Unstacker

A technology of unstacking machine and lifting mechanism, which is applied in the direction of unstacking of objects, conveyors, stacking of objects, etc., which can solve the problems of inconvenience, low efficiency of unstacking, increased workload and labor intensity, etc., to improve safety performance, improve the efficiency of unstacking, and save time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

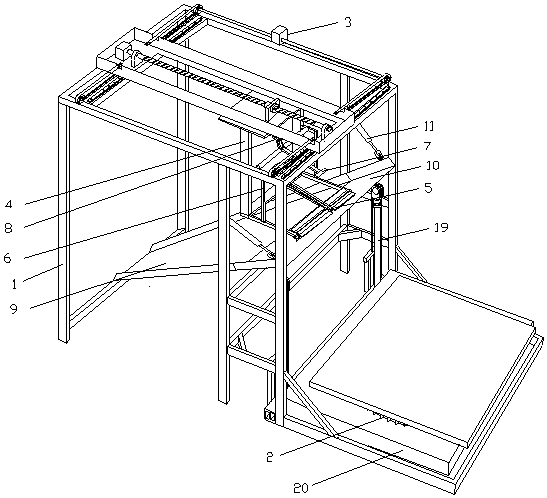

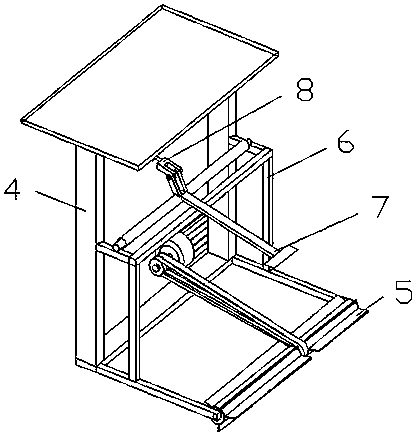

[0027] Embodiment 1: A depalletizer, comprising a depalletizing device and an empty pallet transfer device. Such as figure 1 Said, the destacking device comprises a first support 1 and a second elevating mechanism 19 located on one side of the first support 1, the first support 1 comprises two vertical and parallel rectangular plates, the rectangular The plates are connected by beams. The lifting device includes a second lifting mechanism 19 and a supporting plate 20 fixed to the movable end of the second lifting mechanism 19. The supporting plate 20 is located on one side of the first support 1 and a small part is inserted between two rectangular plates. Two guide rails are affixed to the first support 1, and bar-shaped grooves arranged in opposite directions are vertically arranged on the guide rails. The two ends of the supporting plate 20 near the side of the first support 1 are affixed with square blocks, and the square blocks are inserted into the corresponding bars. I...

Embodiment 2

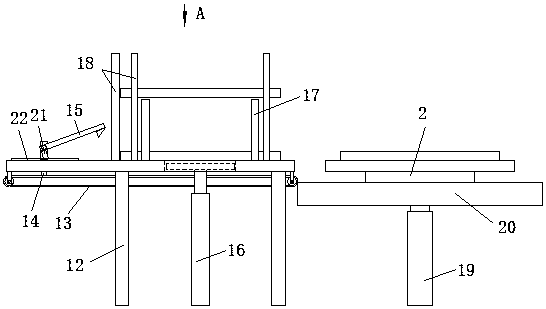

[0036] Embodiment 2: In this embodiment, three driving mechanisms and split bag clamping devices are provided respectively, and the driving mechanism is a ball screw transmission mechanism, which can convert rotation into linear movement, and has the function of reciprocating linear movement , is the prior art, and will not be repeated here. Crossbeams are arranged between the upper two corners of the two rectangular plates, and the ball screw transmission mechanism is fixedly connected to the crossbeams of the first bracket 1 in parallel with each other, and the moving direction of the ball slider is consistent with the direction of the drag bag. The disassembled bag clamping devices are respectively fixedly connected to the ball sliders of the corresponding ball screw transmission mechanism, so as to realize the linear reciprocating movement in the direction of dragging the bag.

[0037] Among them, the position of the ball screw transmission mechanism in the middle is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com