Roller changing trolley, system and method for scale breaker

A technology of roll changing trolley and phosphorus breaking machine, which is applied in workpiece surface treatment equipment, metal rolling, manufacturing tools, etc. It can solve the problems of accelerating pickling speed, reducing the service life of work rolls, and sticking oil on the roll surface, achieving Increase flexibility and stability, improve roll changing efficiency, and avoid movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

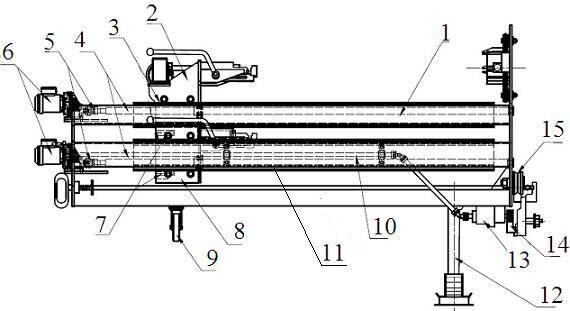

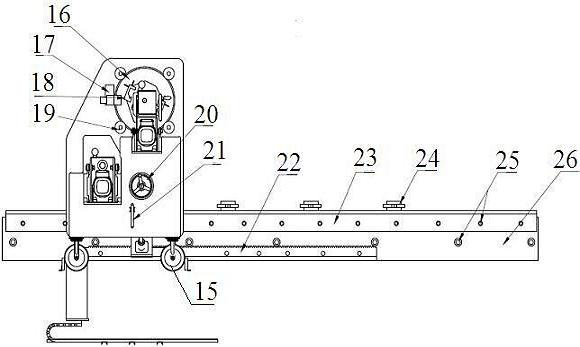

[0041] This embodiment provides a roll changing trolley for a phosphorus breaking machine, comprising a vehicle frame 1, wheels are arranged under the vehicle frame 1, a moving seat, an angle adjustment mechanism and a driving device are arranged on the vehicle frame 1, and the moving The seat is connected with the driving device, and the angle adjustment mechanism is set on one side of the moving seat, and the angle adjusting mechanism is used to guide the moving seat after adjusting the angle of the roller system of the phosphorus breaker, and the moving seat is drawn out by the driving device. Old rolls and replacement with new rolls.

[0042] Use process:

[0043] After the roll changing trolley of the phosphorus breaker moves to the roll change position of the phosphorus breaker through the wheels, the angle adjustment mechanism matches the angle adjustment of the roll system of the phosphorus breaker, and then the driving device drives the moving seat to catch the old ro...

Embodiment 2

[0046]On the basis of Embodiment 1, this embodiment provides a roll changing trolley for a phosphorus breaker, the driving device includes a lead screw 4, a torque limiter 5 and a reduction motor 6, and the lead screw 4 is equipped with a nut, The moving seat is fixedly connected with the nut, the reduction motor 6 is arranged at one end of the lead screw 4, and the torque limiter 5 is arranged on the rotation shaft of the reduction motor 6;

[0047] A proximity switch 7 is installed on the vehicle frame 1, and the proximity switch 7 is connected with the torque limiter 5 through an electric signal.

[0048] The reduction motor 6 starts, drives the lead screw 4 to rotate, and the nut drives the moving seat to reciprocate in a straight line along the lead screw 4, approaching or principle roller changing position. Roll position), the proximity switch 7 senses, and transmits the signal to the torque limiter 5, and the torque limiter 5 is opened to disengage the geared motor 6 fr...

Embodiment 3

[0050] On the basis of Embodiment 1, this embodiment provides a roll changing trolley for a phosphorus breaker, and a guide rail 1 is also provided on the frame 1, and the guide rail 1 is arranged on one side of the driving device. A guide wheel is provided on one side, and the moving seat is slidably connected with the guide rail through the guide wheel.

[0051] When the moving seat moves under the drive of the driving device, the guide wheel moves along the guide rail to guide the movement of the moving seat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com