A fully automatic special tape splice and roll change device

A fully automatic and special technology, applied in thin material processing, strip winding, transportation and packaging, etc., can solve the problems of difficult to meet production, inconvenient processing, low production efficiency, etc., to improve production efficiency and prevent docking misalignment , the effect of saving labor and processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

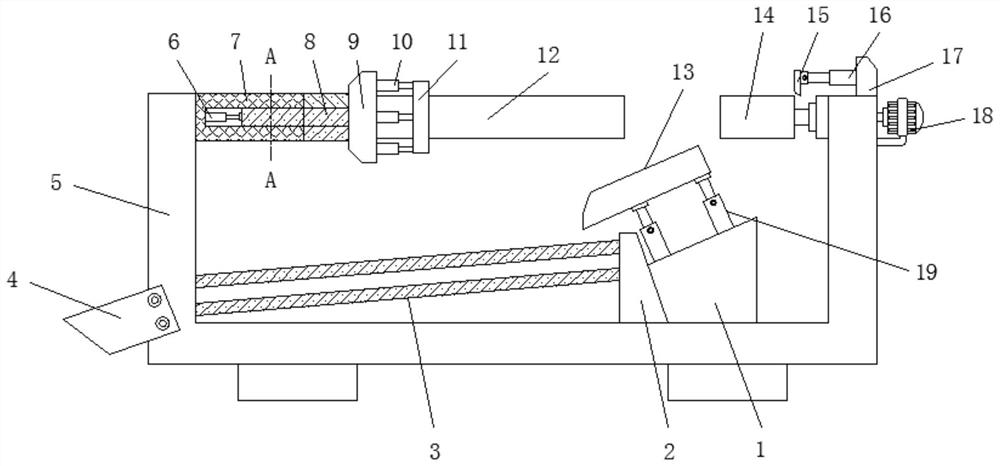

[0025] Embodiment 1, with reference to Figure 1-5 , a full-automatic special tape splicing and changing device, including a device body 5, the device body 5 is a U-shaped structure, a horizontal frame 7 is welded on the inner side of one of the vertical ends of the device body 5, and a connecting frame 7 is clamped inside the horizontal frame 7. One end of the shaft 8 and the connecting shaft 8 is welded with a mounting plate 9, and the center of the side of the mounting plate 9 away from the connecting shaft 8 is welded with an empty reel shaft 12, and the other vertical end of the device body 5 is connected with a winding shaft 14 in rotation on the inner side. One side of the outer wall of the device body 5 is fixed with a winding motor 18 by frame bolts, the output shaft of the winding motor 18 is welded to one end of the winding shaft 14, and the device body 5 is welded with a vertical plate near the vertical end of the winding shaft 14 17. One side of the vertical plate...

Embodiment 2

[0027] Embodiment 2, with reference to figure 1 with Figure 3-5 , there are three material receiving roller shafts 3 in total, and the three material receiving roller shafts 3 are parallel to each other, the three material receiving roller shafts 3 are distributed in an equilateral triangle, two of the three material receiving roller shafts 3 are located at the top, and one Located below, the two receiving roller shafts 3 above are on the same horizontal plane, the inclination angles of the three receiving roller shafts 3 are 15°, the upper surface of the material receiving plate 13 is an arc-shaped structure, and the inclination angle of the material receiving plate 13 is 15°-30°, the center line of the material receiving plate 13, the center line of the reel 14 and the center line of the receiving roller shaft 3 located below are on the same plane, and the reel 14 can be moved up and down through the material receiving plate 13 The adhesive tape is caught and sent to the t...

Embodiment 3

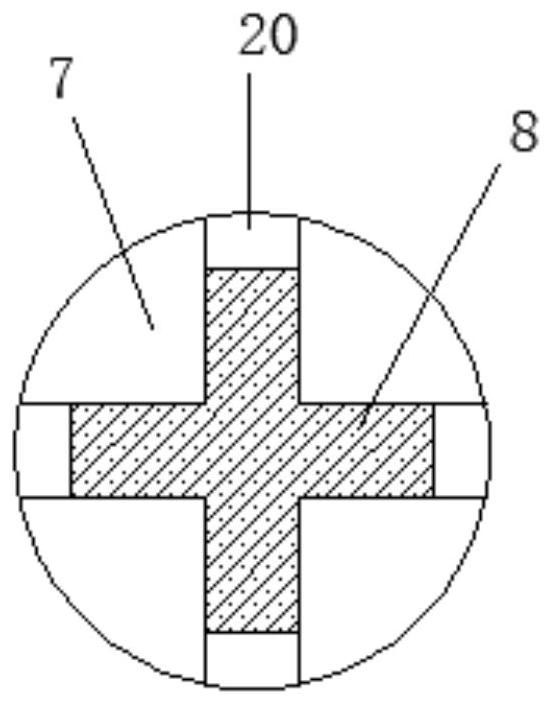

[0028] Embodiment 3, with reference to figure 1 with figure 2 , the bolt on the inner wall of the horizontal frame 7 is fixed with an electric push rod A6, the free end of the electric push rod A6 is welded to one end of the connecting shaft 8, the vertical section of the connecting shaft 8 is a cross-shaped structure, and the horizontal frame 7 is equipped with a Card slot 20, when the electric push rod A6 is running, push the connecting shaft 8 to slide inside the card slot 20, so that the empty roll sleeve shaft 12 moves to the winding shaft 14, so that the empty roll of the tape on the empty roll sleeve shaft 12 moves to the winding shaft 14 On the other hand, the structural arrangement of the cross-shaped shaft 8 makes the sliding in the card slot 20 more stable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com