Roll replacing mechanism

A material roll and reel technology, applied in the field of roll change mechanism, can solve the problems of low roll change efficiency, troublesome roll change, low efficiency, etc., and achieve the effect of improving roll change efficiency and reducing material preparation frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

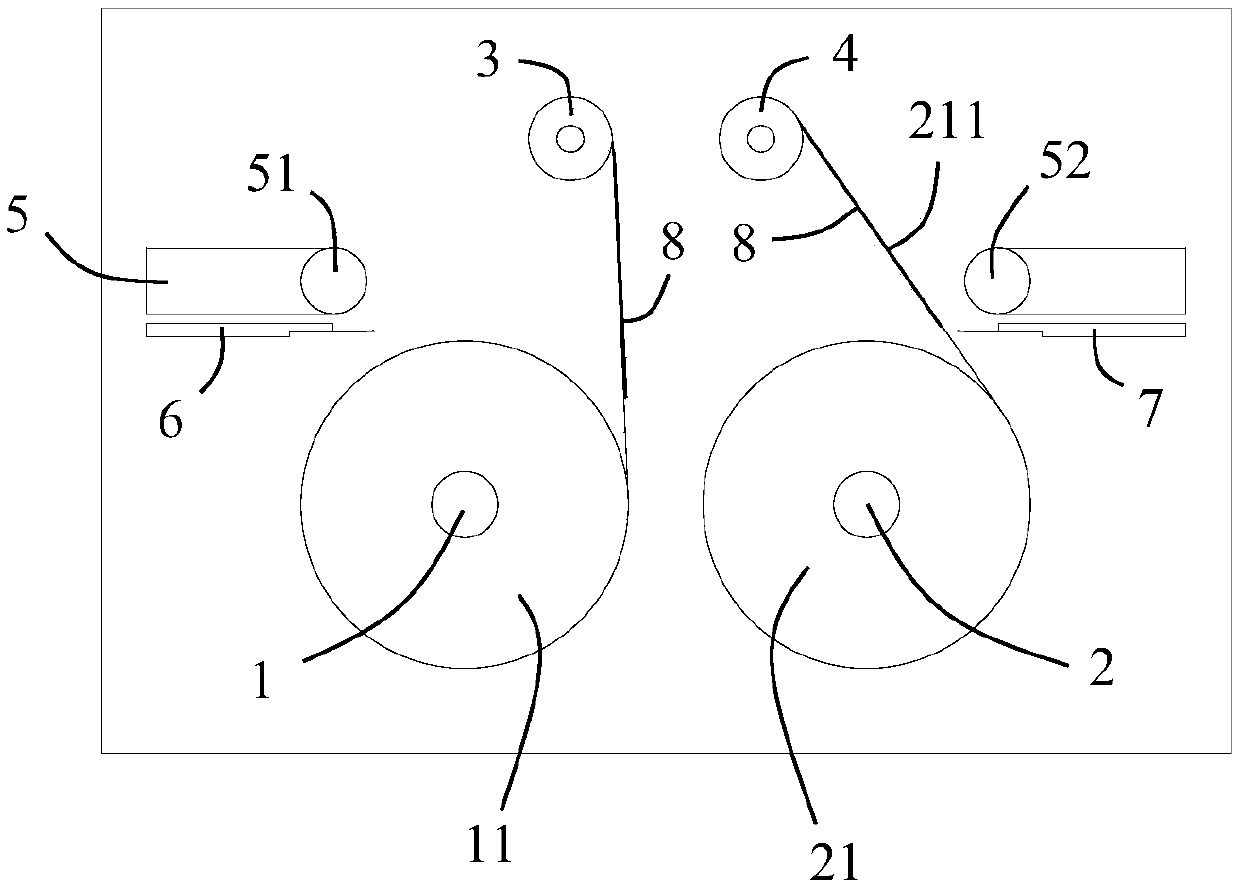

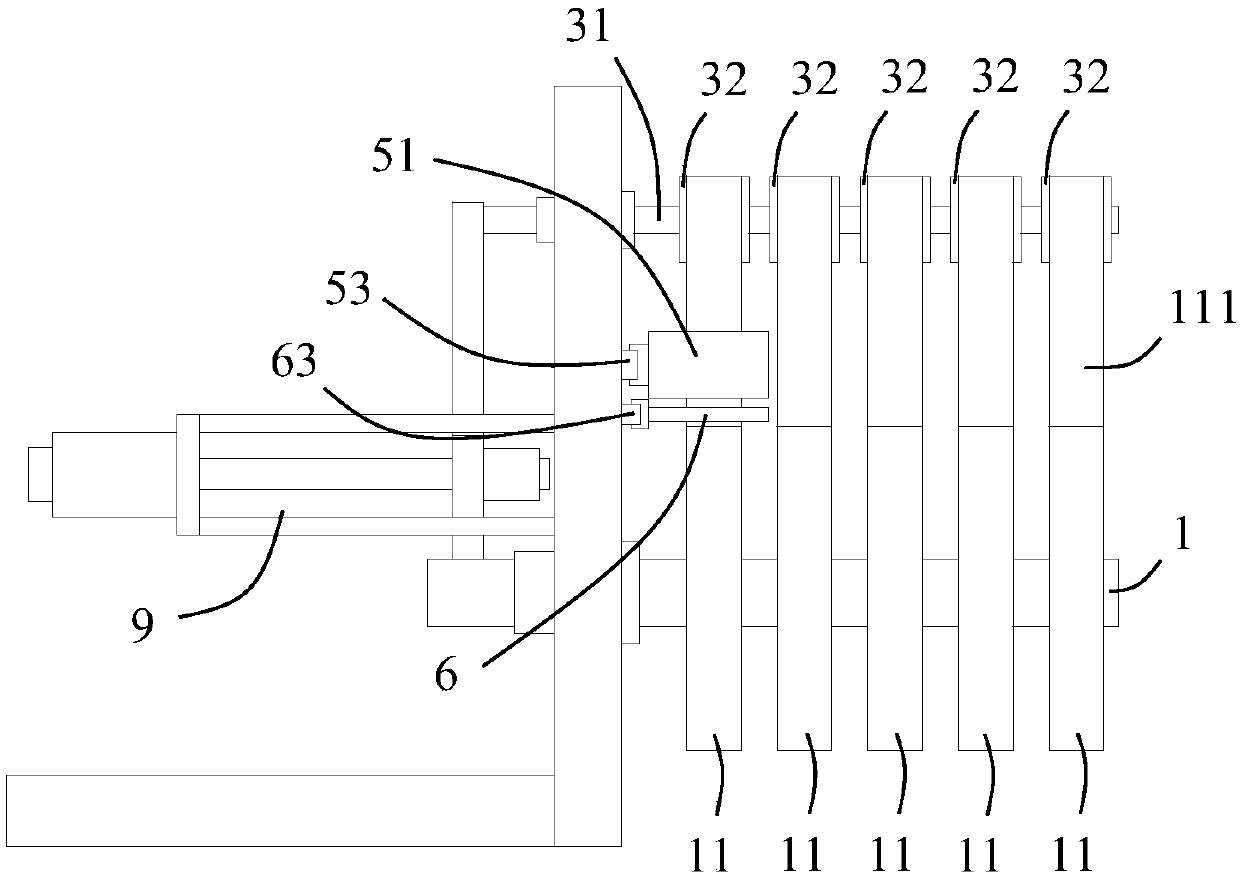

[0021] Please refer to Figure 1 to Figure 6 As shown, the present invention discloses a roll changing mechanism, which includes a first material reel 1, a second material reel 2, a first passing roller 3, a second passing roller 4, a roller assembly 5, and a first cutting assembly 6 And the second cutting assembly 7. The first passing roller 3 and the second passing roller 4 are respectively located at the discharge ends of the first material reel 1 and the second material reel 2 .

[0022] The first material reel 1 is used in conjunction with the second material reel 2, and when one of them is a discharge reel, the other is a material preparation reel. Please refer to figure 2 As shown, in order to avoid frequent material preparation, multiple groups of material rolls can be stored on the first material reel 1 and / or the second material reel 2, wherein multiple groups means greater than or equal to two groups. Preferably, multiple groups of material rolls are stored on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com