TPU film continuous coating production system and method

A production system and production method technology, applied in the field of TPU, can solve the problems of difficult bonding, difficult pasting, poor heat resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

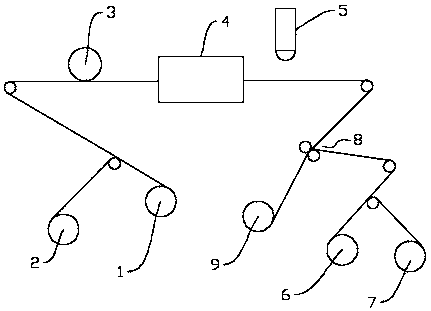

[0038]The continuous coating production system of the TPU film includes a first unwinding unit 1 for unwinding the TPU base film. The TPU base film includes a TPU film and a protective film attached to the upper and lower surfaces of the TPU film; Leading unit, used to attach the leading film to the protective film on one side surface of the unwound TPU base film for connection; the first peeling unit 2, used to bond the other side surface of the TPU base film that is not connected with the leading film The protective film is peeled off; the coating unit 3 is used to coat the polymer on the surface of the TPU base film that has peeled off the protective film to form a coating layer; the drying unit 4 is used to complete the coating of the TPU base film by an oven The film is subjected to surface drying treatment; the UV curing unit 5 is used to perform ultraviolet curing treatment on the dried TPU base film through a UV lamp. This production system is suitable for the case whe...

Embodiment 2

[0040] The continuous coating production system of the TPU film includes a first unwinding unit 1 for unwinding the TPU base film. The TPU base film includes a TPU film and a protective film attached to the upper and lower surfaces of the TPU film; The introduction unit is used to connect the two sections of TPU base film on the same side of the two sections of TPU base film through the introduction film. The protective film is peeled off; the coating unit 3 is used to coat the polymer on the surface of the TPU base film that has peeled off the protective film to form a coating layer; the drying unit 4 is used to complete the coating of the TPU base film by an oven Carry out surface drying treatment; UV curing unit 5 is used to perform ultraviolet curing treatment on the dried TPU base film by UV lamp. This production system is suitable for the case where the product produced by coating on the first roll is TPU base film. When the first roll of TPU base film is unrolled, it ca...

Embodiment 3

[0042] The continuous coating production system of the TPU film includes a first unwinding unit 1 for unwinding the TPU base film. The TPU base film includes a TPU film and a protective film attached to the upper and lower surfaces of the TPU film; Leading unit, used to attach the leading film to the protective film on one side surface of the unwound TPU base film for connection; the first peeling unit 2, used to bond the other side surface of the TPU base film that is not connected with the leading film The protective film is peeled off; the coating unit 3 is used to coat the polymer on the surface of the TPU base film that has peeled off the protective film to form a coating layer; the drying unit 4 is used to complete the coating of the TPU base film by an oven The film is subjected to surface drying treatment; the UV curing unit 5 is used to carry out ultraviolet curing treatment to the dried TPU base film by a UV lamp; the second unwinding unit 6 is used to unwind the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com