Automatic destacking system for bagged material packages

A material package and automatic technology, which is applied in the direction of object destacking, object stacking, transportation and packaging, etc., can solve the problems of material package drop, difficult precise positioning, low linkage, etc., to avoid falling and improve Unstacking efficiency, ensuring a stable gripping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

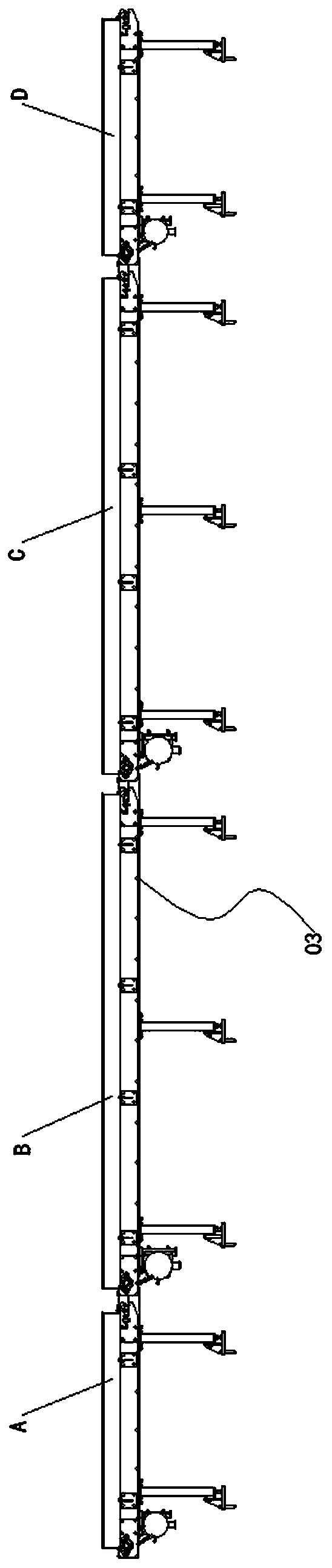

[0048] A kind of automatic unstacking system of bagged material package of this embodiment, such as figure 1 , figure 2 , image 3 , Figure 14 As shown, it includes an automatic unstacker 01, an empty pallet recovery device 02, and a material storage device 03. The feeding end of the automatic unstacker 01 is provided with a lifting and rotating platform 1, and one end of the lifting and rotating platform 1 is opposite to The discharge end of the material storage device 03 should be set, and the other end of the lifting and rotating platform 1 is set corresponding to the tray inlet of the empty pallet recovery device 02; the top of the discharging end of the automatic destacker 01 is provided with Grasp the plane mobile manipulator 2 of the material on the lifting and rotating platform 1; the bottom of the plane mobile manipulator 2 slides along the discharge direction and is provided with a discharge conveying device 3 for unloading, and one side of the discharge conveyin...

Embodiment 2

[0056] This embodiment is further optimized on the basis of the above-mentioned embodiment 1, such as Figure 4 , Figure 5 , Figure 6 As shown, the lifting and rotating platform 1 includes a lifting platform assembly 11 and a rotating platform assembly 12. The lifting platform assembly 11 is slidably arranged on the feeding end of the automatic destacker 01 along the vertical direction, and the rotating platform assembly 12 rotates It is arranged on the top of the lifting platform assembly 11, and one end of the rotating platform assembly 12 is set corresponding to the discharge end of the material storage device 03, and the other end of the rotating platform assembly 12 is set corresponding to the tray inlet of the empty tray recovery device 02; The platform assembly 12 includes a rotary platform 121, a transmission roller 122, a rotary drive device 123, and a transmission roller drive motor 124. The rotary platform 121 is rotatably arranged on the top of the lifting platf...

Embodiment 3

[0066] This embodiment is further optimized on the basis of above-mentioned embodiment 1 or 2, such as Figure 5 As shown, the discharge end of the rotary platform 121 is provided with a lifting and blocking device, and the two sides of the rotary platform 121 parallel to the transmission direction of the transmission roller 122 are provided with telescopic monolithic devices parallel to the axial direction of the transmission roller 122 .

[0067] The lifting and stopping material device is a lifting and stopping material cylinder, and the end of the push rod of the lifting and stopping material cylinder is rotated to be provided with a buffer roller. The roller 122 conveys, and only the side with the material package is blocked by the push rod of the lifting and blocking material cylinder. The buffer roller at the end of the push rod effectively buffers the collision between the material package and the push rod. When placing the material package from the rotary platform 121...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com