High-rigidity small-sized steel row straightening machine with movable operation side rack

A row straightening machine and operation side technology, which is applied in the field of small steel row leveling machines with mobile racks on the operation side and high rigidity, can solve the problems of low technical and economic advantages, high maintenance requirements, and unsuitable equipment selection requirements And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings.

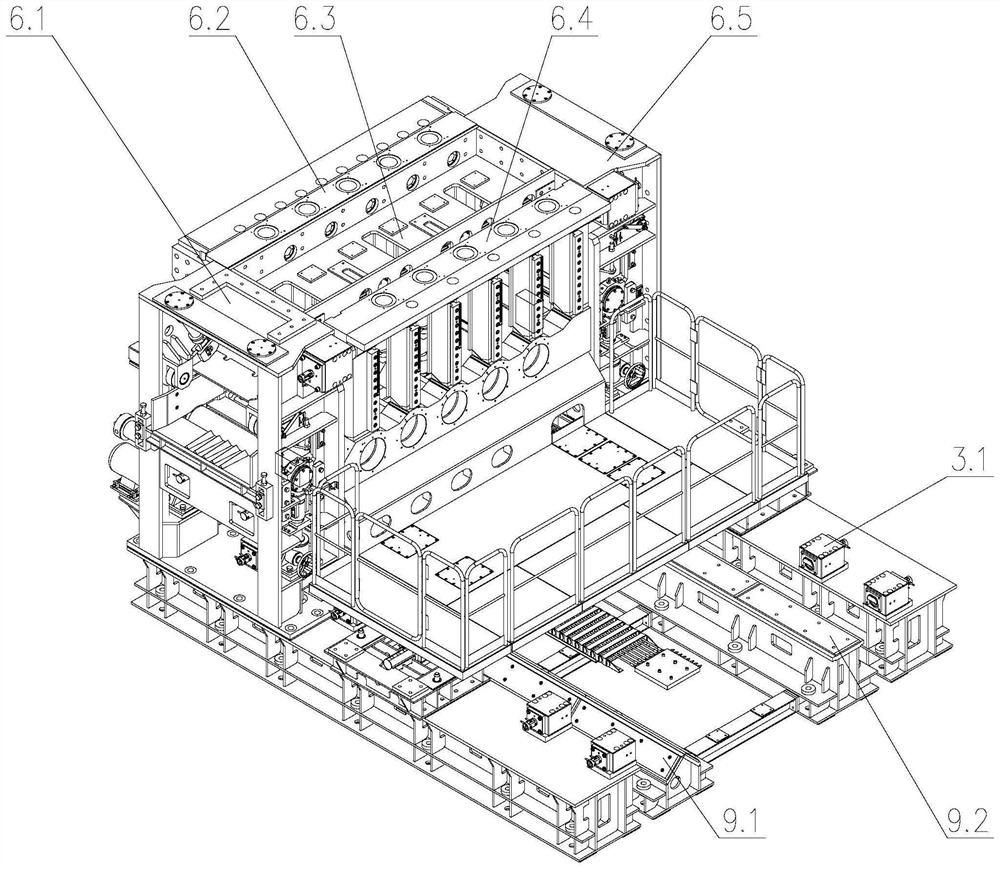

[0050] like Figure 1 to Figure 19 As shown, a mobile high-rigidity small-sized steel row straightening machine with an operation side frame of the present invention includes a fixed base 1, a comprehensive base 3, a longitudinal moving track 9, a high-rigidity combined frame 6, and an automatic locking type upper straightening machine. Roll assembly 5, automatic locking type lower straightening roll assembly 4, clutch type pressing device 7, automatic roll changing device 2 and transmission system 8.

[0051] The fixed base 1 is arranged under the transmission side frame 6.2 of the combined frame 6, between the front frame 6.1 and the rear frame 6.5, is fixed on the civil foundation, and carries the combined frame 6 together with the integrated base 3.

[0052] The integrated base 6 is arranged vertically to the rolling line, and is located outside and parallel to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com