and the right direction by the left-right direction driving devices. Front-back direction walking guide rails are installed on the movable bases. Walking bases cooperating with the guiding direction of the front-backdirection walking guide rails are arranged on the front-back direction walking guide rails. Grabbing mechanical arms arranged in an extending manner in up-down direction are installed on the walking bases. The grabbing mechanical arms can move in the up-down direction. According to the automatic coordinate type unstacker, unstacking efficiency is high, the operation cost, the installation cost andthe maintenance cost of the equipment are low, automatic coordinate type unstacking is achieved, and the unstacker is applicable to application to cigarette production enterprises.

Owner:CHINA TOBACCO HENAN IND +1

Toggle unstacking device and method

PendingCN109436816AAvoid deformationReduce the impact of subsequent operationsConveyorsControl devices for conveyorsEngineering

The invention discloses a toggle unstacking device and method, and relates to the technical field of logistics equipment. The toggle unstacking device comprises a receiving assembly and a splitting assembly with a splitting moving mechanism and a toggle splitting mechanism, a splitting station is arranged at the position close to the splitting moving mechanism, the receiving assembly comprises a receiving platform, one side of the receiving platform is arranged close to the splitting station, and can be close to the bottom edge of top-layer goods of a goods stack; the splitting moving mechanism can drive a splitting toggle part to move, and thus the splitting toggle part is inserted into a gap of the top-layer goods or located at the edge of the top-layer goods; and the splitting moving mechanism can further drive the splitting toggle part to move towards the receiving platform, and thus the splitting toggle part toggles towards the receiving platform, so that all or part of the top-layer goods enter the receiving platform. According to the toggle unstacking device and method, the unstacking efficiency is high, goods deformation is not prone to being caused in the unstacking process, and the goods are not prone to being stacked.

Owner:CHINA HEFEI TAIHE OPTOELECTRONICS TECH

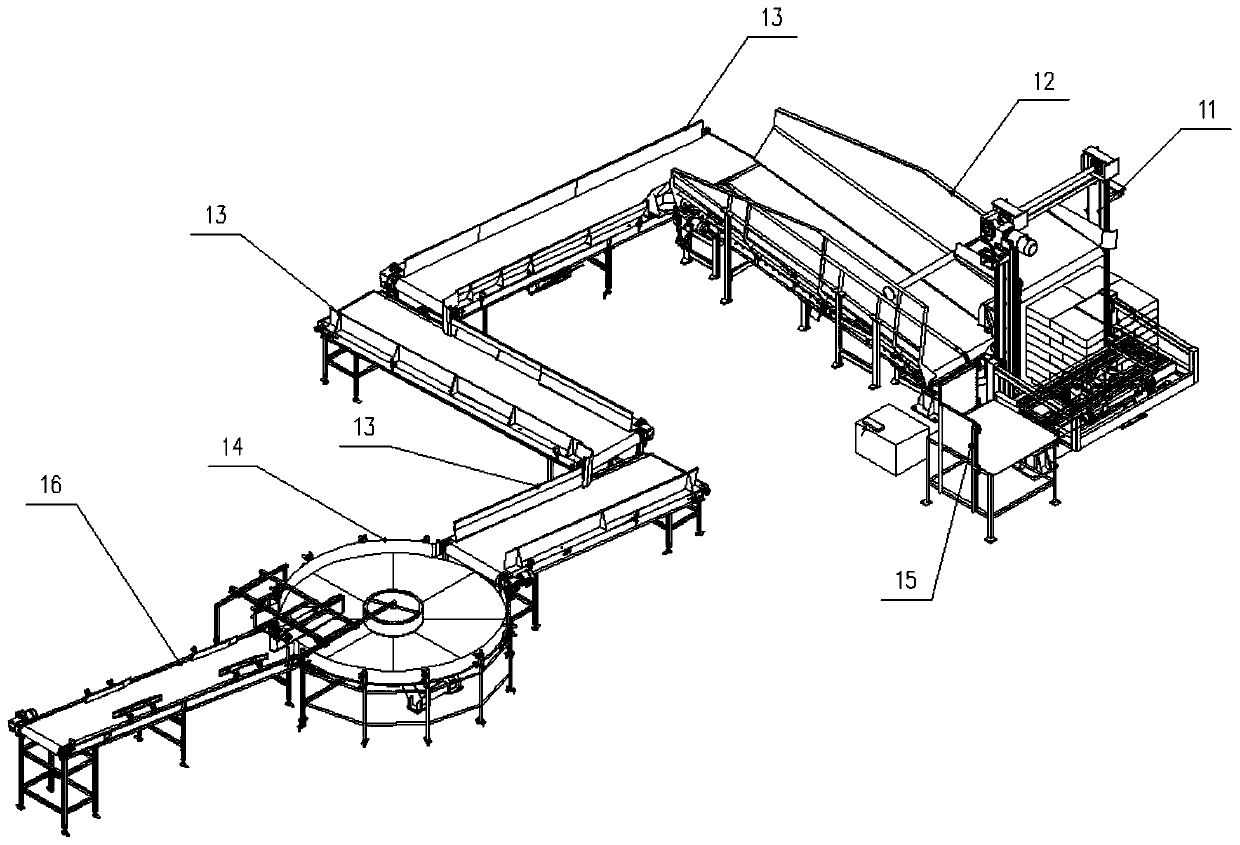

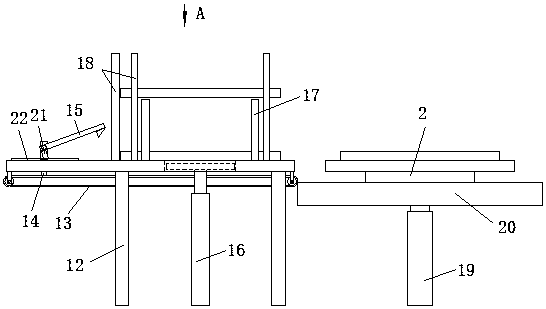

Unstacking production line

PendingCN110371621AReduce operating costsImprove work efficiencyConveyorsDe-stacking articlesProduction lineAssembly line

The invention provides an unstacking production line, and belongs to the technical field of unstacking assembly lines. The unstacking production line aims at solving the problems that a traditional unstacking production line is low in mechanization degree, low in unstacking efficiency and poor in stability. The output end of an unstacking machine is connected with the input end of a separation machine. The output end of the separation machine is connected with the input end of a disc type shaping machine through one or more first belt conveyors. The output end of the disc type shaping machineis connected with one or more second belt conveyors. By means of the unstacking production line, the automatic operation of the unstacking work can be conveniently completed, and the unstacking efficiency is improved.

Owner:HARBIN BOSHI AUTOMATION

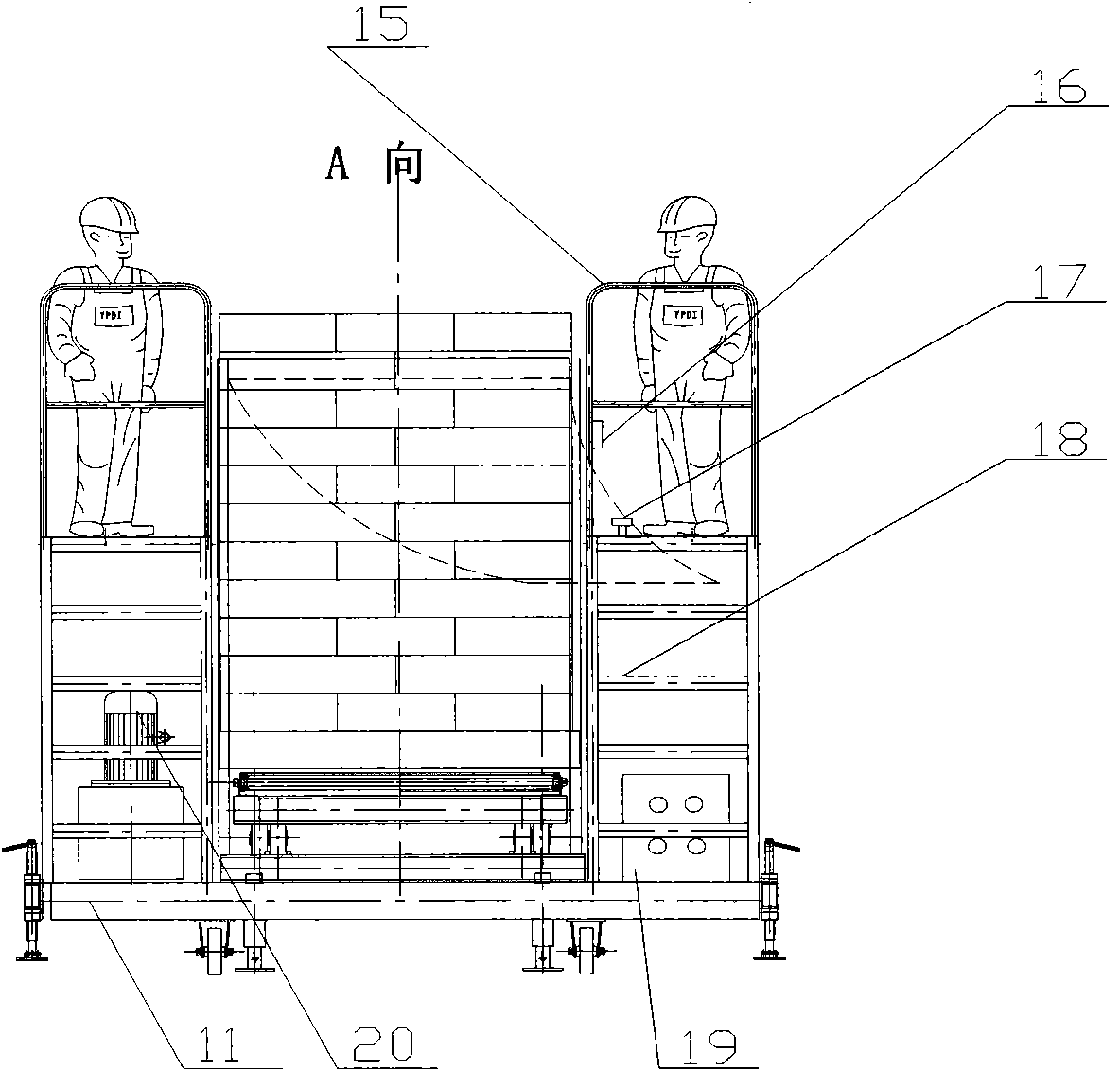

Bagged material unstacker

ActiveCN114148766AEasy to carryImprove slipPlastic recyclingDe-stacking articlesVehicle frameButt joint

The invention discloses a bagged material unstacker which comprises a movable frame, the movable frame comprises an operation platform and supporting legs which are arranged at the two ends of the operation platform and extend downwards, and the operation platform is provided with an XYZ-axis moving mechanism and an unstacking clamping jaw installed on the XYZ-axis moving mechanism; and the discharging mechanism is in butt joint with the movable frame, and the discharging mechanism is provided with a discharging chute. According to the unstacking device, single-bag materials can be taken out through three-dimensional movement of the unstacking clamping jaw, after being taken out, the single-bag materials can be conveyed to the discharging chute to automatically slide down, workers do not need to climb to a high position for carrying, the unstacking clamping jaw does not need to downwards run for a long distance to put down bagged materials, and the unstacking efficiency can be improved.

Owner:CHANGSHA RUNDA INTELLIGENT EQUIP CO LTD

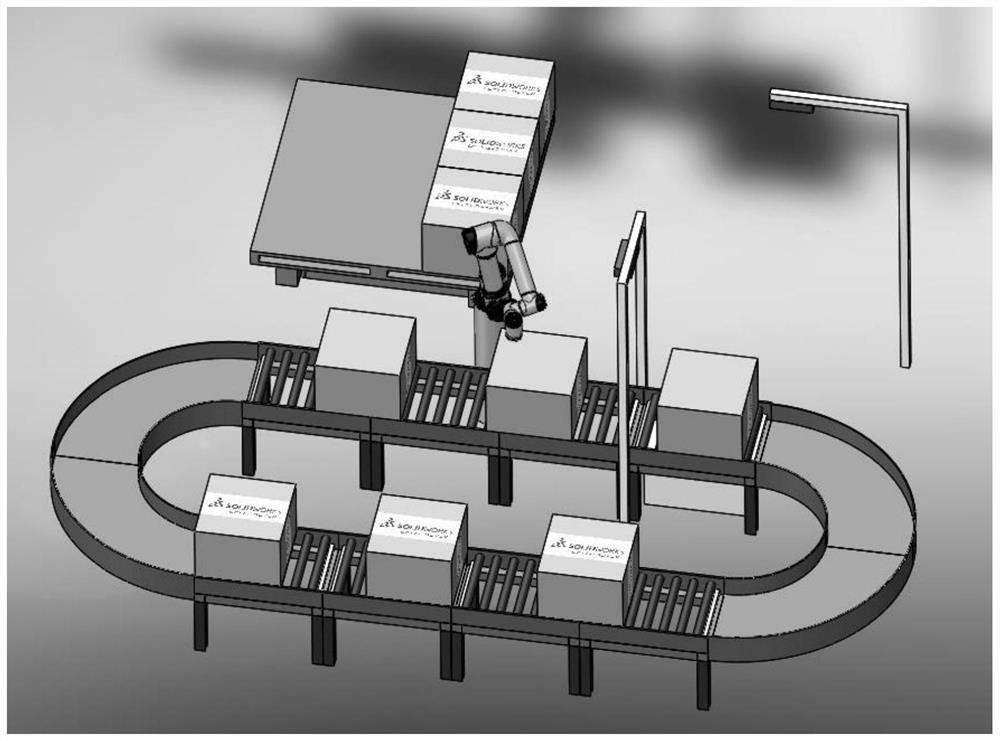

Mixed unstacking and stacking method based on 3D vision

ActiveCN112850186AGuaranteed stabilityAvoid problems prone to collapseControl devices for conveyorsStacking articlesRobot handEngineering

The invention provides a mixed unstacking and stacking method based on 3D vision. The mixed unstacking and stacking method comprises the following steps that a gravity sensing device is arranged on a tray for loading a box body, and the horizontal gravity center position of the box body on the tray is obtained in real time; a 3D vision device is arranged to recognize the size and the edge position of the box body, and a mechanical arm is guided to grab the box body; a grabbing and weighing device is arranged on the mechanical arm, and the weight of the box body is detected while the box body is grabbed; and according to the horizontal gravity center position of the box body on the tray, the size and edge position of the box body and the weight of the box body, the stacking and unstacking sequence is determined, and the mechanical arm is used for completing mixed stacking and unstacking. By means of the above manner, the gravity sensing device can be used for obtaining the overall gravity center position of the box body on the tray in real time, the stacking and unstacking sequence and the stacking position are adjusted, and the safety of the stacking and unstacking process is guaranteed; and the size and the edge of the box body are recognized through the 3D vision device, the space utilization rate on the tray is increased, and the stable and efficient mixed unstacking and stacking process is achieved.

Owner:成都耐视特科技有限公司

A kind of skid destacking truss equipment

ActiveCN110877826BImprove unstacking efficiencyReduce labor costsStacking articlesDe-stacking articlesMoving jawEngineering

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

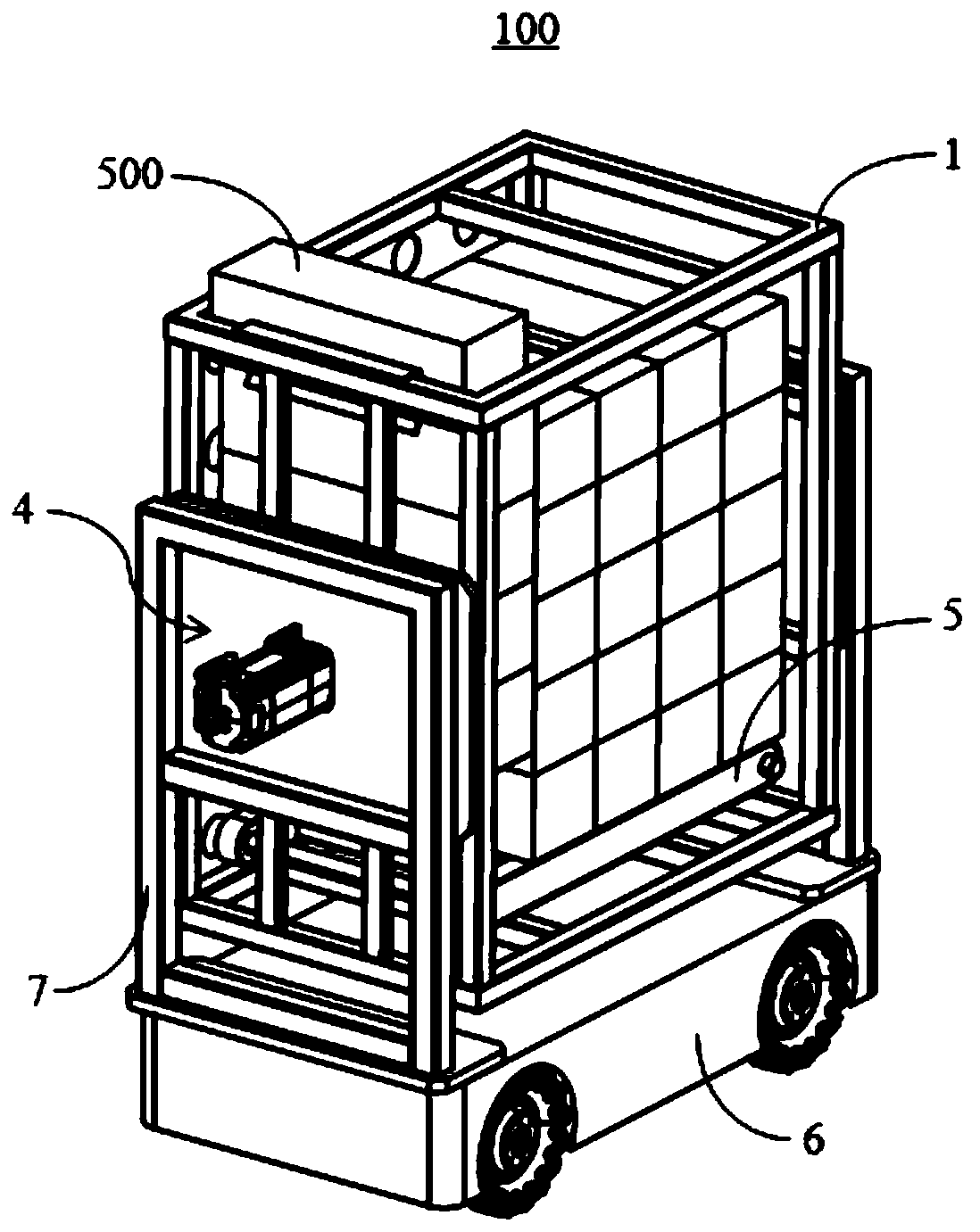

Brick supply vehicle and automatic brick supply system with same

ActiveCN111533048AImprove efficiencyImprove stabilityLifting devicesBuilding material handlingVehicle frameBrick

The invention discloses a brick supply vehicle and an automatic brick supply system with the same. The brick supply vehicle comprises a chassis, a vehicle frame, a positioning frame, an ejection device and an overturning device. The vehicle frame is erected on the chassis; the positioning frame is mounted on the vehicle frame and is provided with an inlet and outlet port; the ejection device is arranged on the positioning frame or the chassis and can eject bricks from the bottom of a brick stack; the overturning device can drive the positioning frame to rotate relative to the vehicle frame, and when a brick stack tray carrying the brick stack needs to be fed into the positioning frame from the inlet and the outlet port, the overturning device drives the positioning frame to rotate till thetop of the positioning frame is positioned at one side close to the chassis; and when the brick stack tray needs to be taken out from a tray outlet, the overturning device drives the positioning frame to rotate till the bottom of the positioning frame is close to one side of the chassis. According to the brick supply vehicle, the brick supply efficiency and safety can be improved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Method and device for unstacking goods

ActiveCN109455527BImprove unstacking efficiencyControl devices for conveyorsStacking articlesProcess engineeringIndustrial engineering

Owner:CHINA HEFEI TAIHE OPTOELECTRONICS TECH

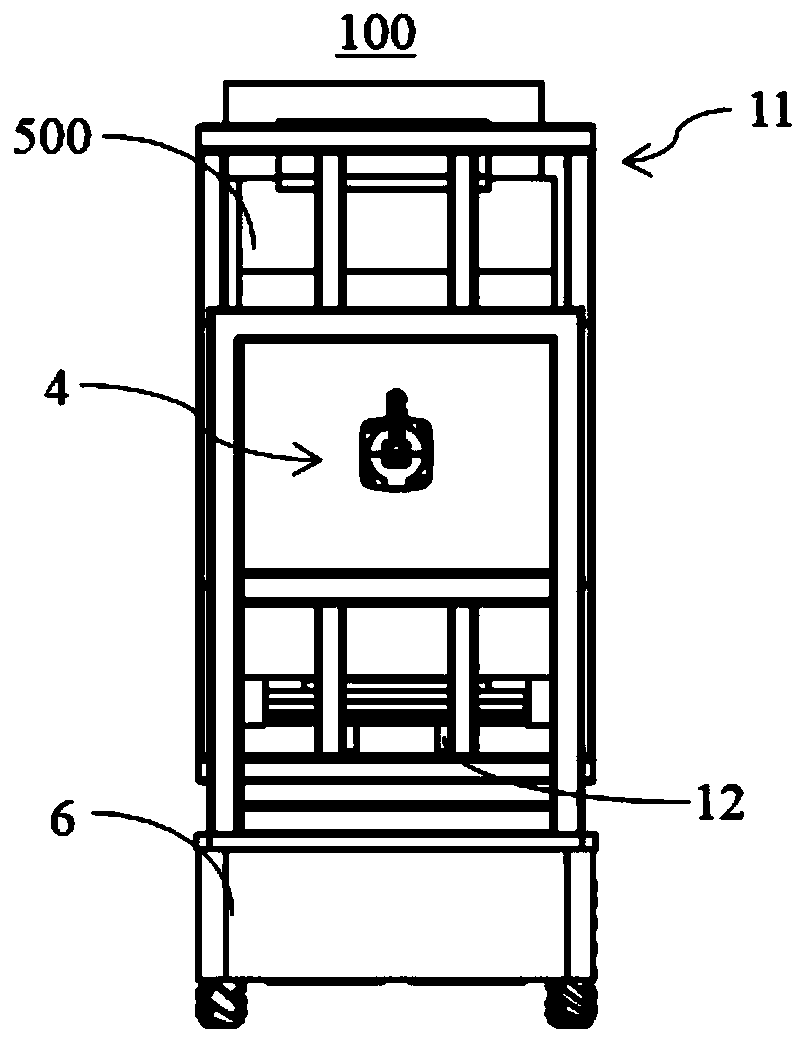

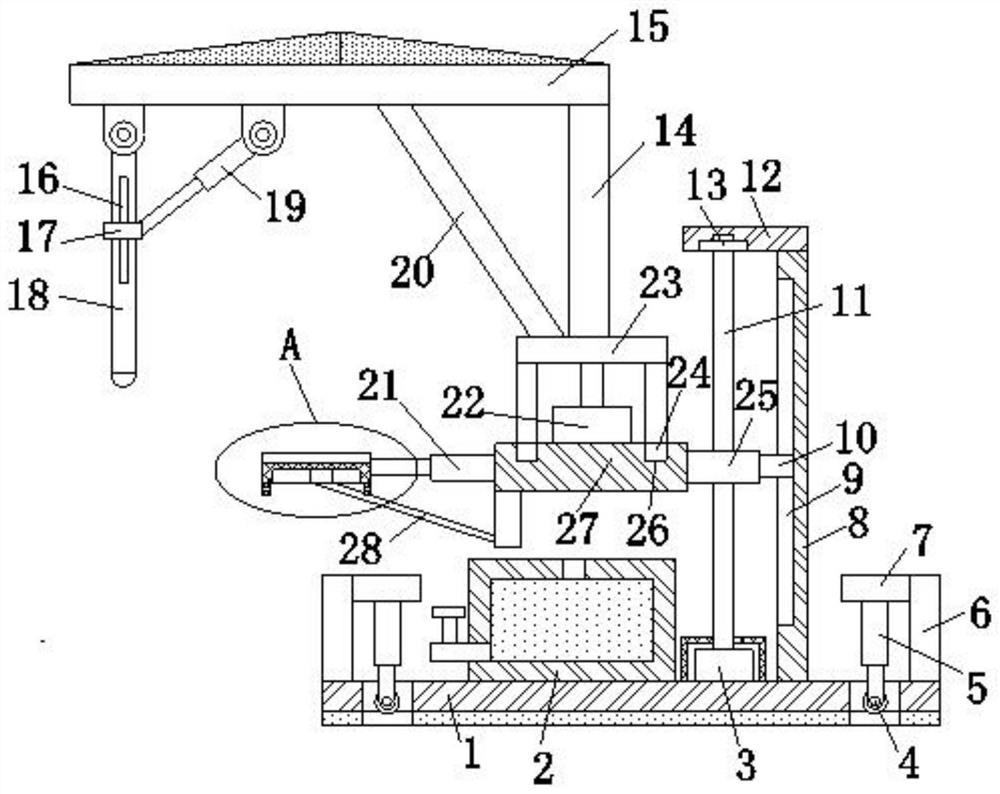

Automatic feeding and positioning equipment for motor rotor

PendingCN111953153APrecise positioningEasy to assembleManufacturing stator/rotor bodiesDe-stacking articlesControl engineeringElectric machinery

An automatic feeding and positioning equipment for a motor rotor is disclosed. The automatic feeding and positioning equipment comprises a bottom frame assembly, a lead screw lifting mechanism is arranged on the side face of the bottom frame assembly, a lead screw translation mechanism is fixedly connected to the upper end of the bottom frame assembly, and a pneumatic rotary unstacking mechanism is fixedly connected to the upper end of the bottom frame assembly; the pneumatic rotary unstacking mechanism is located at the upper end of the lead screw translation mechanism, the upper end of the bottom frame assembly is fixedly connected with a first feeding conveying belt, the rear end of the pneumatic rotary unstacking mechanism is fixedly provided with a pneumatic gripper translation mechanism, and the upper end of the bottom frame assembly is fixedly connected with a pneumatic material taking and positioning mechanism; and the pneumatic material taking and positioning mechanism is located at the right end of the first feeding conveying belt, a second feeding conveying belt is fixedly installed on the inner side of the bottom frame assembly, and the upper end of the second feeding conveying belt is fixedly connected with the pneumatic material taking and positioning mechanism. According to the automatic feeding and positioning equipment for the motor rotor, through the materialdistributing and positioning equipment, the unstacking efficiency is greatly improved, and the accurate uniformity of the directivity of rotor feeding is guaranteed.

Owner:赣州中科拓又达智能装备科技有限公司

Method, device and system for unstacking goods

ActiveCN109592433BPrecise positioningImprove unstacking efficiencyStacking articlesDe-stacking articlesIndustrial engineeringManufacturing engineering

Owner:CHINA HEFEI TAIHE OPTOELECTRONICS TECH

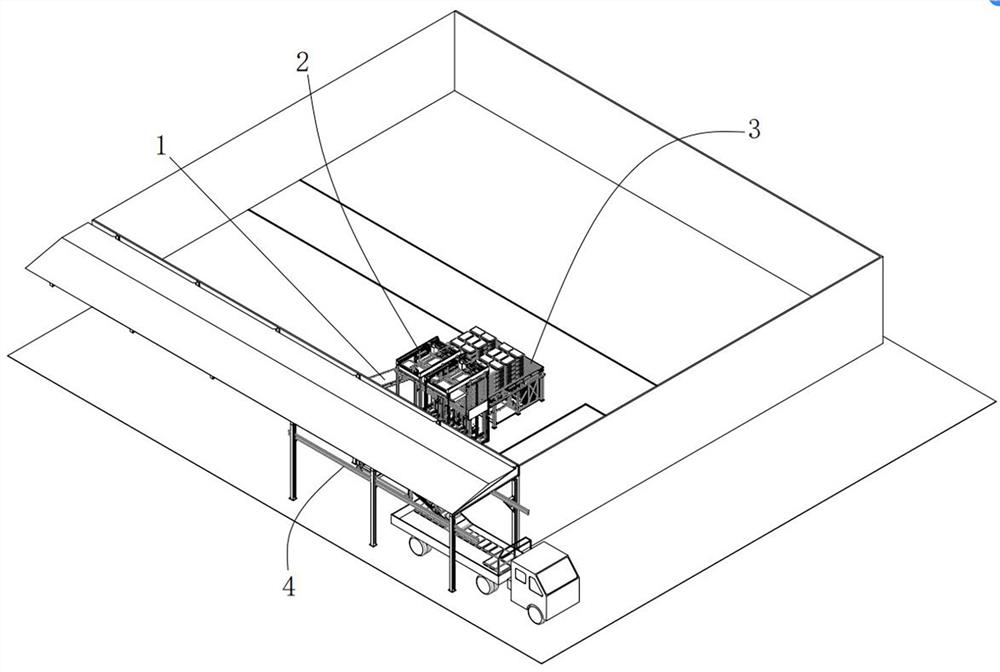

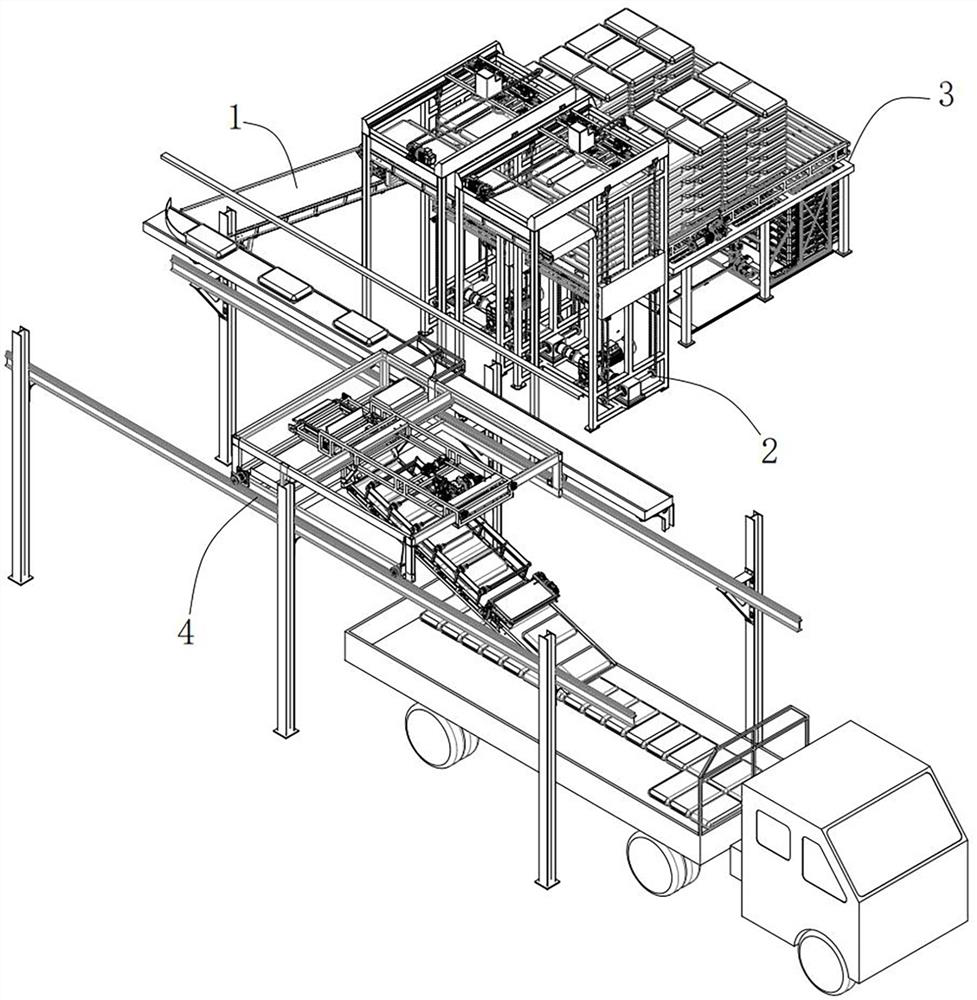

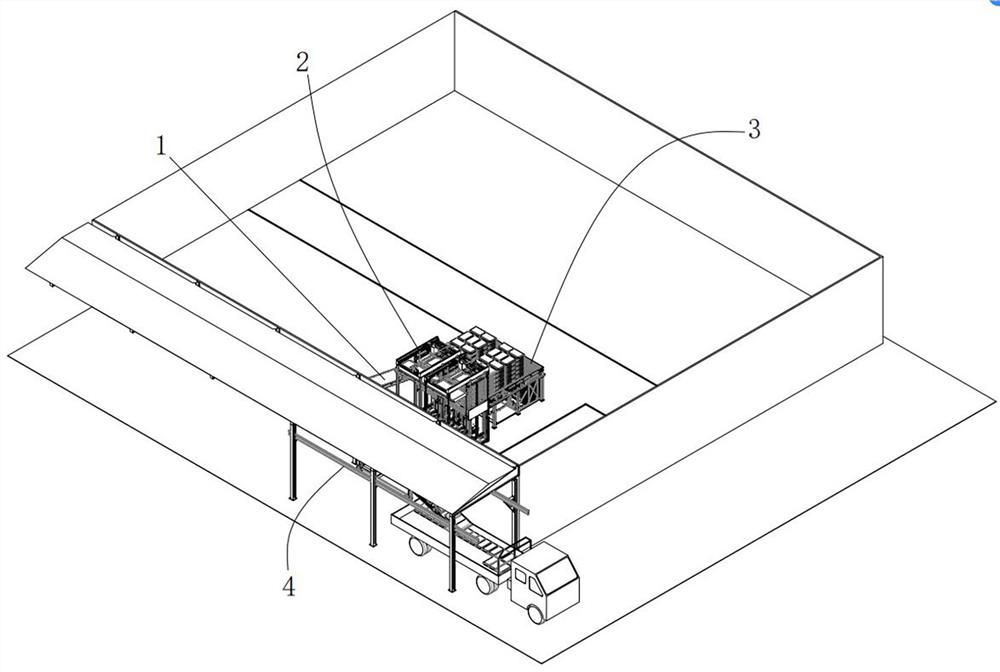

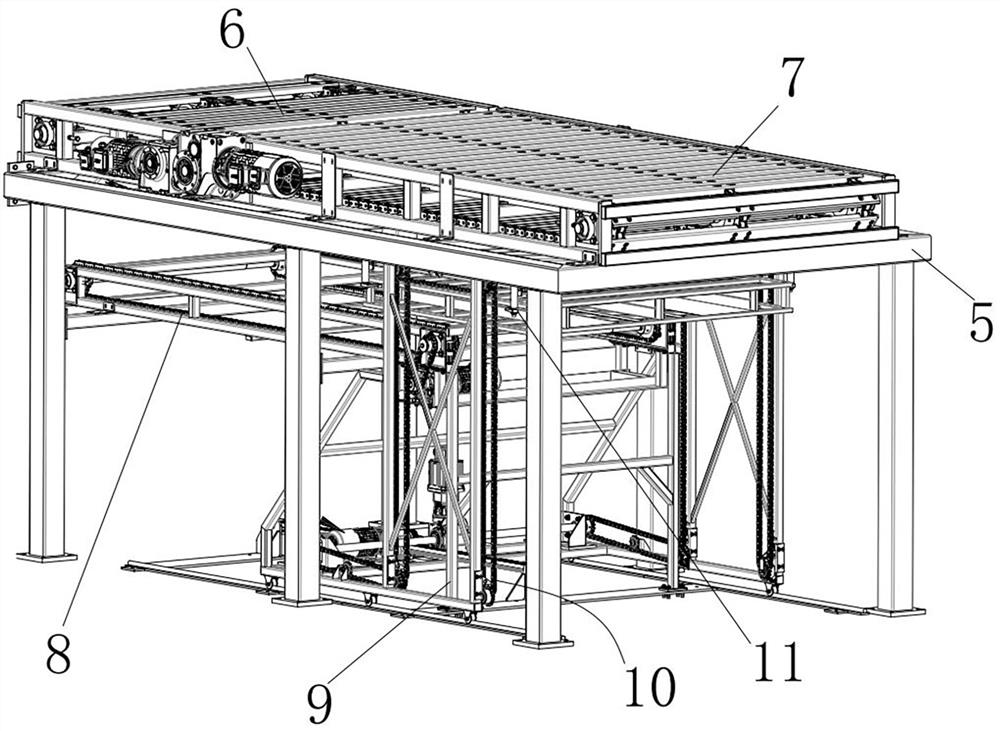

An intelligent high-speed unattended shipping line

ActiveCN113401676BRecycling takes less timeNot easy to damageStacking articlesDe-stacking articlesProcess engineeringMaterial transport

The invention relates to the technical field of material transportation, and discloses an intelligent high-speed unattended shipping line, which includes a transfer conveyor installed between the workshop and the transport vehicle, and the inner end of the transfer conveyor is equipped with an automatic destacking system and an automatic Feeding system, the outer end of the transfer conveyor is equipped with an automatic loading system. The automatic feeding system transfers the material stacks to the automatic unstacking system and recovers the carrier carrying the materials. The automatic unstacking system automatically disassembles the material stacks. Open and transport the materials one by one to the inner end of the transfer conveyor. The invention realizes the automatic loading of material stacks from the workshop to the outside of the workshop for a long distance, without manual dismantling, manual loading and stacking, which takes a short time and reduces The cost is reduced, the loading speed is fast, the loading efficiency is high, the degree of automation is high, and it has extremely high practicability. High stacking efficiency.

Owner:山东加法智能科技有限公司

Unstacking trolley of press line

InactiveCN110918816AQuick splitAvoid adsorptionMetal-working feeding devicesPositioning devicesVehicle frameTransmission belt

The invention provides an unstacking trolley for a press line. The trolley comprises a frame, a placement plate is arranged in the middle of the surface of the frame, servo jacking air cylinders are arranged on the two sides of the lower end of the placement plate, a detachable baffle is disposed on the front side of the frame, a support is arranged on the frame, a mounting frame is arranged on the support, a servo lifting air cylinder is arranged between the support and the mounting frame, conveying belts are arranged on the left and right sides in the mounting frame, a plurality of vacuum suction cups are arranged on the surfaces of the conveying belts at equal intervals, vacuum generators are arranged in the conveying belts, and the vacuum generators are movably connected with the vacuum suction cups. The servo jacking air cylinder drives plate materials to ascend through the placement plate, the conveying belts drive the vacuum suction cups to be sequentially connected with the vacuum generators, the plate materials on the upper side are driven to be conveyed and unstacked, the unstacking efficiency is effectively improved, and the trolley is applicable to production.

Owner:安徽戎发冲压机器人有限公司

Unstacker

PendingCN110482244AReduce lossImprove securityConveyorsStacking articlesReciprocating motionEngineering

The invention relates to an unstacker. The unstacker comprises a first support, a supporting plate located on one side of the first support, and a second lifting mechanism for driving the supporting plate to vertically move. A demounting and bag clamping device located on one side above the supporting plate is arranged on the first support, and the demounting and bag clamping device comprises a clamp matched with material bags. A driving mechanism for driving the demounting and bag clamping device to do reciprocating motion in the bag dragging direction is further included. According to the unstacker, a traditional manual unstacking mode is changed, reciprocating motion is done according to the path set by a user procedure, the moving stroke is not increased along with lowering of a stack,energy consumption is reduced, and the stacking time is saved; the unstacking efficiency is improved, the unstacking labor force is freed up, and a large amount of time is saved; and unstacked emptytrays can be automatically collected and stacked in one row, potential danger occurring when workers recycle the trays is avoided, and the safety of the workers is improved.

Owner:山东腾阳智能装备有限公司

Automatic unstacker

PendingCN113548485AReduce maintenance costsReduce use costConveyorsDe-stacking articlesElectric machineEngineering

The invention discloses an automatic unstacker. The automatic unstacker comprises a bottom plate, wherein the top of the bottom plate is fixedly connected with a third fixing plate through a jacking mechanism, and a rotating motor is mounted at the top of the third fixing plate. According to the automatic unstacker, an output shaft of the rotating motor drives a second connecting plate to rotate so as to drive a top plate to rotate, the top plate drives a dip angle oil cylinder hinged to the lower portion of the top plate and a shifting plate to rotate so as to adjust the angle of a shifting plate, the shifting plate is adjusted to the back face of bagged grain products stacked on a tray, a piston rod of the dip angle oil cylinder contracts to pull a connecting column, so that a connecting block drives a fixing column to move upwards in a rectangular opening formed in the front face of a stirring plate, the stirring plate is pulled to push the bagged grain products stacked on the tray, the bagged grain products stacked on the tray are dumped, then a material receiving mechanism is used for receiving materials, the device is low in use cost and low in maintenance cost, bagged grain products stacked on the tray can be unstacked on a large scale through the shifting plate, and the unstacking efficiency is high.

Owner:滁州哈工库讯智能科技有限公司

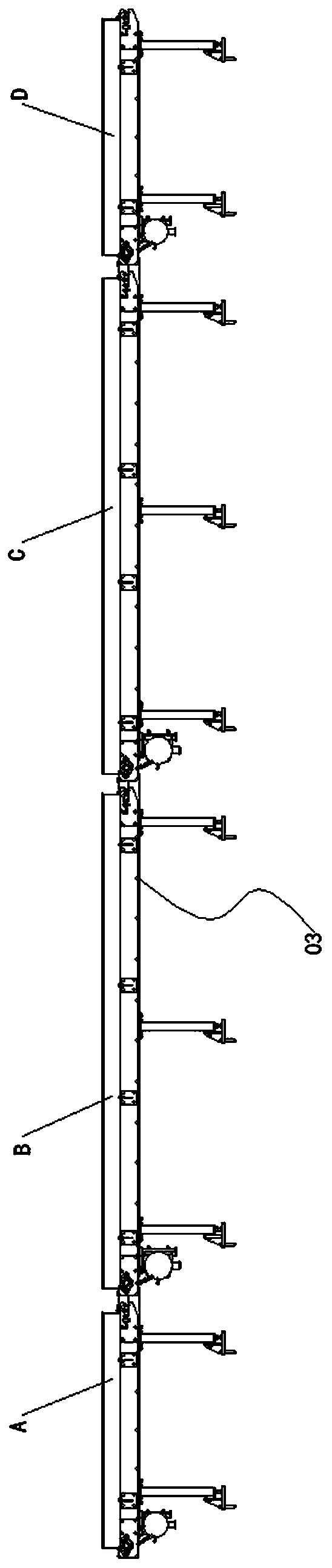

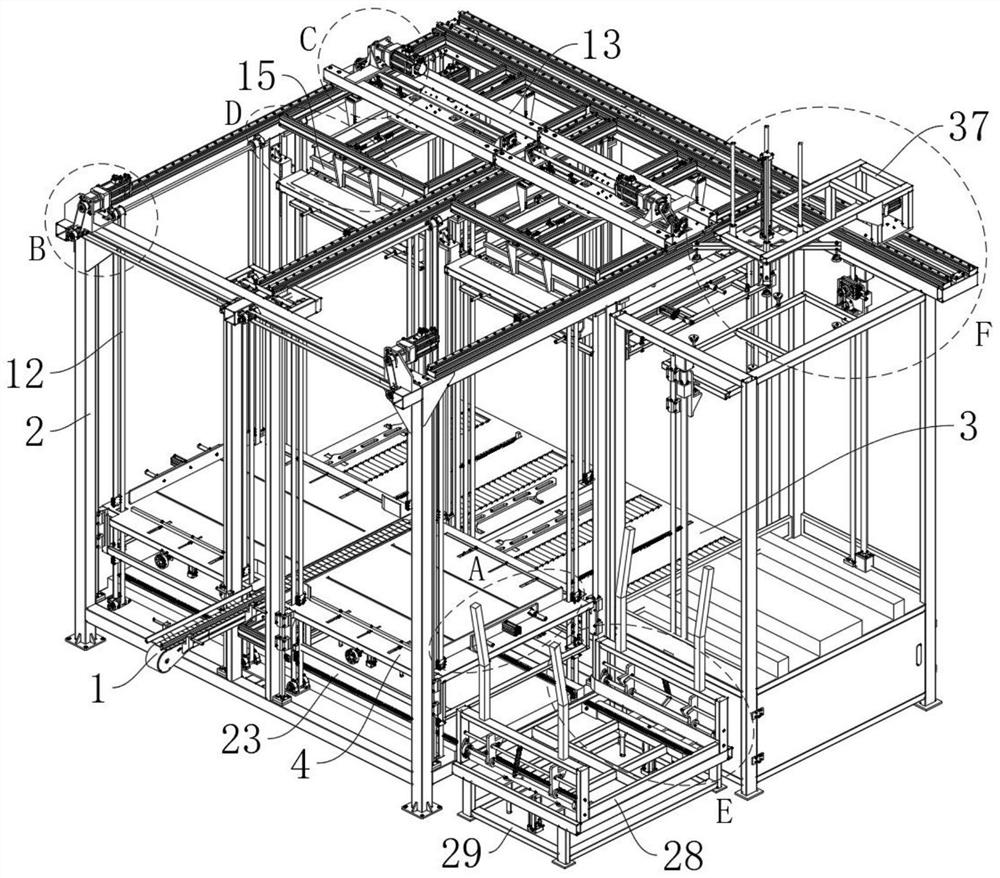

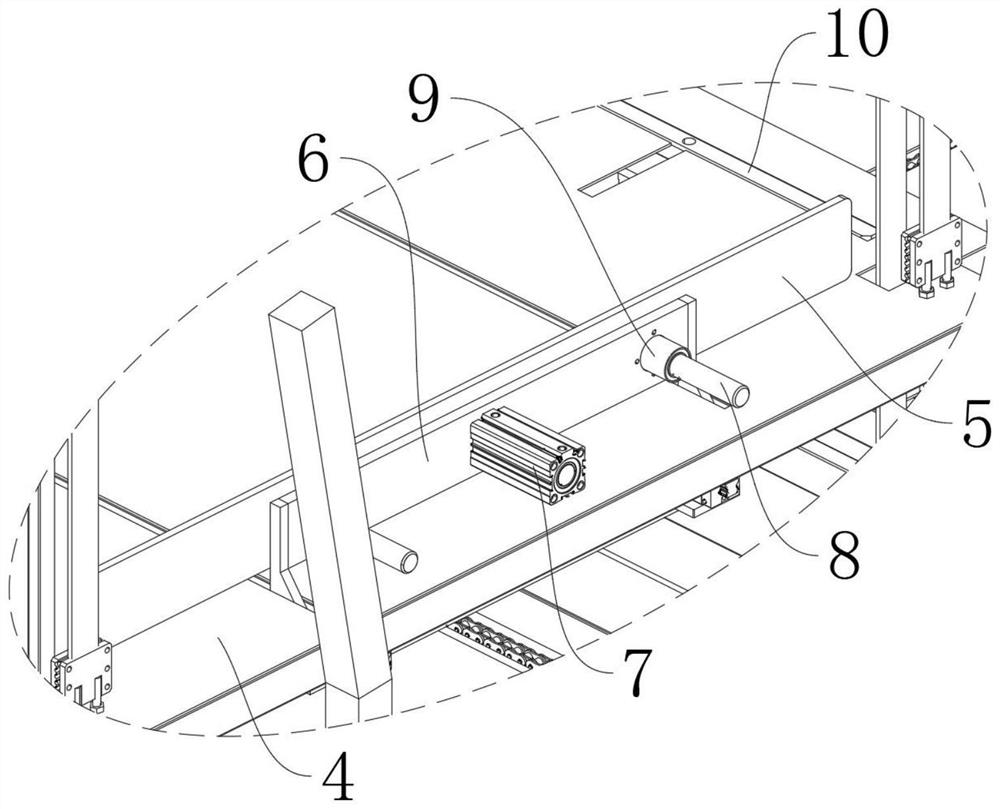

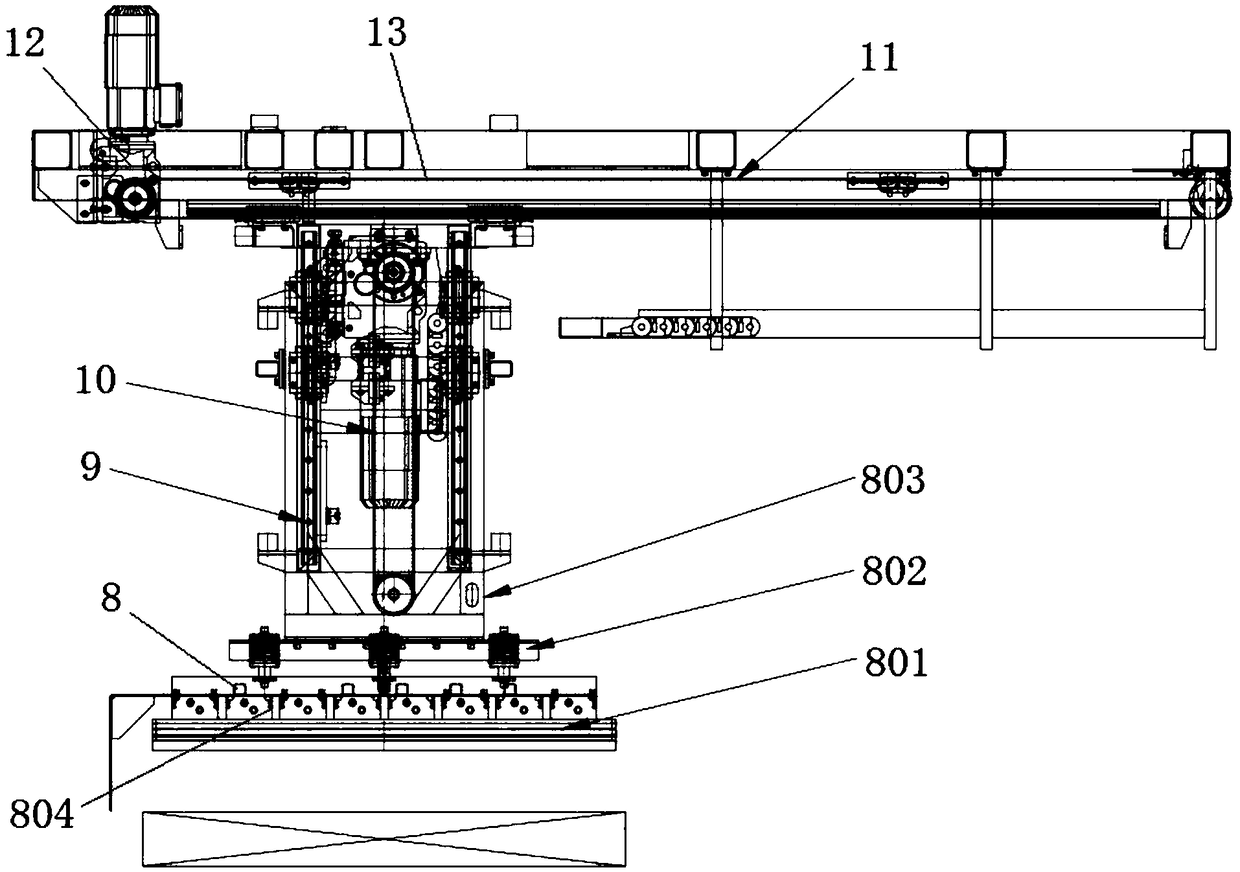

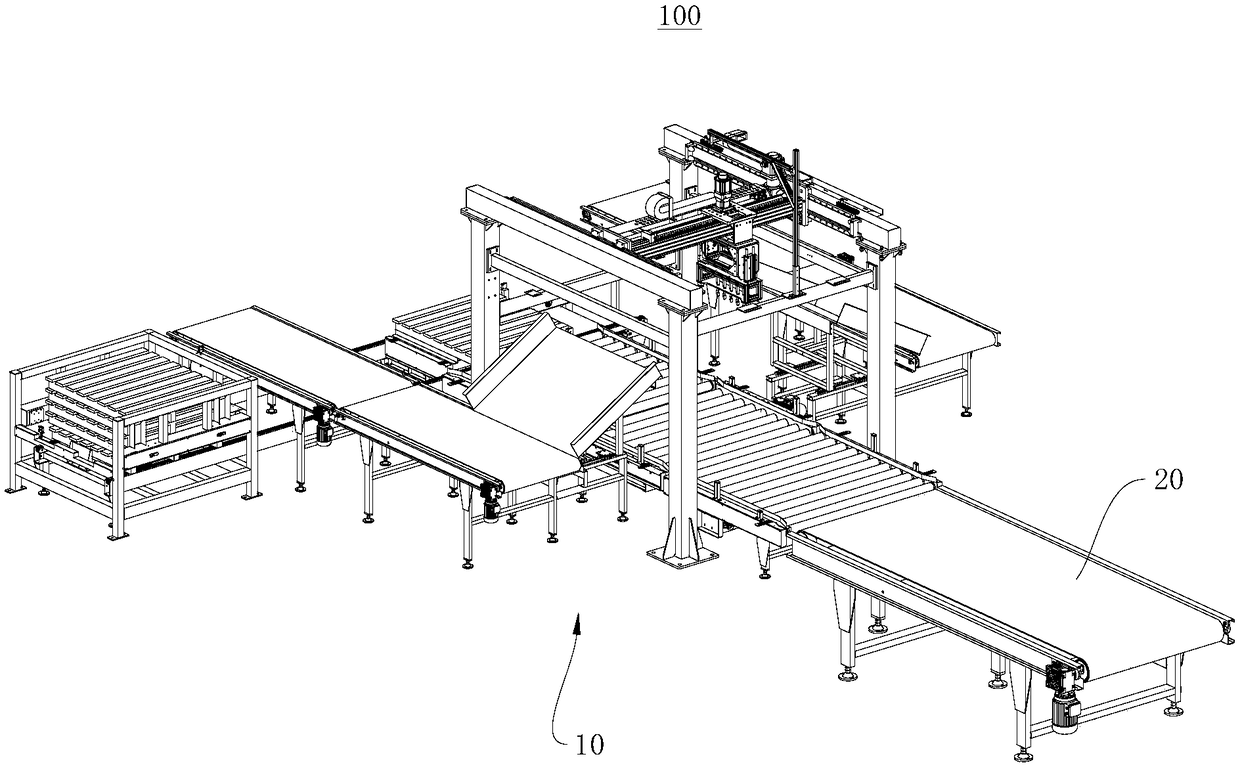

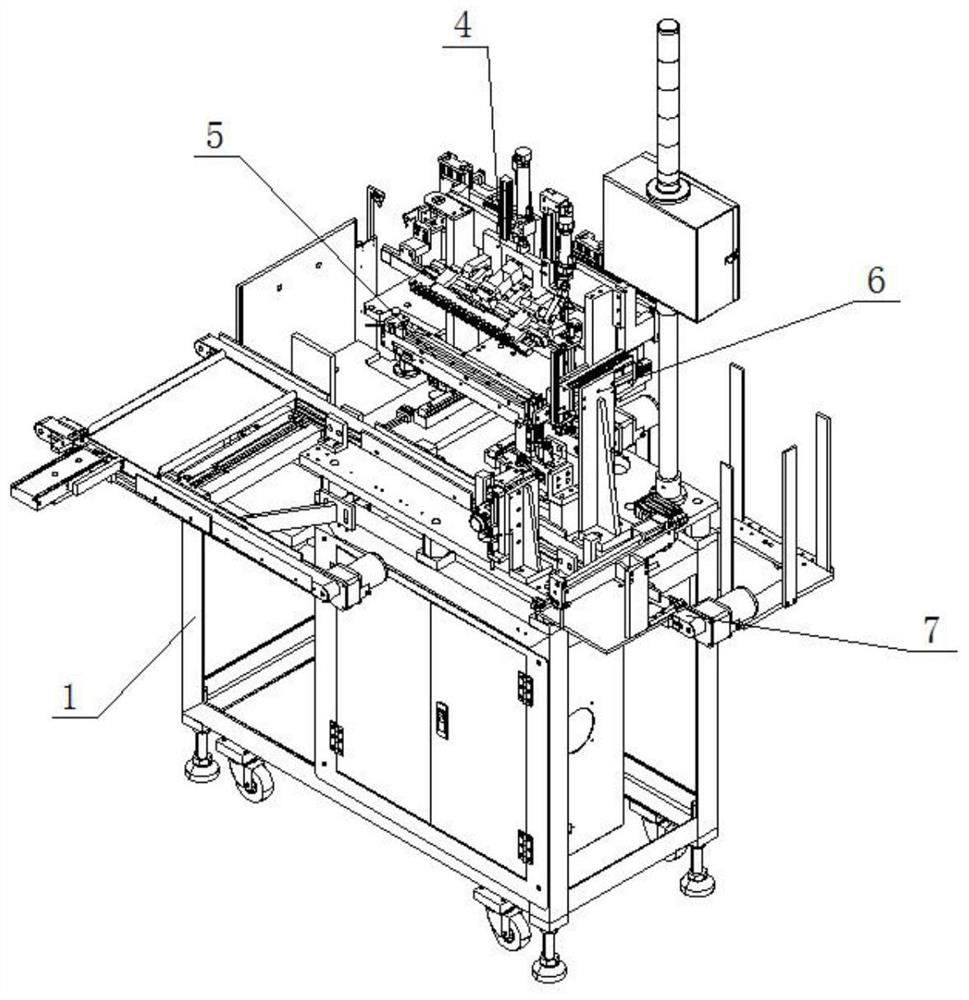

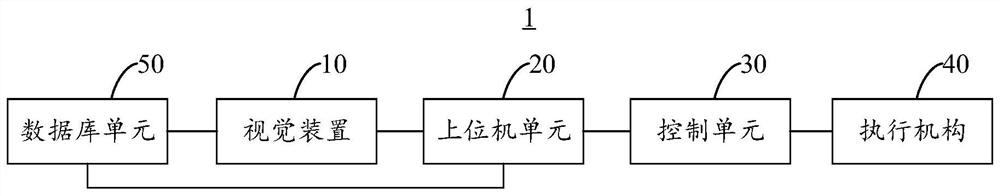

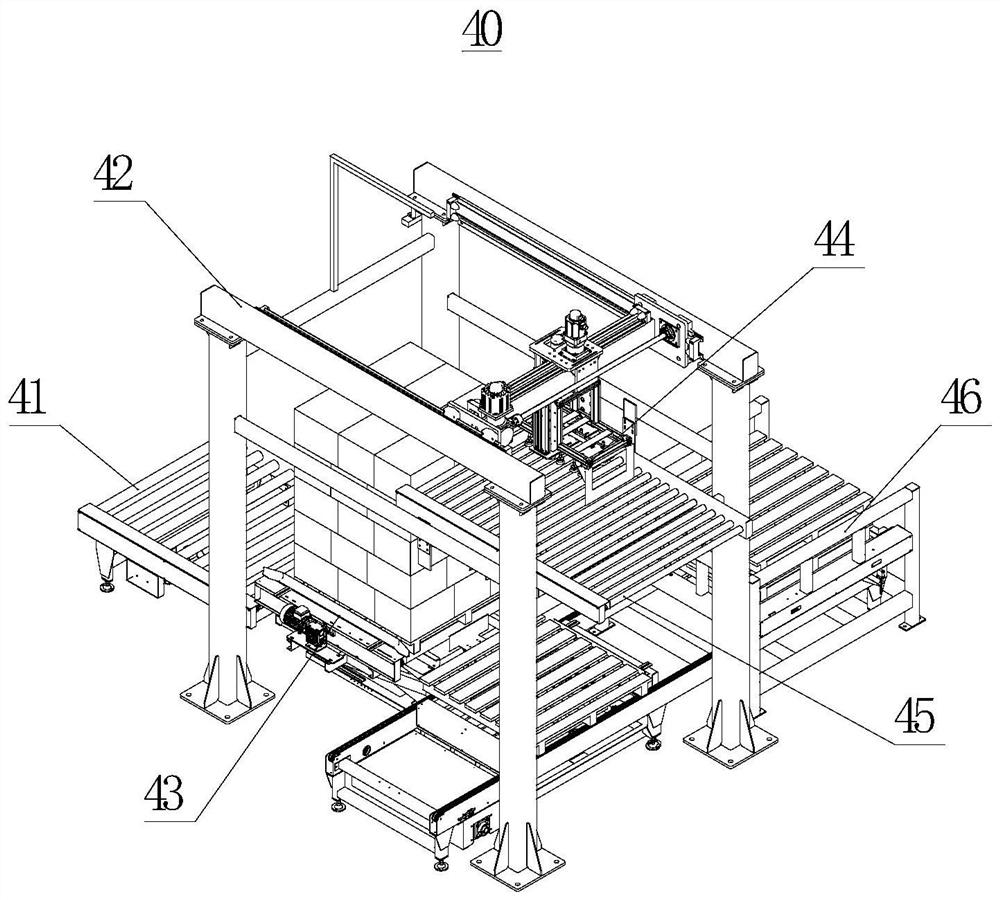

Intelligent high-speed unattended dispatching assembly line

ActiveCN113401676AShort time spentLow costStacking articlesDe-stacking articlesAutomotive engineeringAssembly line

The invention relates to the technical field of material conveying, and discloses an intelligent high-speed unattended dispatching assembly line which comprises a transfer conveyor arranged between a workshop and a transport vehicle. An automatic unstacking system and an automatic feeding system are installed at the inner end of the transfer conveyor, and an automatic loading system is installed at the outer end of the transfer conveyor. The automatic feeding system transfers material stacks into the automatic unstacking system and recycles and arranges carriers bearing the materials, the automatic unstacking system automatically unstacks the material stacks and conveys the materials to the inner end of the transfer conveyor one by one, automatic loading of the material stacks from the interior of the workshop to the exterior of the workshop at a long distance is achieved, and manual unstacking is not needed. By means of manual loading and stacking, consumed time is short, cost is reduced, loading speed is high, loading efficiency is high, the automation degree is high, practicability is extremely high, carrier recycling and sorting time is short, the carriers are not prone to damage, cost can be effectively reduced, and the automation degree, the unstacking speed and the unstacking efficiency are high.

Owner:山东加法智能科技有限公司

Roller unstacking deviceand method

PendingCN109436817AAvoid deformationReduce the impact of subsequent operationsConveyorsControl devices for conveyorsMechanical engineeringEngineering

The invention discloses a roller unstacking device and method, and relates to the technical field of logistics equipment. The roller unstacking device comprises a splitting assembly and a receiving assembly, the splitting assembly comprises a splitting moving mechanism and a friction splitting mechanism, the friction splitting mechanism comprises a splitting roller connected to the splitting moving mechanism, a splitting station is arranged at the position, close to the splitting moving mechanism, the position, on one side of a receiving platform, of the receiving assembly is arranged close tothe splitting station, and can be close to the edge of the bottom of top-layer goods of a goods stack, the splitting moving mechanism can drive the splitting roller to move towards thetop-layer goods, thus the splitting roller is pressed on part or all of the top-layer goods, the splitting roller can rotate, and drives the part or all of the top-layer goods to move towards the receiving platformto make the corresponding goods enter the receiving platform. According to the roller unstacking device and method, the unstacking efficiency is high, goods deformation is not prone to being caused inthe unstacking process, and the goods are not prone to being stacked.

Owner:CHINA HEFEI TAIHE OPTOELECTRONICS TECH

Skid destacking truss device

ActiveCN110877826AImprove unstacking efficiencyReduce labor costsStacking articlesDe-stacking articlesStructural engineeringControl theory

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

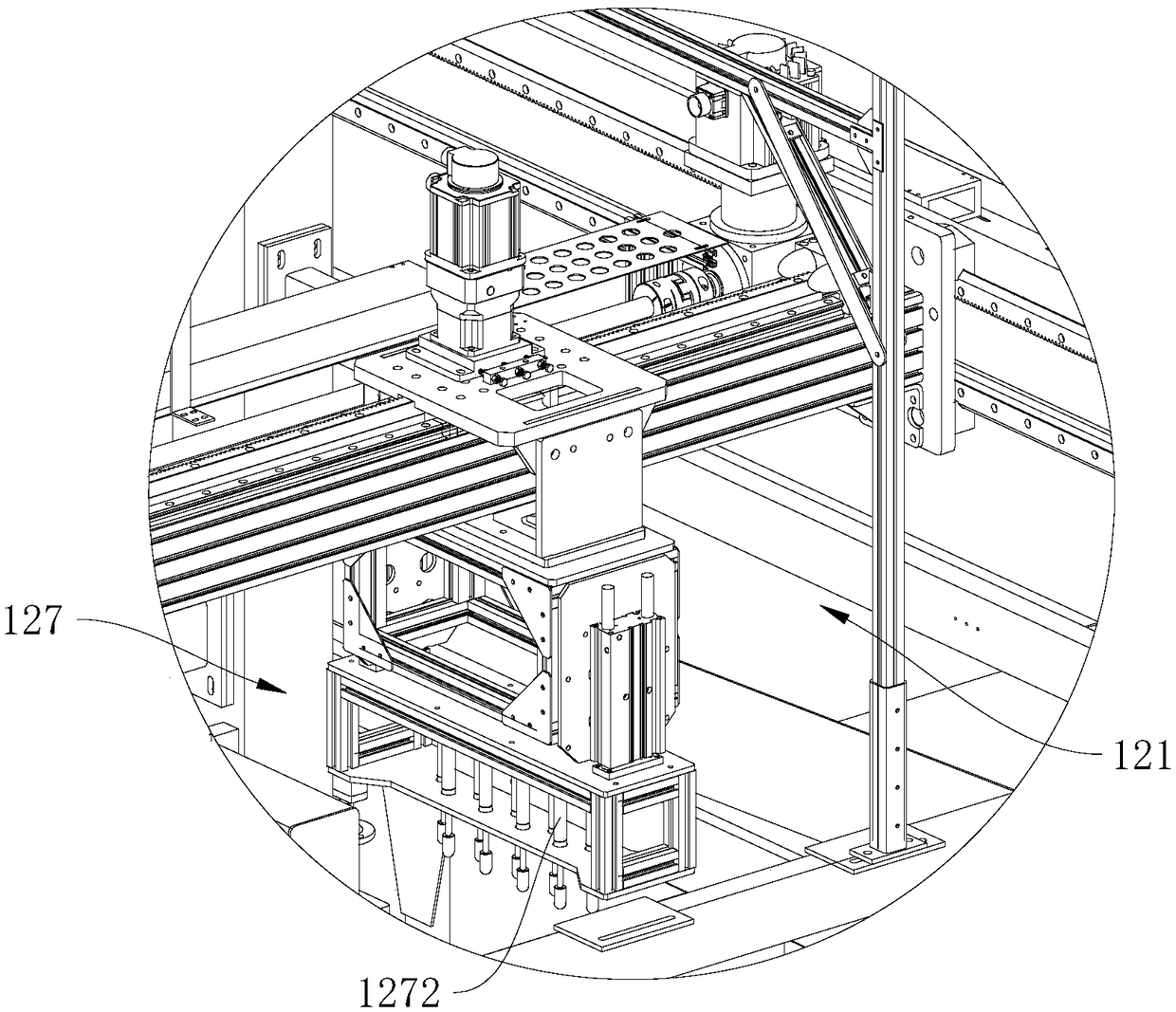

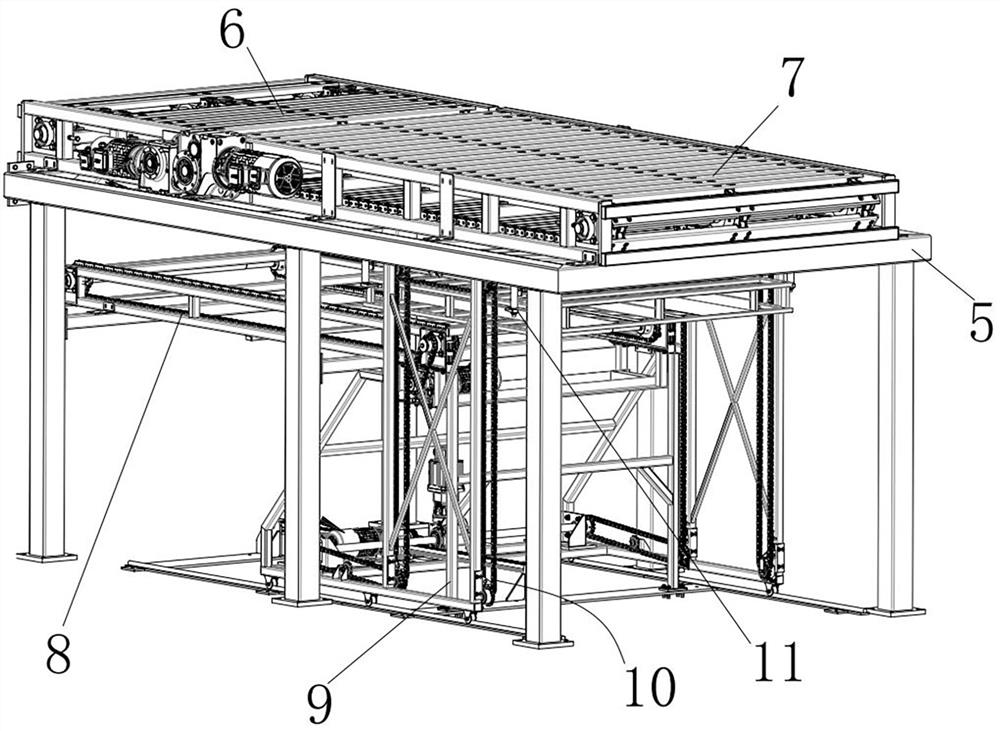

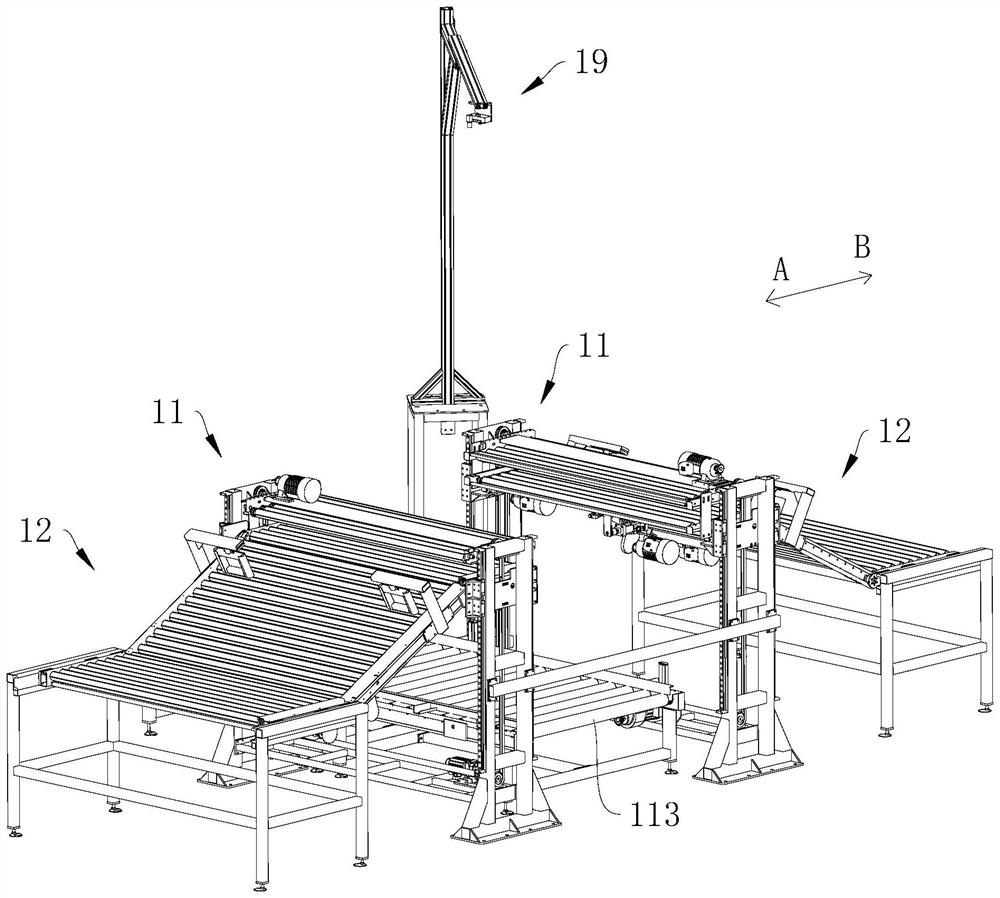

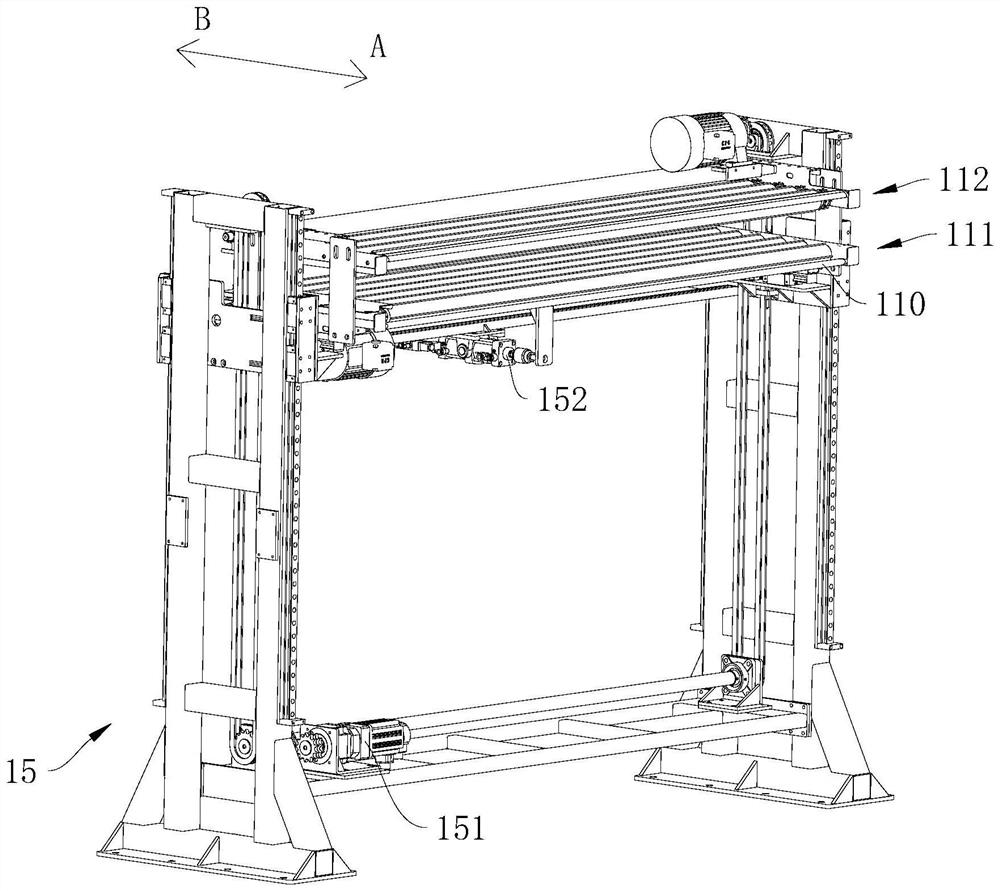

Unstacking device, unstacking system and unstacking method

PendingCN111908145AStable depalletizing operationHigh depalletizing efficiencyConveyorsDe-stacking articlesEngineeringStructural engineering

The invention discloses an unstacking device, an unstacking system and an unstacking method, and relates to the technical field of unstacking. The unstacking device comprises an unstacking assembly and an unstacking and moving mechanism, wherein the unstacking assembly comprises a first unstacking and conveying mechanism, and the unstacking and moving mechanism is connected with the first unstacking and conveying mechanism and can be used for driving the first unstacking and conveying mechanism to lift, so that the starting end of the first unstacking and conveying mechanism is abutted with the sides of bag cargoes with different heights on cargo stacks. When the starting end of the first unstacking and conveying mechanism is abutted with the sides of the bag cargoes, the bag cargoes can be driven to move, so that the bag cargoes pass through the starting end and the top of the first unstacking and conveying mechanism in sequence and move to the tail end of the first unstacking and conveying mechanism, and the bag cargoes are taken out from the cargo stacks. The unstacking device, the unstacking system and the unstacking method have the characteristics of high stability and high unstacking efficiency in unstacking the bag cargoes.

Owner:CHINA HEFEI TAIHE OPTOELECTRONICS TECH

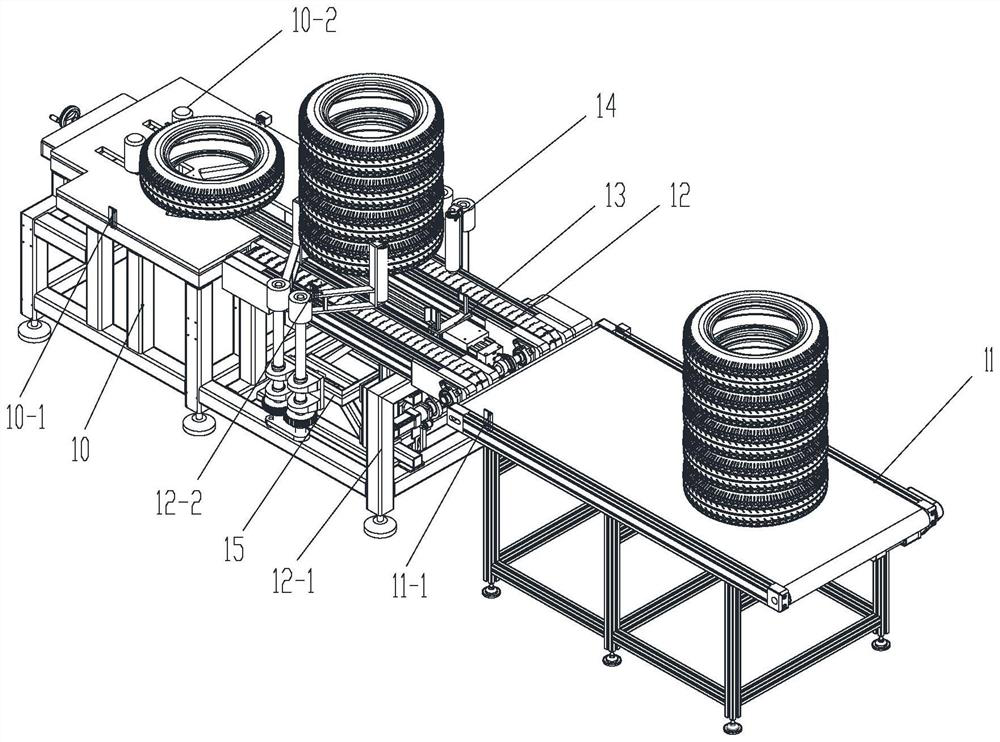

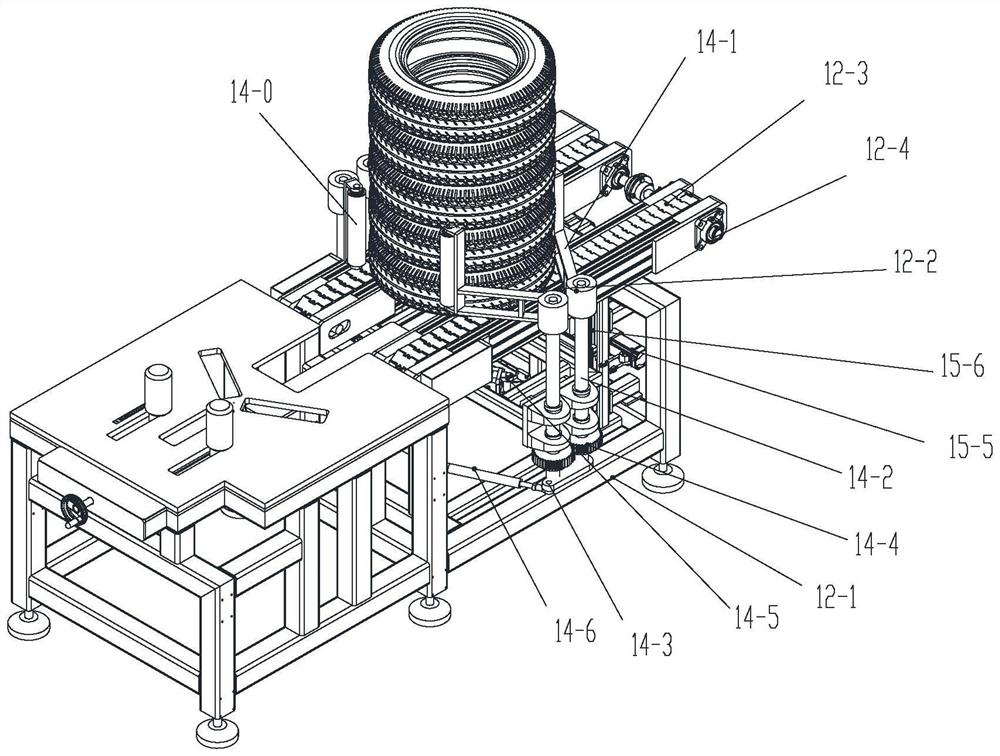

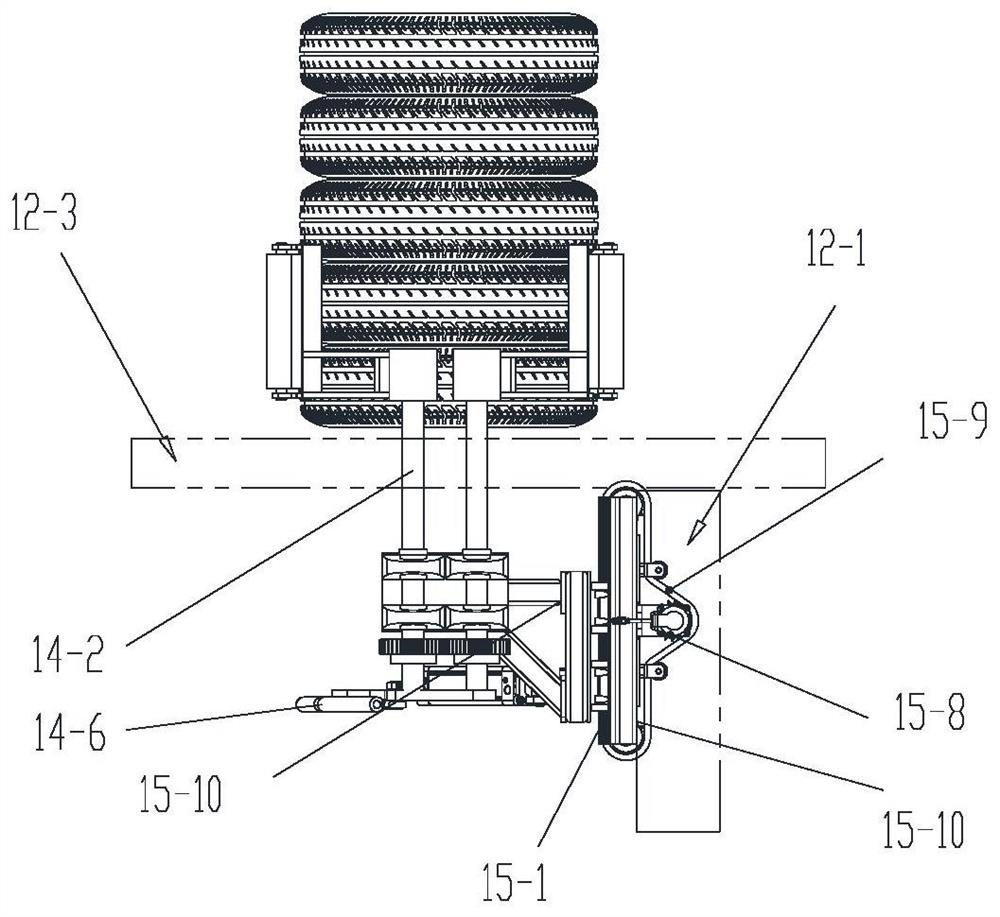

Motorcycle tire final assembly unstacking and conveying method

ActiveCN113086558AImprove production efficiencyReduce manufacturing costConveyorsPlastic recyclingBelt conveyorLeather belt

The invention discloses a motorcycle tire final assembly unstacking and conveying method. An unstacking and directional pushing device and method specially matched with final assembly production are provided, manual field operation is expected to be completely replaced through self-localized and intelligent special equipment, the production efficiency is improved, and an inner supporting piece filling technology is refined. The motorcycle tire final assembly unstacking and conveying method comprises the steps that 1, a whole stack of motorcycle tires is conveyed on a belt conveyor of a first conveying assembly; 2, the whole stack of tires continue to be conveyed forwards along a second conveying assembly; 3, other tires except the bottommost tire in the whole stack of tires are clamped in the circumferential direction by a clamping assembly, and the tires are lifted in the vertical direction under the driving of a lifting transmission assembly; 4, the tires located on a bottommost layer are pushed forwards to a center frame body through a tire pushing assembly; and 5, the clamping assembly clamps the remaining tires and is driven by the lifting transmission assembly to descend in the vertical direction so that the remaining tires can be placed on the second conveying assembly again, and the clamping assembly resets and loosens the tires.

Owner:QINGDAO WANLONG INTELLIGENT CONTROL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com