Un-stacking method and stack bag detachment device

A technology for pallets and bags, applied in the field of destacking, stacking and unpacking devices, and can solve problems such as low operation efficiency, high labor intensity of workers, and inability to connect conveying systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

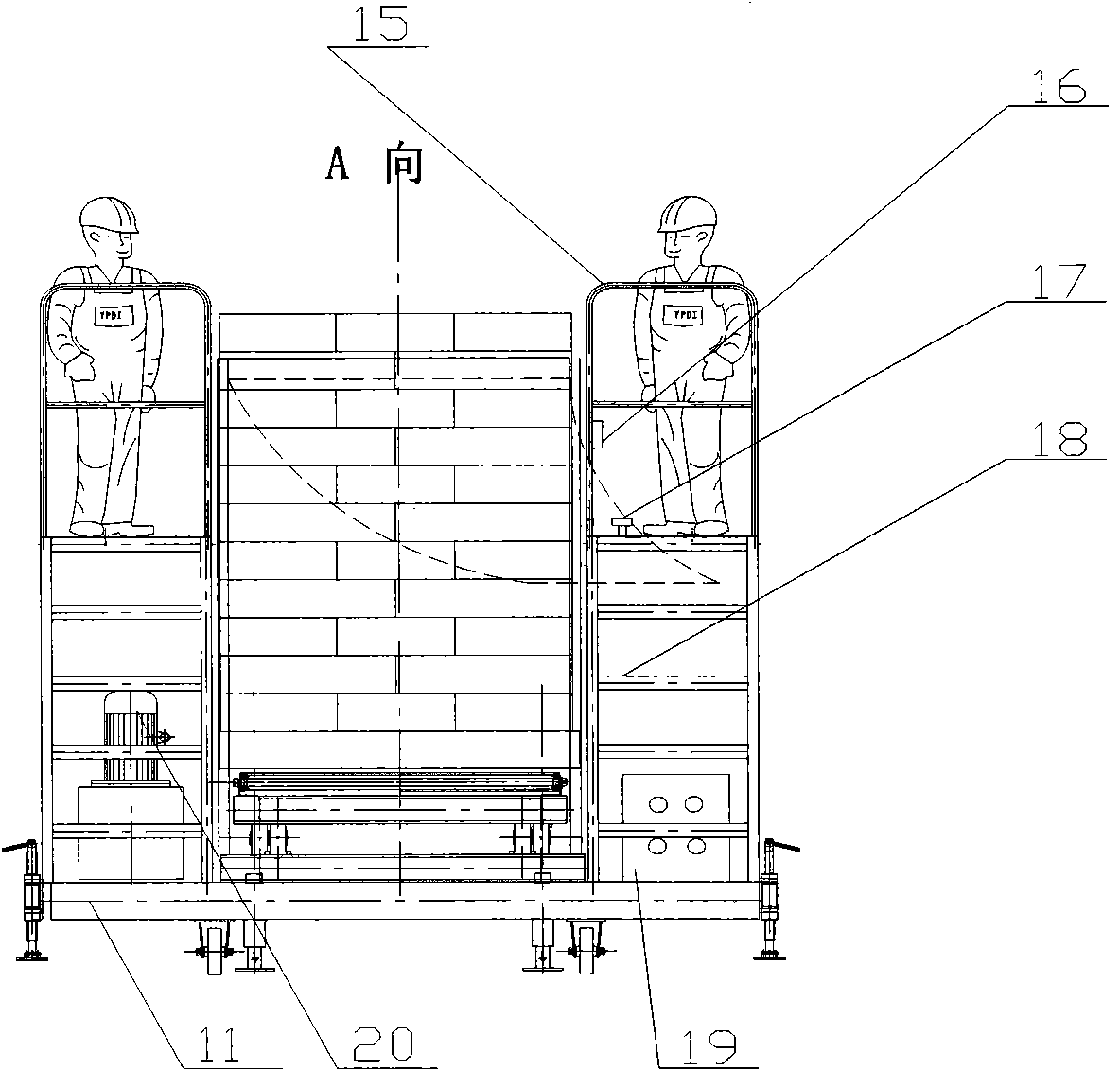

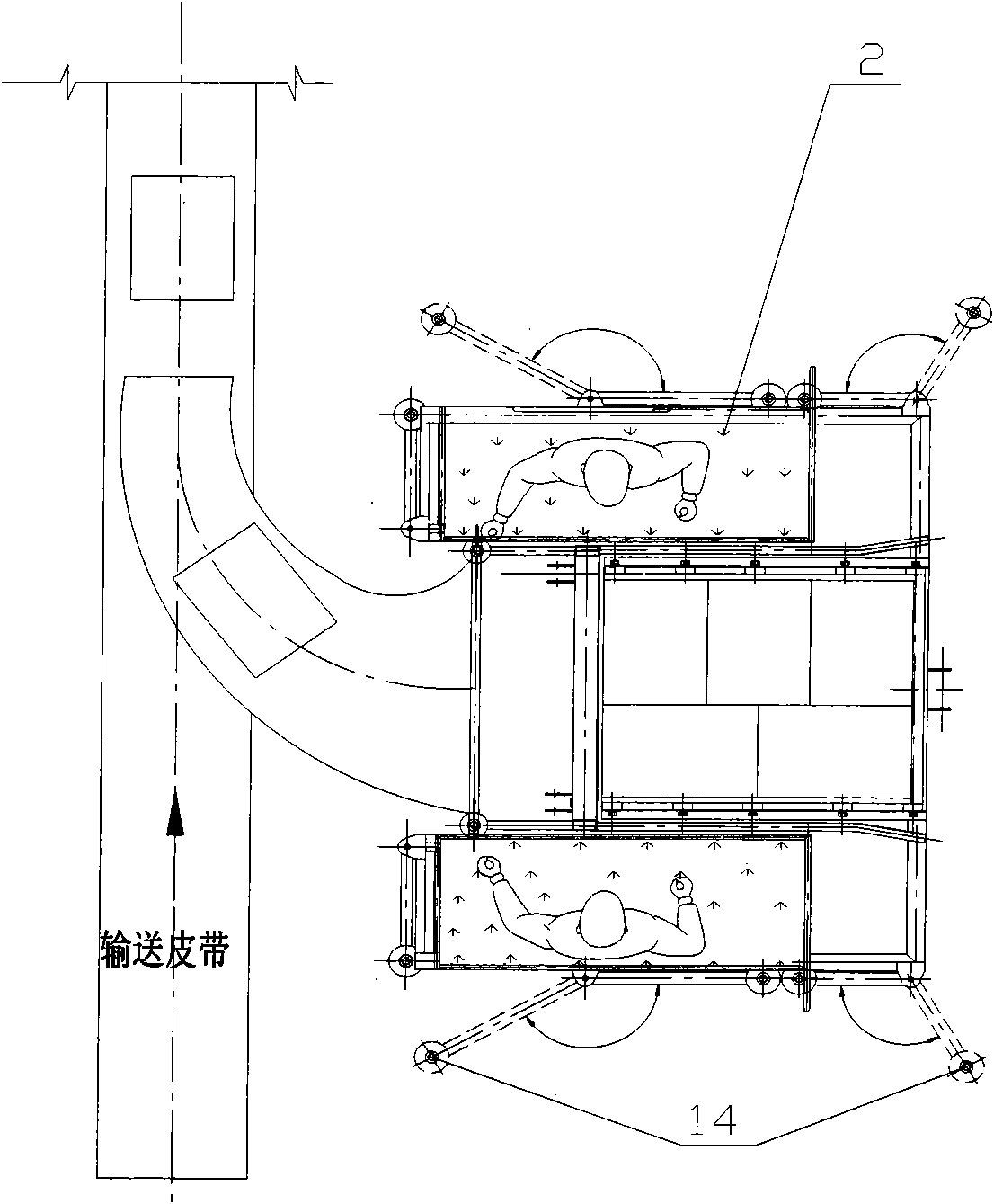

[0035] Such as Figure 1-Figure 6 Shown, underframe (11) is the chassis of whole machine in the pallet dismantling device of the present invention, is equipped with moving wheel (10), fixed support leg (13) and swing arm support leg (14) below it. The four moving wheels (10) are traveling mechanisms for moving the unpacking device; the two fixed legs (13) are located under the front two corners of the underframe (11), and the four swing arms (14) To increase the stability of the destacker, it can be rotated to an appropriate position according to the site conditions and then fixed.

[0036] On the bottom frame (11) are equipped with stacking warehouse (3), tiltable chassis (9), operating platform (2), climbing ladder (18), distribution box (19), hydraulic station (20) and chute (1 ).

[0037] The stacking bin (3) is surrounded by three side fixed bin walls, and one side opening is used for stacking. The two side walls of the stacker (3) are perpendicular to the bottom frame...

Embodiment 2

[0054] The stacking and unpacking device of the present invention may not be provided with a tilting mechanism, but the lifting frame of the lifting mechanism is directly mounted on the bottom frame, and one end of the lifting hydraulic cylinder is connected to the connecting rod B of the lifting frame, and the other end is connected to the connecting rod C or Attaches directly to the chassis. Thus, the tilting hydraulic cylinder, solenoid valve B and corresponding control switches can be omitted. All the other parts are the same as embodiment one.

Embodiment 3

[0056] The front wall of the stacker in the first embodiment above is fixed at an angle, which cannot be adjusted after being determined. The bottom of the front wall of the present embodiment is fixed on the tiltable chassis, and the inclination angle of the front wall is synchronized with the tiltable chassis, that is, the tiltable chassis drives the front wall to tilt together. The structure of other parts and the unstacking method are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com