Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about How to "Improve roll changing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Counterflow roller changing method for realizing online roller changing of ESP (endless strip production) finishing mill unit

ActiveCN106269888AImprove roll changing efficiencyImprove stabilityRoll force/gap control deviceMetal rolling stand detailsPulp and paper industryChanging equipment

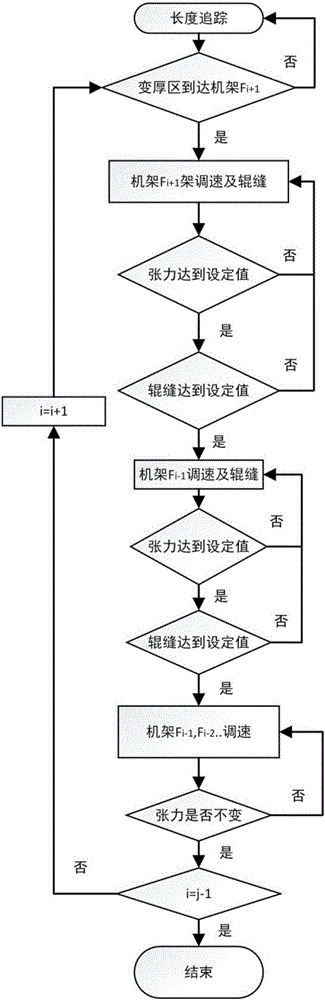

The invention provides a counterflow roller changing method for realizing online roller changing of ESP (endless strip production) finishing mill unit. The method is used for ESP finishing mill unit online roller changing equipment equipped with six racks. During normal rolling production, any five racks are put into operation, and one rack is used as a standby rack. The method adopts a counterflow roller changing strategy and comprises the following steps: (1) collecting and inputting of collecting technology, strip and mill parameters; (2) roller lifting and speed regulation of the roller changing rack Fi; (3) roller speed regulation and roller gap adjustment of the transition rack F (i+1); (4) roller speed regulation and roller gap adjustment of the transition rack F (i+2); (5) adjustment of the transition racks in the upstream of the standby rack Fj; (6) pressing down and roller speed regulation of the standby rack Fj. By control of the roller changing process according to the mathematic model provided by the method, the roller changing efficiency and the roller changing process stability can be improved, the control precision of the product thickness is improved, and the industrial application accuracy requirement can be met.

Owner:YANSHAN UNIV

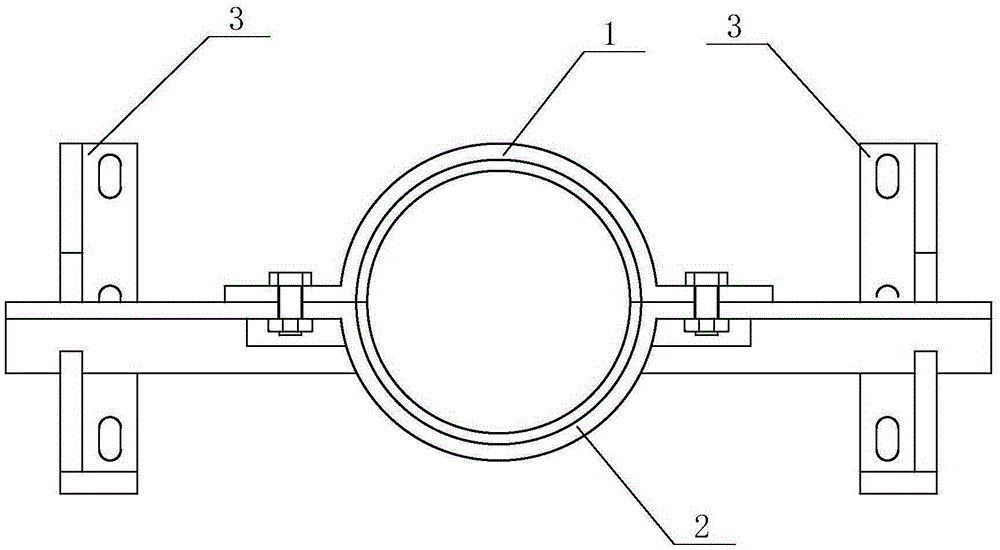

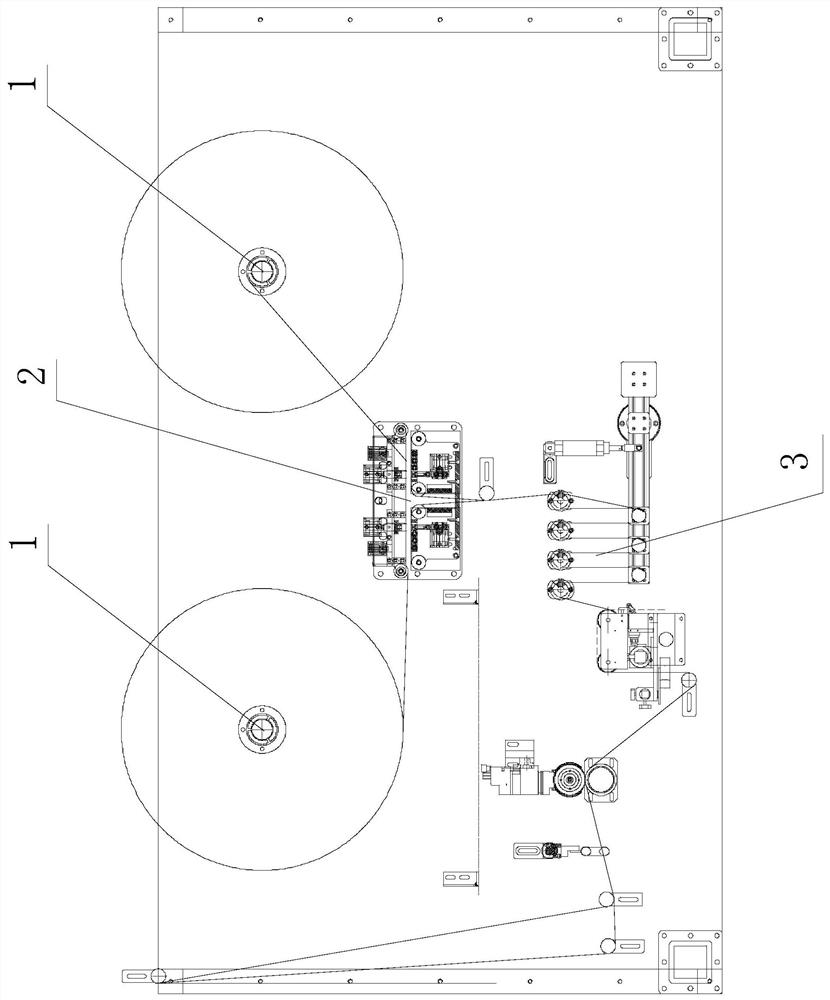

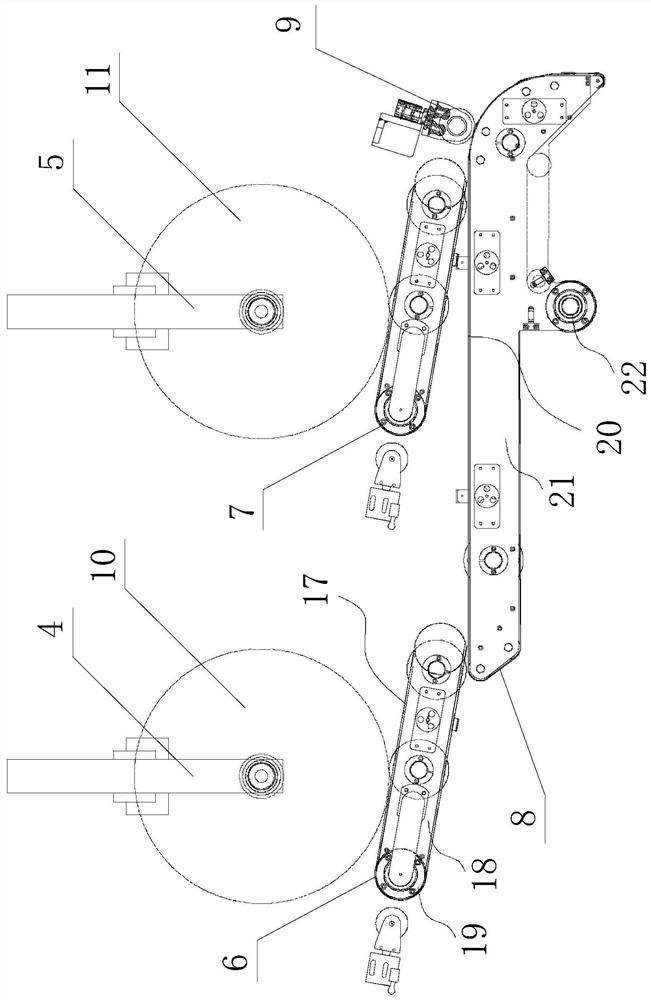

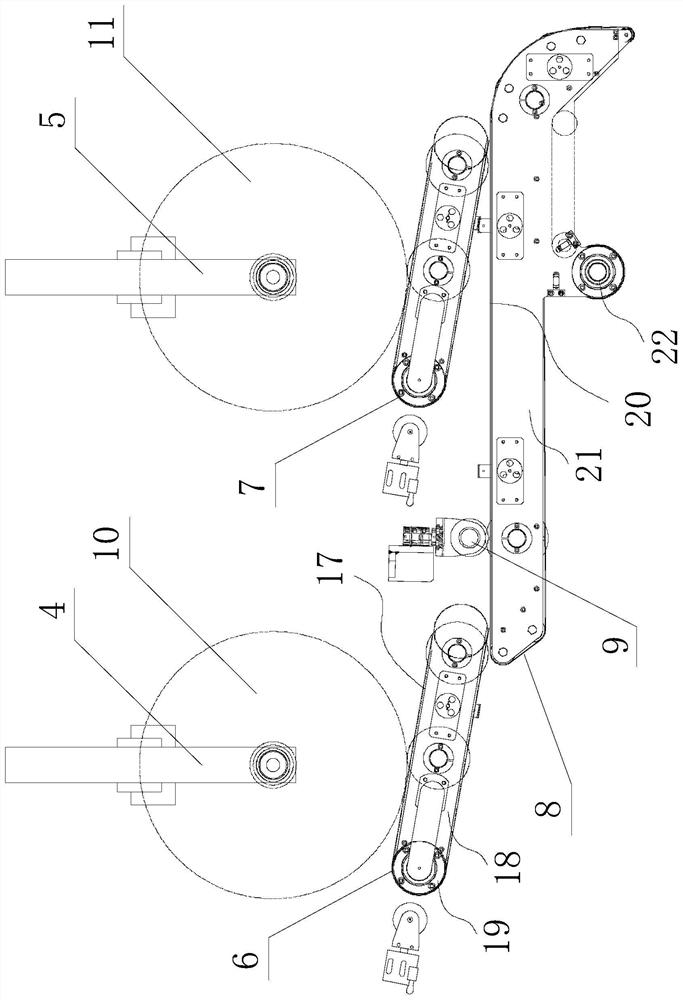

Double-station winding mechanism for polyimide film winding system

InactiveCN104860103AReduce labor costsImprove roll changing efficiencyWebs handlingEngineeringClutch

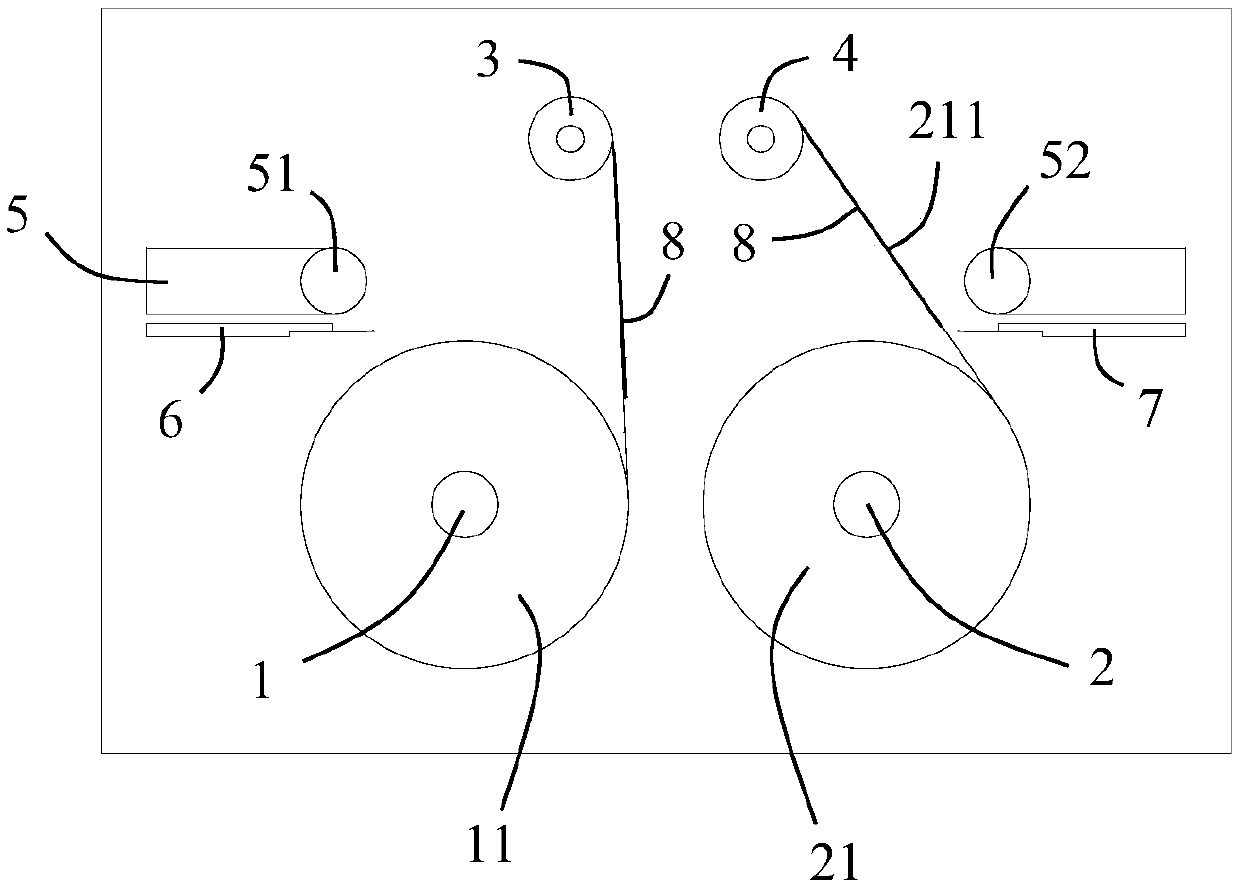

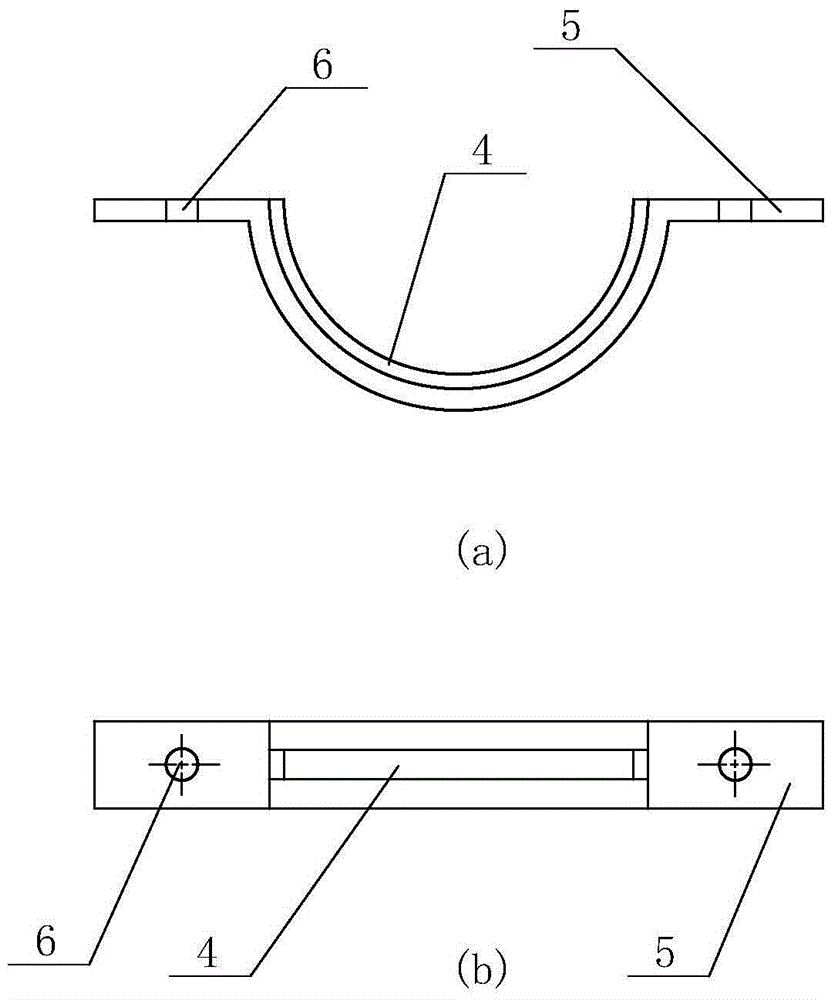

The invention discloses a double-station winding mechanism for a polyimide film winding system. The double-station winding mechanism comprises winding rollers (1), and the two ends of each winding roller (1) are arranged in a fixed shaft base (2) and a disengagement and engagement shaft base (3) respectively. The double-station winding mechanism is characterized in that a supporting base (4) is arranged under one end of each winding roller (1), and each supporting base (4) is located under the end, close to the corresponding disengagement and engagement shaft base (3), of the corresponding winding roller (1). The supporting bases are arranged under the ends, close to the disengagement and engagement shaft bases, of the winding rollers, so that only one worker is needed in the roll fetching process to open a clutch, the disengagement and engagement shaft bases are deviated, one end of each winding roller is exposed and located on the corresponding supporting base, the worker takes the winding rollers down with hand, roll fetching work is completed, and labor cost is reduced because only one worker is needed in the winding process; meanwhile, because of double-station winding, roll change efficiency is further improved, and the double-station winding mechanism is suitable for application and popularization.

Owner:WUXI SHUNXUAN NEW MATERIALS

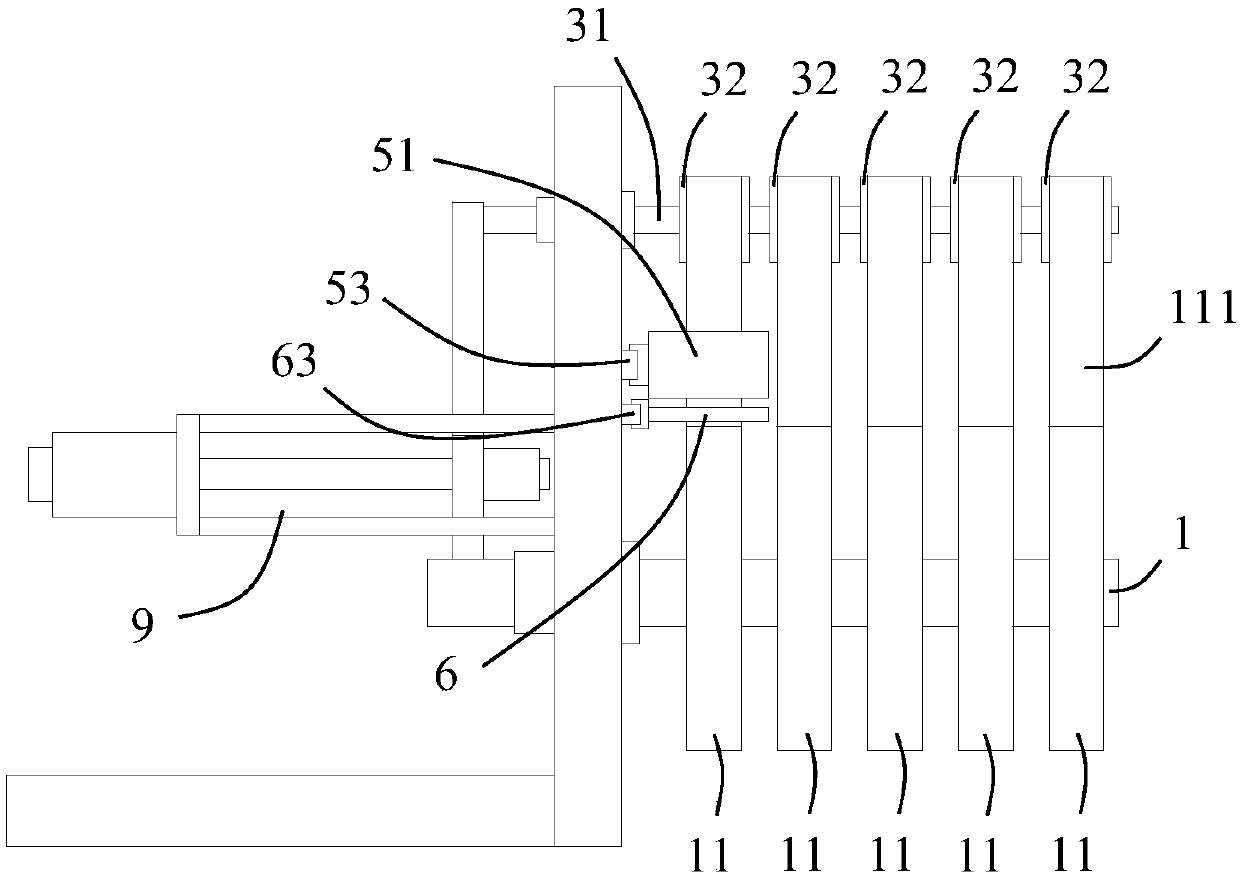

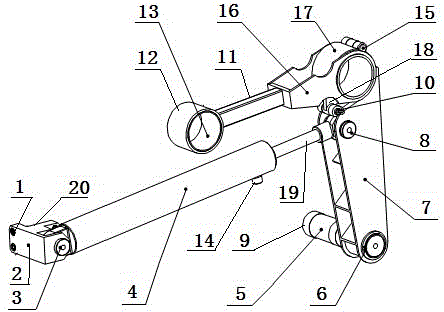

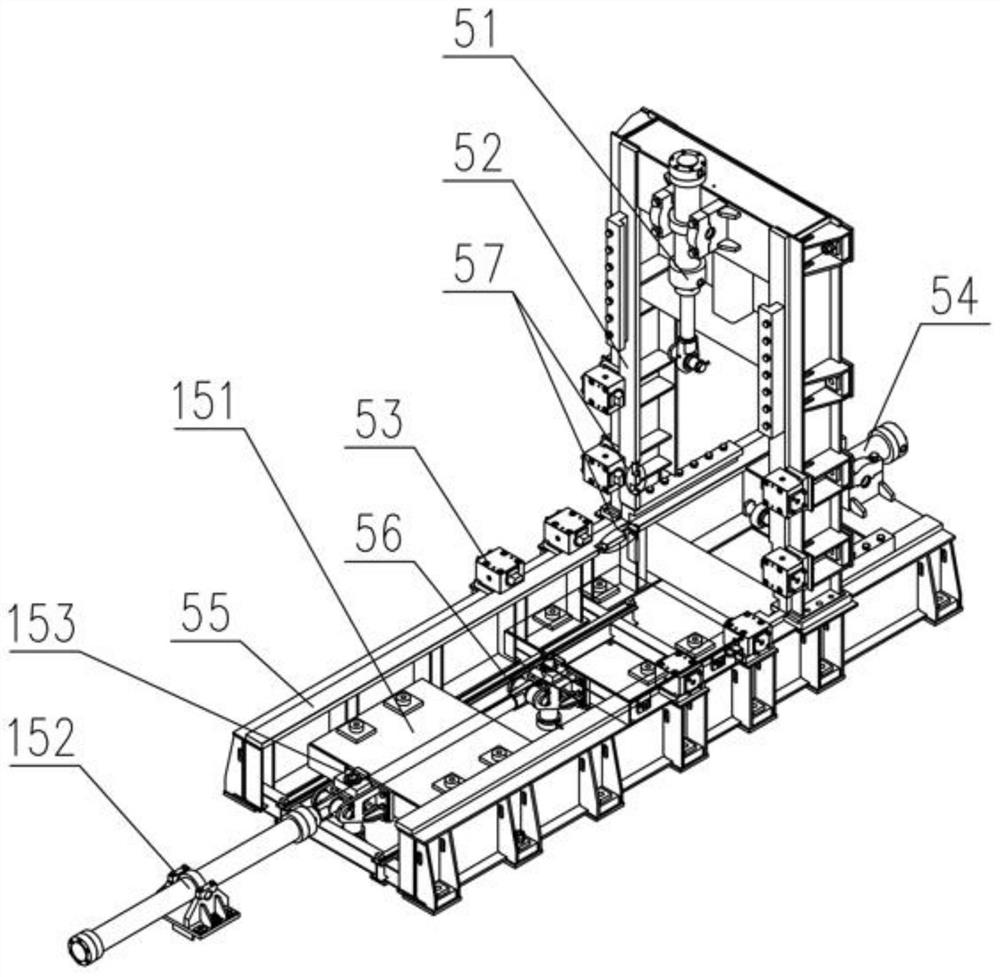

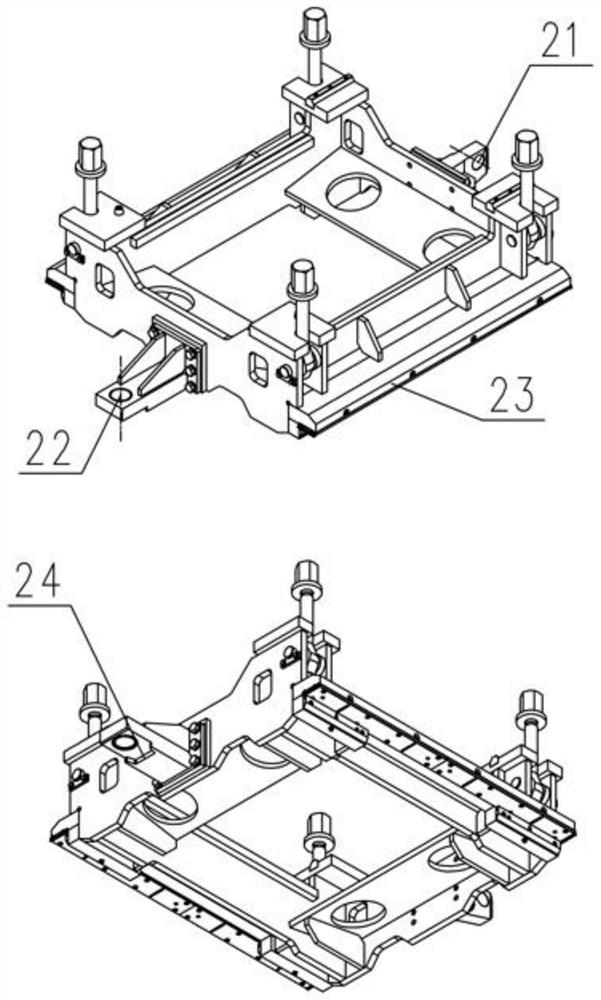

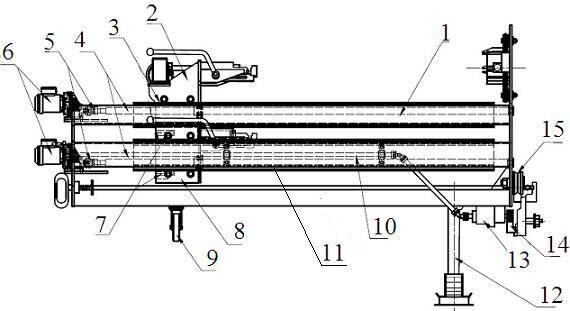

Roll changing carriage for steel belt machining line and roll changing method

ActiveCN106424148AQuick changeImprove roll changing efficiencyMetal rolling stand detailsMetal rolling arrangementsSteel platesEngineering

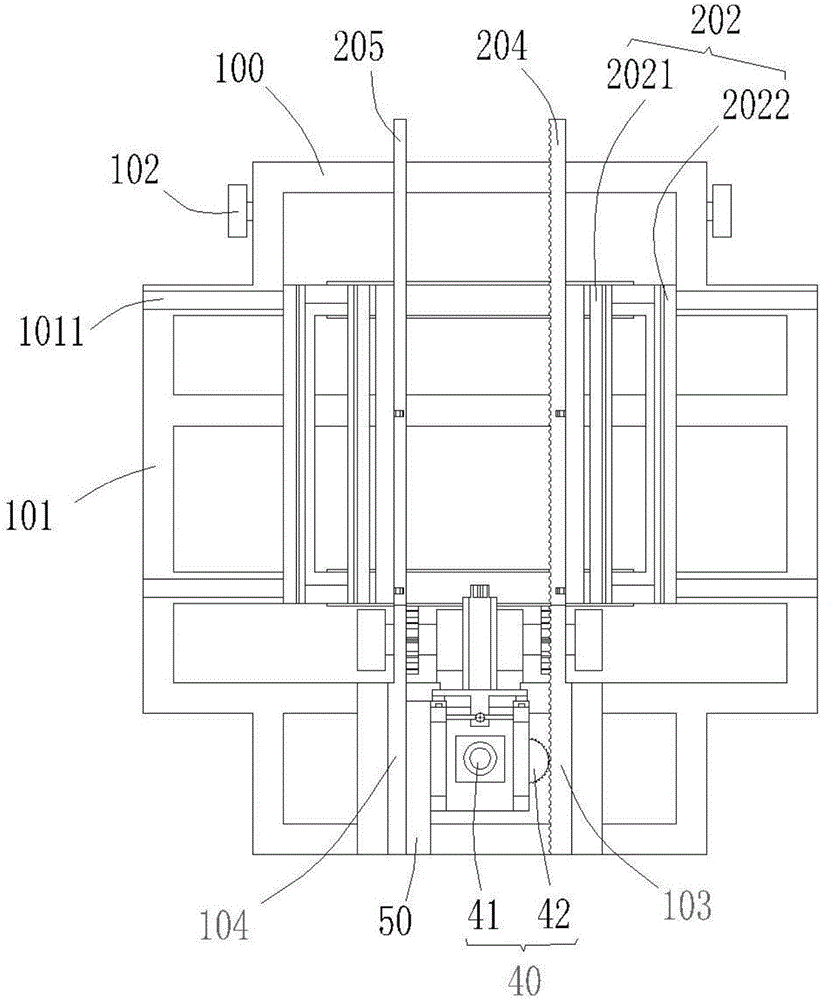

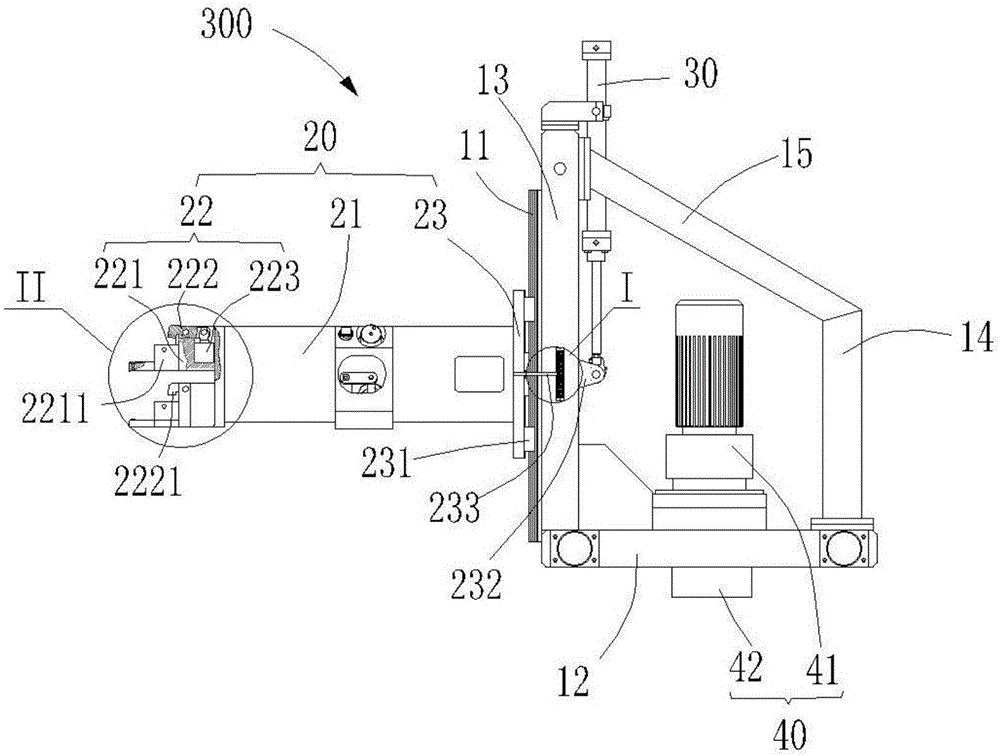

The invention provides a roll changing carriage for a steel belt machining line. The roll changing carriage for the steel belt machining line comprises a tackle, a support frame and a gripper device, wherein two guide tracks are arranged on the tackle in parallel in the transverse direction; a first gear sliding track and a first guide groove sliding track are longitudinally arranged at one end of the tackle to form a fixed guide track group which is used for mounting the gripper device; the support frame is slidably mounted on the two guide tracks of the tackle; the support frame comprises an underframe and roll storage racks formed on two sides of the underframe; a second gear sliding track and a second guide groove sliding track are arranged on sides, which are opposite to the two roll storage racks, of the underframe to form a middle guide track group of the support frame; the gripper device comprises a rack and a roll changing gripper mechanism which is mounted on the rack and can slide vertically relative to the rack; and the middle guide track group is aligned to the fixed guide track group by enabling the support frame to slide, so that the gripper device slides into the middle guide track group. The invention further provides a roll changing method of the roll changing carriage. By the roll changing carriage, rolls can be changed quickly, and roll changing efficiency and production efficiency of rolled steel plates are improved.

Owner:福建宏旺实业有限公司 +1

Roll replacing mechanism

PendingCN109677971AReduce stock preparation frequencyImprove roll changing efficiencyWebs handlingMechanical engineeringNew materials

The invention discloses a roll replacing mechanism. The mechanism comprises a first material rolling shaft and a second material rolling shaft, the first material rolling shaft and / or the second material rolling shaft are / is sleeved with multiple material rolls, when one of the first material rolling shaft and the second material rolling shaft is an unrolling shaft, the other one is a preparing shaft. When the unrolling shaft is located on the unrolling station, and the unrolled old material roll is about to be used up, the new material roll, on the unrolling station, of the preparing shaft isconnected to a material belt of the old material roll and enables the preparing shaft to become the new unrolling shaft, and the roll replacing efficiency is improved.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

Roller replacement device

ActiveCN104646429AEasy to pushEasy to adjustMetal rolling stand detailsMetal rolling arrangementsDegrees of freedomEngineering

The invention relates to a roller replacement device, which comprises a sliding plate, wherein limiting parts matched with the lower end faces of lower bearing pedestals connected with the two ends of a lower roller are arranged on the sliding plate, and are used for limiting the displacement of the sliding plate and the lower bearing pedestals along the axial direction of the rollers and parallel to the advancing direction of a material; the sliding plate forms guide sliding fit with guide rails on a base of a rolling mill. According to the roller replacement device, the degrees of freedom of the sliding plate and the lower bearing pedestals along the axial direction of the rollers and in the advancing direction of the material are restricted by the limiting parts on the sliding plate, and the lower bearing pedestals are arranged on the sliding plate, so that the lower bearing pedestals are probably not required to move downwards, and the rollers move together with the sliding plate in a movement process of the sliding plate, and can be conveniently pushed into and pulled out of a rack of the rolling mill.

Owner:HEFEI BAISHENG SCI & TECH

Coil replacement mechanism

PendingCN109677972AFirmly connectedReduce stock preparation frequencyWebs handlingEngineeringMechanical engineering

A coil replacement mechanism comprises a first coil shaft, a second coil shaft, a cutting assembly, a backing roller assembly and a rotating device. The first coil shaft and / or the second coil shaft are / is used for being provided with multiple coils in a sleeved manner. When one of the first coil shaft and the second coil shaft is a discharging shaft, the other of the first coil shaft and the second coil shaft is a preparation shaft. When old coils which are located on the uncoiling station and are already uncoiled on the discharging shaft are about to be used up, the backing roller assembly clamps a band, the band is cut off by the cutting assembly, the band clamped by the backing roller assembly is driven by the rotating device to be turned over, and the back face of the cut-off band andthe back face of a band on the preparation shaft are on the same face. The cut-off band and the band on the preparation shaft are connected together so that the preparation shaft can become a new discharging shaft. By means of the arrangement, the coil replacement efficiency is improved.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

Six-roll mill with upper middle roll capable of being rapidly changed, and roll changing method

PendingCN109500083AEasy to operateFlexible roll changeMetal rolling stand detailsMetal rolling arrangementsWork rollWear resistant

The invention provides a six-roll mill with an upper middle roll capable of being rapidly changed, and a roll changing method. The six-roll mill comprises a rack, wherein the upper middle roll, an upper working roll, a lower working roll and a lower middle roll are arranged in the rack; a roll changing rail for the lower working roll and a roll changing rail for the lower middle roll are further arranged in the rack; a roll bending device for the upper middle roll is further arranged on the rack; the roll bending device for the upper middle roll comprises roll bending cylinders for the upper middle roll and arranged at an operation side and a transmission side; a wear-resistant lining plate is arranged at the top of a piston rod of each roll bending cylinder for the upper middle roll; a group of rolling wheels is arranged at the two sides of an upper wing of a bearing seat for the upper middle roll separately; two connection rails are arranged between the operation side and the transmission side of the roll bending device for the upper middle roll; and the two connection rails are matched with the two groups of rolling wheels on the bearing seat for the upper middle roll separately. The six-roll mill is provided with a device for changing the upper middle roll independently, the upper middle roll can be changed independently and changed with the working rolls, and flexible rollchanging is achieved, so that the roll changing steps are simplified, and the roll changing efficiency is remarkably increased.

Owner:WISDRI ENG & RES INC LTD

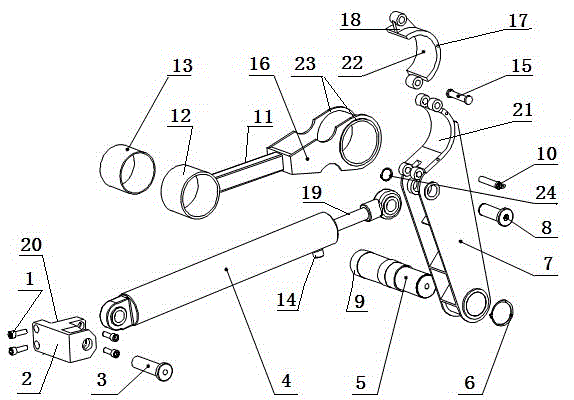

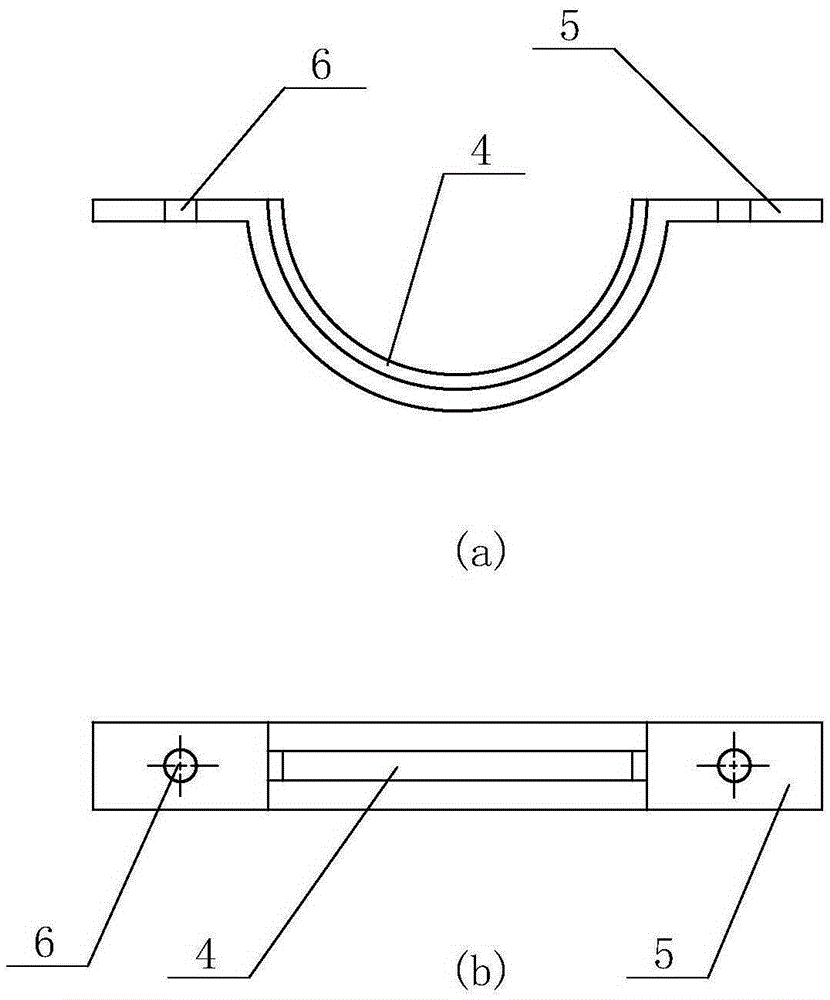

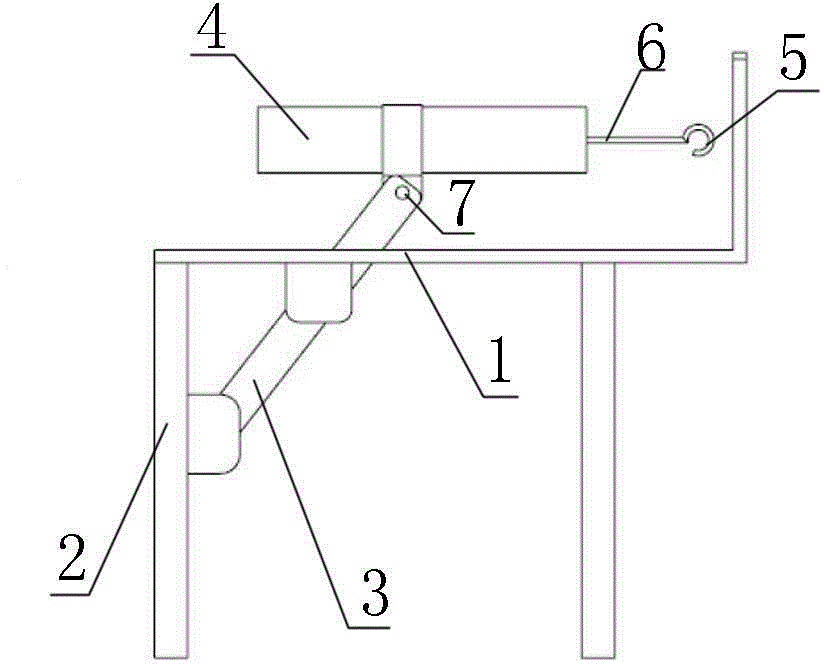

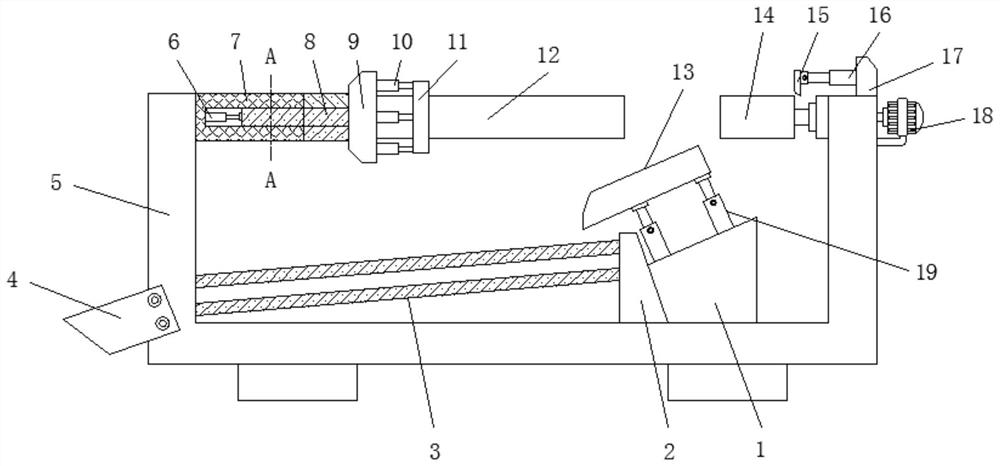

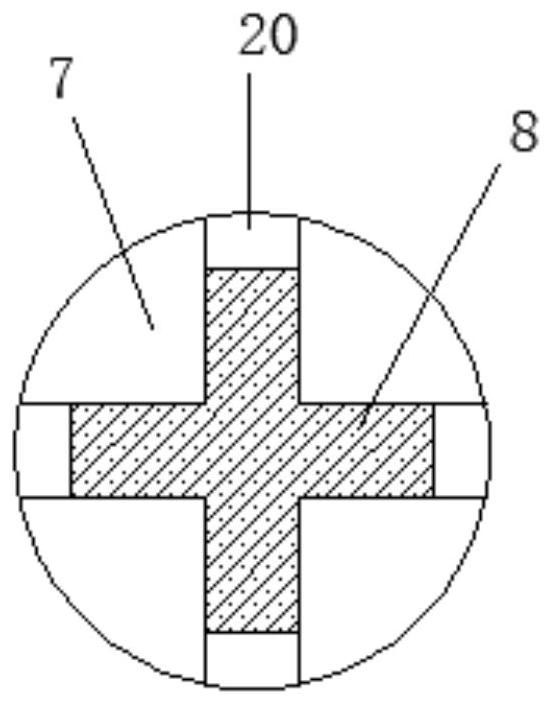

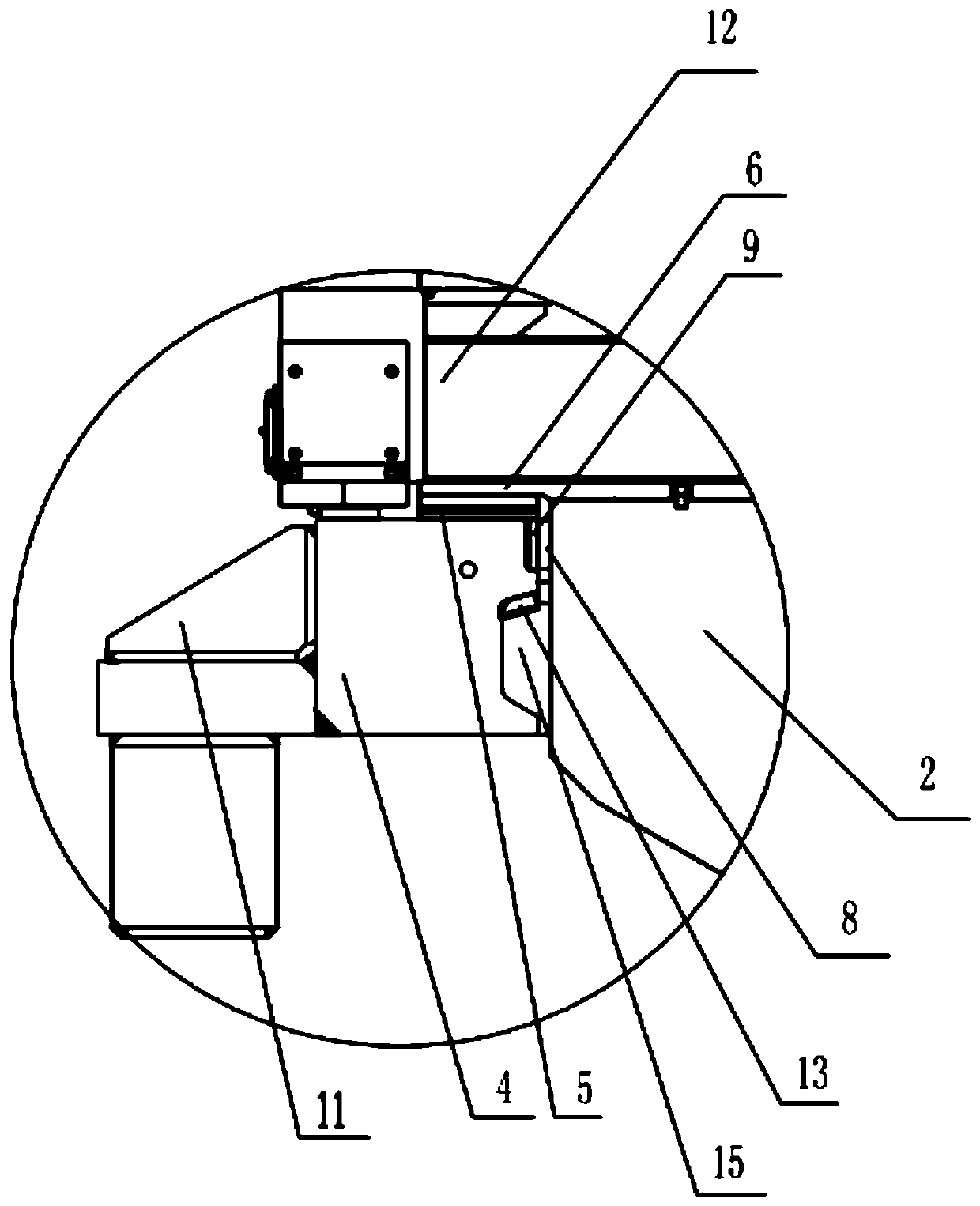

A mounting and dismounting device for oil material rollers

The invention relates to a mounting and dismounting device for oil material rollers. The device comprises a hydraulic transmission mechanism, a crank-slider transmission mechanism and a fixed connection mechanism. The hydraulic transmission mechanism comprises a double-acting oil cylinder (4), a piston rod (19) acting with the double-acting oil cylinder (4) cooperatively, an oil cylinder tail stock (2) and a hinge pin (3). The crank-slider transmission mechanism consists of a hydraulic rotating arm (7) equivalent to a crank, a connecting rod (11), a support shaft (5), a large retainer ring (6), an arc-shaped cover (17) arranged on the hydraulic rotating arm (7) via a rotating shaft (15), a clamp head (18) on the arc-shaped cover (17) and an insertion pin (10). The mechanism also employs the structure that the connecting rod (11) equivalent to a slider and a roller rear roller shaft sleeve (12) and a rear roller rubber sheath (13) and a fixing sleeve (23), which are arranged in front of and behind the connecting rod (11), are replaced by a roller adjusting shaft sleeve (28), a jackscrew (27), a nut (26) and a bolt (29). The device has the advantages of safe and stable structure, safe and accurate mounting and dismounting, high quality and efficiency and low cost.

Owner:ZHAODONG DONG LONG SAVING ENERGY NEW TECH

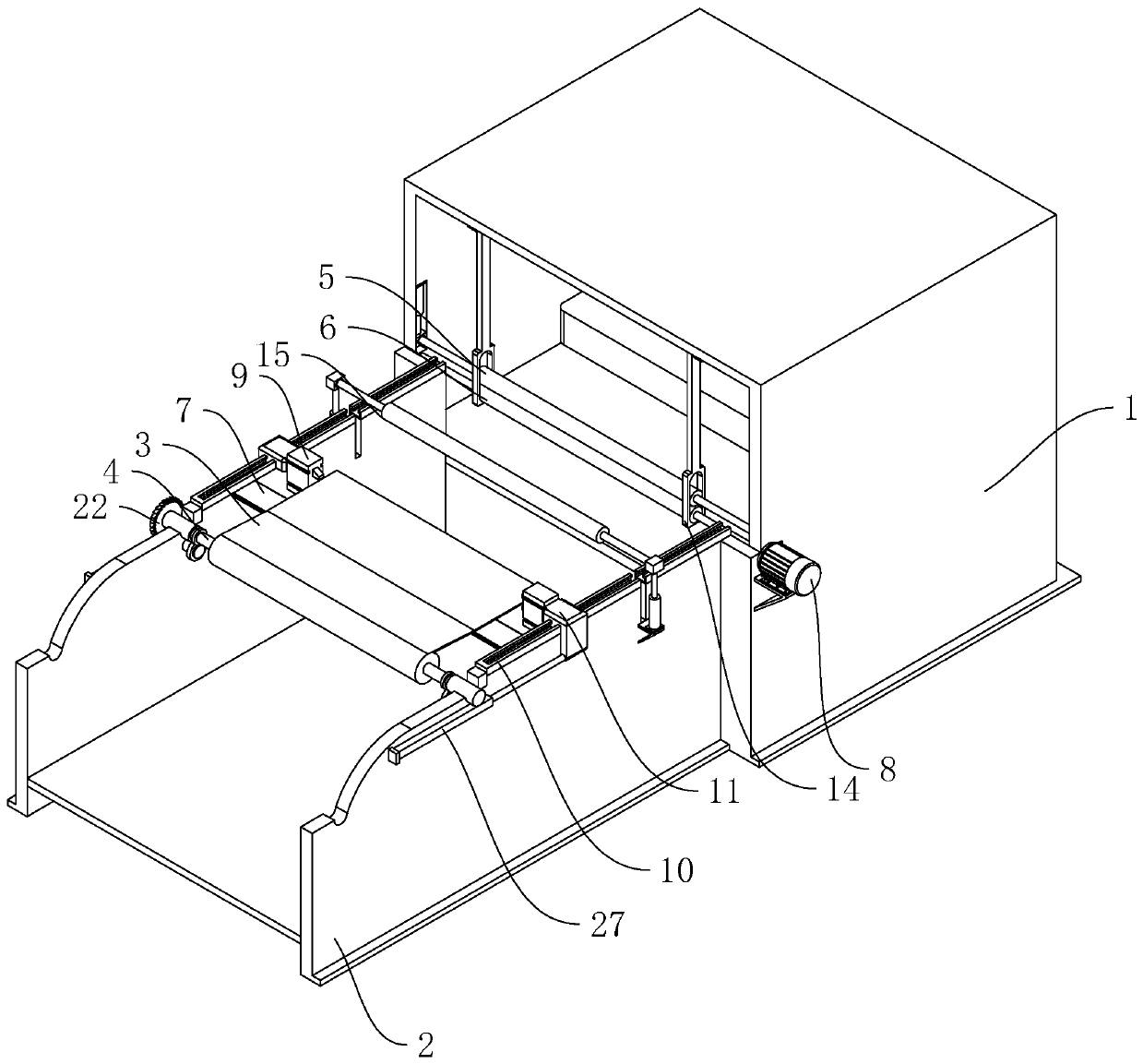

TPU film continuous coating production system and method

ActiveCN109532040APrevent deformationHigh strengthLiquid surface applicatorsFlat articlesEngineeringUltimate tensile strength

The invention discloses a TPU film continuous coating production system and method. The TPU film continuous coating production system comprises a first unreeling unit, a guiding-connecting unit, a first stripping unit, a coating unit, a drying unit and a UV solidification unit. A film body is unreeled by the first unreeling unit, the guiding connecting unit is used for connecting a protection filmon the surface of the side, attached with a guiding film, of an unreeled TPU substrate film; the first stripping unit is used for stripping a protection film on the surface of the other side, not connected with the guiding film, of the TPU substrate film; the coating unit is used for coating polymers to the surface of the TPU substrate film with the stripped protection film to form a coating layer; the drying unit is used for drying the surface of the coated TPU substrate film through a drying oven; and the UV solidification unit is used for conducting ultraviolet solidification treatment onthe dried TPU substrate film through a UV light. According to the TPU film continuous coating production system and method, a traditional direct roll-to-roll connection method for a to-be-coated material is abandoned, the disadvantages that an interlayer material is not easily connected and is difficult to firmly bond are avoided, and by adding a middle bearing film as the guiding film, the effects that the production efficiency is accelerated, the connection strength is improved, TPU film heating in the drying oven is avoided, and thus the product quality is improved are achieved.

Owner:浙江耀阳新材料科技有限公司

Material roll changing device

The invention discloses a material roll changing device. The material roll changing device comprises a material preparation shaft, a material roll shaft and a driving mechanism, wherein the driving mechanism is used for driving the material preparation shaft and the material roll shaft to be close to each other, and the material preparation shaft is used for storing at least one set of prepared material rolls. The material roll shaft is used for receiving the prepared material rolls from the material preparation shaft, so that a material roll changing is achieved, and material roll changing efficiency is improved.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

Automatic high-speed vacuum blister forming machine

InactiveCN110696335AQuick roll changeImprove roll changing efficiencyMolding machineElectric machinery

The invention discloses an automatic high-speed vacuum blister forming machine, and relates to the field of blister forming equipment. According to the technical key points, the automatic high-speed vacuum blister forming machine comprises a blister forming machine body and a feeding device, wherein the feeding device comprises a placing frame, and a material roller with a plastic sheet wound around is rotationally connected on the placing frame; one end, close to the blister forming machine body, of the placing frame is rotationally connected with an upper pressing roller and a lower pressingroller, wherein a placing plate is horizontally arranged on the side, facing the lower pressing roller, of the material roller, the placing plate is arranged in the axial direction of the material roller, the upper surface of the placing plate is coplanar with the highest point of the surface of the lower pressing roller, and one end of the lower pressing roller is provided with a motor for driving the lower pressing roller to rotate; and the two ends, located on the placing plate, of the placing frame are correspondingly provided with finger air cylinders for clamping the plastic sheet, sliding rails are arranged on the placing frame in the moving direction of the plastic sheet, sliding blocks are slidably connected in the sliding rails, the sliding blocks are fixedly connected with cylinder bodies of the finger cylinders, and a driving device for driving the sliding blocks to move along the sliding rails are arranged on the placing frame. The automatic high-speed vacuum blister forming machine has the advantages of being high in roll changing efficiency and capable of reducing potential safety hazards.

Owner:苏州耀鑫新型包装材料有限公司

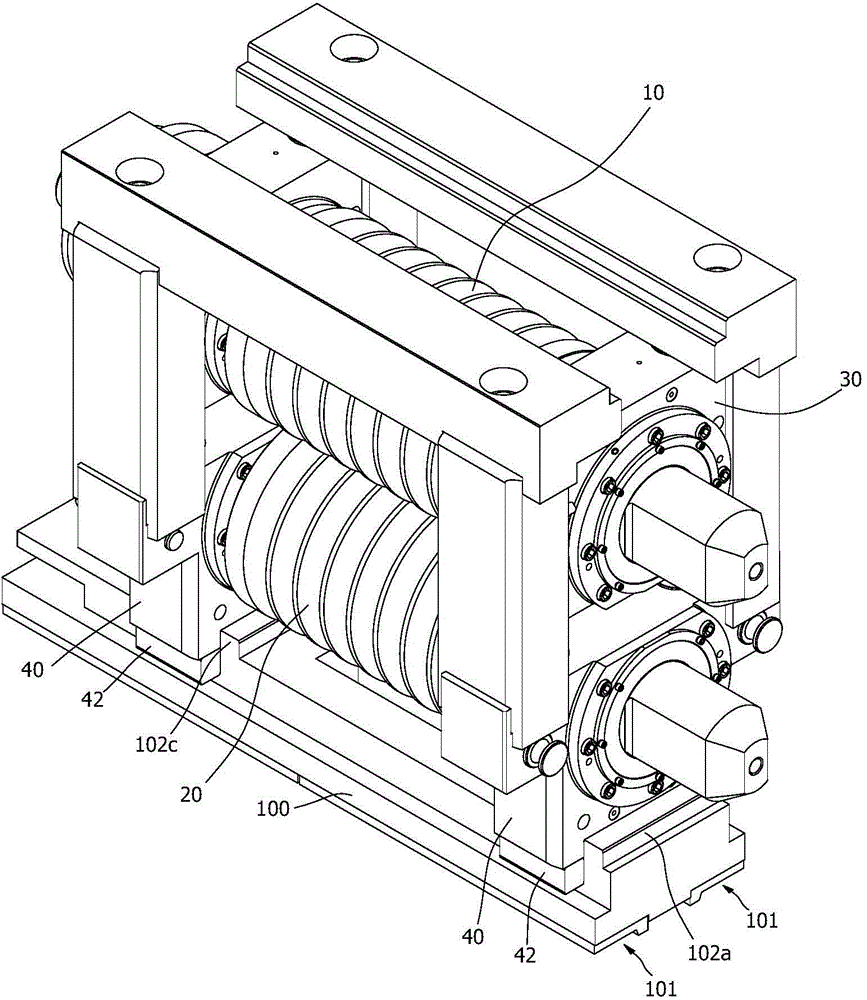

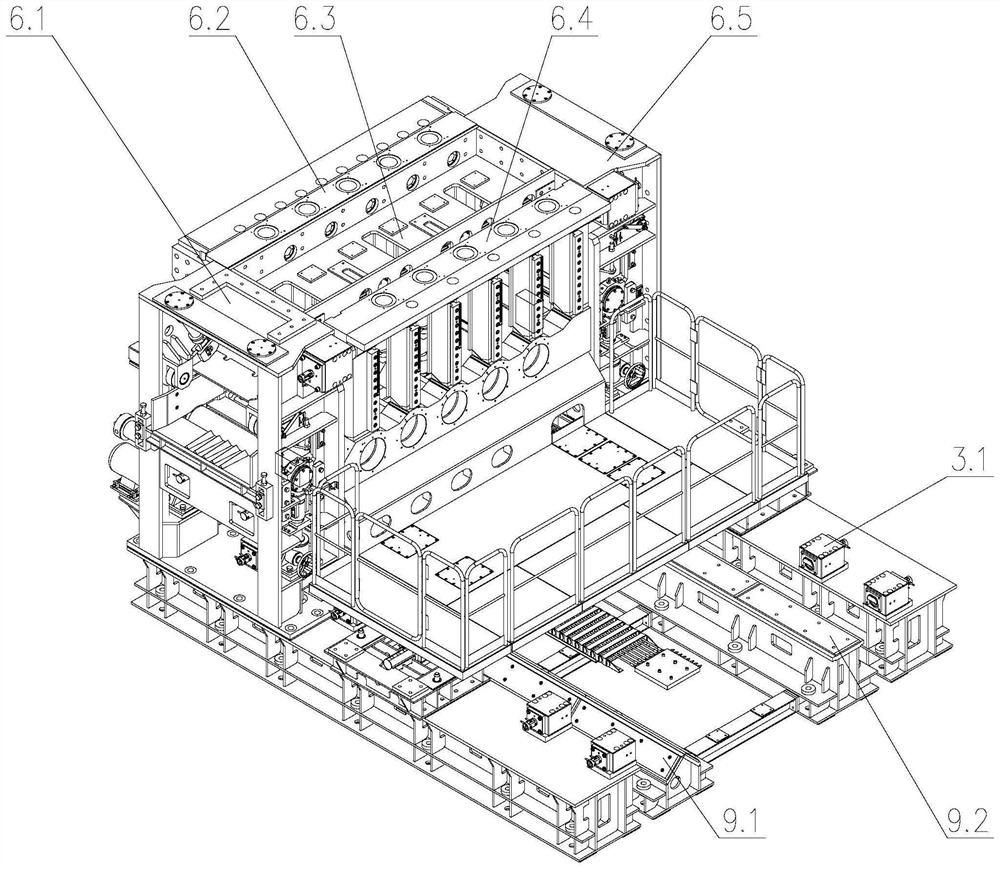

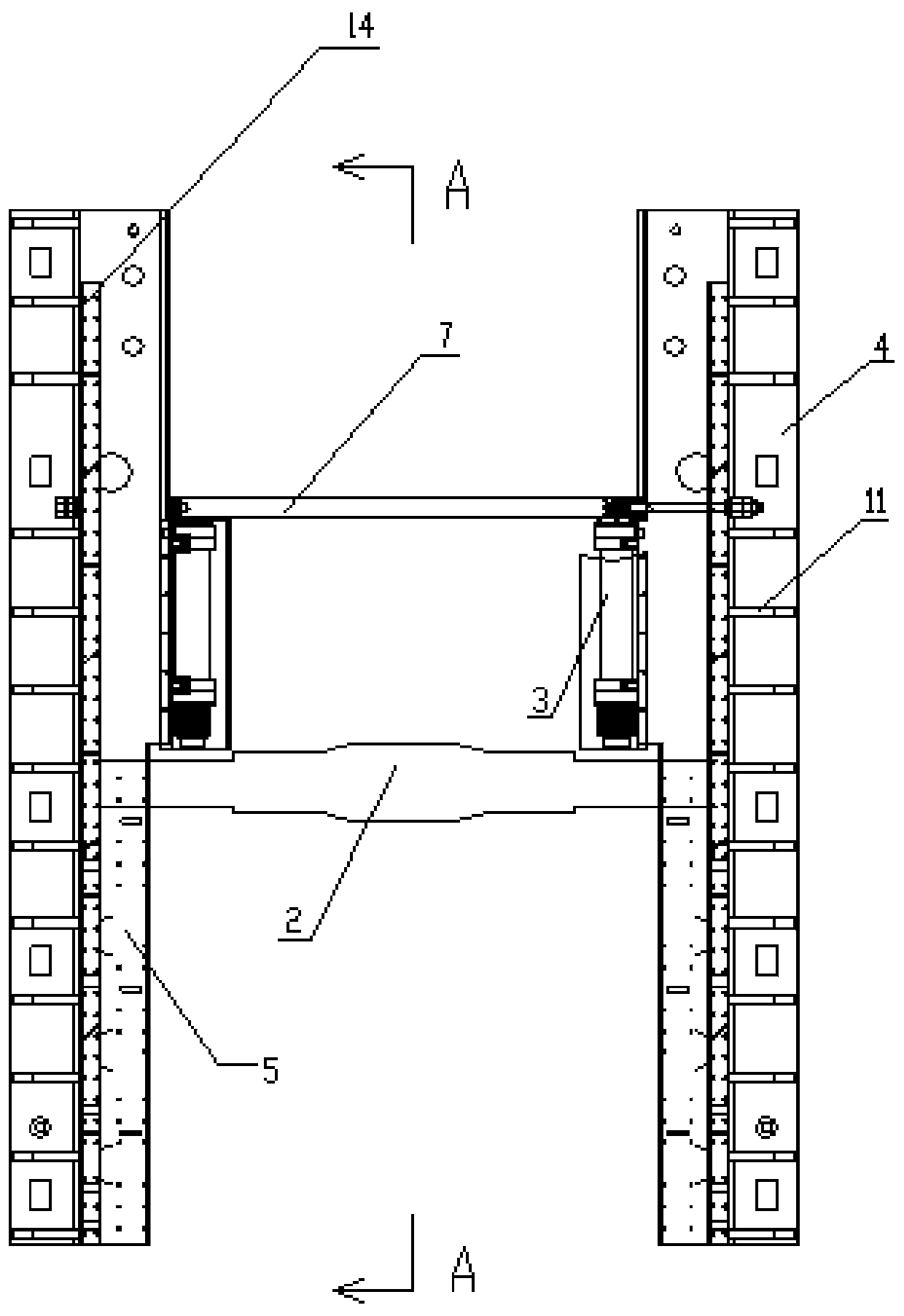

High-rigidity small-sized steel row straightening machine with movable operation side rack

PendingCN112547849AReduce bouncingImprove equipment utilizationShaping toolsSupporting systemMachine

The invention discloses a high-rigidity small-sized steel row straightening machine with a movable operation side rack. The high-rigidity small-sized steel row straightening machine comprises a high-rigidity combined rack, an automatic locking type upper straightening roller, an automatic locking type lower straightening roller, a clutch type pressing device, an automatic roller replacing device,a longitudinal moving rail, a base and a transmission system, wherein bearing supporting systems at the two ends of the automatic locking type lower straightening roller are installed in fixed installation holes formed in the lower portion of the high-rigidity combined rack in advance; bearing seats at the two ends of the automatic locking type upper straightening roller are installed in sliding grooves of upper window structures of racks on the two sides in the high-rigidity combined rack; the clutch type pressing device is mounted at the top of a pressing device rack in the high-rigidity combined rack; screws on the two sides of the clutch type pressing device are connected with bearing seats on the two sides of the automatic locking type upper straightening roller respectively; and theautomatic roller replacing device is installed in the high-rigidity combined rack, an automatic roller replacing vehicle is left in the machine during straightening operation, and an upper roller setbracket retreats from the machine. The high-rigidity small-sized steel row straightening machine has the characteristics of compact structure, good economy, high automation degree and the like.

Owner:HUATIAN ENG & TECH CORP MCC

Roller replacing method for supporting rollers of fourteen-roller copper belt cold-rolling mill

ActiveCN105234183AGuarantee continuous and stable operationReduce labor intensityMetal rolling stand detailsMetal rolling arrangementsEngineeringCopper

The invention discloses a roller replacing method for supporting rollers of a fourteen-roller copper belt cold-rolling mill. A roller replacing sequence is reasonably arranged according to a specific structure of the fourteen-roller copper belt cold-rolling mill. A roller replacing tool with higher practicability is used. Furthermore, a shaft holding device is arranged at the shaft head of a universal connecting shaft to fix the shaft head before the connection between the supporting roller and the universal connecting shaft is broken, and then an arc plate for fixing a granny knot is arranged above a platform and under the granny knot. Thus, the shaft head and the granny knot always remain at the original positions in a roller replacing process after the connection is broken, the transmitting end of the lower supporting roller and the transmitting end of the upper supporting roller can be successfully inserted into the shaft head in one time when rollers are assembled again, and the roller replacing efficiency is improved. In addition, the other rollers are prevented from being affected, the time for replacing the rollers is reduced, and the labor intensity of workers is reduced; and the continuous stable operation of the fourteen-roller cold-rolling mill is guaranteed, and the normal production of copper belts is guaranteed.

Owner:中色正锐(山东)铜业有限公司

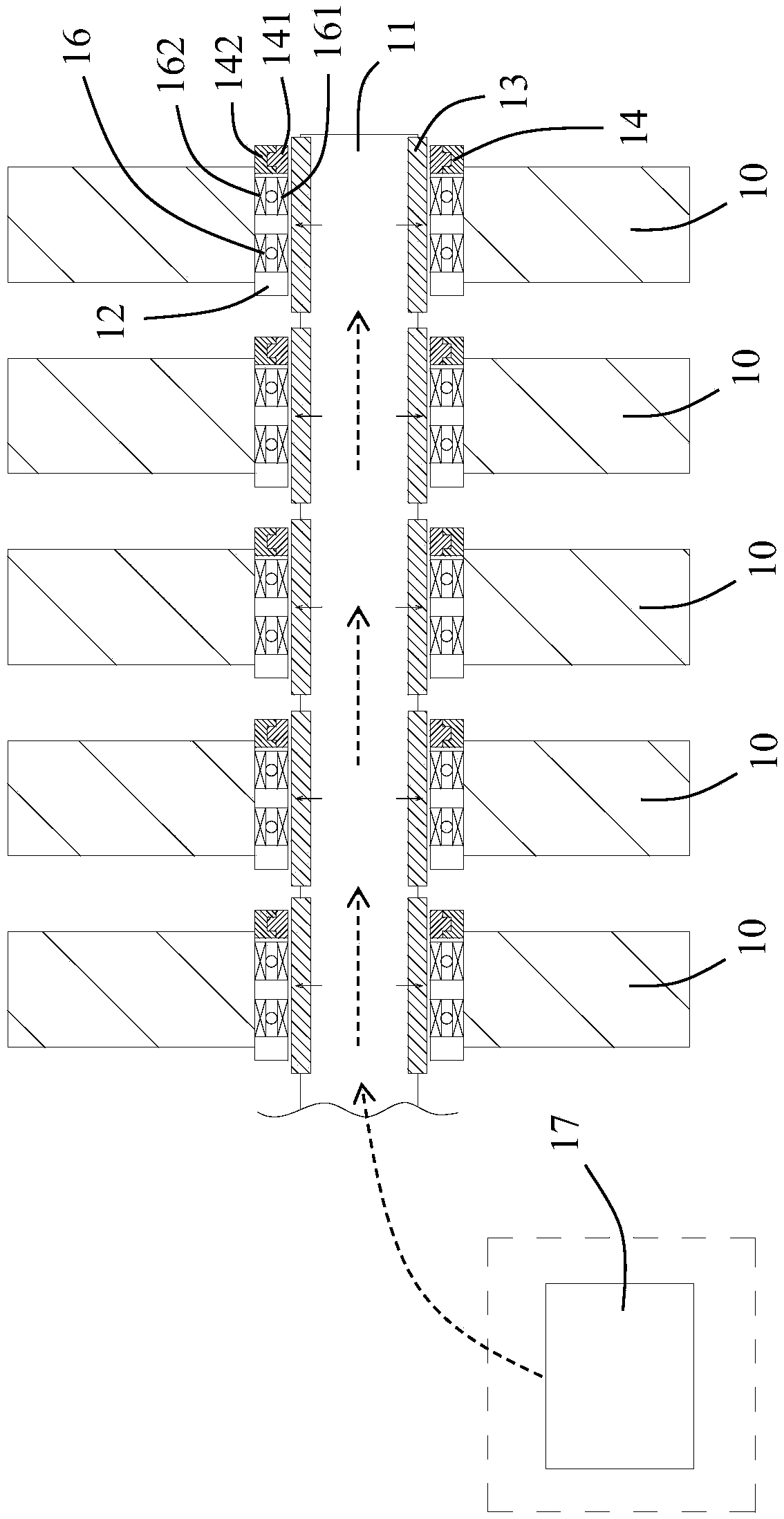

Automatic roll changing system of row straightener

PendingCN112427490AReduce bouncingImprove equipment utilizationShaping toolsControl systemControl engineering

The invention discloses an automatic roll changing system of a row straightener. The automatic roll changing system comprises a high-rigidity combined rack, an automatic locking type upper straightening roll assembly, an automatic locking type lower straightening roll assembly, a clutch type pressing device, an automatic roll changing device, a roll changing track, a base, a standby automatic rollchanging device and a measurement and control system. The standby automatic roll changing device before roll changing is used for preparing the row straightener, the automatic roll changing device isused for lifting a to-be-changed straightening roll set, an old straightening roll set is moved out, a roll changing separation platform is separated for the second time, a new straightening roll setand an old straightening roll set are rapidly replaced, the roll changing separation platform is positioned and locked, an operation side rack is reset and locked, the straightening roll set is locked, after roll changing is completed, roll changing auxiliary equipment is withdrawn, and the automatic roll changing of the straightener is completed through the eight steps of the automatic roll changing system.

Owner:HUATIAN ENG & TECH CORP MCC

Rapid roll changing mechanism

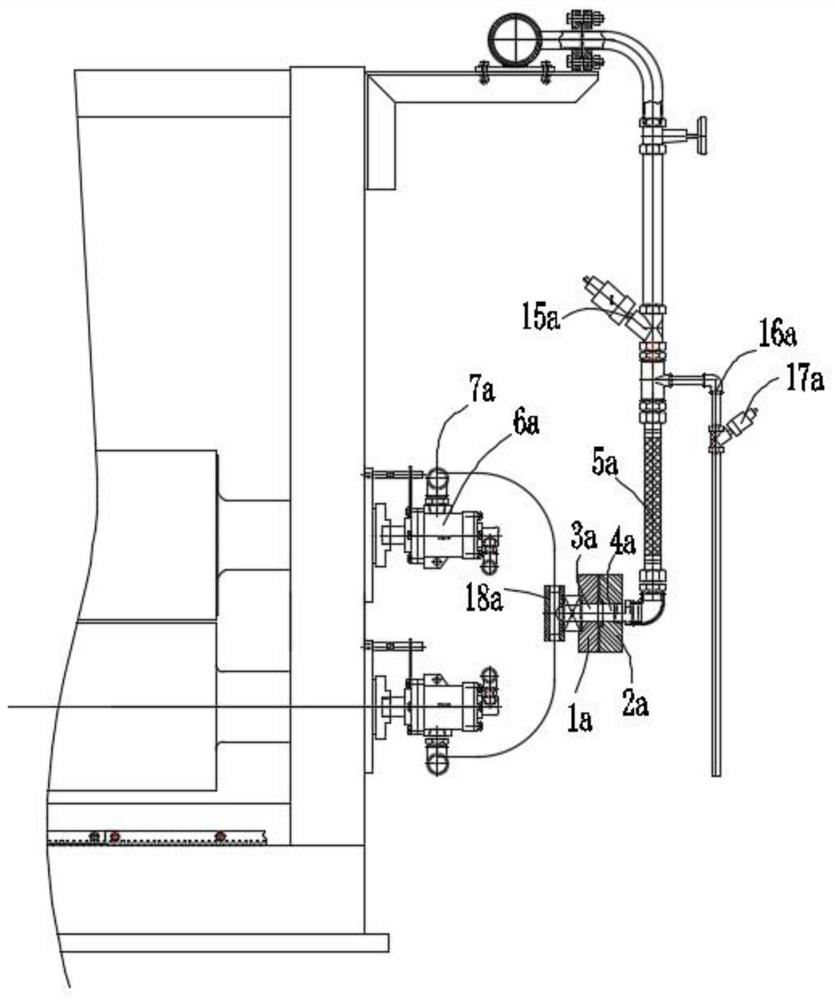

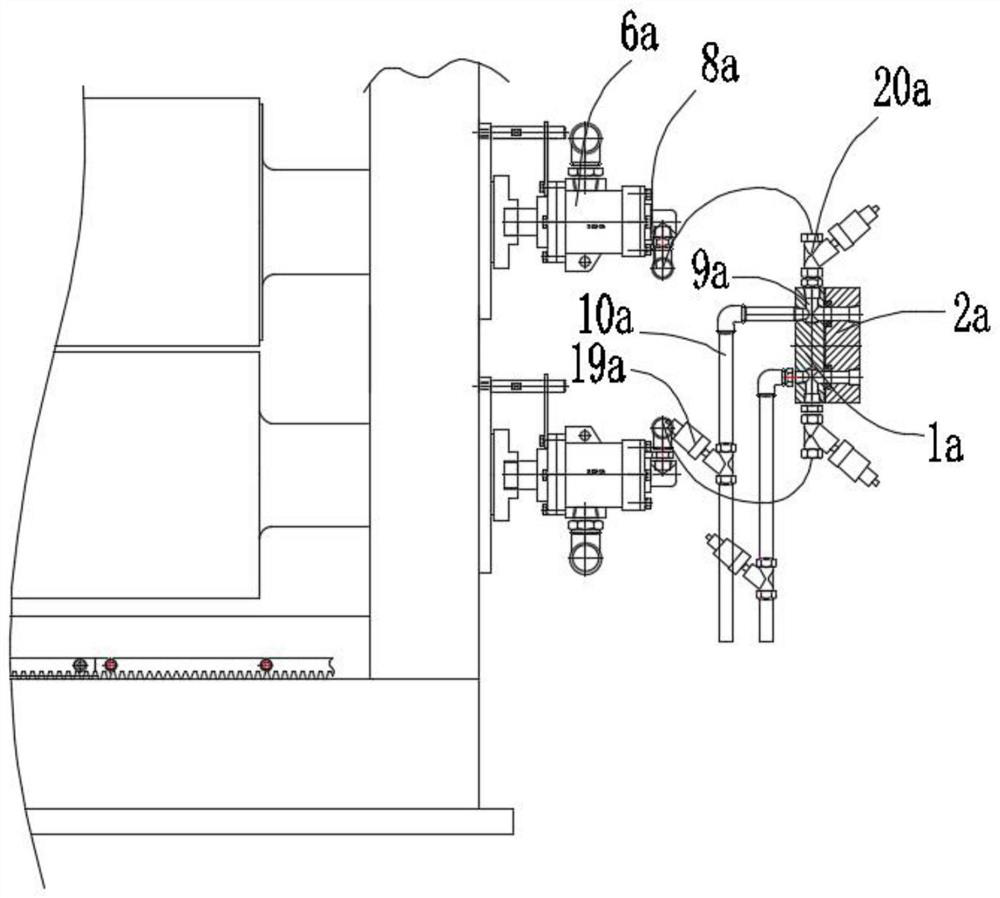

ActiveCN113319124AShort timeImprove roll changing efficiencyMetal rolling stand detailsRollsDrive shaftElectric machinery

The invention relates to a rapid roller changing mechanism. The rapid roller changing mechanism comprises a rack, the rack is provided with a power mechanism and a steam locking mechanism, the power mechanism comprises a tensioning assembly, the tensioning assembly can drive a tensioning pulley to move so that the tensioning pulley can pull a transmission synchronous belt, so that the transmission synchronous belt is in meshed connection with a tooth roller pulley, a transmission shaft of a transmission motor rotates, trough transmission of a transition synchronous belt, the transmission synchronous belt drives the tooth roller pulley to rotate, namely, an upper tooth roller and a lower tooth roller can be driven to rotate, when the tooth rollers need to be replaced, the tensioning assembly drives the tensioning pulley to reset, the transmission synchronous belt is loosened, the tooth rollers can be moved away for the tooth roller replacing procedure when the transmission synchronous belt is not in meshed connection with the tooth roller pulley, consumed time is short, the roller replacing efficiency is high, after steam in a drainage metal hose is completely discharged, an upper valve body and a lower valve body can be separated, the defects that the rollers can be rapidly replaced without detaching steam inlet and drainage metal hoses, and scalding is prone to occurring are overcome, a conveying trolley is arranged below the rack, the tooth rollers are conveyed through the conveying trolley, and the roller replacing efficiency is improved.

Owner:广东肇庆西江机械制造有限公司

Transfer device and roll changing equipment

PendingCN114314111AHigh degree of automationImprove roll changing efficiencyArticle deliveryWebs handlingMaterials preparationAdhesive belt

The invention relates to a transfer device and roll changing equipment. The transfer device comprises a moving assembly, a rubberizing assembly and a material preparation shaft assembly, the rubberizing assembly and the material preparation shaft assembly are in driving connection with the moving assembly, and the moving assembly is used for driving the rubberizing assembly and the material preparation shaft assembly to synchronously move in the first direction and pass through a rubberizing station, a starting processing station and a tape connecting station; when the rubberizing assembly and the material preparation shaft assembly move to the adhesive preparation station, the rubberizing assembly is used for receiving the adhesive tape; when the rubberizing assembly and the material preparation shaft assembly move to the starting processing station, the material belt starting end of the standby material belt on the material preparation shaft assembly is lifted, and the rubberizing assembly fixes the lifted material belt starting end; and when the rubberizing assembly and the material preparation shaft assembly move to the tape connecting station, the rubberizing assembly is used for sticking an adhesive tape between the starting end of the material tape and the cutting end of the working material tape.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

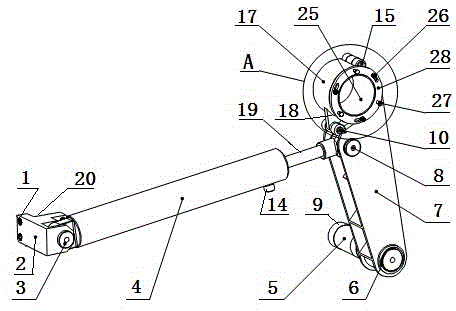

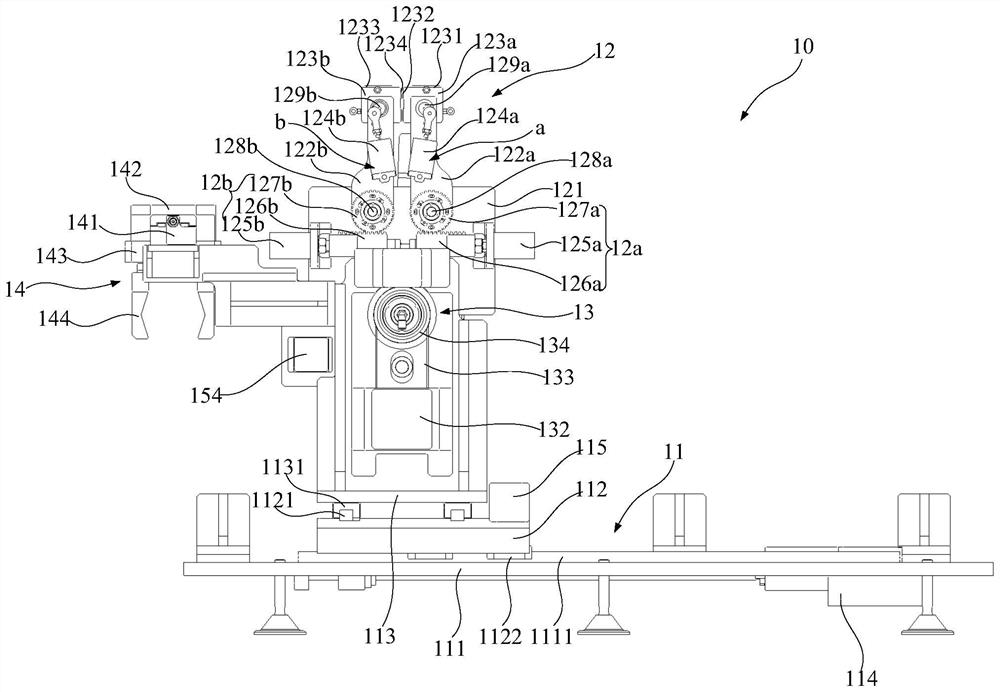

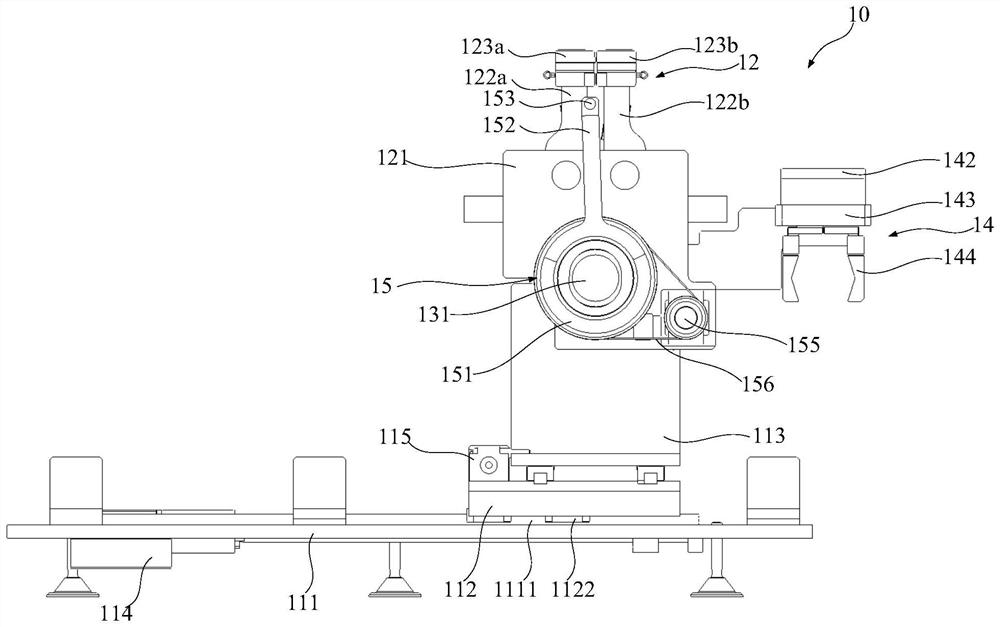

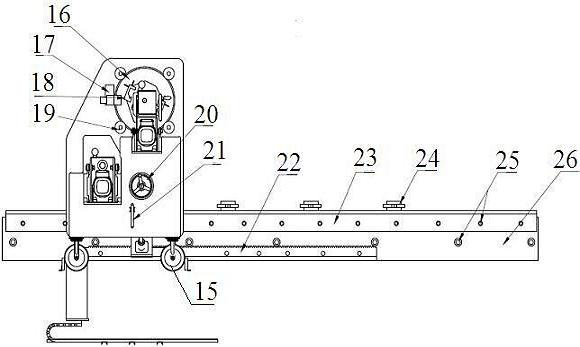

Roll changing car and roll changing method of the same

ActiveCN106734225BEasy to storeEasy accessMetal rolling stand detailsMetal rolling arrangementsEngineeringPulley

The invention provides a roller changing carriage. The roller changing carriage comprises a pulley, a supporting frame and a gripper device. One end of the pulley is longitudinally provided with a first gear sliding rail and a first guide groove sliding rail, so that a fixing guide rail set is formed. The fixing guide rail set is used for installing the gripper device. The supporting frame is installed on the pulley in a slideable mode. The supporting frame comprises an undercarriage and roller storage racks formed at the two sides of the undercarriage. Supporting protrusions are arranged at the top ends of the opposite sides of each roller storage rack and used for bearing roller bodies. Side guide rail sets are formed at the bottom ends of the opposite sides of each roller storage rack. The gripper device comprises a rack and a roller changing gripper mechanism which is installed on the rack and can slide up and down relative to the rack. The side guide rail sets of the two roller storage racks can selectively align the fixing guide rail set by sliding the supporting frame, and accordingly the gripper device can slip into the side guide rail set at one side or the side guide rail set at the other side. The invention further provides a roller changing method of the roller changing carriage. By means of the roller changing carriage, the roller bodies can be replaced quickly, and roller changing efficiency is improved.

Owner:福建宏旺实业有限公司 +1

Work roll storage bracket

InactiveCN109675930AImprove roll changing efficiencyIncrease productivityMetal rolling stand detailsMetal rolling arrangementsSoftware engineeringWork roll

The invention provides a work roll storage bracket. The work roll storage bracket comprises an under carriage and a plurality of supporting beams installed on the under carriage. Each supporting beamis provided with first supporting blocks and second supporting blocks at intervals, the first supporting blocks are located above the second supporting blocks, the multiple first supporting blocks arelocated at the same height, and the second supporting blocks are located at the same height. Each first supporting blocks comprises a first fixed portion and first extension portions, wherein the first extension portions extend from the two ends of the first fixed portion respectively. Each first fixed portion is fixed to the corresponding supporting beam. Each first extension portion is providedwith a supporting groove. Each second supporting block comprises a second fixed portion and second extension portions, wherein the second extension portions extend from the two ends of the second fixed portion respectively. Each second fixed portion is fixed to the corresponding supporting beam. Each second extension portion is provided with a supporting groove. With the work roll storage bracket, the efficiency of roll replacement can be effectively improved, and the production efficiency is improved.

Owner:SHANDONG HONGWANG INDUSTRY CO LTD

Tape connecting device and lamination equipment

PendingCN111924606AHigh degree of automationImprove roll changing efficiencyWebs handlingPhysicsEngineering

The invention relates to a tape connecting device and lamination equipment. The tape connecting device comprises a fixed seat and further comprises a first tape connecting assembly and a second tape connecting assembly which can be connected to the fixed seat in the mode of getting close to or away from each other; an output channel allowing a membrane material to penetrate through is formed between the first tape connecting assembly and the second tape connecting assembly; the first tape connecting assembly comprises a first adsorption surface and a first cutter mechanism used for cutting offthe membrane material adsorbed on the first adsorption surface, and the second tape connecting assembly comprises a second adsorption surface; and the tape connecting device includes a first tape connecting state, when the tape connecting device is in the first tape connecting state, the first adsorption surface adsorbs the membrane material penetrating through the output channel, the first cutter mechanism cuts off the membrane material adsorbed on the first adsorption surface, the second adsorption surface is used for absorbing tape with a standby membrane material attached, and in the process of getting close to each other of the first tape connecting assembly and the second tape connecting assembly, the cut-off end of the membrane material on the first adsorption surface is pasted onto the tape on the second adsorption surface.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

Hydraulic roll changing device for rolling mill work roller

InactiveCN104550245ASolve the problem of difficult accessEasy to change rollsMetal rolling stand detailsMetal rolling arrangementsPulp and paper industryRolling mill

The invention discloses a hydraulic roll changing device for a rolling mill work roller. The hydraulic roll changing device for the rolling mill work roller comprises a fixing shelf arranged at the front end of the rolling mill work roller, the outer side wall of the fixing shelf is jointed with a hydraulic support rod, which is arranged obliquely and upwards, the end of the hydraulic support rod is connected with a hydraulic oil cylinder flatly arranged, the hydraulic oil cylinder is connected with the a pull rod provided with a drag hook and hanged to the rolling mill work roller corresponding to the end of the rolling mill work roller; the hydraulic oil cylinder is horizontally located above the fixing shelf and the lower part of the middle thereof is jointed to the end of the hydraulic support rod through a connection end; the hydraulic roll changing device for the rolling mill work roller is simple in structure, convenient and reliable in use, can raise the roll changing efficiency and reduce the use cost.

Owner:浙江富日进精密金属股份有限公司

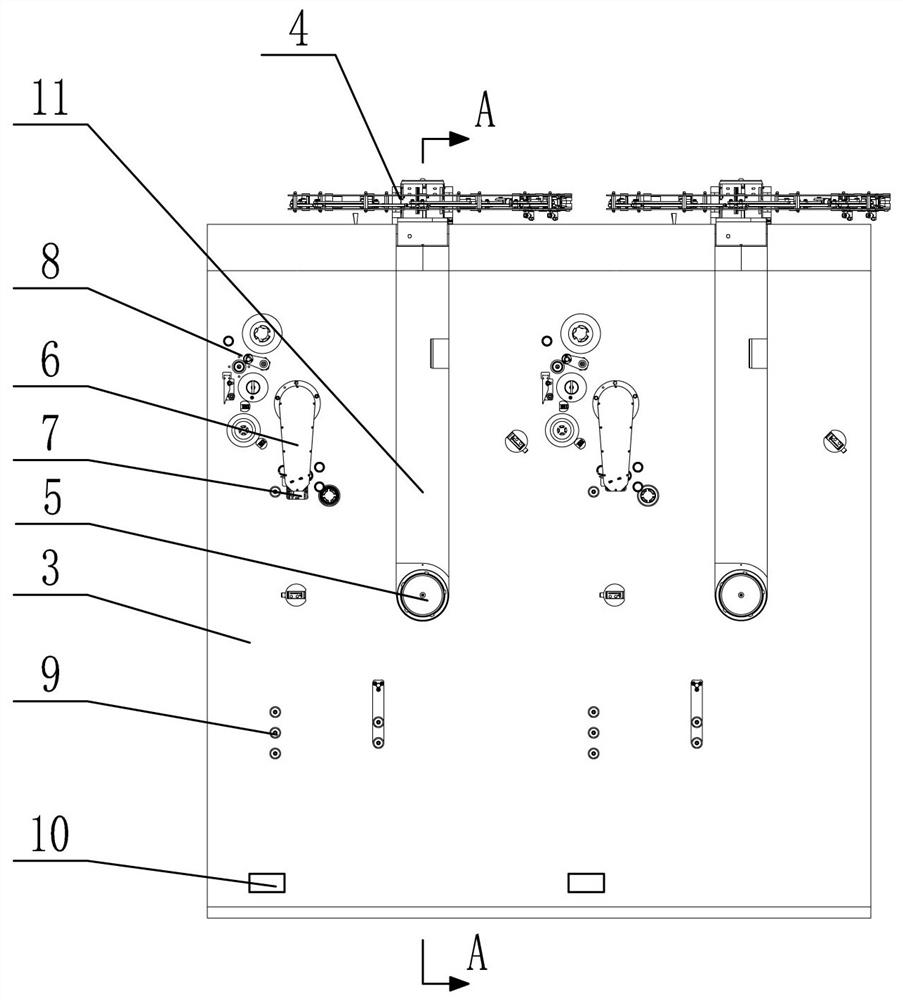

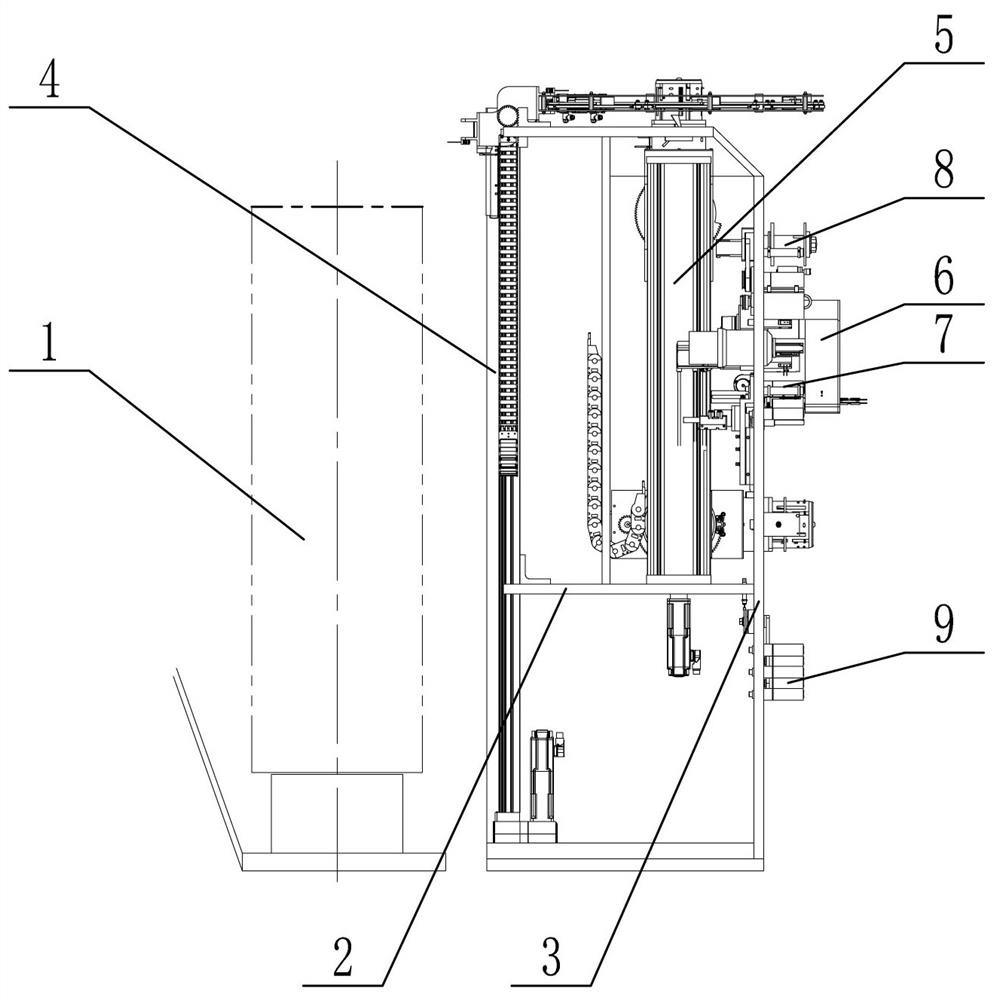

Station changing and unwinding mechanism of material station for belt material processing

PendingCN111908216ARealize roll changeRealize unwindingWebs handlingCigarette manufactureEngineeringStructural engineering

The invention provides a station changing and unwinding mechanism of a material station for belt material processing. The station changing and unwinding mechanism comprises two vertically-arranged andbilaterally-symmetric vertical station changing devices, wherein unwinding driving heads of the vertical station changing devices are driven by electric cylinder assemblies to vertically move up anddown, can turn over relative to the electric cylinder assemblies, and then can be arranged vertically upward or perpendicular to the electric cylinder assemblies; furthermore, the unwinding driving heads of the two vertical station changing devices are arranged on a common axis, namely a symmetric axis between the two vertical station changing devices; when arranged vertically upward, the unwinding driving heads move up and are used for grabbing belt material trays at a material supply station; when arranged perpendicular to the electric cylinder assemblies, the unwinding driving heads are used for performing the unwinding operation; and the the unwinding driving heads of the two vertical station changing devices act alternately, so that the reel replacement and the unwinding of belt materials can be achieved.

Owner:HENAN XINZHILIN ELECTROMECHANICAL DEVICE CO LTD

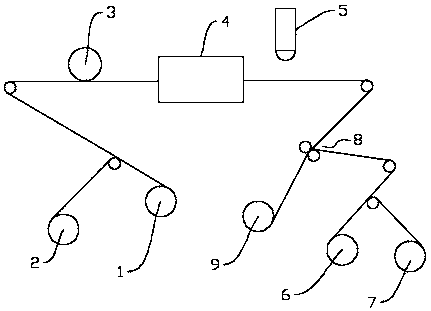

Automatic roll changing and splicing system and method for disposable sanitary product production equipment

The invention discloses an automatic roll changing and splicing system and method for disposable sanitary product production equipment. In the system, a first coil is arranged on a first unwinding mechanism, the first coil is discharged and then is conveyed by a first unwinding negative pressure conveying device and sent to a main negative pressure conveying device, a second coil is arranged on asecond unwinding mechanism, and the second coil is discharged and then is conveyed by a second unwinding negative pressure conveying device and sent to the main negative pressure conveying device; anultrasonic pressing device is arranged on one side of the main negative pressure conveying device, in the conveying direction of materials, and the ultrasonic pressing device is arranged in front of the first unwinding negative pressure conveying device and the second unwinding negative pressure conveying device. The method comprises the following steps that the first unwinding negative pressure conveying device and the second unwinding negative pressure conveying device alternately convey the coil to the main negative pressure conveying device, and splicing is completed under the cooperationof the main negative pressure conveying device and the ultrasonic pressing device. According to the system, traditional manual operation can be replaced, the roll changing efficiency is high, the waste amount of a tail material is small, and the production cost can be effectively reduced.

Owner:GUANGZHOU XINGSHI EQUIPS

Roll changing device of horizontal and vertical rolling mill

PendingCN114130830AQuick roll changeImprove roll changing efficiencyMetal rolling stand detailsMetal rolling arrangementsSpare parts managementStructural engineering

The invention discloses a roll changing device of a horizontal and vertical rolling mill, and belongs to the technical field of roll changing of rolling mills. The roller replacing device comprises a trolley, a roller replacing hydraulic cylinder and a bolt mechanism, a piston rod of the roller replacing hydraulic cylinder is connected with the bolt mechanism, the front end of the bolt mechanism is connected with the trolley, a roller replacing bolt cylinder and a plunger rod are arranged on the surface of the bolt mechanism, and a guide positioning block is further arranged on the surface of the bolt mechanism. One end of the bolt mechanism is connected with the movable base, and a rolling mill body is installed on the surface of the movable base. The roller replacing device is used for roller replacing operation of a fixed type horizontal and vertical rolling mill train, rapid roller replacing of horizontal rolling and vertical rolling can be achieved, and the roller replacing efficiency is high; the roller replacing device has the advantages of being simple and reliable in structure and convenient to maintain, the roller replacing device can be rapidly moved in and out of the rolling mill body and the movable base, meanwhile, the requirement for rapid roller replacing operation of flat rolling and vertical rolling is met, main body structures can be interchanged and universally used, spare part specifications are reduced, and spare part management is convenient.

Owner:HUATIAN ENG & TECH CORP MCC

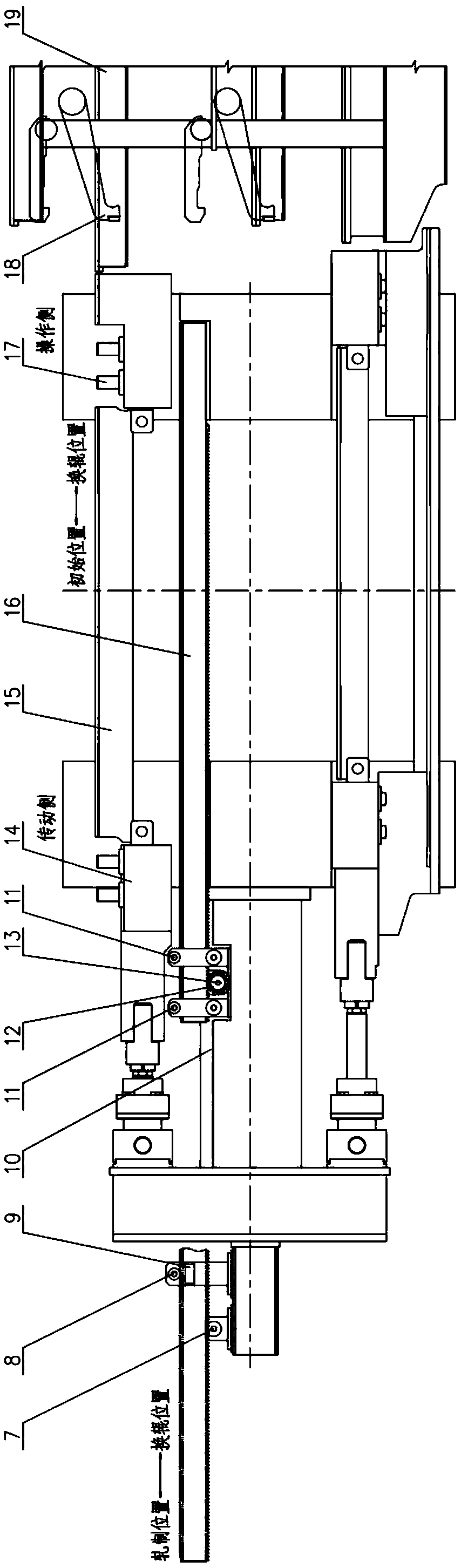

Roller changing trolley, system and method for scale breaker

ActiveCN112935747AIncrease flexibilityImprove stabilityWork treatment devicesMetal working apparatusVehicle frameControl engineering

The invention provides a roller changing trolley, system and method for a scale breaker. The trolley comprises a frame, wheels are arranged under the frame, a moving seat, an angle adjusting mechanism and a driving device are arranged on the frame, the moving seat is connected to the driving device, the angle adjusting mechanism is arranged on one side of the moving seat, the angle adjusting mechanism is used for conducting angle guiding on the moving seat after matching angle adjustment of a scale breaker roller system, and the moving seat pulls out an old roller system and replaces the same with a new roller system through the driving device. The roll changing or mounting angle of the moving seat matches the angle adjustment of the scale breaker roller system through the angle adjusting device, so that the roll changing angle is prevented from being repeatedly adjusted and confirmed by naked eyes of an artificial user, and the roll changing efficiency is improved. When an upper roller is replaced, the angle is adjusted through a worm and gear device, it is guaranteed that a deflection angle of a clamping groove of a rotating shaft of the moving seat is consistent with the angle of an upper roller system of the scale breaker and is fixed, and the roller replacing efficiency is improved. By arranging a first upper guide rail and a first lower guide rail simultaneously, the upper roller and a lower roller can be replaced simultaneously, and the roller replacing efficiency is further improved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Automatic roll replacing and receiving system and method for flexible rolled materials

The invention discloses an automatic roll replacing and receiving system and an automatic roll replacing and receiving method for flexible rolled materials. According to the system, a first rolled material is arranged on a first unwinding mechanism, after the first rolled material is unwound, the first rolled material is conveyed by a first unwinding negative-pressure conveying device and conveyedto a main negative-pressure conveying device, a second rolled material is arranged on a second unwinding mechanism, and after the second rolled material is unwound, the second rolled material is conveyed through a second unwinding negative-pressure conveying device and conveyed to the main negative-pressure conveying device; and a gluing device is arranged on one side of the main negative-pressure conveying device and is arranged in front of the first unwinding negative-pressure conveying device and the second unwinding negative-pressure conveying device in the material conveying direction. The method comprises the steps that the first unwinding negative-pressure conveying device and the second unwinding negative-pressure conveying device alternately convey the rolled materials to the main negative-pressure conveying device, and splicing is completed under cooperation of the main negative-pressure conveying device and the gluing device. Traditional manual operation can be replaced, the roll replacing efficiency is high, meanwhile, the waste amount of leftover materials is small, and thus the production cost can be effectively reduced.

Owner:GUANGZHOU XINGSHI EQUIPS

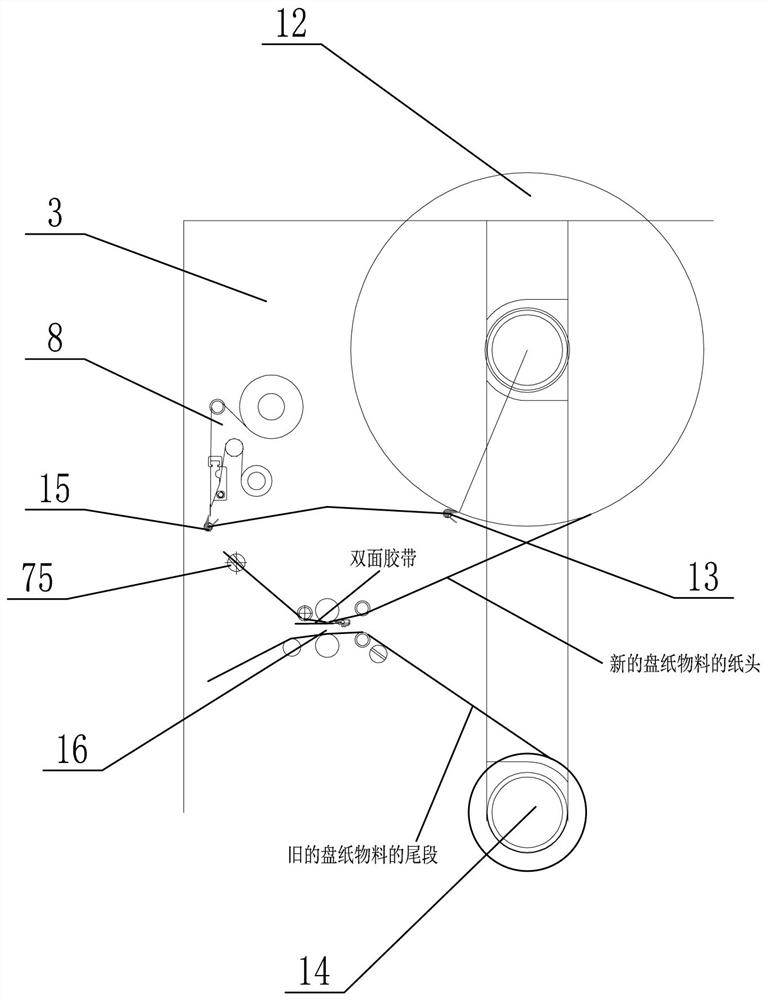

Material station for belt material processing

PendingCN111908219AGuaranteed level statusGuaranteed flip angleWebs handlingStructural engineeringMaterials processing

The invention provides a material station for belt material processing. According to the material station, a material warehouse is designed to be used for the vertical stacking of belt material trays;a grabbing and lifting device is designed to grab the belt material trays in the material warehouse and convey the belt material trays to a material supply station; a station changing and unwinding mechanism in a straight path is designed to convey one of the belt material trays at the material supply station to an unwinding station and perform the unwinding operation; a traction device is designed to pull the belt head of a new belt material tray and a double-sided adhesive sheet to an overlapping station; an overlapping device is designed to achieve the splicing of new and old belt materials; and consequently, the automatic replacement of the belt material trays during belt material production, the automatic pulling of the belt head and the double-sided adhesive sheet, as well as the automatic splicing of the new and old belt materials can be achieved, no manual operation is needed, the production efficiency can be effectively improved, and the production cost can be reduced.

Owner:HENAN XINZHILIN ELECTROMECHANICAL DEVICE CO LTD

A fully automatic special tape splice and roll change device

ActiveCN109987433BIncrease productivityReduce labor costsWebs handlingAdhesive beltElectric machinery

The invention discloses a full-automatic special adhesive tape receiving and roll changing device which comprises a device body, wherein the device body is of a U-shaped structure; a cross frame is welded to the inner side of one vertical end of the device body; a connecting shaft is clamped in the cross frame; an installation plate is welded to one end of the connecting shaft; an empty winding sleeve shaft is welded to the center of the side, far away from the connecting shaft, of the installation plate; and a winding shaft is rotatably connected on the inner side of the other vertical end ofthe device body, an output shaft of a winding motor is welded to one end of the winding shaft, a vertical plate is welded to the position, near the upper part of the vertical end of the winding shaft, of the device body, and a coil unwinding plate is connected to one side of the vertical plate through an electric push rod C. The full-automatic special adhesive tape receiving and roll changing device is suitable for changing rolls of adhesive tapes and receiving materials in the production of the adhesive tapes, and the device achieves the effects of automatic roll changing and automatic unwinding the rolls of the adhesive tapes through the mutual matching use of an electric push rod A, an electric push rod B and the electric push rod C.

Owner:安徽长正升科技有限公司

Roll changing device for rolling mill

ActiveCN106734226BImprove roll changing efficiencyImprove rolling efficiencyMetal rolling stand detailsMetal rolling arrangementsHydraulic cylinderEngineering

The invention provides a novel rolling mill roller changing device which comprises guide rails, a mill housing, auxiliary hydraulic cylinders, two rolling mill bed plate, bed plate lining plates and a mill housing lining plate. The two rolling mill bed plates are parallelly arranged, a connecting rod is arranged between the two rolling mill bed plates. The mill housing is perpendicularly arranged between the two rolling mill bed plates. The auxiliary hydraulic cylinders are arranged between the connecting rod and the mill housing. The bed plate lining plates are arranged on all the inner side upper surfaces and the inner side faces of the rolling mill bed plates. The mill housing lining plate is fixedly connected into a groove below the mill housing. The mill housing lining plate and the bed plate lining plates are subjected to contact friction when the mill housing slides. By adoption of the novel rolling mill roller changing device, the archway and a roller system which are located on the operation side are pulled out through the auxiliary roller changing hydraulic cylinders, the roller changing efficiency is improved, the roller changing time is shortened, and the novel rolling mill roller changing device has great significance for improving the roller changing efficiency and the rolling efficiency.

Owner:中重科技(天津)股份有限公司

A system and method for automatic roll changing and receiving of flexible coils

The invention discloses a system and method for automatically changing coils and receiving materials for flexible coils. In the system, a first coil is provided on a first unwinding mechanism, and after the first coil is released, it is carried out by a first unwinding negative pressure conveying device. Convey and send to the main negative pressure conveying device. The second unwinding mechanism is equipped with a second coil. After the second coil is released, it is conveyed by the second unwinding negative pressure conveying device and sent to the main negative pressure conveying device. The gluing device is located on one side of the main negative pressure conveying device, and along the conveying direction of the material, the gluing device is arranged in front of the first unwinding negative pressure conveying device and the second unwinding negative pressure conveying device. The method is that the first unwinding negative pressure conveying device and the second unwinding negative pressure conveying device alternately convey coils to the main negative pressure conveying device, and complete the splicing under the cooperation of the main negative pressure conveying device and the gluing device. The invention can replace the traditional manual operation, has high roll changing efficiency, and has less tailing waste, which can effectively reduce the production cost.

Owner:GUANGZHOU XINGSHI EQUIPS

A method for changing the back-up rolls of a fourteen-high cold rolling mill for copper strips

ActiveCN105234183BGuarantee continuous and stable operationReduce labor intensityMetal rolling stand detailsMetal rolling arrangementsEngineeringCopper

The invention discloses a roller replacing method for supporting rollers of a fourteen-roller copper belt cold-rolling mill. A roller replacing sequence is reasonably arranged according to a specific structure of the fourteen-roller copper belt cold-rolling mill. A roller replacing tool with higher practicability is used. Furthermore, a shaft holding device is arranged at the shaft head of a universal connecting shaft to fix the shaft head before the connection between the supporting roller and the universal connecting shaft is broken, and then an arc plate for fixing a granny knot is arranged above a platform and under the granny knot. Thus, the shaft head and the granny knot always remain at the original positions in a roller replacing process after the connection is broken, the transmitting end of the lower supporting roller and the transmitting end of the upper supporting roller can be successfully inserted into the shaft head in one time when rollers are assembled again, and the roller replacing efficiency is improved. In addition, the other rollers are prevented from being affected, the time for replacing the rollers is reduced, and the labor intensity of workers is reduced; and the continuous stable operation of the fourteen-roller cold-rolling mill is guaranteed, and the normal production of copper belts is guaranteed.

Owner:中色正锐(山东)铜业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com